fly ash bricks machine sourcing guide

Knowleage about fly ash bricks machine

Fly ash bricks have become a popular alternative to traditional clay bricks due to their eco-friendly nature and cost-effectiveness. Fly ash, a byproduct of coal combustion, is mixed with water and cement to make these bricks. The use of fly ash bricks has the potential to significantly reduce carbon emissions and landfills while also saving money.

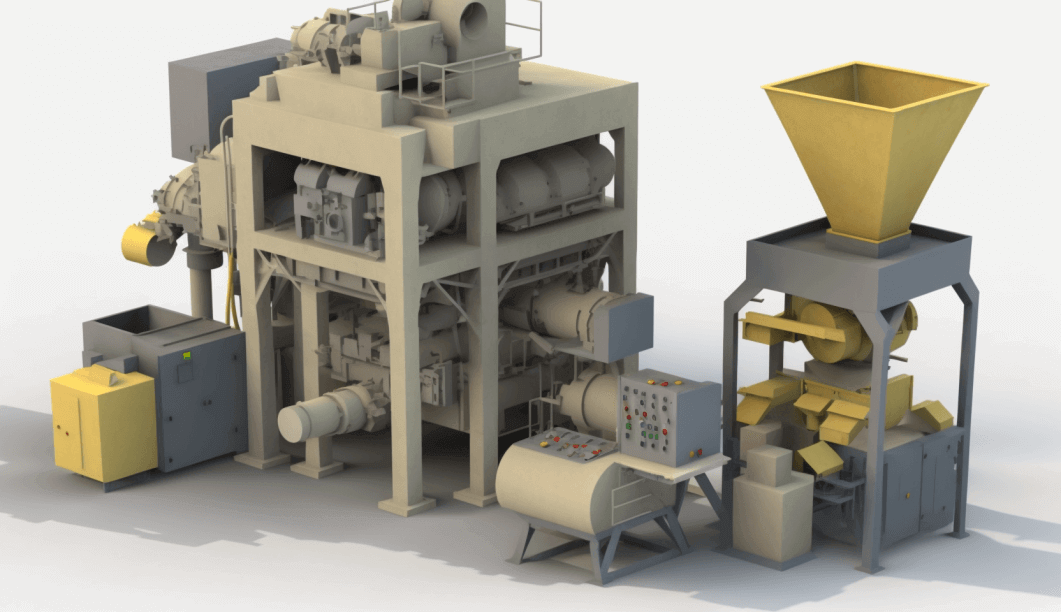

Fly ash bricks are made using a fly ash bricks machine, which is designed to produce bricks in large quantities with minimal labor. These machines come in different sizes and capacities, and can produce varying numbers of bricks per hour. The machine uses a hydraulic system to compress the raw materials into a brick shape, which is then cured and dried.

There are several advantages of using a fly ash bricks machine. Firstly, it reduces the need for manual labor, making the process more efficient and cost-effective. Secondly, the machine can produce bricks of uniform size and shape, which is important for construction projects. Thirdly, the use of fly ash bricks reduces the need for clay bricks, which is a non-renewable resource.

When purchasing a fly ash bricks machine, there are several factors to consider. The capacity of the machine, the quality of the bricks produced, and the durability of the machine are all important considerations. Some machines come with additional features such as automatic feeding and mixing systems, which can further increase efficiency.

It is also important to ensure that the machine is maintained properly to ensure its longevity and efficiency. Regular cleaning, greasing, and oiling of the machine can help prevent breakdowns and ensure that it operates smoothly. It is also important to follow the manufacturer’s instructions for use and maintenance.

In conclusion, the use of fly ash bricks and a fly ash bricks machine can have significant benefits for the environment and construction industry. By choosing the right machine and maintaining it properly, businesses can produce high-quality bricks efficiently and cost-effectively. This can ultimately lead to a more sustainable and eco-friendly approach to construction.

Various Types fly ash bricks machine

Fly ash bricks are becoming increasingly popular due to their cost-effectiveness, durability, and eco-friendliness. Fly ash bricks are made from fly ash, a by-product of coal-fired power plants, and are considered to be a sustainable alternative to traditional clay bricks.

Fly ash bricks machines have revolutionized the brick manufacturing industry by automating the process and making it more efficient. There are various types of fly ash bricks machines available in the market, each with its unique features and advantages. In this article, we will discuss some of the most popular types of fly ash bricks machines.

1. Fully automatic fly ash bricks machine

Fully automatic fly ash bricks machines are the most advanced type of machines available in the market. These machines are equipped with an automatic material feeding system, automatic mixing system, and automatic brick forming system. The bricks are formed using hydraulic pressure, and the machine can produce up to 24,000 bricks per hour. This machine is ideal for large-scale production and requires minimal labor.

2. Semi-automatic fly ash bricks machine

Semi-automatic fly ash bricks machines are a popular choice for small and medium-scale brick manufacturing units. These machines require some manual intervention, such as feeding the raw materials and removing the finished products. The machine can produce up to 6,000 bricks per hour and is more affordable than fully automatic machines.

3. Hydraulic fly ash bricks machine

Hydraulic fly ash bricks machines use hydraulic pressure to form bricks. These machines are highly efficient and can produce up to 12,000 bricks per hour. The hydraulic system allows for precise pressure control, resulting in uniform brick size and shape. These machines are ideal for large-scale production and require minimal labor.

4. Manual fly ash bricks machine

Manual fly ash bricks machines are the most basic type of machines available in the market. These machines are operated manually, and the bricks are formed using manual pressure. The machine can produce up to 2,000 bricks per hour and is ideal for small-scale production. These machines are more affordable than other types of machines but require more labor.

In conclusion, fly ash bricks machines have revolutionized the brick manufacturing industry by automating the process and making it more efficient. The type of machine you choose depends on your production requirements and budget. Fully automatic machines are ideal for large-scale production, while manual machines are suitable for small-scale production. Hydraulic machines are highly efficient and produce uniform bricks, while semi-automatic machines are affordable and require less labor. Choose the machine that best suits your needs and start producing high-quality fly ash bricks today!

Sourcing fly ash bricks machine from China manufacturer

Fly ash brick making machine is a popular choice among brick manufacturers today. Fly ash brick, also known as AAC brick, is an environmentally friendly material used in the construction industry and is made from finely ground clay and other materials such as fly ash and cement. Fly ash brick making machines are made in China and have become a popular choice for those looking to source their equipment from a reliable supplier.

When sourcing a fly ash brick making machine from a Chinese manufacturer, there are several factors to consider. First, it is important to understand the type of machine needed. Fly ash brick making machines come in several types with different features and capabilities. For example, some machines are designed to produce smaller bricks while others are capable of producing larger bricks. Additionally, some machines can be used to produce multiple types of bricks, such as facing bricks and hollow bricks.

The next step is to research the various Chinese manufacturers and to assess their quality and reputation. There are several ways to do this including reading online reviews and visiting the manufacturer’s website. It is also important to inspect the machine in person to ensure that it is suitable for the intended purpose.

When negotiating the terms of purchase, the buyer should consider the size of the order, delivery times, payment terms, and warranties. The buyer should also inquire about the manufacturer’s after-sales service and the availability of spare parts.

Finally, it is important to consider the cost of the machine. Fly ash brick making machines are available at a range of prices and it is important to compare the quality and features of the machines from different manufacturers. Additionally, it is important to factor in the cost of shipping, installation and maintenance when calculating the cost of the machine.

By undertaking adequate research and understanding the available options, buyers can ensure that they source a reliable and cost-effective fly ash brick making machine from a reputable Chinese manufacturer.

Applications of fly ash bricks machine

Fly ash bricks machine is a revolutionary innovation in the field of construction. It is a modern technology that has brought a significant change in the way bricks are produced. Fly ash bricks are made using fly ash, lime, and other materials, which make them stronger, durable, and eco-friendly. This machine has found applications in various areas and has become an essential part of the construction industry. In this article, we will talk about the various applications of the fly ash bricks machine.

1. Construction of Buildings

Fly ash bricks are used in the construction of buildings, including residential, commercial, and industrial buildings. These bricks are highly durable and have better strength than traditional bricks. They can withstand harsh weather conditions and are resistant to fire and water. Moreover, fly ash bricks are eco-friendly, as they are made from fly ash, a waste material generated by thermal power plants, reducing the carbon footprint of the construction industry.

2. Road Construction

Fly ash bricks are also used in the construction of roads. They are mixed with cement and other materials to make a strong and durable road surface. The use of fly ash bricks in road construction ensures better stability, durability, and strength, making the roads last longer than traditional roads.

3. Dam Construction

Fly ash bricks are also used in the construction of dams. Dams require strong and durable materials, and fly ash bricks provide the same. They are mixed with cement and other materials to make a strong and durable structure that can withstand the pressure of water.

4. Landscaping

Fly ash bricks are used in landscaping projects, such as garden pathways, retaining walls, and decorative walls. They provide a natural and aesthetic look to the landscape and are highly durable, making them perfect for outdoor projects.

5. Infrastructure Projects

Fly ash bricks are used in infrastructure projects, such as bridges, tunnels, and flyovers. These projects require strong and durable materials that can withstand heavy traffic and environmental factors. Fly ash bricks provide the same and are an ideal choice for infrastructure projects.

In conclusion, the fly ash bricks machine has found applications in various areas of construction and infrastructure development. Its eco-friendliness, durability, and strength make it an ideal choice for modern construction projects. The machine has revolutionized the construction industry and has become an essential part of it.

Manufactured Products made of fly ash bricks machine

Fly ash bricks machine is a technology that has revolutionized the construction industry by providing an eco-friendly and cost-effective alternative to traditional bricks. Fly ash bricks are made from a mixture of fly ash, cement, and sand, which are compressed and shaped into bricks using a specialized machine.

One of the primary advantages of using fly ash bricks is that they are made from waste material, fly ash, which is a by-product of coal combustion. Fly ash is abundantly available, and using it in brick production reduces the amount of waste sent to landfills, thus reducing the environmental impact.

Fly ash bricks are also stronger and more durable than traditional bricks, making them ideal for construction projects. The bricks have a uniform size and shape, which makes them easy to work with, and they require less mortar than traditional bricks.

Using fly ash bricks also results in faster construction times, as the bricks are lighter and easier to handle. This translates to lower labor costs and shorter construction times, which can save developers both time and money.

In addition to being used in construction, fly ash bricks can also be used to create a range of other products. These include pavers, blocks, and tiles, which can be used for landscaping and outdoor projects. Fly ash bricks can also be used to create decorative elements such as sculptures and fountains.

The use of fly ash bricks is gaining popularity worldwide, with many countries adopting the technology as a sustainable alternative to traditional bricks. India, in particular, has been at the forefront of fly ash brick production, with the government incentivizing the use of fly ash bricks in construction projects.

Fly ash bricks are an excellent example of how technology can be used to create sustainable solutions for the construction industry. By using waste materials to create high-quality building materials, we can reduce our environmental impact while still meeting the demands of the construction industry. It is time for more countries to adopt this technology and embrace sustainable construction practices.

The Evolution history of fly ash bricks machine

Fly ash bricks have become an increasingly popular alternative to traditional clay bricks in recent years. These bricks are made using fly ash, a byproduct of coal combustion, which is mixed with cement and other materials to create a durable, eco-friendly building material. However, the process of manufacturing fly ash bricks has undergone a significant evolution over the years.

The first fly ash bricks were produced manually using wooden molds. This process was slow and labor-intensive, with workers having to manually mix the materials, pour them into molds, and then allow them to dry before removing the bricks. The resulting bricks were often of varying quality and shape, making them unsuitable for large-scale construction projects.

In the 1980s, the first mechanized fly ash brick machines were introduced. These machines automated the process of mixing the materials, molding the bricks, and drying them. This greatly increased the speed and efficiency of the manufacturing process, while also improving the quality and consistency of the bricks.

Over the years, fly ash brick machines have continued to evolve and improve. Today, there are a variety of different machines available, each with its own unique features and capabilities. Some machines are designed for small-scale production, while others can produce thousands of bricks per hour.

One of the most significant developments in the evolution of fly ash brick machines has been the introduction of hydraulic technology. Hydraulic machines use hydraulic pressure to compress the materials and create the bricks. This allows for greater precision and control in the manufacturing process, resulting in bricks that are stronger, more uniform, and more resistant to cracking and chipping.

Another important development has been the integration of computerized controls and automation. Modern fly ash brick machines can be programmed to precisely control the mixing, molding, and drying processes, ensuring that each brick is of consistent quality and size. This also allows for greater flexibility in the manufacturing process, making it easier to produce custom designs and shapes.

In addition to these technological advancements, there has also been a growing focus on sustainability in the manufacturing of fly ash bricks. Many modern machines are designed to minimize waste and energy consumption, while also using environmentally friendly materials and processes.

Overall, the evolution of fly ash brick machines has been driven by a combination of technological innovation, market demand, and a growing awareness of the need for sustainable building materials. As these machines continue to evolve and improve, they are likely to become an even more important part of the construction industry, offering a cost-effective and eco-friendly alternative to traditional clay bricks.

The Process of fly ash bricks machine

Fly ash bricks are a popular alternative to traditional clay bricks due to their cost-effectiveness, durability and eco-friendliness. The manufacturing process of fly ash bricks involves the use of a fly ash bricks machine, which is a specialized equipment designed to produce high-quality bricks using fly ash as the primary raw material.

The process of manufacturing fly ash bricks using a fly ash bricks machine involves several steps, which include:

Step 1: Feeding of Raw Materials

The first step in the manufacturing process of fly ash bricks is the feeding of raw materials into the machine. The raw materials used in the production of fly ash bricks include fly ash, cement, sand, water, and other additives. These materials are fed into the machine in the right proportion, depending on the desired quality and strength of the bricks.

Step 2: Mixing and Grinding

Once the raw materials are fed into the machine, they are mixed and ground to form a homogeneous mixture. The mixing and grinding process is critical to ensure that the fly ash bricks have a consistent quality and strength. The machine uses powerful motors and blades to grind and mix the raw materials into a fine powder.

Step 3: Molding

After the mixing and grinding process, the next step is molding. The fly ash bricks machine uses a hydraulic system to mold the mixture into the desired shape and size. The machine can produce various sizes and shapes of bricks, depending on the mold used.

Step 4: Curing

Once the bricks are molded, they are left to cure for a specific period. The curing process involves the exposure of the bricks to air and moisture, which allows them to harden and gain strength. The duration of the curing process depends on the quality and strength of the bricks.

Step 5: Drying and Stacking

After the curing process, the bricks are removed from the machine and left to dry in the sun or in a drying chamber. The drying process is critical to ensure that the bricks have the required strength and durability. Once the bricks are dry, they are stacked and packed for transportation and distribution.

In conclusion, the manufacturing process of fly ash bricks using a fly ash bricks machine is a highly efficient and cost-effective alternative to traditional clay bricks. The process involves several steps, including the feeding of raw materials, mixing and grinding, molding, curing, and drying and stacking. The use of fly ash bricks can significantly reduce the environmental impact of construction and provide a sustainable solution for the building industry.

Benefits Advantages of Utilizing fly ash bricks machine

Fly ash bricks machine is a revolutionary technology that is gaining popularity in the construction industry. This technology is used to manufacture fly ash bricks that are not only durable but also cost-effective. Fly ash bricks machine is designed to use fly ash, a by-product of coal-fired power plants, as the main raw material. Fly ash is a waste product that is usually disposed of in landfills, but with the use of fly ash bricks machine, it can be turned into a valuable resource.

There are many benefits of utilizing fly ash bricks machine in construction. Here are some of the advantages of using fly ash bricks machine:

1. Cost-effective: Fly ash bricks machine is a cost-effective technology as it uses fly ash, a waste product that is available at a low cost. The cost of manufacturing fly ash bricks is much lower than that of traditional clay bricks, making them an affordable option for construction projects.

2. Environmentally friendly: Fly ash bricks machine is an environmentally friendly technology as it uses a waste product that would otherwise end up in landfills. By using fly ash bricks, construction projects can reduce their carbon footprint and contribute to a greener environment.

3. Durable: Fly ash bricks are known for their durability and strength. They are resistant to heat, moisture, and chemicals, making them an ideal choice for construction projects. Fly ash bricks also have a longer life span compared to traditional clay bricks, reducing the need for frequent repairs and replacements.

4. Easy to manufacture: Fly ash bricks machine is easy to operate and requires minimal manual intervention. The machine can produce a large number of bricks in a short period, making it an ideal choice for large construction projects.

5. Versatile: Fly ash bricks can be used for a wide range of construction projects, including residential, commercial, and industrial buildings. They can also be used for paving driveways, walkways, and other outdoor areas.

In conclusion, fly ash bricks machine is a game-changer in the construction industry. It is a cost-effective, environmentally friendly, durable, easy-to-manufacture, and versatile technology that is ideal for a wide range of construction projects. By utilizing fly ash bricks machine, construction projects can save money, reduce their carbon footprint, and build structures that are strong and long-lasting.

Disadvantages fly ash bricks machine

Fly ash bricks are a popular choice in the construction industry due to their cost-effectiveness and durability. However, the production of these bricks requires the use of fly ash bricks machines, which come with their fair share of disadvantages.

One of the major disadvantages of using fly ash bricks machines is their high initial cost. The machines require a significant investment, which can be a challenge for small-scale brick manufacturers. The cost of maintenance and repairs can also be high, adding to the overall cost of production.

Another disadvantage of fly ash bricks machines is their energy consumption. These machines require a significant amount of energy to operate, which can result in high electricity bills. This is especially true for large-scale manufacturers who need to run multiple machines simultaneously.

The production process of fly ash bricks machines also generates a lot of noise and dust, which can be harmful to workers’ health. The dust and debris produced during the manufacturing process can cause respiratory problems and other health issues if not controlled properly.

Fly ash bricks machines are also limited in terms of the size and shape of bricks they can produce. This can be a disadvantage for manufacturers who require a variety of brick sizes and shapes to meet the demands of their customers.

Finally, fly ash bricks machines require skilled operators who have experience in handling the machines. This can be a challenge for small-scale manufacturers who may not have the resources to hire skilled workers.

In conclusion, while fly ash bricks machines offer many advantages in terms of cost-effectiveness and durability, they come with their fair share of disadvantages. These include high initial costs, high energy consumption, health hazards, limited production capacity, and the need for skilled operators. As such, brick manufacturers must weigh the pros and cons of using fly ash bricks machines before investing in them.

Selecting the Ideal fly ash bricks machine Manufacturer

Fly ash bricks are becoming increasingly popular due to their eco-friendly nature, durability, and cost-effectiveness. As a result, the demand for fly ash bricks machines is on the rise. However, not all fly ash bricks machine manufacturers are created equal. Choosing the ideal manufacturer is crucial to ensuring that you get a quality machine that meets your specific needs. Here are some key factors you need to consider when selecting the ideal fly ash bricks machine manufacturer.

1. Experience and reputation

One of the most important factors to consider when choosing a fly ash bricks machine manufacturer is their experience and reputation. Look for a manufacturer that has been in the industry for many years and has a good reputation for producing high-quality machines. You can check their website for reviews from previous customers or ask for references.

2. Quality of machines

The quality of the machines produced by the manufacturer is another important factor to consider. Look for a manufacturer that uses high-quality materials and parts to ensure that their machines are durable and reliable. You can also ask for a demonstration of the machine to see how it performs and check the finished products for quality.

3. Customization options

Every construction project is unique, and you need a fly ash bricks machine that can be customized to meet your specific needs. Look for a manufacturer that offers customization options such as different sizes and shapes of bricks, different molding options, and the ability to use different types of raw materials.

4. After-sales support

A good fly ash bricks machine manufacturer should offer after-sales support to help you with any issues that may arise with the machine. Look for a manufacturer that offers training, technical support, and spare parts to ensure that your machine stays in good condition and operates smoothly.

5. Price

While price is an important factor to consider, it should not be the only factor. Look for a manufacturer that offers a fair price for their machines while also considering the quality and features of the machine.

In conclusion, choosing the ideal fly ash bricks machine manufacturer requires careful consideration of several factors, including experience and reputation, quality of machines, customization options, after-sales support, and price. By taking these factors into account, you can find a manufacturer that will provide you with a high-quality machine that meets your specific needs.

Things to Consider When Purchasing fly ash bricks machine

Fly ash bricks have gained significant popularity in the construction industry due to their durability, strength, and cost-effectiveness. These bricks are made from fly ash, which is a byproduct of coal combustion, and are known for their eco-friendliness. If you are planning to invest in a fly ash bricks machine, there are several things to consider. In this article, we will discuss some of the critical factors to keep in mind when purchasing a fly ash bricks machine.

1. Production Capacity

One of the vital factors to consider when selecting a fly ash bricks machine is its production capacity. The production capacity of the machine determines the number of bricks it can produce in a given time. Therefore, it is essential to choose a machine that can meet your production needs. If you plan to produce a large quantity of bricks, a machine with a high production capacity would be suitable.

2. Quality of Bricks

The quality of bricks produced by a fly ash bricks machine depends on the quality of the machine itself. Therefore, it is essential to choose a machine that produces high-quality bricks. The machine should be capable of producing bricks that are uniform in size, shape, and strength. A machine that produces low-quality bricks can lead to wastage of time, money, and resources.

3. Cost

The cost of the fly ash bricks machine is another crucial factor to consider. The price of the machine will depend on its production capacity, quality, and features. Therefore, it is essential to set a budget and choose a machine that fits within your budget. However, you should not compromise on the quality of the machine to save money. It is better to invest in a high-quality machine that will provide better returns in the long run.

4. Maintenance and Support

Like any other machine, a fly ash bricks machine requires regular maintenance to ensure optimal performance. Therefore, it is essential to choose a machine that is easy to maintain and comes with adequate support from the manufacturer. The manufacturer should provide training on how to operate and maintain the machine to ensure its longevity and maximum productivity.

5. Reputation of the Manufacturer

The reputation of the manufacturer is another crucial factor to consider when selecting a fly ash bricks machine. You should choose a manufacturer with a good reputation in the market. A reputable manufacturer will provide high-quality machines, excellent customer service, and technical support. You can research online, read reviews, and ask for recommendations from other users to find a reputable manufacturer.

In conclusion, purchasing a fly ash bricks machine requires careful consideration of several factors. You should consider the production capacity, quality of bricks, cost, maintenance and support, and the reputation of the manufacturer. By keeping these factors in mind, you can choose a machine that will provide you with excellent returns on your investment and help you produce high-quality bricks.

Properties fly ash bricks machine

Fly ash bricks have become increasingly popular in the construction industry. These bricks are made from fly ash, which is a byproduct of coal combustion. The use of fly ash bricks is not only environmentally friendly, but also cost-effective. In order to produce these bricks, a fly ash bricks machine is required. In this article, we will discuss the properties of a fly ash bricks machine.

The fly ash bricks machine is a hydraulic press that compresses fly ash and other materials into bricks. The machine is designed to produce high-quality bricks that are strong, durable, and resistant to weathering. The properties of the machine are as follows:

1. Sturdy construction – The machine is made of high-quality materials that are sturdy and durable. The frame of the machine is made of steel, which provides strength and stability.

2. High efficiency – The machine is designed to produce a large number of bricks in a short period of time. It has a high production capacity and can produce up to 10,000 bricks per hour.

3. Low maintenance – The machine is easy to maintain and requires minimal maintenance. It has a simple design and is easy to operate, which makes it ideal for small-scale production.

4. Energy-efficient – The machine is designed to be energy-efficient and consumes less power. It is equipped with a hydraulic system that reduces energy consumption and increases efficiency.

5. Versatile – The machine can be used to produce different types of bricks, including interlocking bricks, hollow bricks, and solid bricks. It can also be used to produce fly ash blocks and paver blocks.

6. Environmentally friendly – The machine uses fly ash, which is a byproduct of coal combustion. By using fly ash, the machine reduces the amount of waste generated and helps to protect the environment.

In conclusion, the fly ash bricks machine is an essential tool for the production of high-quality bricks. It is designed to be sturdy, efficient, low-maintenance, energy-efficient, versatile, and environmentally friendly. With the increasing demand for fly ash bricks, the use of this machine has become more popular in the construction industry.

How to use fly ash bricks machine

Fly ash bricks are made using a combination of fly ash, cement, sand, and water. These bricks are lightweight, durable, and eco-friendly. They are an excellent alternative to traditional clay bricks as they offer many advantages such as high strength, low cost, and reduced environmental impact. To produce fly ash bricks, you need a fly ash brick machine. In this article, we will discuss how to use a fly ash bricks machine.

Step 1: Preparing the raw materials

The first step in using a fly ash bricks machine is to prepare the raw materials. You need to mix fly ash, cement, sand, and water in the right proportions to make a slurry. The slurry should have a consistency that allows it to be easily molded into bricks. The ratio of fly ash, cement, and sand may vary depending on the type of machine and the quality of the raw materials.

Step 2: Loading the raw materials into the machine

Once the slurry is prepared, it is loaded into the fly ash bricks machine. There are different types of machines available in the market, such as manual, semi-automatic, and fully automatic machines. The operator needs to follow the instructions provided by the manufacturer to load the raw materials into the machine. The machine will then mold the bricks into the desired shape.

Step 3: Curing the bricks

After the bricks are molded, they need to be cured. Curing is the process of keeping the bricks in a controlled environment for a specific period to allow them to gain strength. The curing time may vary depending on the type of machine and the quality of the raw materials. Usually, fly ash bricks are cured for 7-14 days.

Step 4: Removing the bricks from the machine

After the curing period, the bricks are ready to be removed from the machine. The operator needs to follow the manufacturer’s instructions to remove the bricks carefully. The bricks should be handled gently to avoid any damage.

Step 5: Stacking the bricks

Once the bricks are removed from the machine, they need to be stacked in a dry and shaded area. The bricks should be stacked in a way that allows air to circulate between them. This helps in the drying process and prevents moisture from getting trapped between the bricks.

In conclusion, using a fly ash bricks machine is a simple process that requires careful attention to detail. By following the manufacturer’s instructions, you can produce high-quality fly ash bricks that are durable, eco-friendly, and cost-effective. With the growing demand for eco-friendly construction materials, fly ash bricks are an excellent alternative to traditional clay bricks.

Glossary Terminology Terms fly ash bricks machine

In the construction industry, fly ash bricks are becoming increasingly popular due to their durability, strength, and eco-friendliness. They are made using fly ash, a byproduct of burning coal, which is mixed with cement, water, and sometimes sand to produce a high-quality brick.

However, producing fly ash bricks manually can be time-consuming and labor-intensive. This is where the fly ash bricks machine comes in handy. It is a machine used for mass production of fly ash bricks in a shorter time and with less labor.

The fly ash bricks machine is a heavy-duty machine that can produce up to 1000 bricks per hour. It is powered by an electric motor and has a hydraulic system that ensures efficient production. The machine has a conveyor belt that carries the raw materials to the mixer, where they are mixed thoroughly before being poured into the molds.

The molds are then transferred to the hydraulic press, where the bricks are compressed with a force of up to 250 tons. This ensures that the bricks are compacted and have a uniform shape and size. The bricks are then removed from the molds and stacked on pallets for curing.

The curing process involves keeping the bricks in a humid environment for a specific period, usually 14-21 days, to allow for proper hardening. After curing, the bricks are ready for use in construction projects.

The fly ash bricks machine has several advantages over the traditional manual method of producing fly ash bricks. First, it produces bricks of consistent quality and size, which is essential for construction projects. Secondly, it reduces labor costs and increases production output, making it an efficient and cost-effective option.

In conclusion, the fly ash bricks machine is a valuable tool for the construction industry, especially for those looking to produce high-quality, eco-friendly bricks in large quantities. Its efficiency, cost-effectiveness, and consistency in producing bricks make it a popular choice for many construction projects.

Fly ash bricks machine price

contact [email protected], get the price for fly ash bricks machine.

Fly ash bricks are an environment-friendly alternative to traditional clay bricks. They are made using fly ash, a byproduct of coal-fired power plants, mixed with cement and water. Due to their eco-friendly nature and durability, fly ash bricks have become increasingly popular in construction projects.

If you are planning to invest in a fly ash bricks machine, it is essential to know about the price range. The cost of these machines varies depending on the size, capacity, and features of the equipment. In this article, we will discuss the different factors that influence the price of fly ash bricks machines.

Size and Capacity

One of the primary factors that affect the price of a fly ash bricks machine is its size and capacity. The size of the machine determines how many bricks it can produce at a time. The larger the machine, the higher its production capacity. As a result, the price of a larger capacity machine is naturally higher than that of a smaller one.

Features

The features of a fly ash bricks machine also play a crucial role in determining the cost. Some machines come with advanced features like automatic feeding systems, hydraulic pressure control, and high-speed motors. These features enhance the efficiency and productivity of the machine, but they also increase the cost.

Brand and Manufacturer

The brand and manufacturer of the fly ash bricks machine can also affect the price. Established brands with a good reputation for quality and reliability usually charge a premium for their products. On the other hand, lesser-known brands may offer lower prices but may not be as reliable or durable as the established ones.

Location

The location of the manufacturer or supplier can also influence the price of a fly ash bricks machine. Machines manufactured in countries with lower labor costs may be priced lower than those produced in countries with higher labor costs. However, it is essential to consider the quality of the machine and the manufacturer’s reputation before making a purchase.

Conclusion

In conclusion, the price of a fly ash bricks machine depends on several factors, including size, capacity, features, brand, manufacturer, and location. Investing in a high-quality machine may cost more initially, but it can save you money in the long run by reducing maintenance and repair costs. It is also essential to compare prices and features of different machines before making a purchase to ensure that you get the best value for your money.