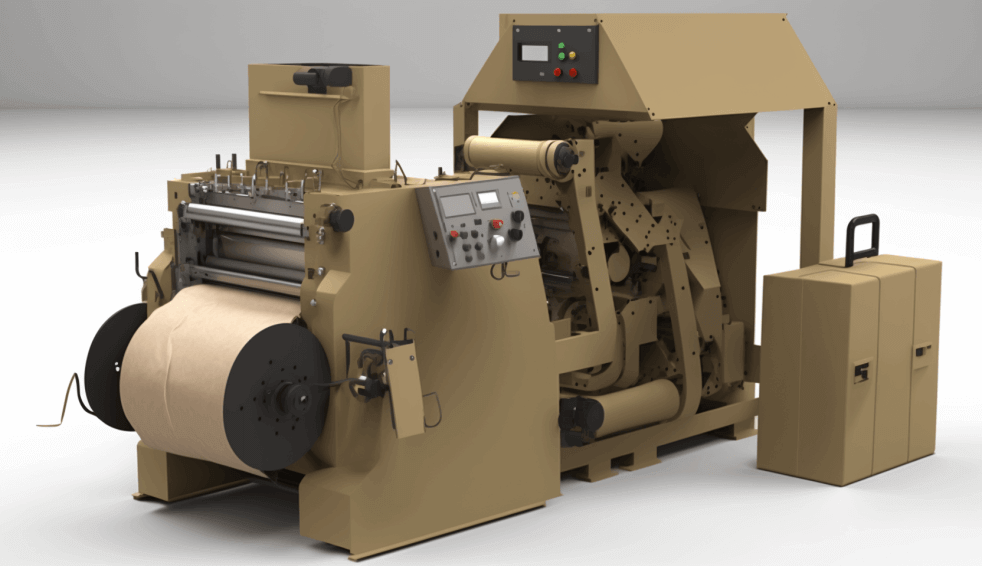

paper bag making machine

Wenzhou Hualing Intelligent Technology Co., Ltd is a manufacturer of protective packaging machinery including honeycomb paper making machine, pre-opened bag making machine, paper cushion machine, autobag bagging machine, and paper bubble making machine.

Knowleage about paper bag making machine

Paper bag making machines have become a popular choice for businesses that are looking for cost-effective and eco-friendly packaging solutions. These machines are designed to produce high-quality and durable paper bags that can be used in a range of industries, including retail, food, and hospitality.

If you are considering investing in a paper bag making machine for your business, it is important to have a good understanding of the different types of machines available, their features, and their specifications. Here are some key things to keep in mind as you evaluate your options:

1. Types of paper bag making machines:

There are several types of paper bag making machines available, including fully automatic machines, semi-automatic machines, and manual machines. Fully automatic machines are the most advanced and efficient, as they can produce a large number of bags in a short amount of time. Semi-automatic machines require some manual intervention, but are still fairly efficient. Manual machines are the least efficient, as they require a lot of manual labor to operate.

2. Production capacity:

The production capacity of a paper bag making machine is an important factor to consider. This refers to the number of bags that the machine can produce in a given time period. Different machines have different production capacities, so it is important to choose one that can meet your business’s specific needs.

3. Bag size and style:

Paper bag making machines can produce bags in a variety of sizes and styles, depending on the machine’s specifications. Some machines are designed to produce only one type of bag, while others can produce multiple types. Make sure to choose a machine that can produce the size and style of bags that you need for your business.

4. Material compatibility:

Paper bag making machines are designed to work with different types of paper, such as kraft paper, coated paper, and art paper. Make sure to choose a machine that is compatible with the type of paper that you want to use for your bags.

5. Maintenance and support:

Like any piece of machinery, paper bag making machines require regular maintenance and occasional repairs. Look for a machine that is easy to maintain and comes with good customer support from the manufacturer.

In conclusion, investing in a paper bag making machine can be a great way to improve your business’s packaging capabilities and reduce your environmental impact. By considering factors such as machine type, production capacity, bag size and style, material compatibility, and maintenance and support, you can choose a machine that will meet your business’s specific needs and help you achieve your goals.

Various Types paper bag making machine

Paper bags are used for various purposes such as shopping, packaging, and storage. With an increase in demand for eco-friendly products, paper bags have become a popular choice among consumers. To meet this demand, paper bag making machines have been developed that can produce different types of paper bags to cater to various needs.

Here are some of the different types of paper bag making machines available in the market:

1. Automatic Paper Bag Making Machine: This machine can produce various sizes of paper bags with high efficiency. It can produce up to 200 bags per minute, which makes it ideal for large-scale production. It comes with advanced features such as touch screen operation, automatic counting, and automatic stop when the bags are not in the correct position.

2. Semi-Automatic Paper Bag Making Machine: This machine is designed for small-scale production and can produce up to 60 bags per minute. It requires manual operation for some of its functions, such as feeding the paper roll, but it has automatic functions for cutting, gluing, and folding the bags.

3. Roll Fed Paper Bag Making Machine: This machine uses a continuous roll of paper to produce bags. It can produce a variety of bag sizes and shapes, and it is ideal for producing bags in large quantities. The machine has automatic functions for cutting, folding, and gluing the bags.

4. Sheet Fed Paper Bag Making Machine: This machine uses sheets of paper to produce bags. It can produce bags of different sizes and shapes, and it is ideal for producing bags in small quantities. The machine requires manual operation for feeding the paper sheets, but it has automatic functions for cutting, folding, and gluing the bags.

5. Flat Bottom Paper Bag Making Machine: This machine is designed to produce bags with a flat bottom. It is ideal for producing bags for packaging products such as food, pet food, and other items that require a stable base. The machine has automatic functions for feeding the paper, cutting, folding, and gluing the bags.

In conclusion, paper bag making machines have become an essential tool for producing eco-friendly and sustainable packaging solutions. With the different types of machines available, businesses can choose the one that best suits their production needs. From small-scale production to large-scale production, there is a paper bag making machine that can meet the demand for eco-friendly paper bags.

FAQ sourcing paper bag making machine from China manufacturer

In recent years, the demand for eco-friendly paper bags has been on the rise, and with it, the demand for paper bag making machines. China has emerged as a leading manufacturer of these machines, with many companies offering a wide range of options to choose from. However, with so many options available, it can be challenging to navigate the market and make an informed decision. In this article, we will address some of the frequently asked questions about sourcing paper bag making machines from China.

1. What types of paper bag making machines are available from China?

China offers a wide range of paper bag making machines, including flat and satchel paper bag machines, square bottom paper bag machines, and automatic paper bag machines. The machines are available in different sizes and capacities to accommodate different production needs.

2. How do I choose the right paper bag making machine for my business?

Choosing the right paper bag making machine depends on various factors, such as the type of bags you want to produce, the production capacity you require, and your budget. It is essential to do your research and compare different machines to find the one that best suits your business needs.

3. What is the cost of sourcing a paper bag making machine from China?

The cost of paper bag making machines from China varies depending on the type of machine, capacity, and features. Generally, machines with higher production capacity and advanced features tend to be more expensive. It is essential to have a budget in mind and compare prices from different manufacturers to find a machine that fits your budget.

4. What are the quality standards for paper bag making machines from China?

China has stringent quality standards for its manufacturing industry, and paper bag making machines are no exception. It is essential to source machines from reputable manufacturers who adhere to these quality standards and have a good track record of producing high-quality machines.

5. How do I ensure the safe transportation and delivery of my paper bag making machine from China?

Transporting and delivering heavy machinery like paper bag making machines requires expertise and specialized equipment. It is essential to work with a reputable freight forwarder who has experience in handling such cargo. Additionally, it is crucial to purchase insurance to protect your investment in case of any damage during transportation.

In conclusion, sourcing paper bag making machines from China can be a cost-effective and efficient way to start or expand your paper bag production business. However, it is essential to do your due diligence, research your options, and work with reputable manufacturers and freight forwarders to ensure a smooth and successful transaction.

Applications of paper bag making machine

Paper bags have become a popular alternative to plastic bags due to their environmentally friendly nature. As a result, the demand for paper bag making machines has increased. These machines can produce high-quality paper bags in large quantities, which are suitable for various applications. Here are some of the applications of paper bag making machines:

1. Retail Stores

Paper bags are commonly used in retail stores to pack products for customers. The bags are lightweight, durable, and can be customized with the store’s logo or design. With a paper bag making machine, retail stores can produce their own bags in-house, which reduces the cost of purchasing bags from suppliers. In addition, the ability to customize bags with the store’s branding helps to promote the store’s brand identity.

2. Grocery Stores

Paper bags are also used in grocery stores to pack groceries for customers. The bags are ideal for carrying heavy items, such as fruits, vegetables, and canned goods. With a paper bag making machine, grocery stores can produce their own bags in various sizes to meet the needs of their customers. This reduces the cost of purchasing bags from suppliers and ensures that the store has an adequate supply of bags for customers.

3. Restaurants

Paper bags are commonly used in restaurants to pack food for takeout orders. The bags are lightweight, easy to carry, and can be printed with the restaurant’s logo or design. With a paper bag making machine, restaurants can produce their own bags in-house, which reduces the cost of purchasing bags from suppliers. In addition, the ability to customize bags with the restaurant’s branding helps to promote the restaurant’s brand identity.

4. Gift Shops

Paper bags are commonly used in gift shops to pack gifts for customers. The bags are ideal for carrying small to medium-sized gifts, such as jewelry, books, and clothing. With a paper bag making machine, gift shops can produce their own bags in various sizes and designs to meet the needs of their customers. This reduces the cost of purchasing bags from suppliers and ensures that the shop has an adequate supply of bags for customers.

5. Events

Paper bags are also used in events, such as conferences, trade shows, and exhibitions. The bags can be printed with the event’s logo or design and used to pack promotional materials, such as brochures, flyers, and samples. With a paper bag making machine, event organizers can produce their own bags in-house, which reduces the cost of purchasing bags from suppliers. In addition, the ability to customize bags with the event’s branding helps to promote the event’s brand identity.

In conclusion, paper bag making machines have various applications in different industries. The machines are cost-effective, efficient, and environmentally friendly. With the ability to produce high-quality paper bags in large quantities, businesses can reduce the cost of purchasing bags from suppliers and promote their brand identity by customizing bags with their logo or design.

Industries That Use paper bag making machine

Paper bags have become increasingly popular in recent years as more people become aware of the negative effects of plastic bags on the environment. As a result, the demand for paper bags has grown, and the need for paper bag making machines has risen as well. These machines are used in various industries to produce paper bags of different sizes and shapes.

One industry that uses paper bag making machine is the food and beverage industry. Restaurants, cafes, and food outlets use paper bags to package their food and drinks for takeaway orders. These bags are usually made of grease-resistant paper to prevent oil and grease from seeping through the bag. Paper bags are also used to package dry food items such as bread, cakes, and pastries.

The retail industry is another major user of paper bags. Stores use paper bags to package items purchased by customers. These bags are usually made of high-quality paper and come in different sizes and colors. Paper bags are also used in the fashion industry to package clothes, shoes, and accessories.

The pharmaceutical industry also uses paper bags to package medicines and drugs. These bags are made of medical-grade paper and are designed to be tamper-evident to ensure the safety of the drugs. Paper bags are also used in the beauty industry to package cosmetic products such as skincare, haircare, and makeup.

The agriculture industry also uses paper bags to package seeds, fertilizers, and other agricultural products. These bags are made of durable paper that can withstand the weight of the products and protect them from moisture and pests.

In conclusion, paper bag making machines are used in various industries to produce paper bags of different sizes and shapes. These industries include the food and beverage industry, retail, pharmaceuticals, beauty, and agriculture. As the demand for paper bags continues to grow, the use of paper bag making machines will also increase. This is a positive trend as it promotes the use of eco-friendly packaging materials and helps to reduce the negative impact of plastic on the environment.

Manufactured Products made of paper bag making machine

Paper bag making machines have revolutionized the way we produce paper products. They have made it possible to produce high-quality paper bags in large quantities with ease. These machines are not only efficient but are also environment-friendly as they use recyclable materials.

The products that can be manufactured using paper bag making machines are numerous. From shopping bags to gift bags, paper bags have become an essential product for our day-to-day lives. Here are some of the most common products that are made using paper bag making machines.

Shopping Bags

Shopping bags are one of the most common products made using paper bag making machines. These bags are used by supermarkets and retailers to package and carry items purchased by customers. They come in different sizes and shapes and are often printed with the brand’s logo or message.

Gift Bags

Gift bags are another popular product made using paper bag making machines. They are used to package gifts and often come with a ribbon or handle for easy carrying. Gift bags also come in different sizes and shapes and can be customized to suit specific occasions or events.

Food Bags

Paper bags are also used to package food products such as bread, fruits, and vegetables. These bags are often coated with a special layer that prevents moisture and grease from seeping through. They are also recyclable, making them an ideal choice for environmentally-conscious consumers.

Paper Cups

Paper cups are also manufactured using paper bag making machines. They are used to serve hot and cold beverages in cafes, restaurants, and other food establishments. These cups are often printed with the brand’s logo, message, or design.

Wrapping Paper

Wrapping paper is another product that is made using paper bag making machines. It is used to wrap gifts and comes in different designs and colors. Wrapping paper is also recyclable, making it an eco-friendly option for consumers.

In conclusion, paper bag making machines have made it possible to produce a wide range of paper products with ease. These products are not only efficient but are also environment-friendly, making them an ideal choice for consumers who are conscious about the impact of their purchases on the environment.

The Evolution history of paper bag making machine

The paper bag making machine has come a long way since its inception in the 19th century. The evolution of this machine has been driven by the need to make paper bags faster, more efficiently, and with less waste. Today, paper bags are a staple in retail stores and supermarkets, and the machines that produce them are highly advanced and sophisticated.

The first paper bag making machine was developed in 1852 by Francis Wolle, a schoolteacher from Pennsylvania. His machine was designed to produce flat-bottomed bags and was operated manually. The process involved feeding sheets of paper into the machine, which would then be cut, folded, and glued together to form a bag. This machine was a significant improvement over the traditional method of making paper bags, which was done by hand.

In 1871, Margaret Knight, a woman from Massachusetts, invented a machine that could produce square-bottomed paper bags. Her machine was driven by steam power and was capable of producing up to 200 bags per hour. This was a significant improvement over Wolle’s machine and helped to revolutionize the paper bag industry.

Over the years, paper bag making machines continued to be improved upon, with new features being added to increase efficiency and productivity. In the 1920s, machines were developed that could produce bags with handles, making them easier to carry. In the 1940s, machines were developed that could print designs and logos onto the bags, making them an effective marketing tool.

In the 1960s, the first fully automated paper bag making machine was developed. This machine could produce up to 600 bags per minute and was capable of handling a wide range of paper types and sizes. This was a game-changer for the industry, as it allowed manufacturers to produce large quantities of bags quickly and efficiently.

Today, paper bag making machines are highly advanced and sophisticated. They are designed to produce bags with a high level of precision and accuracy, with minimal waste. Many machines are fully automated, requiring little or no human intervention, and can produce thousands of bags per hour.

In recent years, there has been a growing demand for environmentally friendly paper bags, and many manufacturers have responded by developing machines that can produce bags made from recycled materials. These machines are designed to minimize waste and reduce the carbon footprint of the paper bag industry.

In conclusion, the evolution of the paper bag making machine has been driven by the need to increase efficiency, productivity, and sustainability. From the manual machines of the 19th century to the highly advanced machines of today, the paper bag industry has come a long way. As demand for environmentally friendly products continues to grow, we can expect to see further advancements in the technology used to produce paper bags.

The Process of paper bag making machine

The process of making paper bags has become an essential aspect in the packaging industry. Paper bags are eco-friendly and recyclable, which has made them a preferred option for many businesses. The production of paper bags is facilitated by the use of a paper bag making machine. This machine has revolutionized the production of paper bags, making it faster and more efficient.

The paper bag making machine is an automatic machine that produces paper bags from a roll of paper. The machine is equipped with a series of mechanisms that work together to produce high-quality paper bags. The process of making paper bags using this machine involves the following steps:

Step 1: Loading of Paper Roll

The first step in the process is loading the paper roll onto the machine. The paper roll is loaded onto the machine at the unwinding station. The unwind station controls the tension of the paper roll and ensures that it is fed through the machine smoothly.

Step 2: Printing

The machine is equipped with a printing mechanism that allows for the printing of designs, logos, and other details on the paper. The printing mechanism uses flexographic printing technology, which ensures that the print quality is top-notch.

Step 3: Cutting

After printing, the paper is cut to the required size using a cutting mechanism. The cutting mechanism is equipped with a series of blades that cut the paper into the desired shape and size.

Step 4: Gluing

The cut paper is then fed through the gluing mechanism. The gluing mechanism applies glue to the edges of the paper to ensure that it sticks together to form a bag.

Step 5: Folding

Once the paper has been glued, it is then folded to form the actual paper bag. The folding mechanism is computer-controlled, which ensures that the folding is precise and consistent.

Step 6: Bag Formation

After folding, the paper bag is then formed using a bag formation mechanism. The bag formation mechanism shapes the bag and adds any necessary finishing touches such as handles.

Step 7: Packaging

The finished paper bags are then packaged and ready for use. The packaging is done using an automatic packaging machine that packages the bags in bundles.

In conclusion, the process of making paper bags using a paper bag making machine is a highly automated and efficient process. The machine can produce high-quality paper bags in large quantities, which makes it an ideal option for businesses that require a lot of paper bags. The use of paper bags has become more popular due to their eco-friendliness and recyclability, making the paper bag making machine an essential tool in the packaging industry.

Benefits Advantages of Utilizing paper bag making machine

Paper bags have become increasingly popular over the years due to their eco-friendliness and cost-effectiveness. The demand for paper bags has led to the development of advanced machines that can produce high-quality bags in large quantities. One such machine is the paper bag making machine. In this article, we will explore the benefits and advantages of utilizing paper bag making machines.

1. Increased Production Efficiency

The use of paper bag making machines increases production efficiency. These machines are designed to produce a large number of bags in a short period. The speed of production is much faster than manual production, which enables businesses to deliver orders on time. The machines also require minimal supervision, allowing business owners to focus on other aspects of the business.

2. Consistency in Quality

One of the significant advantages of using paper bag making machines is the consistency in quality. The machines are designed to produce bags of the same size, shape, and thickness. This consistency is essential for businesses that require uniform packaging for their products. Consistency in quality also helps to maintain the brand image of the business.

3. Cost-Effective

The use of paper bag making machines is cost-effective. The cost of the machine is a one-time investment, and the maintenance cost is minimal. The machines also require less labor, which reduces the cost of production. The use of paper bags is also cheaper than plastic bags, which further reduces the overall cost of production.

4. Eco-Friendly

Paper bags are eco-friendly, and the use of paper bag making machines promotes sustainability. The machines use renewable resources such as paper pulp, which is biodegradable and recyclable. The use of paper bags also reduces the amount of plastic waste in the environment. The eco-friendliness of paper bags and the machines used to produce them is a significant selling point for businesses that are environmentally conscious.

5. Versatility

Paper bag making machines are versatile and can produce various types of bags. The machines can produce bags of different sizes, shapes, and colors. This versatility is essential for businesses that require customized bags for their products. The machines can also produce bags with different handles, such as twisted handles, flat handles, and rope handles.

In conclusion, the use of paper bag making machines has significant benefits and advantages for businesses. The machines increase production efficiency, consistency in quality, are cost-effective, eco-friendly, and versatile. These benefits make the machines a worthwhile investment for businesses that require large quantities of paper bags. Paper bags and the machines used to produce them are also an excellent choice for businesses that are environmentally conscious.

Disadvantages paper bag making machine

Paper bags have become a popular alternative to plastic bags in recent years, as they are more environmentally friendly and sustainable. However, the production of paper bags requires the use of a paper bag making machine, which comes with its own set of disadvantages.

The first disadvantage of paper bag making machines is their cost. These machines are expensive, and not every business can afford to purchase one. This can be a barrier to entry for small businesses that want to switch to paper bags but cannot afford the machinery.

The second disadvantage is the maintenance of the machines. Paper bag making machines require regular maintenance and repairs, which can be time-consuming and costly. If the machine breaks down, it can halt production and lead to delays in fulfilling orders, which can negatively affect the business.

Another disadvantage is the limited production capacity of paper bag making machines. These machines can only produce a certain number of bags at a time, and the production process can be slow. This can limit the amount of bags a business can produce and can be a hindrance when trying to meet high demand.

In addition to these disadvantages, paper bag making machines also require a significant amount of energy to operate. The production process requires the use of electricity, which can increase the business’s energy bills and have a negative impact on the environment.

Finally, the production of paper bags also requires the use of paper, which can lead to deforestation and habitat loss for wildlife. While paper bags are biodegradable, their production process can have significant environmental impacts.

In conclusion, while paper bags are a more sustainable alternative to plastic bags, the production of paper bags using paper bag making machines comes with its own set of disadvantages. These include the cost of the machinery, the maintenance and repairs required, the limited production capacity, the energy consumption, and the impact on the environment. Businesses should carefully consider these factors before investing in a paper bag making machine and explore alternative options for sustainable packaging.

Selecting the Ideal paper bag making machine Manufacturer

In the world of packaging, paper bags are a popular choice. They are eco-friendly, reusable, and cost-effective. With the growing demand for paper bags, paper bag making machines have become essential for businesses producing them. However, choosing the right manufacturer for your paper bag making machine is crucial to ensure its quality, durability, and efficiency.

Here are some essential factors to consider when selecting the ideal paper bag making machine manufacturer.

Experience and Reputation

The first thing to consider is the manufacturer’s experience and reputation. Look for companies that have been in the industry for several years and have a good reputation. You can check their website, read reviews, and ask for references from other customers. A reputable manufacturer will provide you with high-quality machines, reliable customer service, and technical support.

Quality of Machines

The quality of the machines is another critical factor to consider. A low-quality machine will not only affect the quality of your paper bags but also result in frequent breakdowns, leading to production downtime and financial loss. Ensure that the manufacturer uses high-quality materials and advanced technology to produce their machines. You can also ask for a demonstration or visit their factory to see the production process and the quality of machines they produce.

Customization and Flexibility

Every business has unique requirements and preferences. A good manufacturer should be able to customize their machines to meet your specific needs. They should be flexible enough to modify their machines according to your production requirements. For instance, you may need a machine that can produce bags of different sizes, shapes, and designs. Ensure that the manufacturer can provide you with a machine that can handle your specific requirements.

After-Sales Support

After-sales support is crucial when it comes to paper bag making machines. A good manufacturer should provide you with technical support, training, and maintenance services. They should be available to answer your queries, provide remote assistance, and send their technicians if necessary. Ensure that the manufacturer offers a warranty and a guarantee for their machines.

Cost

Finally, consider the cost of the machine. Although the price should not be the only factor to consider, it is essential to ensure that you get a machine that meets your budget. Compare the prices of different manufacturers and select the one that offers you the best value for your money.

In conclusion, selecting the ideal paper bag making machine manufacturer requires careful consideration of several factors. Look for a manufacturer with experience, a good reputation, high-quality machines, customization and flexibility, after-sales support, and reasonable pricing. With the right manufacturer, you can be assured of getting a machine that meets your needs and produces high-quality paper bags.

Things to Consider When Purchasing paper bag making machine

Paper bags are an essential part of our lives. They are used in various places, including grocery stores, retail shops, and food outlets. With the increasing demand for paper bags, the need for paper bag making machines has also increased. However, purchasing a paper bag making machine is not an easy task. There are various things that you need to consider before making the final purchase. In this article, we’ll discuss some of the critical factors that you need to consider when purchasing a paper bag making machine.

1. Machine type:

The first thing you need to consider is the type of paper bag making machine that you want to purchase. There are different types of machines available in the market, including flat and satchel, square bottom, and shopping bag making machines. Each machine has its own set of features and functions, so it’s crucial to choose the one that suits your requirements.

2. Production capacity:

Another crucial factor to consider is the production capacity of the machine. You need to determine the amount of paper bags that you require to produce in a day to meet the demand. Based on this, you can select a machine with the appropriate production capacity.

3. Quality of machine:

The quality of the machine is another critical factor to consider. You need to ensure that the machine is made of high-quality materials and is built to last. A durable machine will save you money in the long run as you won’t need to replace it frequently.

4. Cost:

The cost of the machine is also an essential factor to consider. You need to determine your budget and look for a machine that fits within it. However, you should not compromise on the quality of the machine for the price.

5. After-sales services:

Lastly, you need to consider the after-sales services provided by the manufacturer. A good manufacturer will provide you with excellent after-sales services, including installation, training, and maintenance.

In conclusion, purchasing a paper bag making machine is a significant investment, and you need to consider all the factors mentioned above before making the final purchase. By doing so, you can ensure that you choose a machine that meets your requirements, is of high quality, and provides excellent after-sales services.

Properties paper bag making machine

Paper bags have become increasingly popular as an eco-friendly alternative to plastic bags. As the demand for paper bags grows, so does the need for efficient and reliable paper bag making machines. Properties paper bag making machines are one of the most advanced machines on the market.

Properties paper bag making machines are designed to produce high-quality paper bags in various sizes and shapes. They are easy to operate and require minimal maintenance. These machines are capable of producing up to 300 bags per minute, making them ideal for large-scale production.

One of the key features of Properties paper bag making machines is their flexibility. They can produce bags of different sizes and shapes, including square-bottom, flat-bottom, and gusseted bags. They can also produce bags with various handles, such as twisted handles, flat handles, and rope handles.

Another advantage of Properties paper bag making machines is their durability. They are made from high-quality materials that are resistant to wear and tear. They are also designed to operate continuously for long periods without any breakdowns.

Properties paper bag making machines are also highly efficient. They use minimal energy and produce minimal waste, making them eco-friendly. They are also equipped with advanced control systems that ensure accurate bag making and reduce the risk of errors.

In addition to their efficiency and durability, Properties paper bag making machines are also user-friendly. They come with easy-to-use interfaces that allow operators to control and monitor the machine easily. They also have safety features that prevent accidents and ensure the safety of the operator.

In conclusion, Properties paper bag making machines are a great investment for businesses that require high-quality paper bags in large quantities. They are efficient, durable, flexible, and user-friendly. With their advanced features and capabilities, they are sure to meet the demands of any business that needs to produce paper bags.

How to use paper bag making machine

Paper bags have become a popular alternative to plastic bags due to their eco-friendliness and affordability. If you are a small business owner, creating your own paper bags can be a great option to reduce costs and promote sustainability. However, making paper bags manually can be a time-consuming process. That’s where paper bag making machines come in handy.

Using a paper bag making machine is not complicated. In fact, it’s a straightforward process that anyone can follow with a little bit of practice. Here’s a step-by-step guide on how to use a paper bag making machine effectively:

Step 1: Set up the machine

Before using the paper bag making machine, ensure that it is properly set up. Follow the manufacturer’s instructions to assemble the machine correctly. Once you’ve assembled the machine, plug it in, and turn it on.

Step 2: Load the paper

The next step is to load the paper into the machine. Choose the type of paper you want to use and ensure that it is the correct size for the machine. Roll the paper onto the machine and ensure that it is properly aligned.

Step 3: Adjust the settings

The machine will have various settings that you can adjust depending on the paper type and bag size you want to create. Be sure to adjust the settings correctly to avoid any mishaps.

Step 4: Start the machine

Once you’ve loaded the paper and adjusted the settings, you can start the machine. The machine will automatically create the paper bags, and it’s important to keep an eye on the process to avoid any errors.

Step 5: Collect the bags

Once the machine has finished creating the paper bags, collect them and ensure that they are properly folded and glued. You can then store them in a safe place until ready to use.

It’s essential to note that different paper bag making machines have different features and settings. Therefore, it’s crucial to read the manufacturer’s instructions before using the machine to avoid any accidents or mistakes.

In conclusion, using a paper bag making machine is an efficient way to create eco-friendly paper bags for your business. With a little bit of practice and patience, you can master the art of using a paper bag making machine and enjoy the benefits of cost-effectiveness and sustainability.

Glossary Terminology Terms paper bag making machine

Paper bag making machines are essential tools in the production of paper bags. These machines are used in various industries, including food packaging, grocery stores, and shopping centers. They are designed to produce paper bags in different sizes and shapes, and they are available in various models to suit the needs of different businesses.

The process of making paper bags with a paper bag making machine involves several steps. First, the machine takes in a roll of paper and feeds it through a series of rollers that flatten and crease the paper. The paper is then cut into the desired size and shape, and the edges are glued together to form a bag. The bag is then folded and glued at the bottom to create a strong, sturdy base.

There are several terminology terms associated with paper bag making machines. Here are some of the most common:

1. Roll stand – This is the part of the machine that holds the roll of paper.

2. Web guide – This is a mechanism that ensures that the paper is fed straight into the machine and is aligned properly.

3. Creasing unit – This unit consists of a series of rollers that crease the paper to create the folds for the bag.

4. Cutting unit – This unit consists of a blade that cuts the paper to the desired size and shape.

5. Gluing unit – This unit applies adhesive to the edges of the paper to form the bag.

6. Folding unit – This unit folds the bag and glues the bottom to create a strong base.

7. Delivery unit – This is the final part of the machine that delivers the finished bags.

Paper bag making machines are available in different types, including flat bottom bag making machines, satchel bag making machines, and square bottom bag making machines. Each type of machine is designed to produce a specific type of bag, and businesses should choose the machine that best suits their needs.

In conclusion, paper bag making machines are essential tools in the production of paper bags. They are available in different models and types, and businesses should choose the machine that best suits their needs. Understanding the terminology terms associated with these machines can help businesses make informed decisions when purchasing and using them.