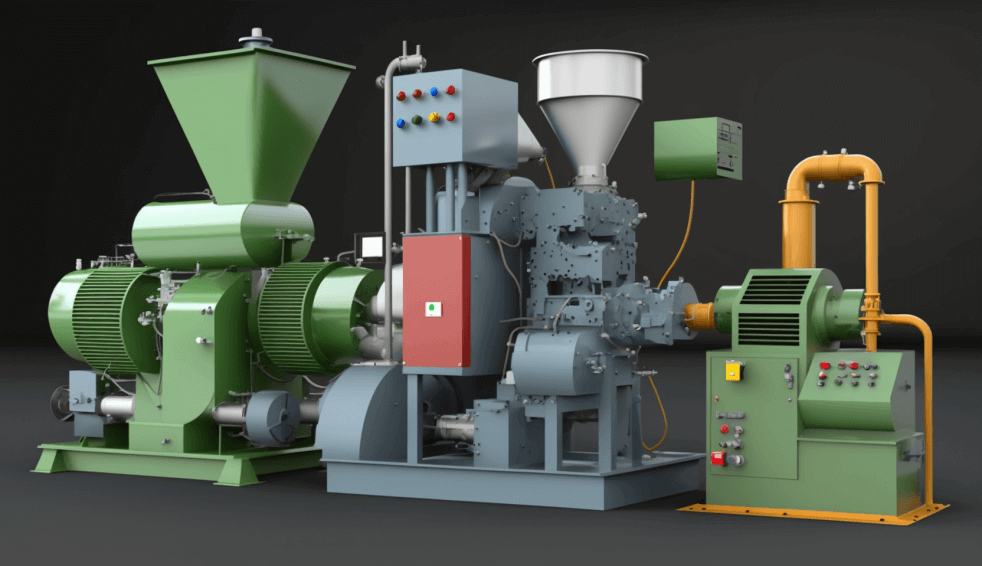

pellet machine

Knowleage about pellet machine

Pellet machines are becoming increasingly popular among people who want to produce their own fuel. Pellet machines are easy to use, and they can produce a high-quality product that is perfect for heating homes and businesses. However, before you invest in a pellet machine, it is important to understand some key facts about them.

First, it is important to understand how pellet machines work. Pellet machines take raw materials, such as sawdust, wood chips, and other biomass materials, and compress them into small pellets. These pellets can then be used as fuel in pellet stoves, furnaces, and boilers.

There are two main types of pellet machines: flat die and ring die. Flat die pellet machines are smaller and less expensive than ring die pellet machines. They are also easier to maintain and repair. Ring die pellet machines are larger and more expensive, but they can produce a larger volume of pellets in a shorter amount of time.

When choosing a pellet machine, it is important to consider the type of raw material you will be using. Some pellet machines are designed to work with specific types of materials, while others can handle a wider range of materials. It is also important to consider the size of the pellets you want to produce. Some pellet machines can produce pellets in different sizes, while others are designed to produce pellets of a specific size.

Another important factor to consider when choosing a pellet machine is the quality of the machine itself. Look for a machine that is well-built and made from high-quality materials. A good pellet machine should be durable, reliable, and easy to use.

Finally, it is important to consider the cost of the pellet machine. Pellet machines can range in price from a few hundred dollars to several thousand dollars. While it may be tempting to choose a cheaper machine, it is important to remember that you get what you pay for. A higher-priced machine may be more expensive upfront, but it will likely be more efficient and produce higher-quality pellets in the long run.

In conclusion, a pellet machine can be a great investment for anyone looking to produce their own fuel. However, it is important to understand how pellet machines work, what type of machine is best for your needs, and how to choose a high-quality machine that will last for years to come. With the right knowledge and equipment, producing your own pellets can be a cost-effective and sustainable way to heat your home or business.

Various Types pellet machine

Pellet machines are a great investment for anyone who wants to make their own pellets. They can be used to create pellets for a variety of purposes, including heating, cooking, and animal feed. There are several different types of pellet machines, each with their own unique features and benefits.

1. Flat Die Pellet Machine

The flat die pellet machine is the most common type of pellet machine. It is a small machine that can be used to make pellets for home heating or animal feed. The flat die pellet machine is relatively simple and easy to use, and it is also very affordable.

2. Ring Die Pellet Machine

The ring die pellet machine is a larger machine that is designed for commercial use. It is capable of producing large quantities of pellets quickly and efficiently. The ring die pellet machine is more expensive than the flat die pellet machine, but it is also more efficient.

3. Vertical Ring Die Pellet Machine

The vertical ring die pellet machine is a newer type of pellet machine that is designed for industrial use. It is similar to the ring die pellet machine, but it is more compact and easier to operate. The vertical ring die pellet machine is also more efficient than the ring die pellet machine.

4. Electric Pellet Machine

The electric pellet machine is a type of pellet machine that is powered by electricity. It is ideal for home use, as it is quiet and easy to operate. The electric pellet machine is also very efficient and produces high-quality pellets.

5. Diesel Pellet Machine

The diesel pellet machine is a type of pellet machine that is powered by diesel fuel. It is ideal for use in remote areas where electricity is not readily available. The diesel pellet machine is also very efficient and produces high-quality pellets.

In conclusion, there are several different types of pellet machines available on the market today. Each type has its own unique features and benefits, so it is important to choose the right type of machine for your specific needs. Whether you are looking for a small machine for home use or a larger machine for commercial use, there is a pellet machine out there that will meet your needs.

FAQ sourcing pellet machine from China manufacturer

Pellet machines are becoming increasingly popular for the production of biomass fuel pellets from a variety of materials, including wood, sawdust, straw, and other agricultural waste. As the demand for biomass fuel pellets continues to grow, many companies are looking for affordable and reliable pellet machines manufactured in China.

If you’re considering purchasing a pellet machine from a Chinese manufacturer, here are some frequently asked questions that can help you make an informed decision:

1. What types of pellet machines are available from Chinese manufacturers?

Chinese pellet machine manufacturers offer a range of models, including flat die pellet mills and ring die pellet mills, which are designed for different production capacity and pellet size requirements. Flat die pellet mills are ideal for small-scale pellet production, while ring die pellet mills are better suited for large-scale pellet production.

2. What materials can be used to produce pellets with a pellet machine?

Pellet machines can be used to produce pellets from a variety of materials, including wood, sawdust, straw, corn stalks, and other agricultural waste. It’s important to choose a pellet machine that’s designed to handle the specific material you plan to use.

3. What’s the production capacity of a pellet machine?

The production capacity of a pellet machine can vary widely depending on the model and manufacturer. Most Chinese manufacturers provide information about the production capacity of their pellet machines, which can range from a few hundred kilograms per hour to several tons per hour.

4. What’s the price range of a pellet machine from a Chinese manufacturer?

The price of a pellet machine from a Chinese manufacturer can vary depending on the model, production capacity, and quality of the machine. Prices for flat die pellet mills typically start at around $500, while ring die pellet mills can cost several thousand dollars or more.

5. How can I ensure the quality of a pellet machine from a Chinese manufacturer?

To ensure the quality of a pellet machine from a Chinese manufacturer, it’s important to do your research and choose a reputable company with a good track record. Look for customer reviews and testimonials, and ask the manufacturer to provide you with details about their quality control processes.

6. What are the payment and delivery terms when sourcing a pellet machine from a Chinese manufacturer?

Payment and delivery terms can vary depending on the manufacturer. It’s important to clarify these terms before placing an order to avoid any misunderstandings or delays. Many Chinese manufacturers require a deposit upfront, with the balance paid upon delivery.

In conclusion, sourcing a pellet machine from a Chinese manufacturer can be a cost-effective way to produce biomass fuel pellets. By understanding the key considerations and asking the right questions, you can find a high-quality pellet machine that meets your production needs and budget.

Applications of pellet machine

Pellet machines have become increasingly popular in recent years due to their versatility and the many applications they can be used for. These machines have proven to be incredibly useful for a variety of industries, from agriculture to energy production, and beyond. Here are some of the top applications of pellet machines.

1. Agriculture

Pellet machines are widely used in agriculture for animal feed production. They can be used to convert raw materials such as corn, soybeans, and wheat into pellets that are easier to store, transport, and feed to livestock. This process helps to reduce feed waste and ensures that animals receive the necessary nutrients they need to thrive.

2. Energy production

Pellet machines can also be used to produce wood pellets, which are an excellent source of renewable energy. These pellets are made from compressed wood shavings, sawdust, and other wood by-products. They can be used in pellet stoves, boilers, and other heating systems, providing a clean and efficient source of heat.

3. Waste management

Pellet machines can also be used to process waste materials such as paper, cardboard, and other biomass waste. These materials can be turned into pellets that can be used as fuel, reducing the amount of waste that ends up in landfills.

4. Industrial manufacturing

Pellet machines are also used in industrial manufacturing processes. They can be used to produce plastic pellets, which are used in the production of a wide range of plastic products. These pellets can be customized to meet specific requirements, such as color, size, and shape.

5. Chemical manufacturing

Pellet machines can also be used in chemical manufacturing processes. They can be used to produce catalysts, which are used in a variety of chemical reactions. The pellets produced by these machines can be customized to meet specific requirements, such as size, shape, and chemical composition.

In conclusion, pellet machines have a wide range of applications, making them incredibly versatile and useful for a variety of industries. They offer a cost-effective and efficient way to convert raw materials into pellets that can be used for a variety of purposes. Whether you are in agriculture, energy production, waste management, or chemical manufacturing, a pellet machine can help you streamline your processes and improve your bottom line.

Industries That Use pellet machine

Pellet machines have been gaining popularity across various industries, and for good reason. These machines are incredibly versatile and efficient, making them ideal for a wide range of applications. In this article, we’ll take a closer look at some of the industries that use pellet machines and the benefits they offer.

1. Agriculture

Pellet machines are commonly used in the agricultural industry to produce animal feed. They can be used to process a variety of materials, including corn, wheat, soybean meal, and alfalfa. The resulting pellets are high in nutritional value and provide a convenient and consistent feed source for livestock.

2. Energy

The energy industry has also embraced the use of pellet machines. Biomass pellets, made from organic materials such as wood chips, sawdust, and agricultural waste, are an excellent source of renewable energy. Pellet machines can produce these pellets quickly and efficiently, making them an attractive option for energy production.

3. Woodworking

Woodworking companies also use pellet machines to create wood pellets, which are used for heating and cooking. These pellets are made from waste products such as sawdust and wood shavings, making them an eco-friendly alternative to traditional fuels.

4. Chemicals

Pellet machines are also used in the chemical industry to produce chemicals in pellet form. This allows for easier handling and transport of the chemicals, as well as more precise dosing. Pelletized chemicals are also less prone to dust and spills, improving safety in the workplace.

5. Food

Finally, the food industry has also started using pellet machines to produce food products in pellet form. This includes products such as breakfast cereals, snack foods, and pet food. Pelletization can improve the shelf life and texture of these products, making them more appealing to consumers.

In conclusion, pellet machines have become an essential tool for various industries. Their versatility and efficiency make them an ideal choice for producing a wide range of products, from animal feed to renewable energy. As technology continues to advance, we can expect to see even more applications for pellet machines in the future.

Manufactured Products made of pellet machine

Pellet machines have become an important tool for many industries to produce a variety of products. These machines have revolutionized the way manufacturers produce goods, offering an efficient and cost-effective way to create large quantities of products. The process involves compressing raw materials using high pressure and heat, creating uniform-shaped pellets that can be used for various applications.

One of the most common products made using pellet machines is wood pellets. These small, compressed pieces of wood are used as fuel for heating homes and businesses. They are made by compressing sawdust and other wood waste, creating a renewable energy source that is environmentally friendly. Wood pellets are a popular alternative to traditional fossil fuels, as they produce less pollution and are much more sustainable.

Another popular product made using pellet machines is animal feed. Pellets are an ideal form of animal feed as they are easy to handle, store and transport. They are also nutritionally balanced, providing a complete diet for many animals. Pelleted feed can be made from a variety of raw materials, including grains, grasses, and even insects. The process of pelletizing animal feed ensures that the nutrients are evenly distributed throughout the feed, making it more digestible for the animal.

Pellet machines are also used to make biomass pellets, which are used in the production of biofuels. Biomass pellets are made from organic materials such as wood, straw, and agricultural waste. They are used in power plants to generate electricity or as fuel for vehicles. The process of creating biomass pellets is an efficient way to use waste materials, reducing the amount of waste that goes to landfill.

In addition to these products, pellet machines are also used to make fertilizers, cat litter, and even BBQ pellets. The versatility of these machines makes them a valuable asset to many industries. Pellet machines are also affordable and easy to operate, making them accessible to small business owners and entrepreneurs.

In conclusion, pellet machines have revolutionized the manufacturing industry, offering an efficient and cost-effective way to produce a variety of products. From wood pellets to animal feed, biomass pellets to fertilizers, these machines have proven to be a valuable asset to many industries. As demand for renewable energy and sustainable products continues to grow, pellet machines will undoubtedly play an increasingly important role in meeting these needs.

The Evolution history of pellet machine

Pellet machines have come a long way since their inception in the early 20th century. Initially, pellet machines were developed to process animal feed and other agricultural products. But over time, their usage has expanded to include a wide range of applications, from producing fuel pellets to manufacturing plastic pellets.

The first pellet machine was invented by a Canadian engineer named Dr. Norman Pellet in the 1930s. Pellet’s machine was designed to produce animal feed pellets using a combination of heat and pressure. The machine was a success, and it quickly gained popularity among farmers and ranchers.

In the 1940s, pellet machines began to be used for industrial purposes. The machines could now produce pellets from various materials, including sawdust, wood chips, and other biomass materials. The resulting pellets were used as fuel for heating and cooking.

The 1950s saw the introduction of the ring die pellet machine, which was much more efficient than its predecessors. The ring die machine used a flat die with holes drilled into it, which allowed for a higher rate of production. This machine was used extensively in the production of animal feed pellets.

The 1960s saw the introduction of the first plastic pellet machine. This machine was used to manufacture plastic pellets from various materials, including polyethylene, polypropylene, and PVC. The resulting pellets were used in the production of plastic products such as toys, containers, and pipes.

In the 1970s, pellet machines saw a surge in popularity due to the energy crisis. The machines were used extensively to produce fuel pellets from biomass materials such as sawdust, wood chips, and agricultural waste. These fuel pellets were used to heat homes and power industrial processes.

In the 1980s, pellet machines began to be used in the production of biofuels. The machines were used to produce pellets from various materials such as corn, wheat, and soybeans. The resulting pellets were used as a renewable source of energy to power vehicles and other machinery.

Today, pellet machines continue to evolve and improve. The latest machines are highly efficient and can produce pellets from a wide range of materials. They are used in the production of fuel pellets, animal feed pellets, and plastic pellets. Pellet machines are also used in the production of biofuels, which are becoming increasingly important as the world looks for renewable sources of energy.

In conclusion, the evolution of pellet machines has been a fascinating journey. From their humble beginnings as animal feed processors to their current role in the production of renewable energy, pellet machines have come a long way. With continued innovation and development, the future of pellet machines looks bright.

The Process of pellet machine

Pellet machines are devices used to create pellets from materials such as wood chips, sawdust, straw, and other biomass. These pellets are used as fuel for stoves, boilers, and other heating systems. The process of pellet machine involves several steps to create high-quality pellets. In this article, we will discuss the process of pellet machine in detail.

Step 1: Preparation of Raw Materials

The first step in the process of pellet machine is the preparation of raw materials. The raw materials used for pellet making should be clean, dry, and free from any foreign materials. It is important to ensure that the raw materials are of consistent quality to produce consistent pellets.

Step 2: Grinding

Once the raw materials are ready, they are ground into small particles using a hammer mill or a wood chipper. This is done to reduce the size of the raw materials, making them more suitable for pelletizing.

Step 3: Drying

After grinding, the raw materials are dried to reduce the moisture content. This is important as excess moisture can affect the quality of the pellets. The drying process can be done using a dryer or by leaving the raw materials in the sun.

Step 4: Pelletizing

The dried raw materials are then fed into the pellet machine. The pellet machine compresses the raw materials, using heat and pressure, to form pellets of a uniform size and shape. The pellets are then cooled and stored for future use.

Step 5: Packaging

The final step in the process of pellet machine is packaging. The pellets are packaged in bags, which are then sealed to prevent moisture and contamination. The bags are labeled with the type of pellets, the date of manufacture, and other relevant information.

Conclusion

The process of pellet machine is a complex process that involves several steps. From the preparation of raw materials to the packaging of pellets, every step is important in ensuring the production of high-quality pellets. With the increasing demand for renewable energy sources, the use of pellet machines is becoming more popular. By understanding the process of pellet machine, you can create your own pellets and contribute to a greener environment.

Benefits Advantages of Utilizing pellet machine

Pellet machines have become increasingly popular among farmers, industrialists and homeowners in recent times. They are highly efficient machines that are used to convert waste material into high-quality fuel pellets. Pellet machines are designed to process various materials such as wood chips, sawdust, straw, cornstalks, and many others.

There are numerous benefits and advantages of utilizing pellet machines. Firstly, pellet machines produce high-quality fuel pellets that are environmentally friendly. These fuel pellets are carbon-neutral, meaning they do not contribute to global warming. As such, they can be used as a substitute for fossil fuels such as coal, oil and natural gas. This is beneficial for the environment as it helps to reduce greenhouse gas emissions.

Secondly, pellet machines are highly efficient. They are designed to produce large quantities of fuel pellets in a short period of time. This means that farmers and industrialists can produce large amounts of fuel pellets in a short period of time, which can be sold for profit. Additionally, pellet machines are easy to operate and maintain, making them a cost-effective investment in the long run.

Thirdly, fuel pellets produced by pellet machines have a high-energy content. This makes them an excellent source of fuel for heating homes, industrial boilers, and other applications. Additionally, fuel pellets are easy to transport and store, making them a convenient option for homeowners and industrialists alike.

Fourthly, pellet machines can be used to process a wide range of materials. This means that farmers and industrialists can utilize waste materials such as sawdust, wood chips, and other agricultural waste to produce fuel pellets. This reduces the amount of waste that is sent to landfills, which is beneficial for the environment.

In conclusion, pellet machines are beneficial for farmers, industrialists, and homeowners alike. They produce high-quality fuel pellets that are environmentally friendly, highly efficient, and easy to use. Additionally, pellet machines can be used to process a wide range of materials, reducing waste and contributing to a sustainable future.

Disadvantages pellet machine

Pellet machines have become increasingly popular in recent years due to their ability to produce high-quality pellets for various applications. These machines are utilized in industries such as agriculture, animal feed, energy, and many more. Despite their popularity, however, there are some significant disadvantages to using a pellet machine that are worth considering.

First and foremost, pellet machines require a significant amount of energy to operate. This energy requirement can come from either electricity or fuel, both of which can be costly. Additionally, the production of pellets requires a lot of heat, which can make the manufacturing process expensive and time-consuming.

Another disadvantage of pellet machines is that they can be quite noisy when in operation. This can be a problem for workers who need to be in close proximity to the machines for extended periods. The noise pollution can also be a problem for those living nearby, particularly in residential areas.

Pellet machines can also be quite bulky and take up a lot of space. This can be a problem for smaller operations that have limited storage space. Additionally, the machines can be quite heavy, making them difficult to move around or transport.

Finally, pellet machines require regular maintenance to keep them in good working order. This can be time-consuming and expensive, as parts may need to be replaced or repaired regularly. If not properly maintained, pellet machines can break down, which can lead to costly repairs and downtime.

Despite these disadvantages, pellet machines remain a popular choice for many industries due to their ability to produce high-quality pellets quickly and efficiently. However, before investing in a pellet machine, it is important to carefully consider the associated disadvantages and ensure that the benefits outweigh the costs.

Selecting the Ideal pellet machine Manufacturer

Pellet machines are becoming increasingly popular among farmers, entrepreneurs, and even homeowners who want to make their own fuel or animal feed. However, with so many pellet machine manufacturers out there, it can be challenging to know which one to choose. Here are some factors to consider when selecting the ideal pellet machine manufacturer.

Quality of the Machine

The quality of the pellet machine is the most critical factor to consider when selecting a manufacturer. You want a machine that is reliable, durable, and produces high-quality pellets. Look for manufacturers who use high-grade materials in their machines and have a track record of producing quality products.

Production Capacity

The production capacity of the pellet machine is another factor to consider. If you plan to use the machine for commercial purposes, you need a machine that can produce a large volume of pellets per hour. On the other hand, if you plan to use the machine for personal use, a smaller machine may suffice.

Ease of Maintenance

A pellet machine requires maintenance to keep it running smoothly. Look for manufacturers who provide easy-to-follow maintenance instructions and offer customer support for any issues that may arise. Also, consider the availability of replacement parts for the machine.

Price

The price of the pellet machine is also a crucial factor to consider. You want a machine that fits your budget, but you also want to ensure that you are getting a quality machine. Compare prices from different manufacturers and choose the one that offers the best value for your money.

Warranty

A warranty is an essential aspect of any purchase. Look for manufacturers who offer a warranty on their machines. A warranty gives you peace of mind that you are protected in case of any defects or malfunctions in the machine.

Customer Reviews

Finally, customer reviews are an excellent way to know the performance of a pellet machine manufacturer. Look for reviews from other customers who have purchased and used the machine. This will give you an idea of the quality of the machine and the level of customer support that the manufacturer provides.

In conclusion, selecting the ideal pellet machine manufacturer requires careful consideration of several factors. By choosing a quality machine, with a large production capacity, easy maintenance, a reasonable price, a warranty, and positive customer reviews, you can be confident that you are making a wise investment.

Things to Consider When Purchasing pellet machine

Pellet machines have become increasingly popular in recent years. They are used for making pellets from various materials, including wood, biomass, and feed. These machines are ideal for anyone who wants to make pellets for personal or commercial use. However, with so many pellet machines available in the market, it can be challenging to choose the right one. Here are some things to consider when purchasing a pellet machine.

1. Purpose of the Pellet Machine

Before purchasing a pellet machine, you need to determine why you need it. Is it for personal use or commercial use? If you only plan on making pellets for personal use, then a small pellet machine will suffice. However, if you plan on using it for commercial use, then you will need a larger machine that can produce pellets in large quantities.

2. Pellet Machine Output

The output of the pellet machine is another crucial factor to consider. The output is the amount of pellets that the machine can produce in an hour. If you plan on using the machine for commercial purposes, then you need to choose a machine with a high output capacity. However, if you only plan on using it for personal use, then a machine with a lower output capacity will suffice.

3. Pellet Machine Power

The power of the pellet machine is also important. The power rating of the machine determines its efficiency and performance. If you plan on using the machine for commercial purposes, then you need to choose a machine with a high power rating. However, if you only plan on using it for personal use, then a machine with a lower power rating will suffice.

4. Pellet Machine Price

The price of the pellet machine is another important consideration. Pellet machines are available in different price ranges, and you need to choose one that fits your budget. However, you should not compromise on quality for the price. Ensure that you choose a machine that is affordable and of high quality.

5. Pellet Machine Brand and Reputation

The brand and reputation of the pellet machine manufacturer are important considerations. You should choose a machine from a reputable manufacturer with a good track record. This will ensure that you get a high-quality machine that will last for a long time.

Conclusion

Purchasing a pellet machine can be a daunting task, but with the right information, it can be a smooth process. When purchasing a pellet machine, you need to consider the purpose of the machine, the output, power, price, brand, and reputation of the manufacturer. With these considerations in mind, you can choose a pellet machine that will suit your needs and budget.

Properties pellet machine

Pellet machines are becoming increasingly popular as a means of processing biomass materials into fuel pellets. These machines are particularly useful for those who have access to large quantities of waste wood, straw, corn stalks, and other biomass materials and want to convert it into a more compact and efficient fuel source.

The properties of pellet machines can vary depending on the specific model and manufacturer. However, there are some common features that are typically found in most pellet machines.

Firstly, pellet machines have a hopper or container where the raw materials are loaded. The hopper is usually located at the top of the machine and can hold several pounds of material at once. The raw materials are then fed into the machine through a feeder mechanism, where they are compressed and extruded through a die.

The die is an important component of the pellet machine, as it determines the size and shape of the pellets that are produced. Different dies can be used to produce pellets of varying sizes and shapes, depending on the intended use of the fuel.

Another important property of pellet machines is their capacity. The capacity of a pellet machine refers to the amount of pellets it can produce in a given time period. This is typically measured in pounds per hour, and can range from a few hundred pounds to several tons per hour.

Pellet machines also require a power source to operate. Some machines are powered by electricity, while others use diesel or gasoline engines. The power source is used to drive the various components of the machine, including the feeder mechanism, the compression chamber, and the extrusion die.

One of the key benefits of using a pellet machine is that it can produce a uniform product that is easy to transport and store. Pellets are typically more dense than the raw biomass materials, which means they take up less space and are easier to handle. This makes them an ideal fuel source for heating systems, stoves, and boilers.

In conclusion, pellet machines are becoming an increasingly popular means of processing biomass materials into fuel pellets. These machines offer a number of benefits, including the ability to produce a uniform product, high capacity, and the ability to use a variety of raw materials. If you have access to a large quantity of waste biomass materials, a pellet machine may be a worthwhile investment to help you convert it into a more efficient fuel source.

How to use pellet machine

Pellet machines are becoming increasingly popular among farmers and small-scale industries for producing wood pellets, animal feed and biomass fuel. The machines provide an easy and cost-effective way to convert raw materials into pellets that can be used for various purposes.

If you are new to using pellet machines, this guide will help you get started.

Choose the Right Pellet Machine

The first step in using a pellet machine is to choose the right one based on your needs. There are different types of pellet machines, each designed for specific applications. Factors to consider when choosing a machine include the type of raw materials you want to use, the pellet size you want to produce, and the production capacity you require.

Prepare the Raw Materials

The next step is to prepare the raw materials for pellet production. This involves cleaning, drying, and grinding them into the correct size. Raw materials can include sawdust, wood shavings, corn stalks, rice husks, and other agricultural waste products.

Load the Raw Materials

Once the raw materials are ready, load them into the pellet machine’s hopper. The hopper is the container that holds the raw materials and feeds them into the machine. Make sure to load the hopper with the right amount of raw materials to avoid overloading or underloading the machine.

Start the Pellet Machine

After loading the machine, turn it on and adjust the settings based on the type of raw materials and pellet size you want to produce. Most pellet machines have adjustable settings for temperature, pressure, and speed. Make sure to follow the manufacturer’s instructions when adjusting the settings.

Collect the Pellets

As the machine runs, the pellets will start to form and come out of the machine’s outlet. Collect the pellets in a container or bag and store them in a dry place. Proper storage will ensure the pellets remain in good condition and do not spoil.

Clean the Pellet Machine

After use, make sure to clean the pellet machine thoroughly. This will prevent any leftover raw materials from clogging the machine and causing damage. Use a brush or vacuum cleaner to remove any debris or dust that may have accumulated inside the machine.

In conclusion, using a pellet machine is a straightforward process that anyone can learn. By following these simple steps, you can produce high-quality pellets that can be used for various applications. Remember to choose the right machine, prepare the raw materials correctly, and clean the machine after use to ensure optimal performance.

Glossary Terminology Terms pellet machine

Pellet machines are devices utilized in transforming raw materials into pellets. These pellets serve as a fuel source for heating systems, animal feed, and other purposes. The device is used to compress the raw material into a compact form, which can be used in a variety of ways. Pellet machines come in different sizes, ranging from small machines for household use to large industrial machines.

Pellet machines can be classified into two types: flat die and ring die. Flat die pellet machines are more suitable for small-scale production, while ring die pellet machines are more appropriate for large-scale production. The flat die pellet machine works by rotating a die or plate, which compresses the raw material into pellets. On the other hand, the ring die pellet machine utilizes a rotating ring die and rollers to compress the raw material into pellets.

Pellet machines have become increasingly popular in recent years, especially in the agricultural sector. They are used in the production of animal feed, which can be made from a variety of raw materials, such as corn, wheat, and soybean meal. The pellets produced by the machine are more compact and easier to store, making them more convenient for farmers.

Pellet machines are also used in the production of biomass fuel. Biomass fuel is made from renewable sources such as wood chips, sawdust, and agricultural waste. The pellets produced from these materials are used as fuel for heating systems in homes and businesses. This form of energy is considered to be more sustainable and eco-friendly than traditional fossil fuels.

In addition to their use in the agricultural sector, pellet machines are also used in the production of wood pellets. These pellets are made from sawdust and wood shavings and are used as a fuel source in wood stoves and boilers. They are considered to be a cleaner and more efficient fuel source than traditional firewood.

In conclusion, pellet machines are devices that are used to transform raw materials into pellets. They are used in a variety of industries, including agriculture, biomass fuel production, and wood pellet production. Pellet machines have become increasingly popular in recent years due to their convenience, efficiency, and eco-friendliness.

Pellet machine price

contact [email protected], get the price for Pellet machine

Pellet machine prices can vary widely depending on factors such as the type of machine, its production capacity, brand, and features. Generally, the price range for pellet machines is between a few hundred to several thousand dollars.

For example, a small pellet machine with a production capacity of 100-150 kg/hour may cost around $400-$800 USD. A vertical machine with a production capacity of around 500-700 kg/hour may range between $2,500-$4,500 USD. A large-scale pellet machine with a capacity of more than 1,000 kg/hour can cost upwards of $10,000 USD.

It’s important to note that pellet machines with advance features and automation may cost more than basic models. Additionally, product quality, warranty, and after-sales service also affect pellet machine prices. It’s recommended that you do research and compare different brands and models before making a purchase.