Benefits of Blocks Manufacturing

Blocks manufacturing is a process of producing building blocks used in the construction industry. Blocks are manufactured using a mixture of cement, sand, water, and other materials depending on the required strength and durability. Blocks manufacturing industry has several benefits, which make it an essential process in the construction industry.

One of the benefits of blocks manufacturing is the availability of blocks in different sizes and shapes. Different construction projects require various block sizes and shapes, and blocks manufacturing ensures that builders’ requirements are met. This increases the versatility of the construction industry and provides builders with options on the type of blocks to use in different projects.

Blocks manufacturing also promotes cost savings in the construction industry. Blocks are cheaper to produce than traditional building materials like bricks and stones. Additionally, blocks manufacturing is a mechanized process that ensures energy efficiency and reduces labor costs. This translates to cost savings for builders and enables them to undertake various construction projects affordably.

Another benefit of blocks manufacturing is its durability. Blocks are strong and durable, making them ideal for construction projects requiring firm foundations and structures. Blocks can withstand harsh weather conditions, and they do not deteriorate with time, making them suitable for long-term construction projects.

Blocks manufacturing also promotes sustainability in the construction industry. The raw materials used in blocks manufacturing are obtained from sustainable sources, hence reducing the dependence on non-renewable resources. Additionally, blocks are recyclable, and they can be reused in other construction projects, reducing environmental waste.

In conclusion, the benefits of blocks manufacturing are numerous, and they make it an essential process in the construction industry. Blocks manufacturing reduces labor costs, promotes energy efficiency, sustainability, and cost savings. Additionally, blocks come in various sizes and shapes, making them versatile and suitable for various construction projects.

Features of Blocks Manufacturing

Block manufacturing is a process that involves the production of interlocking blocks using a machine. The blocks produced are used for building walls, walkways, and other structures. These blocks are preferred due to their durability, strength, and ease of installation. Here are some features of block manufacturing:

1. Machine Capacity: The machine used for block manufacturing has a capacity that makes it possible to produce a significant number of blocks within a short period. Depending on the machine’s capacity, it can produce between 1000 to 3000 blocks per day.

2. Material: The raw materials used in block manufacturing include cement, sand, gravel, and water. These materials are mixed in specific proportions, and the resulting product is poured into moulds to form the blocks.

3. Quality Control: Block manufacturers must be mindful of quality control to ensure that the blocks produced meet the required standards. The blocks must be strong enough to withstand pressure and durable enough to last long. The quality of the blocks is determined by a series of tests conducted in the laboratory.

4. Variety: Blocks come in different shapes and sizes, giving customers a range of options to choose from. Some popular shapes include rectangular, square, and circular blocks. In addition, blocks can be designed with patterns and textures to give a unique appearance.

5. Efficiency: The production process of block manufacturing is efficient, with little or no waste generated. The raw materials are mixed in the correct proportions, which prevents wastage, and the blocks produced are easy to transport and store.

6. Environmental Impact: Block manufacturing is an environmentally friendly process as it uses less energy and generates less waste than traditional brick-making methods.

In conclusion, block manufacturing is an efficient process that produces strong, durable, and environmentally friendly blocks. The process involves the use of high-quality raw materials, advanced machinery, and quality control measures. With its versatility and durability, block manufacturing is a popular choice for builders and construction companies worldwide.

Various Types of Blocks Manufacturing

Blocks manufacturing has been a crucial aspect of construction for several decades, and over time various types of blocks have been designed and invented for multiple purposes. The following are various types of blocks manufacturing.

1. Concrete blocks: These are the most widely used blocks for construction purposes. They are sturdy and are produced by mixing cement, water, sand, and gravel in a predetermined ratio.

2. Cinder blocks: These are made from raw materials, including fly ash, cement, and cinder. They are commonly used in building walls for homes and other structures.

3. Clay blocks: These blocks are made from clay and are dried in a heated kiln. They possess an excellent insulation property and can withstand extreme temperatures, making them suitable for house construction.

4. Cellular lightweight concrete blocks: They are lightweight and have excellent thermal insulation properties. They are produced by mixing cement, fly ash, foam, and water in a predetermined ratio.

5. Autoclaved aerated concrete blocks: They are light in weight and have high thermal insulation properties. They are manufactured by mixing lime, cement, sand, and water, along with an aluminum powder to create pores in the blocks.

6. Glass blocks: These are transparent blocks made from glass and are usually used to create partition walls, floors or walkways in residential, commercial and industrial buildings. They are also used for aesthetic purposes, such as decoration.

7. Interlocking concrete blocks: They are durable and sturdy, made from a mixture of cement, sand, and water. They are designed in a way to interlock with one another, making them easy to install and remove.

In conclusion, there are various types of blocks manufacturing, each with unique properties and purposes. The selection of a particular type of block depends on the intended use of the structure and the customer’s preferences.

Applications of Blocks Manufacturing

Blocks manufacturing is the process of making concrete blocks, which are a popular building material used in construction projects worldwide. These blocks are made of cement, water, and aggregates such as sand, gravel, or crushed stone. Blocks manufacturing has a wide range of applications in the construction industry.

One of the primary applications of blocks manufacturing is making building blocks. Concrete blocks are used to build walls, foundations, and structures for buildings. They are durable and strong, which makes them ideal for construction projects that require stability and longevity. Blocks can be made in a variety of sizes and shapes, making them versatile and suitable for various building designs and purposes.

Another application of blocks manufacturing is paving. Concrete blocks can be made in different colors and shapes, making them an excellent choice for paving driveways, sidewalks, and patios. The blocks are easy to install, cost-effective, and low maintenance, making them a popular choice in the landscaping industry.

Blocks manufacturing also has applications in retaining walls. Retaining walls are structures built to hold back soil and prevent it from sliding or eroding. Concrete blocks are an ideal material for building retaining walls because of their strength and durability. They are easy to install, and their interlocking design allows for building tall and sturdy walls in a short time.

Finally, blocks manufacturing has environmental benefits. Concrete blocks are made from natural materials, and their production process reduces waste and saves energy. The blocks are also recyclable, which reduces the environmental impact of construction projects.

In conclusion, blocks manufacturing has numerous applications in the construction industry. They are an excellent material for building structures and paving surfaces, and their strength and durability make them ideal for retaining walls. Blocks manufacturing also has environmental benefits, making it an ideal choice for sustainable construction projects.

The Process of Blocks Manufacturing

The process of blocks manufacturing is a critical aspect of the construction industry. Blocks are a fundamental building material used in the construction of houses, offices, and other infrastructure.

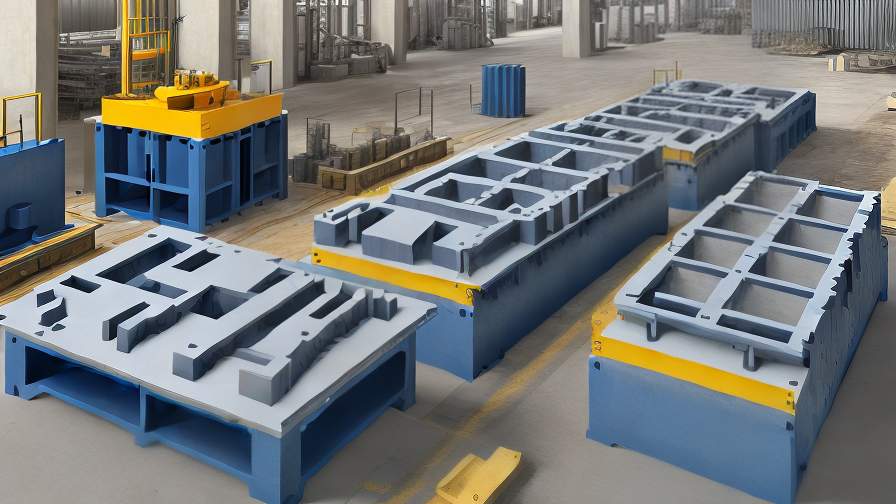

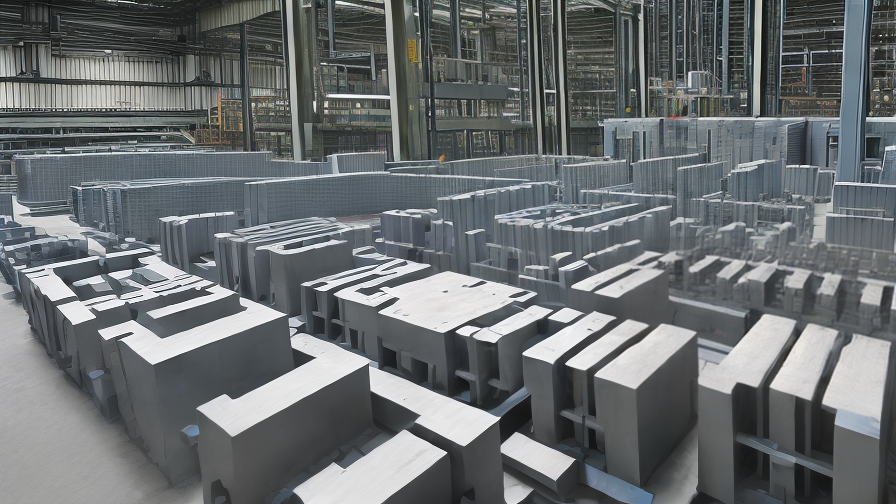

The primary raw materials for manufacturing blocks are cement, water, sand, and aggregate. These materials are mixed in specific proportions in a mixer to form a homogeneous mixture. The mixture is then transferred into the block-making machine to form blocks of various sizes and shapes.

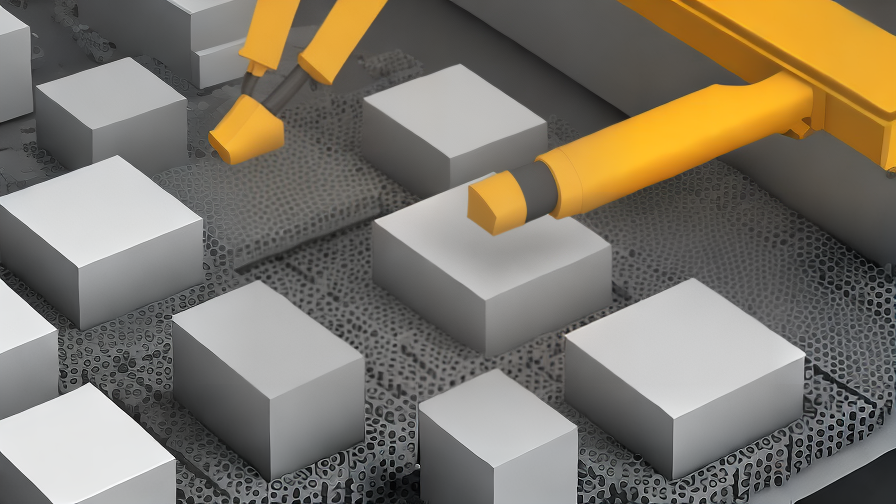

The block-making machine consists of a mold box, hydraulic system, and vibrating table. The mold box is filled with the mixture, which is then compacted using hydraulic pressure. The vibrating table helps to ensure that the mixture is evenly distributed within the mold box and that the blocks are uniform in shape and density.

Once the blocks are formed, they are cured for a specific period. The curing process involves keeping the blocks moist and allowing the cement to harden and gain strength. The length of the curing period depends on the type of block being manufactured and the prevailing weather conditions.

After the curing process, the blocks are removed from the mold box and stacked to air dry for a few days. During this time, the blocks are left exposed to the atmosphere so that any excess moisture can escape, and the blocks can fully dry.

Finally, the blocks are ready for distribution to builders and construction firms. The blocks are transported to different locations, where they are used in the construction of various structures.

In conclusion, the process of blocks manufacturing involves mixing raw materials, using a block-making machine, and curing the blocks before they are distributed. The quality of the blocks depends on the accuracy of the mixing proportions and the efficiency of the block-making machine. The blocks must be cured and air-dried correctly to maximize their strength and durability.

How to use Blocks Manufacturing

Blocks manufacturing is a cost-effective and efficient way to create building materials for construction. With this process, concrete blocks are produced and used as a construction material for buildings, sidewalks, retaining walls, and more. Here’s a guide to use blocks manufacturing effectively.

The first step is to prepare the raw materials. The basic ingredients of concrete blocks are cement, sand, and water. The correct proportions of these ingredients must be measured and mixed. When the raw materials are ready, they are fed into the manufacturing machine.

The manufacturing process begins with the mixing of the raw materials. Concrete is poured into molds and pressed with a hydraulic press to create a solid block. The blocks are then removed from the mold and cured in a drying area. This process allows for the blocks to harden and become durable.

To use blocks manufacturing, it is essential to have the right manufacturing machine. The machine should be able to produce different block sizes and shapes depending on the construction needs. The machine must also have the capacity to handle large quantities of raw materials.

Another crucial thing to consider is the quality of the raw materials. The cement and sand used must be of high quality to produce durable blocks. Poor-quality materials will lead to substandard blocks, which cannot withstand the pressure and wear of everyday use.

Once the blocks are manufactured, they can be used in a wide variety of construction projects. The blocks can be used to create walls, foundations, and other building components. They can also be used to create sidewalks, retaining walls, and garden borders.

In conclusion, blocks manufacturing is a cost-effective way to produce building materials for construction. It is an efficient process that requires careful attention to the raw materials and manufacturing equipment. By following the steps outlined above and utilizing high-quality raw materials and the right manufacturing machine, you can produce durable blocks for various construction needs.

Selecting the Ideal Manufacturer Blocks Manufacturing

Selecting the Ideal Manufacturer for Blocks Manufacturing

Selecting the ideal manufacturer for blocks manufacturing is a crucial decision that determines the quality of the blocks produced. The manufacturer’s expertise, experience, and reputation can have a significant impact on the efficiency and productivity of the blocks manufacturing process, as well as the quality of the final product.

Before choosing a manufacturer, it is important to conduct thorough research and consider several factors. One of the essential factors to consider is the manufacturer’s experience in the industry. A manufacturer who has been in business for many years has acquired extensive knowledge of the manufacturing process, and their experience will be beneficial in ensuring that the blocks are of high quality.

Another factor to consider is the supplier’s reputation in the industry. Take the time to research their past projects and customer feedback to determine the quality and consistency of their products. A reputable manufacturer should have a high customer satisfaction rate, and positive reviews should be readily available.

It is also vital to examine the manufacturer’s production capabilities. The manufacturer’s ability to produce an adequate supply of blocks to sustain your business is a priority. Thus, consider the manufacturer’s facility size, equipment, and workforce to ensure that they can meet your production needs without sacrificing quality.

Communication and availability are also essential factors to consider. The manufacturer should be responsive and willing to discuss any concerns or questions you may have along the way. They should provide updates on the production process, delivery times, and be available to address any challenges that may arise.

In conclusion, selecting the ideal manufacturer for blocks manufacturing is a crucial decision that requires extensive research and consideration of several factors. Key factors include the manufacturer’s experience, reputation, production capacity, communication, and availability. By carefully selecting the right manufacturer, you can ensure that your business runs smoothly and that you consistently produce high-quality blocks.

list FAQ with answer about Blocks Manufacturing

Blocks manufacturing is a crucial industry that offers building blocks to construct homes, offices and other infrastructure. Here are some frequently asked questions with answers about this industry.

Q: What materials are used to make blocks?

A: Blocks can be made from a variety of materials like concrete, clay, fly ash, and cement.

Q: What is the process of making blocks?

A: Blocks are made by mixing the raw materials in a certain proportion with water and shaping them into moulds. After 24-48 hours, the blocks are dried and cured for weeks before they are used for construction purposes.

Q: What are the types of blocks available in the market?

A: The most commonly used blocks are hollow blocks, solid blocks, aerated autoclaved concrete (AAC) blocks, and interlocking blocks.

Q: What is the durability of blocks?

A: The durability of blocks varies depending on the type of material used. Generally, blocks made of concrete and AAC have a higher durability compared to others.

Q: What is the cost of manufacturing blocks?

A: The cost of manufacturing blocks depends on the type of raw materials used, machinery cost, and labour cost.

Q: What are the advantages of using blocks in construction?

A: Blocks are easy to handle, require less time and labour for construction, have good thermal insulation, and are fire-resistant.

Q: How can the quality of blocks be ensured?

A: Blocks can be tested for compressive strength, water absorption, and durability by accredited laboratories to ensure their quality.

In conclusion, Blocks manufacturing is an essential industry that provides building materials for construction. Understanding the basics of the process, types of blocks, costs, advantages, and quality assurance methods can help consumers make informed decisions while choosing blocks for construction purposes.

Things to Consider When Purchasing Blocks Manufacturing

When it comes to purchasing a block manufacturing business, there are several things to consider. Firstly, it is important to assess the location of the business as this can play a significant role in the success of the operation. If the business is located in an area with a high demand for construction materials, it is more likely to thrive.

The quality of the machinery used in the block manufacturing process is also a crucial factor to consider. It is important to ensure that the machinery is up-to-date and in good condition as this can greatly affect the overall quality of the blocks produced.

Another factor to consider is the size of the plant. It is essential to ensure that the plant is sized appropriately to meet the demand for blocks in the local market. If the plant is too small, there may be production shortages leading to loss of sales and revenue.

Furthermore, it is important to consider the type of blocks the business produces. There are various types of blocks including concrete, cement, and cinder blocks. It is important to assess which type of blocks are in high demand within the local market and whether the business is producing the appropriate blocks to meet those demands.

In addition, it is important to consider the skill level of the employees. The success of the block manufacturing business partially depends on the skills of the employees. If the employees lack the required skills, the overall quality of the blocks produced may be subpar leading to loss of business.

Lastly, it is essential to analyze the financial health of the business before making a purchase. This allows the potential buyer to assess the overall profitability of the business and identify any potential risks.

In conclusion, when purchasing a block manufacturing business, it is important to consider the location, machinery, plant size, block type, employee skill level, and financial health of the business to make an informed decision.

Properties of Blocks Manufacturing

Blocks are an essential part of modern construction due to their versatility, durability, and strength. The manufacturing process of blocks involves several critical stages that impact the quality and performance of the blocks. There are several properties of blocks manufacturing, which play a crucial role in achieving the desired product quality.

Materials

The choice of materials for blocks manufacturing is crucial for several properties. Blocks can be made using different materials, such as concrete, clay, or aerated concrete. Concrete blocks are the most commonly used as they are easy to handle, quick to manufacture, and durable. Cement, aggregates, and water are the primary materials used in making concrete blocks. The quality and quantity of the materials significantly impact the blocks’ strength and durability.

Mixing

Mixing is the process of blending raw materials to achieve a homogeneous mixture that can be molded into blocks. Proper mixing ensures uniform distribution of materials, which is crucial for the block’s strength and durability. The mixing should be done according to established standards and using appropriate equipment.

Molding

Molding is the process of shaping the mixed raw materials into blocks of the desired size and shape. During this process, the mixture is poured into molds, and the excess is removed to achieve the desired shape. The molding process influences several properties of blocks, including density, strength, and surface finish. The molds should be made of appropriate materials to prevent sticking or warping during the molding process.

Curing

Curing is the process of allowing the blocks to reach their full strength and durability potential. The blocks are allowed to rest for a specific period under controlled conditions to achieve optimal strength. The curing process should be done according to established standards to ensure uniform and consistent results.

Conclusion

Blocks are an essential component of modern construction due to their versatility, durability, and strength. The properties of blocks manufacturing, including materials, mixing, molding, and curing, play a crucial role in determining the blocks’ quality and performance. Proper control of the manufacturing process ensures the desired product quality and conform to established standards.

Technical Parameters Terms for Blocks Manufacturing

In block manufacturing, technical parameters play an essential role in ensuring the quality and durability of the product. Understanding technical parameters can help manufacturers assess the properties of the materials and make necessary adjustments to produce the best blocks possible. Here are the most common technical parameters to consider:

1. Compressive strength: This parameter represents the maximum load a block can bear under compression. A higher compressive strength indicates a stronger block and is essential for ensuring the stability of structures.

2. Water absorption: This parameter measures the percentage of water absorbed by the block’s surface. Blocks with low water absorption rates are less porous and more resistant to moisture damage.

3. Density: Density is the measure of a block’s weight per unit volume. The density of blocks affects their thermal and acoustic properties, as well as their ease of handling and transportation.

4. Dimensional accuracy: Dimensional accuracy describes how closely a block’s actual dimensions match its intended specifications. Accurate dimensions are crucial for ensuring that building projects meet the required standards.

5. Fire resistance: Blocks are often used for constructing fire-resistant walls, and as such, must have sufficient resistance to high temperatures.

6. Durability: Durability is a measure of a block’s resistance to wear, tear, and aging. Blocks must be durable enough to withstand the stresses of their intended application and maintain their structural integrity over time.

7. Thermal conductivity: This parameter measures the block’s ability to transfer heat. Blocks with low thermal conductivity are more thermally efficient and can help reduce energy consumption.

In conclusion, understanding technical parameters is critical for manufacturing high-quality blocks. These parameters can help manufacturers assess the properties of the materials and make necessary adjustments to produce the best blocks possible. A good understanding of technical parameters is one of the keys to producing robust and durable blocks that meet the required standards.

Blocks Manufacturing Price

Blocks are widely used in construction, making them an essential component of the building industry. The manufacturing price of blocks varies due to the quality, size, and the method used in production. The quality of materials used in the production of blocks affects the durability and strength of the resulting product. Therefore, manufacturers must invest in high-quality raw materials, which ultimately leads to increased manufacturing costs.

The size of blocks also influences the cost of manufacturing. Generally, larger blocks require more raw materials and longer processing time, resulting in higher manufacturing costs. Additionally, the method used in block production, whether manual or machine production, will affect the overall manufacturing price. Machine production is faster and more efficient, but it requires higher capital investment, leading to higher manufacturing costs in the long run.

The price of blocks may also vary depending on the region and the availability of raw materials. In areas where raw materials are readily available, the manufacturing price of blocks will be lower than in locations where raw materials are scarce. Moreover, the cost of transportation from the manufacturing plant to various construction sites also affects the overall cost of blocks.

Manufacturers must also take into consideration labor costs, energy bills, and administrative expenses, all of which add to the manufacturing price. Therefore, the final price of blocks to consumers must include all costs of manufacturing, transportation, and other expenses.

In conclusion, the manufacturing price of blocks varies significantly depending on several factors, including quality, size, production method, region, and availability of raw materials. Therefore, manufacturers must carefully consider these factors and ensure that they produce high-quality blocks at a competitive price to remain competitive in the market.