feed pellet machine

Knowleage about feed pellet machine

Feed pellet machines are becoming increasingly popular among farmers and animal breeders as a way to improve the quality and efficiency of animal feed production. These machines are designed to process various types of feed materials into uniform and concentrated pellets that are easier to store, transport, and feed to livestock.

In order to understand how feed pellet machines work and how to choose the right one for your needs, it is important to have some basic knowledge about their features and capabilities. Here are some key factors to consider when selecting a feed pellet machine:

Type of feed material: Feed pellet machines can process a wide variety of feed materials, such as grains, grasses, alfalfa, soybean meal, fish meal, and more. Depending on the type of feed you want to produce, you may need a machine that is designed for a specific feed material or can handle a mix of ingredients.

Capacity and output: Feed pellet machines come in different sizes and capacities, ranging from small-scale models for home use to large-scale industrial machines that can produce thousands of pounds of feed per hour. The output of the machine will depend on factors such as the size of the pellets, the speed of the machine, and the power source.

Pellet size and shape: The size and shape of the pellets can affect their digestibility and suitability for different animals. Some machines can produce pellets in a range of sizes and shapes, while others are limited to a specific size or shape.

Motor power and efficiency: The motor power of the machine will determine its speed and efficiency in processing feed materials. A higher-powered motor may be necessary for processing tougher materials, but can also consume more energy and produce more noise.

Ease of use and maintenance: A good feed pellet machine should be easy to operate and maintain, with user-friendly controls and accessible parts for cleaning and repair. It is also important to consider the availability of spare parts and technical support in case of any issues.

In addition to these factors, it is also important to consider the cost and durability of the machine, as well as any safety features and certifications. By doing your research and understanding the features and capabilities of different feed pellet machines, you can make an informed decision that will help improve the quality and efficiency of your animal feed production.

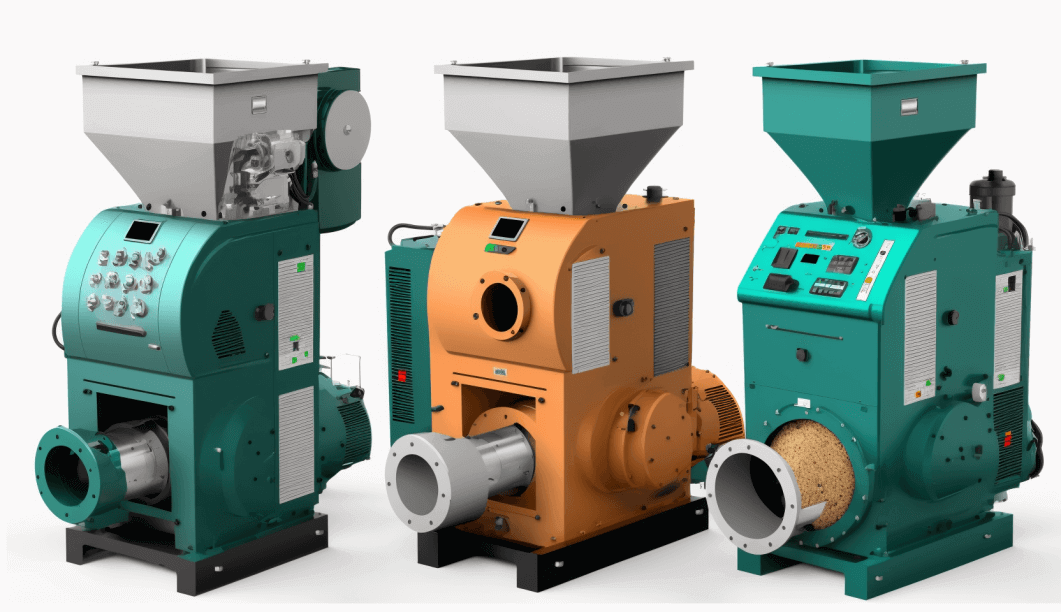

Various Types feed pellet machine

Feed pellet machines are essential equipment for animal husbandry, especially for poultry and livestock farming. These machines are used to make feed pellets that are nutritionally balanced, easily digestible, and free from contaminants. The use of feed pellet machines is becoming increasingly popular as farmers seek to improve the quality of animal feed and reduce feed costs. There are various types of feed pellet machines available in the market, each with unique features and benefits. In this article, we will discuss some of the most common types of feed pellet machines.

Flat Die Pellet Machine

The flat die pellet machine is the most commonly used feed pellet machine. It is simple in design, easy to operate, and suitable for small-scale production. This machine is ideal for making feed pellets for poultry, rabbits, and other small animals. The flat die pellet machine works by compressing the feed material between two rollers that rotate in opposite directions. The resulting pellets are then cut to the desired length.

Ring Die Pellet Machine

The ring die pellet machine is more advanced than the flat die pellet machine. It is suitable for large-scale production and can produce high-quality feed pellets for pigs, cattle, and other large animals. The ring die pellet machine works by using a rotating roller and a stationary ring die to compress the feed material. The resulting pellets are then cut to the desired length.

Vertical Pellet Machine

The vertical pellet machine is a compact machine that is ideal for small-scale production. It is suitable for making feed pellets for poultry, rabbits, and other small animals. The vertical pellet machine has a vertical feeding system that makes it easy to operate and maintain. The machine works by compressing the feed material between a stationary die and a rotating roller. The resulting pellets are then cut to the desired length.

Horizontal Pellet Machine

The horizontal pellet machine is a large-scale machine that is suitable for industrial production. It is ideal for making feed pellets for pigs, cattle, and other large animals. The horizontal pellet machine works by using a rotating roller and a stationary die to compress the feed material. The resulting pellets are then cut to the desired length.

Conclusion

In conclusion, there are various types of feed pellet machines available in the market. Each type has unique features and benefits that make it suitable for different applications. The choice of a feed pellet machine depends on the scale of production, the type of animal, and the type of feed being produced. It is important to choose a machine that is easy to operate, maintain, and has a high production capacity. With the right feed pellet machine, farmers can produce high-quality feed pellets that are nutritionally balanced, easily digestible, and free from contaminants.

FAQ sourcing feed pellet machine from China manufacturer

If you are looking for a reliable and cost-effective way to produce feed pellets for your animals, then sourcing a feed pellet machine from a China manufacturer might be a good idea. However, before you make your purchase, it is important to have all your questions answered to ensure that you get the best possible product for your needs.

Here are some frequently asked questions that you should consider when sourcing a feed pellet machine from China:

1. What is the capacity of the machine?

The capacity of the machine is an important factor to consider when purchasing a feed pellet machine. It will determine how much feed you can produce per hour or per day. You should choose a machine that has the capacity to meet your needs.

2. What is the power source of the machine?

The power source of the machine can vary depending on the manufacturer and model. Some machines are powered by electricity, while others are powered by diesel engines. You should choose a power source that is appropriate for your location and available resources.

3. What is the price of the machine?

The price of the machine can vary depending on the manufacturer and model. You should compare prices from different manufacturers and choose a machine that offers the best value for your money.

4. What is the quality of the machine?

The quality of the machine is an important factor to consider when purchasing a feed pellet machine. You should choose a machine that is durable and reliable, with high-quality components and materials.

5. What is the warranty of the machine?

The warranty of the machine is an important factor to consider when purchasing a feed pellet machine. You should choose a machine that comes with a warranty to protect your investment and ensure that you can get repairs or replacements if needed.

6. What is the delivery time of the machine?

The delivery time of the machine can vary depending on the manufacturer and model. You should choose a manufacturer that can provide a reasonable delivery time and ensure that the machine arrives in good condition.

7. What is the after-sales service of the manufacturer?

The after-sales service of the manufacturer is an important factor to consider when purchasing a feed pellet machine. You should choose a manufacturer that offers good after-sales service, including technical support and spare parts.

In conclusion, sourcing a feed pellet machine from a China manufacturer can be a great way to save money and produce high-quality feed for your animals. However, it is important to do your research and ask the right questions to ensure that you get the best possible product for your needs.

Applications of feed pellet machine

Feed pellet machines are used to process animal feed into pellets. This process is becoming increasingly popular as it is a more efficient way of producing feed for livestock. The pellets have a higher density than traditional animal feed, which means they take up less space and are easier to transport. Here are some of the applications of feed pellet machines.

1. Livestock farming

Feed pellet machines are commonly used in livestock farming. Cattle, sheep, pigs, and poultry can all be fed with pellets. Pellets are easier to digest, and they contain all the necessary nutrients that livestock need to grow and stay healthy. Companies that produce feed pellets can customize the content of pellets to meet the specific needs of different animals.

2. Aquaculture

Fish farming is another industry that benefits from feed pellet machines. Pellets can be made to float on the surface of the water, which makes it easier for fish to find and consume them. Fish farmers can also adjust the size of the pellets to match the size of their fish. Pellets can be made from a variety of ingredients, including fishmeal, soybean, and corn.

3. Pet food manufacturing

Feed pellet machines can also be used in the production of pet food. The pellets can be customized to meet the nutritional needs of different pets. For example, dog food pellets can be made with higher protein content than cat food pellets. Pet food manufacturers can also add flavorings and other ingredients to make the pellets more appealing to pets.

4. Wildlife conservation

Feed pellet machines can also be used in wildlife conservation efforts. In areas where natural food sources are scarce, pellets can be used to supplement the diets of wild animals. This is commonly done in national parks and wildlife reserves. The pellets are designed to mimic the animals’ natural diet, and they are distributed in a way that minimizes the impact on the animals’ behavior.

In conclusion, feed pellet machines have a wide range of applications in the animal feed industry. They are used to produce high-quality feed for livestock, fish, and pets. They can also be used in wildlife conservation efforts to supplement the diets of wild animals. As the demand for animal products continues to increase, the use of feed pellet machines is expected to grow.

Manufactured Products made of feed pellet machine

Feed pellet machines have revolutionized the way animal feed is produced. These machines produce pellets that are not only beneficial to the animal’s health but also eco-friendly. The pellets are made by compressing a mixture of ingredients such as grains, vegetables, and fruits. The pellets are then used as animal feed. However, these pellets have a multitude of uses beyond animal feed. They can be used to produce manufactured products that are beneficial to humans as well.

One of the most common products made from feed pellet machines is fuel. The pellets are used as biomass fuel for heating and cooking. They are an eco-friendly alternative to traditional fossil fuels that contribute to global warming. The pellets are made from renewable sources and produce less carbon dioxide than fossil fuels. They are also cheaper than fossil fuels, making them an affordable option for households and industries.

Another product made from feed pellet machines is fertilizer. The pellets are rich in nutrients and can be used as organic fertilizer. They are an eco-friendly alternative to chemical fertilizers that can harm the environment. The pellets are also cheaper than chemical fertilizers, making them an affordable option for farmers. They help to improve soil quality and increase crop yields.

Pellet bedding is another product made from feed pellet machines. The pellets are compressed into small, round shapes that absorb moisture and odor. They are an eco-friendly alternative to traditional bedding materials such as straw and sawdust. They are also easier to handle and store than traditional bedding materials. The pellets are used as bedding for animals such as horses, chickens, and rabbits.

Feed pellets can also be used to make pet food. The pellets are rich in nutrients and can be used to make pet food for dogs, cats, and other pets. They are an eco-friendly alternative to commercial pet food that can contain harmful additives. The pellets are also cheaper than commercial pet food, making them an affordable option for pet owners.

In conclusion, feed pellet machines have revolutionized the way animal feed is produced. However, the pellets produced by these machines have a multitude of uses beyond animal feed. They can be used to produce eco-friendly products such as fuel, fertilizer, pellet bedding, and pet food. These products are beneficial to humans and the environment. They are also cheaper than traditional products, making them an affordable option for households and industries.

The Evolution history of feed pellet machine

Feed pellet machines have revolutionized the animal feed industry by providing an efficient and cost-effective way of producing animal feeds. The evolution of feed pellet machines dates back to the early 20th century when animal feed was produced manually. In this article, we will take a look at the evolution history of feed pellet machines.

The early 20th century saw the birth of the first animal feed pellet machines. These were manually operated machines that required a lot of energy to produce a small amount of feed pellets. These machines were mainly used by small-scale farmers who wanted to produce their own animal feeds. The pellets produced by these machines were not of high quality, and it was difficult to produce consistent sizes.

In the 1930s, the animal feed industry began to grow, and the demand for animal feed increased. This led to the development of more advanced feed pellet machines that were powered by electricity. These machines were more efficient and could produce a larger number of pellets in a shorter time. They also produced high-quality pellets that were consistent in size.

The 1950s saw the introduction of the first automatic feed pellet machines. These machines were fully automated and required minimal human intervention. They could produce a large number of pellets in a short time, and the pellets produced were of high quality and consistent in size. These machines were expensive and were mainly used by large-scale feed producers.

In the 1970s, the feed pellet machines were further improved with the introduction of computer control systems. These systems allowed for more precise control of the pellet production process, resulting in even higher quality pellets. The computer control systems also made it easier to monitor the production process, making it more efficient and cost-effective.

In the 1990s, the feed pellet machines were further developed to produce specialized animal feeds. These machines could produce feeds for different animals such as poultry, cattle, and fish. They could also produce feeds with different nutritional requirements, making it possible to produce feeds for animals with specific dietary needs.

Today, feed pellet machines have become an integral part of the animal feed industry. They are used by small-scale farmers and large-scale feed producers to produce high-quality, nutritious feeds for animals. They are also used to produce specialized feeds for different animals and different nutritional needs.

In conclusion, the evolution of feed pellet machines has been remarkable. From the early manually operated machines to the fully automated computer-controlled machines of today, the feed pellet machine has come a long way. With the continued development of the feed pellet machines, we can expect even more advanced machines that will further improve the quality and efficiency of animal feed production.

The Process of feed pellet machine

Feed pellet machines are essential equipment in the animal feed production industry. They are used to produce high-quality animal feed pellets that are rich in nutrients and easy to digest. The process of feed pellet machine involves several steps that must be followed carefully to produce high-quality pellets.

The first step in the process of feed pellet machine is the preparation of the raw materials. The raw materials can be in the form of grains, straw, soybean meal, corn, or other types of feed ingredients. The raw materials are then cleaned to remove any impurities or foreign matter that may be present.

After cleaning, the raw materials are ground into a fine powder using a hammer mill or a pulverizer. The grinding process is essential in breaking down the raw materials into smaller particles that can be easily digested by animals.

The next step is the mixing of the ground raw materials. The mixing process is done to ensure that the different ingredients are evenly distributed in the feed. A mixer is used to mix the raw materials, and a small amount of water may be added to make the mixture sticky.

After mixing, the feed mixture is then fed into the feed pellet machine. The feed pellet machine is designed to compress the feed mixture into small pellets. The pellets are formed by forcing the feed mixture through a die that has holes of a specific size and shape.

The feed pellet machine can be of different types, including flat die pellet mills and ring die pellet mills. The flat die pellet mills are suitable for small-scale operations, while the ring die pellet mills are ideal for large-scale operations.

The final step in the process of feed pellet machine is the cooling and drying of the pellets. The pellets are cooled using a pellet cooler to reduce their temperature and moisture content. The cooled pellets are then dried using a pellet dryer to remove any remaining moisture.

In conclusion, the process of feed pellet machine involves several steps that must be followed carefully to produce high-quality animal feed pellets. The raw materials must be properly prepared, ground, mixed, and compressed into pellets using a feed pellet machine. The pellets are then cooled and dried to produce high-quality animal feed. With the right equipment and procedures, the process of feed pellet machine can be efficient and effective in producing quality animal feed pellets.

Benefits Advantages of Utilizing feed pellet machine

As the demand for animal feed increases, the use of feed pellet machines has become a popular method for producing high-quality feed. These machines, which are used to process raw materials into feed pellets, offer numerous benefits and advantages over traditional feed production methods.

One of the most significant advantages of utilizing a feed pellet machine is the ability to control the size, shape, and texture of the feed pellets. This is important because different animals have different feeding requirements, and their digestive systems may not be able to handle certain feed types. With a feed pellet machine, it is possible to customize the feed pellets to meet the specific needs of the animals.

Another benefit of using a feed pellet machine is the ability to improve the nutritional value of the feed. By using high-quality raw materials and controlling the production process, it is possible to create feed pellets that are nutritionally balanced and contain all the necessary nutrients for the animals. This is important for the health and growth of the animals, as well as for the quality of the products they produce.

In addition to improving the quality of the feed, using a feed pellet machine can also improve the efficiency of the feed production process. These machines are designed to process large quantities of raw materials quickly and efficiently, which can save time and money. This is especially important for farmers and feed producers who need to produce large quantities of feed on a regular basis.

Another advantage of using a feed pellet machine is the ability to reduce waste and improve sustainability. These machines are designed to minimize waste by using all parts of the raw materials and producing feed pellets that are easy to store and transport. Additionally, feed pellets are less likely to spoil or be contaminated, which can help to reduce the risk of illness or disease in the animals.

Overall, the benefits and advantages of utilizing a feed pellet machine are numerous. By improving the quality, nutritional value, efficiency, and sustainability of the feed production process, these machines can help farmers and feed producers to meet the growing demand for high-quality animal feed while reducing costs and improving the health and well-being of their animals.

Disadvantages feed pellet machine

Feed pellet machines have become increasingly popular in recent years due to their efficiency and convenience in producing animal feed. However, despite their many advantages, there are also some notable disadvantages that come with using these machines.

One of the main disadvantages of using feed pellet machines is the cost. These machines can be relatively expensive, making it difficult for small-scale farmers or individuals to afford them. Additionally, maintenance costs can be high, and repairs may be required frequently, adding to the overall cost of the machine.

Another significant disadvantage is the quality of the feed produced by the machine. While pelletizing can improve the digestibility of the feed, it can also result in a reduction in nutrient content. This is because the process of pelletizing can cause some nutrients to break down or be lost, reducing the overall nutritional value of the feed.

Moreover, feed pellet machines require a reliable power source, which can be a challenge in areas where electricity supply is unreliable. This means that farmers may need to invest in a backup power supply to prevent interruptions in the production process.

Another concern is that the use of feed pellet machines may lead to the production of feed that is too uniform in size and shape. This can lead to selective feeding by animals, where they pick and choose only certain pellets, resulting in an imbalance in their diet.

Finally, the use of feed pellet machines may also have adverse environmental impacts. The production of pellets requires the use of energy, and the resulting waste products may contribute to environmental pollution if not disposed of properly.

In conclusion, while feed pellet machines can be a useful tool for farmers, it is important to consider their disadvantages as well. Farmers should carefully weigh the costs and potential drawbacks before investing in these machines, and explore alternative feeding methods that may be more suitable for their specific needs.

Selecting the Ideal Feed Pellet Machine Manufacturer

Investing in a feed pellet machine is a great way to produce high-quality animal feeds that can improve the health and productivity of your livestock. However, selecting the right manufacturer is crucial to ensure that you get the best quality machine that can meet your specific needs.

Here are some key factors to consider when selecting the ideal feed pellet machine manufacturer:

1. Reputation and Experience

Choose a manufacturer with a good reputation for producing reliable and high-quality feed pellet machines. Look for reviews and testimonials from previous clients to see what they have to say about the manufacturer’s products and services.

Also, consider the manufacturer’s experience in the industry. A manufacturer with years of experience is likely to have developed better and more advanced machines that can meet your specific needs.

2. Quality of Machines

The quality of the feed pellet machine is crucial to ensuring that you produce high-quality animal feeds. Look for a manufacturer that uses high-quality materials and components to build their machines. The machine should be durable, efficient, and easy to operate and maintain.

Ask the manufacturer about the machine’s features and specifications to ensure that it can produce the type of feed you require. The machine’s output capacity, power consumption, and pellet size are some of the essential features to consider.

3. Customer Support and Service

Choose a manufacturer that offers excellent customer support and service. The manufacturer should be available to answer any questions you may have and assist you in case of any issues with the machine.

Consider the availability of spare parts and the manufacturer’s warranty period. A good manufacturer should offer a reasonable warranty period and provide spare parts in case of any breakdowns.

4. Price

The price of the feed pellet machine is an essential factor to consider when selecting a manufacturer. Compare prices from different manufacturers to ensure that you get the best value for your money.

However, do not compromise on quality for a lower price. A high-quality machine may cost more, but it is worth the investment in the long run.

Conclusion

Selecting the ideal feed pellet machine manufacturer is crucial to ensure that you get a high-quality machine that can meet your specific needs. Consider the manufacturer’s reputation, experience, quality of machines, customer support and service, and price to make an informed decision.

Investing in a high-quality feed pellet machine can improve the health and productivity of your livestock, resulting in higher profits and a better return on investment.

Things to Consider When Purchasing feed pellet machine

As the demand for animal feed continues to increase, many farmers and feed producers are turning to feed pellet machines to make the process more efficient and cost-effective. However, with so many options available on the market, it can be challenging to choose the right machine for your needs. Here are some essential things to consider when purchasing a feed pellet machine.

Capacity

The first thing to consider when purchasing a feed pellet machine is the capacity you need. This will depend on how many animals you are feeding and how often you need to produce feed. If you’re a small-scale farmer or hobbyist, a small machine with a capacity of 100-200kg/hour may be sufficient. However, if you’re a large-scale producer, you will need a machine with a higher capacity to meet your production needs.

Power source

Feed pellet machines can be powered by electricity, diesel, or gasoline. The power source you choose will depend on your location and availability of power sources. If you are located in an area with frequent power outages or no access to electricity, a diesel or gasoline-powered machine may be a better option.

Ease of use

Another important factor to consider is the ease of use of the machine. Look for a machine that is easy to operate and maintain. The machine should come with clear instructions and manuals, and the manufacturer should offer support and training if needed.

Pellet size

The size of the pellets produced by the machine is also an important consideration. Pellets that are too large may be difficult for some animals to eat, while pellets that are too small may not provide enough nutrition. Look for a machine that can produce pellets in the size range suitable for your animals.

Durability

Feed pellet machines can be a significant investment, so it’s essential to choose a machine that is durable and built to last. Look for machines made from high-quality materials that can withstand regular use and wear and tear.

Price

Finally, consider the price of the machine. While it’s tempting to choose the cheapest option, it’s essential to balance cost with quality and durability. A high-quality machine may be more expensive upfront but can save you money in the long run by reducing maintenance and repair costs.

In conclusion, purchasing a feed pellet machine requires careful consideration of capacity, power source, ease of use, pellet size, durability, and price. By taking the time to research and choose the right machine for your needs, you can increase efficiency and reduce costs in your animal feed production.

Properties feed pellet machine

A feed pellet machine is an essential piece of equipment for farmers who wish to produce their own animal feed. It is a machine that is used to compress and shape various materials into small pellets, which are then used as animal feed. The machine is designed to process a variety of raw materials, including grass, straw, corn, wheat, and soybean meal, to name a few.

The primary benefit of using a feed pellet machine is that it enables farmers to produce their own feed, which is cost-effective and ensures that the animals receive high-quality nutrition. Additionally, the pellets produced by the machine are uniform in size and shape, which makes them easier to handle and store. These pellets are also less prone to spoilage and wastage, which makes them ideal for commercial use.

There are several properties of a feed pellet machine that farmers need to consider before purchasing one. The first property is the machine’s capacity, which refers to the amount of feed pellets that the machine can produce in a given period. The capacity of the machine is determined by its motor power, and it is important to choose a machine with the appropriate power output to meet the farmer’s needs.

The second property to consider is the size of the pellets produced by the machine. The size of the pellets is determined by the diameter of the die used in the machine, and it is important to choose a die size that is appropriate for the animals being fed. For example, smaller pellets are suitable for chickens, while larger pellets are suitable for cattle.

The third property to consider is the durability of the machine. A feed pellet machine is a heavy-duty piece of equipment that is subjected to constant wear and tear, and it is important to choose a machine that is built to last. A durable machine will require less maintenance and will be less prone to breakdowns, which will save the farmer time and money in the long run.

Finally, farmers need to consider the price of the machine. Feed pellet machines are available in a range of prices, and it is important to choose a machine that is within the farmer’s budget. However, it is important to note that the cheapest machine may not always be the best quality, and it is important to balance cost with quality and durability.

In conclusion, a feed pellet machine is an essential piece of equipment for farmers who wish to produce their own animal feed. When choosing a machine, farmers need to consider its capacity, the size of the pellets it produces, its durability, and its price. By carefully considering these properties, farmers can choose a machine that meets their needs and budget, and ensures that their animals receive high-quality nutrition.

How to use feed pellet machine

Feed pellet machines are a great way to produce high-quality feed for your livestock. These machines are designed to transform raw materials such as corn, wheat, soybean meal, and other grains into small, compact pellets that are easy for animals to digest. By using a feed pellet machine, farmers can ensure that their animals receive the proper nutrition they need to stay healthy and grow.

Here are some steps to help you use a feed pellet machine:

Step 1: Gather your raw materials

The first step in using a feed pellet machine is to gather the raw materials you’ll need. These materials can include grains such as corn, wheat, and barley, as well as other ingredients like soybean meal and fish meal. Make sure to choose high-quality ingredients to ensure that your animals receive the best nutrition possible.

Step 2: Grind the raw materials

Once you’ve gathered your raw materials, the next step is to grind them into a fine powder. This can be done using a feed grinder, which can be purchased separately or as part of a feed pellet machine. Grinding the raw materials makes it easier for the feed pellet machine to compress them into pellets.

Step 3: Add the raw materials to the feed pellet machine

After grinding the raw materials, add them to the feed pellet machine. Make sure to follow the manufacturer’s instructions for loading the machine. Generally, you’ll need to pour the raw materials into the hopper, which feeds them into the machine.

Step 4: Adjust the settings

Once you’ve loaded the raw materials into the feed pellet machine, it’s time to adjust the settings. Depending on the machine, you may need to adjust the temperature, pressure, or other settings to ensure that the pellets are formed correctly. Follow the manufacturer’s instructions for adjusting the settings.

Step 5: Start the machine

After adjusting the settings, start the feed pellet machine. The machine will compress the raw materials into small, compact pellets that are easy for animals to digest. The pellets will then be discharged from the machine into a collection bin or bag.

Step 6: Store the pellets

Once the pellets have been produced, store them in a dry, cool place until they’re ready to be fed to your livestock. Make sure to label the bags or bins with the date of production and the type of feed.

In conclusion, using a feed pellet machine is a great way to produce high-quality feed for your livestock. By following these steps, you can ensure that your animals receive the proper nutrition they need to stay healthy and grow.

Glossary Terminology Terms for Feed Pellet Machines

Feed pellet machines are essential pieces of equipment in the animal feed production industry. They are used to process various feed ingredients into pellets that can be easily consumed by animals. As with any specialized equipment, there are several terminologies and terms used in the feed pellet machine industry that may be unfamiliar to those who are new to the industry. Here are some of the most common terminologies and terms used in the feed pellet machine industry:

1. Pellet Die

A pellet die is a part of the feed pellet machine that is responsible for shaping the feed ingredients into pellets. It is a cylindrical steel component with several small holes through which the feed ingredients are extruded to form pellets. Pellet dies come in different sizes and shapes, depending on the type of animal feed being produced.

2. Roller Shell

The roller shell is a component of the feed pellet machine that rotates to compress the feed ingredients into the pellet die. It is a steel cylinder with a smooth surface that comes in different sizes and shapes, depending on the feed pellet machine model.

3. Conditioning

Conditioning is the process of adding moisture to the feed ingredients to increase their elasticity and improve their binding properties. This process makes it easier to compress the feed ingredients into pellets and improves the pellet’s quality.

4. Steam Injection

Steam injection is a process used during conditioning, where steam is added to the feed ingredients to increase their moisture content. This process is essential for producing high-quality pellets, as it improves the binding properties of the feed ingredients.

5. Pelletizing

Pelletizing is the final process of the feed pellet machine, where the conditioned feed ingredients are compressed into pellets using the pellet die and roller shell. This process involves high pressure and temperature, which helps to bind the feed ingredients together.

6. Pellet Cooler

After the pellets are formed, they are typically hot and moist. A pellet cooler is a machine that is used to cool the pellets and reduce their moisture content, making them easier to handle and store.

7. Pellet Crumbler

A pellet crumbler is a machine that is used to break down the pellets into smaller sizes. This process is essential for producing feed pellets that are suitable for different animal sizes and ages.

In conclusion, understanding the terminologies and terms used in the feed pellet machine industry is crucial for anyone who wants to produce high-quality animal feed pellets. By knowing these terms, you will be better equipped to make informed decisions about the type of feed pellet machine to buy and how to use it.