clay brick making machine

Knowleage about clay brick making machine

Clay brick making machines have been around for centuries, but they have evolved significantly over time. Today, brick making machines are highly advanced and can produce bricks of different sizes and shapes, from simple rectangular bricks to complex curved bricks.

The process of making bricks involves mixing clay with water, shaping the clay into molds, and then firing the bricks in a kiln. Brick-making machines automate this process, making it faster and more efficient.

There are several types of brick-making machines available in the market. The most common are manual, semi-automatic, and fully automatic machines. Manual machines require human effort to operate, while semi-automatic and fully automatic machines are operated by machines.

The manual machines are the most basic type, and they are suitable for small-scale brick making. They are simple to operate and require minimal maintenance. However, they have a low production capacity and are not suitable for large-scale brick making.

Semi-automatic machines are more advanced than manual machines. They have a higher production capacity and are suitable for medium-scale brick making. They require less human effort to operate and can produce a large number of bricks in a short period.

Fully automatic machines are the most advanced type of brick-making machine. They are suitable for large-scale brick making and have the highest production capacity. They require minimal human intervention and can produce high-quality bricks consistently.

When choosing a brick-making machine, there are several factors to consider. These include the production capacity, the type of bricks the machine can produce, the power source, the maintenance requirements, and the price.

The production capacity of the machine should match the demand for bricks in the local market. The machine should also be able to produce the type of bricks that are in demand, whether they are simple rectangular bricks or more complex curved bricks.

The power source of the machine is also an important factor to consider. Some machines are powered by electricity, while others are powered by diesel or petrol. The maintenance requirements of the machine should also be considered, as this can affect the longevity and efficiency of the machine.

Finally, the price of the machine should be considered in relation to the production capacity and the expected return on investment.

In conclusion, clay brick making machines have come a long way since their invention. Today, they are highly advanced and can produce high-quality bricks efficiently. When choosing a brick-making machine, it is important to consider the production capacity, the type of bricks the machine can produce, the power source, the maintenance requirements, and the price.

Various Types clay brick making machine

Clay brick making machines have been in use for centuries to produce high-quality bricks for construction purposes. Over the years, technological advancements have led to the development of various types of clay brick making machines that offer improved efficiency, productivity, and quality. In this article, we will take a look at some of the different types of clay brick making machines available in the market.

1. Manual Clay Brick Making Machine

The manual clay brick making machine is the simplest and most traditional type of brick making machine. It is operated by hand and requires no electricity or fuel. The machine is ideal for small-scale brick-making operations or for use in rural areas where electricity and fuel are scarce. The machine is designed to produce a limited number of bricks per day.

2. Automatic Clay Brick Making Machine

The automatic clay brick making machine is a highly efficient, large-scale brick-making machine that is designed to produce a high volume of bricks in a short time. The machine is fully automated, with all the necessary functions controlled by a computer. The machine is ideal for large-scale brick-making operations and can produce up to 60,000 bricks per day.

3. Hydraulic Clay Brick Making Machine

The hydraulic clay brick making machine is a type of automatic brick-making machine that uses hydraulic pressure to compress clay into bricks. The machine is highly efficient and can produce up to 30,000 bricks per day. It is ideal for large-scale brick-making operations and offers improved quality and durability of bricks.

4. Interlocking Clay Brick Making Machine

The interlocking clay brick making machine is a type of automatic brick-making machine that produces interlocking bricks that do not require mortar for construction. The machine uses a unique interlocking design that ensures the bricks fit together seamlessly, resulting in a strong and durable structure. The machine is ideal for construction projects that require quick and efficient construction of structures.

5. Soil Clay Brick Making Machine

The soil clay brick making machine is a type of manual brick-making machine that is designed to produce bricks using soil, clay, and water. The machine is ideal for small-scale brick-making operations and can produce up to 500 bricks per day. The machine is simple to operate and requires no electricity or fuel.

In conclusion, there are various types of clay brick making machines available in the market, each with its unique features and benefits. The choice of machine depends on the scale of operation, available resources, and desired quality of bricks. It is advisable to consult a professional brick-making expert before purchasing a machine to ensure that you make an informed decision.

FAQ sourcing clay brick making machine from China manufacturer

If you are considering sourcing clay brick making machines from China, you may have some questions about the process. Here are some frequently asked questions to help guide you in your decision-making.

1. Why source from China?

China is one of the world’s largest manufacturers of brick making machines, and their products are known for their quality and affordability. Chinese companies offer a range of options to suit various budgets and production requirements.

2. What types of brick making machines are available?

There are several types of brick making machines available, including manual machines, semi-automatic machines, and fully automatic machines. Some manufacturers may also offer customized machines to suit specific production needs.

3. What is the cost of a brick making machine from China?

The cost of a brick making machine will depend on the type and level of automation. Manual machines are the most affordable, while fully automatic machines are the most expensive. Prices can range from a few hundred dollars to tens of thousands of dollars.

4. Can I get a sample machine before placing an order?

It is possible to request a sample machine before placing an order. However, some manufacturers may charge a fee for this service. It is important to clarify this with the supplier before placing an order.

5. What is the lead time for delivery?

The lead time for delivery will depend on the type of machine and the manufacturer. Some manufacturers may have machines in stock, while others may need to produce the machine after an order is placed. It is important to clarify the lead time with the supplier before placing an order.

6. What is the warranty period?

The warranty period will vary depending on the manufacturer and type of machine. Some manufacturers may offer a one-year warranty, while others may offer a longer warranty period. It is important to clarify the warranty period with the supplier before placing an order.

7. What are the payment terms?

Payment terms will vary depending on the manufacturer. Some manufacturers may require a deposit before production begins, while others may require full payment before shipment. It is important to clarify the payment terms with the supplier before placing an order.

In conclusion, sourcing a clay brick making machine from China can be a cost-effective option for those looking to start or expand their brick manufacturing business. However, it is important to do your research and clarify all details with the supplier before placing an order. With proper due diligence, you can find a reliable and high-quality machine to meet your production needs.

Applications of clay brick making machine

Clay brick making machines have been used for centuries to create bricks that are used in various construction projects. These machines are designed to compress clay and other materials into a rectangular shape, which is then fired to create a hardened brick. Over the years, the technology used in these machines has evolved, making them more efficient and versatile. In this article, we will discuss some of the applications of clay brick making machines.

Home Construction

One of the primary applications of clay brick making machines is in home construction. Bricks made from these machines are used to build walls, foundations, and other structural elements of a house. Clay bricks are preferred over other materials like concrete because they are strong, durable, and offer good insulation. Additionally, clay bricks are eco-friendly, as they are made from natural materials and can be recycled easily.

Commercial Construction

Clay brick making machines are also used in commercial construction projects. They are used to create bricks that are used to build schools, hospitals, offices, and other commercial buildings. These buildings require durable materials that can withstand heavy use and abuse. Clay bricks are ideal for such projects as they are strong and can withstand wear and tear.

Paving

Clay brick making machines can also be used to create bricks that are used for paving. These bricks are used to create walkways, patios, and other outdoor spaces. They are preferred over other materials like concrete and asphalt because they are more durable and offer better traction. Additionally, clay bricks are more aesthetically pleasing and can be used to create unique designs.

Garden Landscaping

Clay bricks can be used to create various garden landscaping features like raised beds, retaining walls, and garden paths. These features are essential for maintaining a garden and can be used to create a beautiful and functional outdoor space. Clay bricks are preferred over other materials like timber and concrete because they are more durable and require less maintenance.

Conclusion

Clay brick making machines are versatile and can be used in various applications. They are used in home and commercial construction, paving, and garden landscaping. Clay bricks are preferred over other materials like concrete and asphalt because they are strong, durable, and eco-friendly. If you are in the construction industry or are planning to undertake a construction project, consider using clay bricks made from a clay brick making machine.

Manufactured Products made of clay brick making machine

Clay brick making machines have revolutionized the way bricks are made. In the past, bricks were made by hand, a labor-intensive process that took a lot of time and effort. With the advent of brick making machines, the process of making bricks has become much easier and faster. This has led to the production of various manufactured products made of clay brick making machines.

One of the most popular products made using clay brick making machines is bricks. These bricks are made using clay, which is fed into the machine, molded, and then fired in a kiln. The result is a sturdy and durable brick that can be used for a variety of purposes, from building homes to constructing walls and fences.

In addition to bricks, clay brick making machines can also be used to make other products, such as pavers and tiles. Pavers are used for outdoor flooring, while tiles are used for indoor flooring and walls. Both of these products are made using the same process as bricks, but with different molds and shapes.

Another product that can be made using clay brick making machines is roofing tiles. These tiles are made using clay and are designed to be used as a roofing material. They are durable, weather-resistant, and can be made in a variety of colors and styles to suit different architectural styles.

Finally, clay brick making machines can also be used to make decorative items, such as pottery and figurines. These items are made using the same process as bricks, but with a focus on aesthetics rather than function. They can be used to add a touch of elegance and sophistication to any room or outdoor space.

In conclusion, clay brick making machines have revolutionized the way bricks and other products are made. They have made the process faster, more efficient, and more affordable. As a result, a variety of manufactured products made of clay brick making machines have emerged, from bricks and pavers to roofing tiles and decorative items. These products are durable, weather-resistant, and can be made in a variety of colors and styles to suit different needs and preferences.

The Evolution history of clay brick making machine

For centuries, clay bricks have been an essential building material throughout the world. The process of making these bricks has evolved significantly over time, from rudimentary hand-molding techniques to modern, fully-automated brick making machines. In this article, we will trace the evolution of clay brick making machines and explore how technology has transformed the brick-making process.

Historical Origins

Clay brick making has been around for thousands of years, with evidence of brick making found in ancient civilizations such as Egypt, Babylon, and Rome. The earliest bricks were likely made by hand, using a simple mold and sun-drying the clay. As civilization advanced and the demand for bricks grew, new techniques were developed to increase production.

The Industrial Revolution

The 18th and 19th centuries saw major advancements in industrial technology, which had a significant impact on brick making. In 1837, a steam-powered brick-making machine was patented by William Clayton in England. This machine could produce up to 25,000 bricks per day and helped to meet the growing demand for bricks during the building boom of the Industrial Revolution.

Mechanical Brick Making Machines

In the early 20th century, mechanical brick making machines were developed, which further improved the efficiency and speed of brick production. These machines used a combination of mechanical and hydraulic power to mold and press the clay into bricks. One of the most popular machines was the Bradley & Craven Ltd. brick-making machine, which was introduced in 1889 in England.

Modern Brick Making Machines

Today, modern brick making machines are fully automated and use computerized controls to produce high-quality bricks at a rapid pace. These machines can produce thousands of bricks per hour, with consistent size and shape. They are also able to use a variety of different clay mixtures and can produce bricks in a range of colors and textures.

Conclusion

The evolution of clay brick making machines has been a long and fascinating journey, from simple hand-molding techniques to modern, fully-automated machines that can produce thousands of bricks per hour. As technology continues to advance, it is likely that the process of brick making will continue to evolve and improve. However, the timeless appeal and durability of clay bricks will always remain a cornerstone of the building industry.

The Process of clay brick making machine

Clay brick making machines have been around for centuries, but the manufacturing process has evolved significantly over time. Today’s machines are more efficient and produce higher quality bricks than ever before.

The process begins with the collection of raw materials. The primary ingredient in clay bricks is, of course, clay. Other materials such as sand, lime, and fly ash may also be added to achieve specific properties. These materials are mixed in the right proportions to create a homogenous clay mixture.

Once the mixture is prepared, it is fed into the brick making machine. The machine is designed to mold the clay mixture into the desired shape and size. The most common shapes are rectangular or square, and the size can vary depending on the application and market demand.

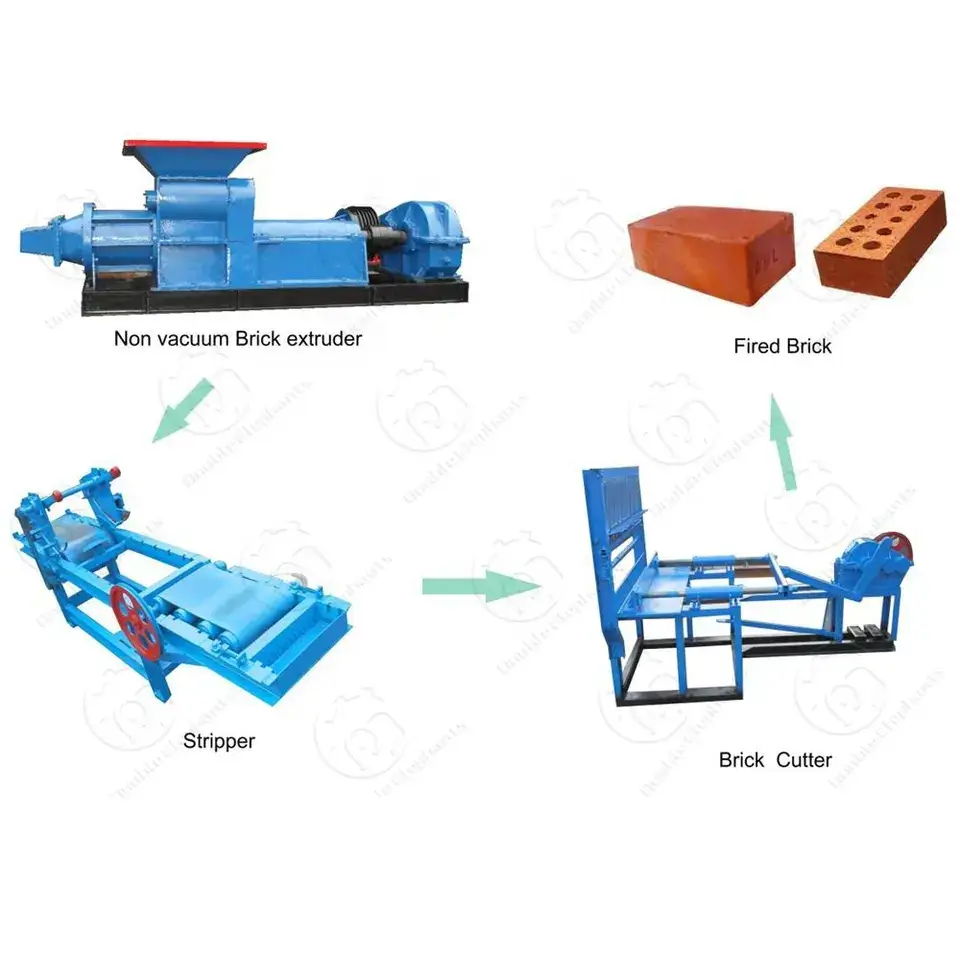

The molding process involves two primary steps. In the first step, the clay mixture is extruded through a die or mold to form a long cylinder. This cylinder is then cut into individual bricks using a wire cutter or other cutting mechanism.

After the bricks are cut, they are placed on drying racks or pallets and left to dry. Drying is a critical step in the process since it removes any excess moisture from the bricks. If the bricks are not adequately dried, they may crack or deform during firing.

Once the bricks are dry, they are ready for firing. Firing is the process of heating the bricks to a high temperature in a kiln to harden them. During firing, the clay particles fuse together, creating a solid and durable brick.

The temperature and duration of firing can vary depending on the type of clay and the desired properties of the brick. Generally, firing temperatures range from 900 to 1200 degrees Celsius and can last anywhere from 24 to 48 hours.

After firing, the bricks are cooled and inspected for quality. Any defective bricks are discarded, and the remaining bricks are sorted and stacked for shipping.

In conclusion, the process of clay brick making machines involves collecting raw materials, mixing them into a homogenous clay mixture, molding the mixture into the desired shape and size, drying the bricks, firing them in a kiln, and finally, sorting and stacking the bricks for shipping. This process has been refined over centuries and continues to evolve as new technologies emerge. Today, clay brick making machines are more efficient and produce higher quality bricks than ever before, making them an essential building material for construction projects around the world.

Benefits Advantages of Utilizing clay brick making machine

Over the years, the construction industry has evolved dramatically, and the utilization of brick-making machines has become a common sight in the industry. Brick-making machines have revolutionized the production of bricks, and clay brick making machines are among the most popular brick-making machines in the market today.

Clay brick making machines are designed to transform raw materials, including clay, into bricks that can be used for construction purposes. These machines have various benefits and advantages that make them a preferred option for many construction companies.

One of the main advantages of utilizing clay brick making machines is that they are cost-effective. The machines are designed to produce bricks in large quantities, which means that you can save a lot of money on labor costs. Additionally, clay brick making machines are easy to operate, which means that you don’t need to hire highly skilled workers to operate them.

Another benefit of clay brick making machines is that they produce high-quality bricks. These machines are designed to ensure that the bricks produced are uniform in size and shape, which makes it easier to build structures that are aesthetically pleasing. Additionally, the bricks produced by clay brick making machines are strong and durable, which means that they can withstand harsh weather conditions and last for years.

Clay brick making machines are also eco-friendly. The machines are designed to use minimal energy and produce minimal waste, which means that they have a low carbon footprint. Additionally, the bricks produced by these machines are recyclable, which means that they can be used for other construction projects.

Finally, clay brick making machines are versatile. These machines can produce a wide range of brick types and sizes, which means that they can be used for various construction projects. Whether you need bricks for a residential or commercial building, a clay brick making machine can produce the bricks you need.

In conclusion, clay brick making machines have various benefits and advantages that make them a preferred option for many construction companies. These machines are cost-effective, produce high-quality bricks, are eco-friendly, and are versatile. If you’re in the construction industry, investing in a clay brick making machine can help you save money, produce high-quality bricks, and make your construction projects more eco-friendly.

Disadvantages clay brick making machine

Clay brick making machines have become increasingly popular in recent years due to their ability to produce high-quality bricks in large quantities. While there are many benefits to using a clay brick making machine, there are also some disadvantages that potential buyers should be aware of.

One of the main disadvantages of using a clay brick making machine is the cost. These machines can be quite expensive, especially if you are looking for a high-end model with advanced features. Additionally, there are ongoing costs associated with operating and maintaining the machine, such as replacement parts, lubricants, and electricity.

Another potential disadvantage of using a clay brick making machine is the environmental impact. These machines require a significant amount of energy to operate, which can contribute to greenhouse gas emissions and other environmental issues. Additionally, the production of clay bricks can be resource-intensive, requiring large amounts of water and other materials.

In some cases, using a clay brick making machine may also result in lower-quality bricks. While these machines are designed to produce consistent, high-quality bricks, there may be variations in the clay mixture or other factors that can affect the final product. This can result in bricks that are weaker or less durable than those made by traditional methods.

Finally, using a clay brick making machine may not be suitable for all types of projects. For example, if you are looking to create custom or unique brick designs, a machine may not be able to provide the level of customization you need. Similarly, if you are working on a small-scale project, it may be more cost-effective to use traditional brick-making methods rather than investing in a machine.

In conclusion, while there are many benefits to using a clay brick making machine, there are also some potential disadvantages that should be considered before making a purchase. Ultimately, the decision to invest in a machine will depend on your specific needs and budget, as well as your willingness to deal with the ongoing costs and environmental impact of using the machine.

Selecting the Ideal clay brick making machine Manufacturer

When it comes to investing in a clay brick making machine, one of the most important decisions you will make is selecting the right manufacturer. With so many manufacturers in the market, it can be overwhelming to choose the right one. However, selecting the ideal manufacturer is crucial to ensure that you get a high-quality machine that meets your specific requirements.

Here are some tips to help you select the ideal clay brick making machine manufacturer:

1. Consider the manufacturer’s experience

Experience is a crucial factor to consider when selecting a manufacturer. A manufacturer with years of experience in the industry is likely to produce high-quality machines that meet the needs of their customers. They are also likely to have a better understanding of the market and the needs of their customers.

2. Check the manufacturer’s reputation

Before selecting a manufacturer, it is essential to check their reputation in the market. You can do this by reading online reviews, asking for references, or checking their website. A good reputation is a sign that the manufacturer produces high-quality machines and provides excellent customer service.

3. Look for a manufacturer that offers customized machines

Every customer has different requirements when it comes to a clay brick making machine. Therefore, it is essential to look for a manufacturer that offers customized machines. This way, you can get a machine that meets your specific needs and requirements.

4. Check the manufacturer’s after-sales service

After-sales service is an essential factor to consider when selecting a manufacturer. A good manufacturer should provide after-sales service such as installation, training, and technical support. This ensures that you can operate the machine correctly and effectively.

5. Compare prices

Price is always a crucial factor when selecting a manufacturer. However, it is essential to note that the cheapest option is not always the best. Instead, you should compare prices from different manufacturers and select the one that offers high-quality machines at a reasonable price.

In conclusion, selecting the ideal clay brick making machine manufacturer requires careful consideration. You need to consider factors such as the manufacturer’s experience, reputation, customized machines, after-sales service, and price. By doing so, you can select a manufacturer that produces high-quality machines that meet your needs and requirements.

Things to Consider When Purchasing clay brick making machine

Brick making is an age-old practice that has been used for centuries to construct buildings and structures. Clay brick making machines are an essential tool for modern brick making, allowing for faster production and consistent quality. However, with so many options available, it can be challenging to select the right machine for your needs. Here are some things to consider when purchasing a clay brick making machine:

1. Production Capacity: The production capacity of the machine determines the number of bricks it can produce in a day. Consider the size of your project and the number of bricks you need to produce to determine the right machine capacity for you.

2. Brick Quality: The quality of the bricks produced by the machine is also essential. Look for a machine that produces bricks with consistent quality, size, and shape. This will ensure that your building structure is strong and durable.

3. Maintenance: Maintenance is crucial for the longevity of the machine. Look for a machine that is easy to maintain and requires minimal maintenance. This will save you time and money in the long run.

4. Energy Efficiency: Energy efficiency is an essential consideration when purchasing any machine. Look for a machine that is energy-efficient and has low operating costs. This will save you money on electricity bills and increase your profitability.

5. Cost: The cost of the machine is also an essential consideration. Look for a machine that fits your budget while still meeting all your requirements. However, avoid compromising quality for a lower price.

In conclusion, purchasing a clay brick making machine requires careful consideration of the factors mentioned above. By selecting the right machine, you can increase your productivity, reduce your operating costs, and produce high-quality bricks that will last for years.

Properties clay brick making machine

Clay brick making machines are becoming increasingly popular due to their ability to produce high-quality bricks in a short amount of time. These machines are designed to produce bricks of different sizes and shapes, making them suitable for various construction projects. In this article, we will discuss the properties of clay brick making machines.

1. Durability

Clay brick making machines are made of high-quality materials that are durable and can withstand the wear and tear of daily use. The machines are designed to operate for long hours without breaking down, which makes them ideal for large-scale brick production.

2. High efficiency

Clay brick making machines are known for their high efficiency. They can produce a large number of bricks in a short amount of time, which makes them ideal for use in construction projects that require a large number of bricks.

3. Low maintenance

Clay brick making machines require minimal maintenance. They are designed with simple mechanisms that are easy to maintain, and the machines come with user manuals that provide instructions on how to maintain them.

4. Customizable

Clay brick making machines are customizable. They can be designed to produce bricks of different sizes and shapes, depending on the specific needs of the construction project. This makes them versatile and suitable for use in a wide range of construction projects.

5. Energy efficient

Clay brick making machines are designed to be energy efficient. They use minimal energy to operate, which makes them environmentally friendly and cost-effective.

6. Easy to operate

Clay brick making machines are easy to operate. They come with user-friendly interfaces that make it easy for operators to control the machines. The machines also come with safety features that ensure the safety of the operators.

In conclusion, clay brick making machines are ideal for large-scale brick production due to their durability, high efficiency, low maintenance, and energy efficiency. They are also customizable and easy to operate, making them suitable for use in a wide range of construction projects. If you are looking for a machine that can produce high-quality bricks in a short amount of time, then a clay brick making machine is the perfect choice for you.

How to use clay brick making machine

Clay brick making machines have revolutionized the brick-making industry, making it faster, more efficient, and cost-effective. With the use of this machine, one can easily produce good quality bricks in large quantities. However, using a clay brick making machine requires some skills and knowledge. In this article, we will guide you through the steps on how to use a clay brick making machine.

Step 1: Preparation of Raw Materials

The first step is to prepare the raw materials. You will need clay, water, and sand. The clay must be of good quality and free of impurities. The sand should be clean and free of debris. The water should also be clean and free of contaminants. Before mixing, ensure that the raw materials are dry and clean.

Step 2: Mixing the Raw Materials

The next step is to mix the raw materials. In a mixing bowl, add the clay, sand, and water in the right proportions. The mixing process should be thorough to ensure that the clay is well distributed throughout the mixture. You can use a mixer or do it manually.

Step 3: Molding the Bricks

After mixing, the next step is to mold the bricks. Place the mixture in the clay brick making machine, and the machine will automatically mold the bricks. Depending on the machine’s capacity, it can mold hundreds or thousands of bricks per hour.

Step 4: Drying the Bricks

After molding, the bricks need to be dried. Arrange the bricks in a sunny area and leave them to dry for several days. Ensure that they are not exposed to rain or any other moisture during the drying process.

Step 5: Firing the Bricks

The final step is to fire the bricks. This process involves heating the bricks in a kiln to high temperatures. This process hardens the clay and makes the bricks strong and durable. The firing temperature and duration will depend on the type of clay used and the desired strength of the bricks.

In conclusion, using a clay brick making machine requires a few simple steps. The key is to ensure that the raw materials are of good quality, the mixing is thorough, and the bricks are dried and fired correctly. With these steps, anyone can produce high-quality bricks using a clay brick making machine.

Glossary Terminology Terms clay brick making machine

Clay brick making machines have become increasingly popular in recent years. They are used to produce bricks from clay, which is a natural material that has been used for construction for thousands of years.

To fully understand the process of using a clay brick making machine, it’s important to familiarize yourself with some of the key terms and phrases used in the industry.

1. Extrusion: This is the process of pushing the clay through a die in order to create the shape of the brick. The die is usually made of metal and is designed to create a specific size and shape of brick.

2. Auger: This is the part of the clay brick making machine that is responsible for moving the clay through the machine. The auger is a screw-like device that rotates and pushes the clay towards the extrusion die.

3. Cutter: Once the clay has been extruded into the desired shape, it needs to be cut into individual bricks. The cutter is a device that is used to cut the clay into the correct size and shape.

4. Kiln: After the bricks have been cut, they need to be fired in a kiln in order to make them hard and durable. The kiln is a large oven that is used to heat the bricks to a high temperature for a period of time.

5. Mould: The mould is the part of the machine that is used to shape the clay into the desired shape before it is extruded. The mould can be made from a variety of materials, including metal and plastic.

6. Mixing chamber: The mixing chamber is where the clay is mixed with water and other additives in order to create a workable clay mixture. The mixture needs to be the right consistency in order to be extruded and cut into bricks.

7. Palletizer: Once the bricks have been fired in the kiln, they need to be stacked and packaged for transport. The palletizer is a device that is used to stack the bricks onto pallets for transport.

Clay brick making machines are an important part of the construction industry. They allow for the efficient production of high-quality bricks that are used in a variety of construction projects. By understanding the terminology and key terms used in the industry, you can gain a better understanding of how these machines work and how they are used to create durable and long-lasting bricks.

Clay brick making machine Price

contact [email protected], get the price for Clay brick making machine.

Clay brick making machines are essential equipment for the production of clay bricks, which are widely used in construction projects for building walls, pavements, and other structures. The machines are designed to make the brick-making process more efficient and faster, reducing the labor required and increasing the output. The price of clay brick making machines varies depending on several factors, including the size, capacity, and features of the machine.

One of the critical factors that determine the price of clay brick making machines is the capacity of the machine. Machines with higher capacities can produce more bricks at a time, which increases efficiency and reduces the overall cost of production. However, higher capacity machines are generally more expensive than lower capacity machines.

Another factor that affects the price of clay brick making machines is the level of automation. Fully automated machines are more expensive than semi-automated or manual machines, but they require less human intervention, which can significantly reduce labor costs.

The size and weight of the machine also play a role in determining the price. Larger machines are generally more expensive than smaller ones, and machines made from high-quality materials are also more costly.

The price of clay brick making machines can range from a few thousand dollars to tens of thousands of dollars, depending on the size, capacity, and level of automation. Buyers should carefully consider their needs and budget when selecting a machine to ensure they get the best value for their money.

It is essential to note that investing in a high-quality clay brick making machine can be a profitable venture in the long run. With the right machine, operators can produce high-quality bricks that meet industry standards, which can increase demand and drive up profits.

In conclusion, the price of clay brick making machines varies depending on several factors, including capacity, level of automation, size, and materials used. Buyers should carefully consider their needs and budget before investing in a machine to ensure they get the best value for their money. Investing in a high-quality machine can be a profitable venture that can increase efficiency and drive up profits in the long run.