aluminium manufacturer

China aluminium Manufacturer: Aluminum coil/sheet/foil

ALUCOVERBOND is an expert manufacturer of Aluminum Composite Panels (ACP) with a specialization in producing cutting-edge materials for industrial, transportation, building, and signage applications. Our reputation is built on the consistent delivery of exceptional products and services, which has enabled us to expand our expertise to the production, promotion, and marketing of ALCOVERBOND ACP.

FAQ about sourcing aluminium products from china manufacturer

1. What is the minimum order quantity for aluminium products sourcing from China manufacturers?

The minimum order quantity for aluminium products sourced from China manufacturers varies depending on the specific supplier and product. However, it is common for manufacturers to require a minimum order quantity of several hundred units or more. It is important to note that smaller orders may be possible, but could result in higher prices per unit due to the additional costs of production and shipping. It is recommended that buyers communicate directly with manufacturers to determine their specific minimum order requirements and negotiate pricing accordingly.

2. How do I ensure the quality of the aluminium products sourced from China manufacturers?

When sourcing aluminium products from Chinese manufacturers, it is important to take steps to ensure their quality. Firstly, conduct thorough research on the manufacturer and their reputation in the market. Check if they have the necessary certifications and experience in producing high-quality aluminium products. Secondly, request samples of the products you intend to purchase and inspect them for any defects or inconsistencies. Consider hiring a third-party inspection agency to conduct quality checks on your behalf to ensure the products meet your standards. Finally, establish clear communication with the manufacturer to discuss your specific quality requirements and expectations. Regularly monitoring the production process and conducting quality checks on the finished products will help ensure the quality of the aluminium products sourced from China manufacturers.

3. What is the estimated lead time for the production and delivery of aluminium products from China manufacturers?

The estimated lead time for the production and delivery of aluminium products from China manufacturers can vary depending on a number of factors. These include the specific product being manufactured, the quantity ordered, and the manufacturer’s production capacity. Generally, lead times can range from a few weeks to several months. It is important to work closely with the manufacturer to understand their production schedule and ensure that all necessary steps are taken to expedite the process. Additionally, factors such as shipping times and customs clearance can impact delivery timelines. Therefore, it is important to plan ahead and allow ample time for production and delivery when sourcing aluminium products from China manufacturers.

4. Can I request for custom designs of aluminium products from China manufacturers?

Yes, you can certainly request for custom designs of aluminium products from China manufacturers. Many manufacturers in China are known for their flexibility and willingness to work with customers to create custom designs that meet their specific needs and requirements. Whether you need a custom size or shape of aluminium product, or you require a unique finish or color, Chinese manufacturers can often accommodate your requests. To get started, you can reach out to manufacturers directly to discuss your needs and see what options are available. With their expertise in aluminium manufacturing and their commitment to customer satisfaction, you’re sure to find a partner in China who can help bring your custom designs to life.

5. How do I make payments to the China manufacturer for my aluminium product orders?

Making payments to a China manufacturer for your aluminium product orders can be done through various methods, depending on the agreement you have with your supplier. Some common payment options include wire transfer, PayPal, Western Union, and credit cards. It is important to note that wire transfer is the most commonly used payment method in China, but it also carries some risks. To mitigate these risks, you can use a third-party payment platform that offers secure and reliable transactions. Before making any payments, make sure to verify the supplier’s credentials and the terms of the order to avoid any misunderstandings or disputes.

6. Is it possible to request for samples of aluminium products from China manufacturers before placing an order?

Yes, it is possible to request for samples of aluminium products from China manufacturers before placing an order. Most manufacturers in China are willing to provide samples to potential customers as a way of demonstrating their product quality and capabilities. It is important to clarify with the manufacturer beforehand if there are any fees associated with obtaining samples, such as shipping costs. Additionally, it is important to thoroughly inspect the samples and verify that they meet the required specifications before placing a larger order. Overall, requesting samples is a common practice in the aluminium manufacturing industry and can be a useful tool for making informed purchasing decisions.

7. What is the cost of shipping aluminium products sourced from China manufacturers to my location?

The cost of shipping aluminium products sourced from China manufacturers to your location can vary depending on several factors. These factors include the distance between the two locations, the weight and volume of the products being shipped, the mode of transportation used, and any additional fees or taxes that may be applicable. To determine the exact cost of shipping, it is best to consult with a shipping or logistics company that specializes in international transportation. They can provide you with a detailed quote based on your specific shipment requirements, and help you navigate any customs or regulatory issues that may arise during the shipping process.

8. What are the common types of aluminium products that I can source from China manufacturers?

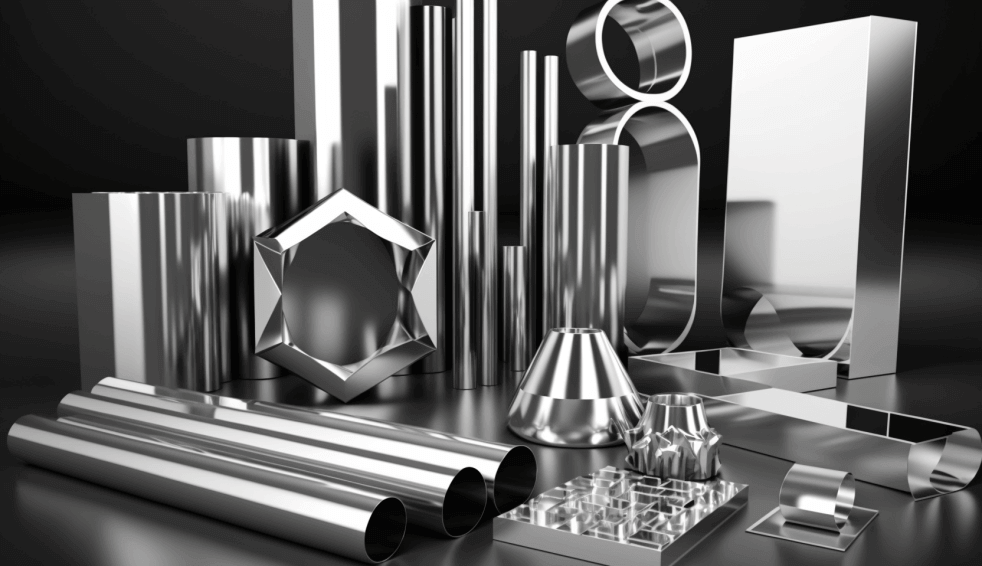

There is a wide range of aluminium products that can be sourced from manufacturers in China. Some of the most common types of aluminium products include extruded profiles, sheet metal, castings, and die-cast parts. These products are used in various industries, such as construction, automotive, aerospace, and electronics. Aluminium extrusions are popular because they can be customized to meet specific design requirements, while sheet metal is commonly used for roofing, siding, and gutters. Castings and die-cast parts, on the other hand, are often used in automotive and industrial applications. With China’s vast manufacturing capabilities and cost-effective pricing, it’s no wonder that many businesses choose to source their aluminium products from Chinese manufacturers.

9. How do I communicate with the China manufacturer during the sourcing process?

When sourcing from a China manufacturer, communication is key to ensure a successful business relationship. There are several ways to communicate with the manufacturer during the sourcing process. One of the most popular methods is email, which allows for clear and concise communication of specifications and requirements. Another option is video conferencing, which allows for a more personal connection and the ability to showcase product samples in real-time. It is also helpful to have a translator or interpreter available to ensure that there are no misunderstandings. Whichever communication method is chosen, it is important to establish clear expectations and maintain open lines of communication throughout the sourcing process.

10. What are the possible risks and challenges involved in sourcing aluminium products from China manufacturers?

Sourcing aluminium products from China manufacturers comes with its own set of risks and challenges. One of the biggest challenges is ensuring the quality of the products, as it can vary greatly from supplier to supplier. There is also a risk of intellectual property theft and counterfeiting as China has a reputation for being a hub for such activities. Additionally, there may be communication barriers due to language differences, leading to misunderstandings in product specifications and delivery timelines. Shipping and logistics can also be a challenge, as delays and customs issues can arise. It is important to conduct thorough research and due diligence before selecting a China manufacturer to mitigate these risks and challenges.

General knowledge about aluminum products

- What is aluminum? Aluminum is a lightweight, non-ferrous metal that is known for its strength, durability, and corrosion resistance. It is a good conductor of electricity and heat and is used in a wide range of applications, from construction to electronics.

- How is aluminum produced? Aluminum is produced from bauxite, a type of rock that contains aluminum oxide. The process of producing aluminum involves extracting the aluminum oxide from bauxite and then refining it into aluminum metal through a series of chemical and electrolytic processes.

- What are some common aluminum products? Aluminum products are used in many industries, including construction, transportation, electronics, and packaging. Some common aluminum products include aluminum sheets, plates, coils, tubes, bars, profiles, and castings.

- What are the benefits of aluminum products? Aluminum products offer a number of benefits, including:

- Lightweight: Aluminum is about one-third the weight of steel, which makes it ideal for transportation applications.

- Corrosion-resistant: Aluminum has a natural oxide layer that protects it from corrosion, which makes it ideal for outdoor applications.

- Easy to fabricate: Aluminum is easy to form, weld, and machine, which makes it easy to fabricate into various shapes and sizes.

- Good conductivity: Aluminum is a good conductor of electricity and heat, which makes it ideal for electrical and thermal applications.

- How to maintain aluminum products? Aluminum products require minimal maintenance. To keep them looking their best, you can clean them with a mild soap and water solution or an aluminum cleaner. Avoid using harsh chemicals or abrasive cleaners that can scratch or damage the surface of the aluminum.

- What are some considerations when sourcing aluminum products? When sourcing aluminum products, it’s important to consider factors such as:

- Quality: Ensure that the aluminum products you source meet your quality standards.

- Certification: Look for suppliers that have the necessary certifications, such as ISO, SGS, and CE.

- Price: Compare prices from different suppliers to get the best value for your money.

- Delivery time: Consider the supplier’s production capacity and delivery time to ensure that they can meet your needs.

- Communication: Work with suppliers that are responsive and communicate effectively to ensure a smooth sourcing process.