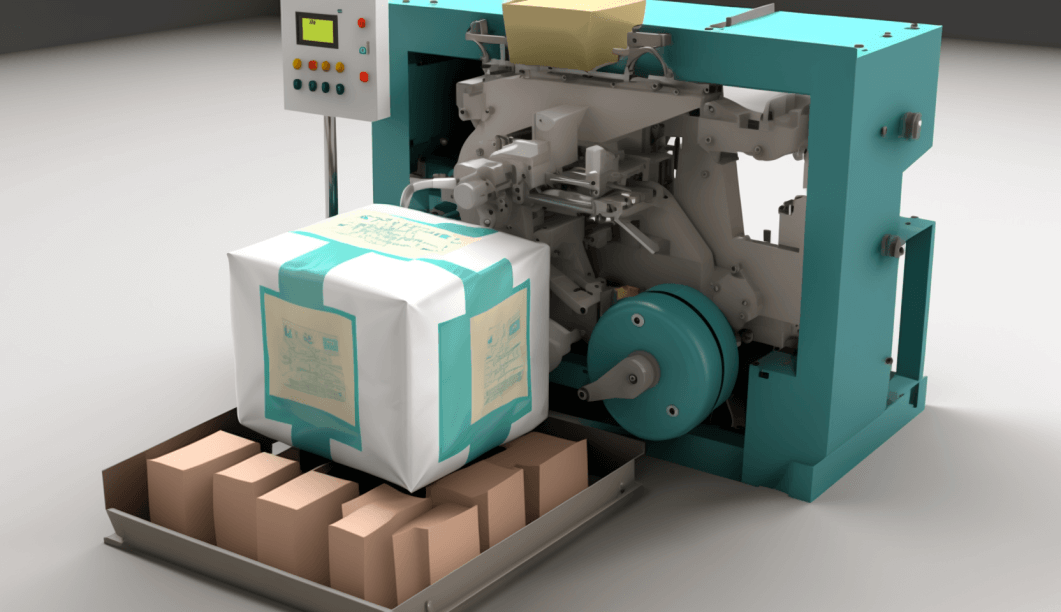

automatic packing machine

Automatic packing machine manufacturing companies and suppliers

Hefei Honor Automation Technology Co., Ltd is a Chinese company that specializes in packing machines and conveyors. They were founded in 2003 and have over 300 employees, including a strong team of over 60 research and development personnel. They are located in Hefei and welcome visitors to their factory.

Xiamen Sengong Packing Equipment Co., Ltd located in Xiamen, southeastern China, is a professional manufacturer of automatic vertical packaging machinery

Shanghai Biaozan Industrial Co., Ltd. specializes in the production of Tube Filling Sealing Machines, Box Packing Machines, Cup & Coffee Capsule Filling Sealing Machines, Bottle Filling Capping Machines, and Labeling Machines.

Danrel Co., Ltd is a High-Tech enterprise that manufactures pharmaceutical, cosmetics, and food machine equipments. They offer a range of products including automatic capsule filling machines, blister packing machines, tube filling and sealing machines, and more.

Knowleage about automatic packing machine

Automatic packing machines are becoming increasingly popular in the manufacturing industry due to their efficiency and effectiveness. These machines are designed to pack products in an automated manner, thereby reducing the need for manual labor and increasing productivity. However, to fully understand the benefits of automatic packing machines, one must have knowledge about their features, working mechanism, and applications.

Features of automatic packing machines

Automatic packing machines come with several features that make them highly efficient and effective. Some of these features include:

1. High speed: These machines are designed to pack products at high speeds, thereby reducing the time required for packaging.

2. Consistency: Automatic packing machines ensure that packaging is consistent, regardless of the product size or shape.

3. Flexibility: These machines can be programmed to handle different types of products, making them versatile in their applications.

4. Accuracy: Automatic packing machines are designed to pack products accurately, ensuring that they are properly sealed and protected.

Working mechanism of automatic packing machines

Automatic packing machines work on a simple principle of automation. The machine is programmed to pick up the product, place it in the packaging material, and seal it. The process is repeated continuously until the desired number of products is packed. The machine is designed to work at high speeds, ensuring that large quantities of products are packed within a short time.

Applications of automatic packing machines

Automatic packing machines are widely used in several industries, including food and beverage, pharmaceutical, and cosmetic industries. These machines are used to pack products such as candies, snacks, medicines, and cosmetics. They are also used to pack products in various forms, including pouches, bottles, and cartons.

In conclusion, automatic packing machines are an essential tool in the manufacturing industry. They are designed to improve efficiency, increase productivity, and reduce manual labor. With the knowledge of the features, working mechanism, and applications of these machines, manufacturers can make informed decisions about investing in them.

Various Types automatic packing machine

In today’s fast-paced world, there is a growing demand for automation in various industries. One such industry is the packaging industry, where automatic packing machines have become a popular choice among manufacturers. These machines not only save time but also increase productivity and efficiency. Let’s take a look at the various types of automatic packing machines available in the market.

1. Form Fill Seal (FFS) Machines

Form Fill Seal machines are one of the most common types of automatic packing machines. These machines can automatically form the packaging material, fill it with the product, and seal it. FFS machines are versatile and can handle a wide range of products, from liquids to powders.

2. Vertical Form Fill Seal (VFFS) Machines

Vertical Form Fill Seal machines are similar to FFS machines, but they are designed to package products in a standing position. These machines are ideal for packaging products that are solid or semi-solid, such as snacks, coffee, and pet food.

3. Horizontal Form Fill Seal (HFFS) Machines

Horizontal Form Fill Seal machines are designed to package products in a horizontal position. These machines are commonly used in the food industry to package products such as biscuits, chocolates, and candy bars.

4. Pouch Packing Machines

Pouch packing machines are used to package products in pouches or sachets. These machines are ideal for packaging products such as snacks, spices, and powders. Pouch packing machines are available in both automatic and semi-automatic configurations.

5. Cartoning Machines

Cartoning machines are used to package products in cartons or boxes. These machines are commonly used in the pharmaceutical and cosmetic industries to package products such as tablets, capsules, and creams.

6. Case Packing Machines

Case packing machines are used to package products in cases or boxes. These machines are ideal for packaging products such as bottles, cans, and jars. Case packing machines are available in both automatic and semi-automatic configurations.

7. Stretch Wrapping Machines

Stretch wrapping machines are used to wrap products in plastic film. These machines are commonly used in the logistics industry to package products on pallets. Stretch wrapping machines can be used to package products of various sizes and shapes.

In conclusion, automatic packing machines have revolutionized the packaging industry. From FFS machines to stretch wrapping machines, there are various types of machines available to suit different packaging needs. These machines not only save time and increase productivity but also ensure consistency in packaging, which is essential for maintaining the quality of the product.

FAQ sourcing automatic packing machine from China manufacturer

Are you looking to source an automatic packing machine from a China manufacturer? If so, you likely have many questions about the process. Here are some frequently asked questions and their answers to help you get started.

1. What types of automatic packing machines are available from China manufacturers?

There are many types of automatic packing machines available from China manufacturers, including vertical form fill seal machines, horizontal form fill seal machines, flow wrap machines, and more. It is important to determine which type of machine will best suit your packaging needs before beginning your search.

2. What should I look for in a China manufacturer of automatic packing machines?

When sourcing from a China manufacturer, it is important to look for a company with a good reputation for quality and reliability. Check reviews and ratings from previous customers, and look for certifications such as ISO and CE. Additionally, consider the manufacturer’s experience, production capacity, and customer service.

3. How can I ensure that the automatic packing machine I source from China meets my standards?

Before making a purchase, it is important to communicate your specific requirements and expectations with the manufacturer. This includes factors such as capacity, speed, packaging materials, and more. Ask for samples or a trial run of the machine before making a final decision.

4. Can I customize my automatic packing machine from a China manufacturer?

Yes, many China manufacturers offer customization options for their automatic packing machines. This can include modifications to the machine’s size, shape, and features, as well as branding and labeling options.

5. How do I handle shipping and logistics when sourcing from a China manufacturer?

Shipping and logistics can be a complex process when sourcing from a China manufacturer. It is important to work with a reliable freight forwarder or shipping agent who can handle customs clearance and transport of the machine to your desired location. Make sure to factor in shipping costs and potential delays when planning your purchase.

In conclusion, sourcing an automatic packing machine from a China manufacturer can be a cost-effective solution for your packaging needs. However, it is important to do your research and choose a reputable manufacturer who can meet your specific requirements and provide reliable customer service. With careful planning and communication, you can successfully source and integrate an automatic packing machine into your production line.

Applications of automatic packing machine

Automatic packing machines have become increasingly popular in recent years, thanks to their ability to streamline the packaging process and increase efficiency. These machines can be used in a variety of industries, including food and beverage, pharmaceuticals, cosmetics, and more. In this article, we will explore some of the most common applications of automatic packing machines.

Food and Beverage Industry

The food and beverage industry is one of the largest users of automatic packing machines. These machines are used to package a vast range of food and beverage products, including snacks, confectionery, canned goods, bottled beverages, and more. Automatic packing machines can handle a wide variety of packaging materials, such as plastic bags, pouches, cartons, and bottles. They can also be programmed to weigh the products accurately and to fill them with the correct amount of product.

Pharmaceuticals and Medical Devices Industry

The pharmaceuticals and medical devices industry is another major user of automatic packing machines. These machines are used to package tablets, capsules, syringes, and other medical devices. They are designed to meet the stringent requirements of the industry, such as accuracy, cleanliness, and sterility. Automatic packing machines can also be used to package products with special requirements, such as those that need to be protected from light or moisture.

Cosmetics Industry

The cosmetics industry is another industry that can benefit from the use of automatic packing machines. These machines can be used to package a wide range of cosmetic products, such as creams, lotions, shampoos, and perfumes. They can handle a range of packaging materials, including plastic bottles, jars, and tubes. Automatic packing machines can also be programmed to apply labels and other promotional materials to the packaging.

E-commerce Industry

With the rise of e-commerce, there has been an increased demand for automatic packing machines in the logistics and fulfillment industry. These machines can be used to package a wide range of products, from small items like electronics and books to larger items like furniture and appliances. The machines can be programmed to create custom-sized boxes to fit the products, reducing waste and improving efficiency.

Conclusion

Automatic packing machines have a wide range of applications in various industries. They can streamline the packaging process, improve efficiency, and reduce waste. With advances in technology, these machines are becoming increasingly sophisticated and versatile, making them an essential tool for many businesses. As the demand for automation and efficiency increases, we can expect to see even more applications for automatic packing machines in the future.

Industries That Use automatic packing machine

In today’s fast-paced world, automation has become the norm in many industries. One such industry that has seen a significant transformation in recent years is the packaging industry. With the advent of automatic packing machines, the packaging process has become more efficient, reliable, and cost-effective. Here, we will discuss the industries that use automatic packing machines.

Food and Beverage Industry

The food and beverage industry is one of the biggest users of automatic packing machines. These machines are used to package a variety of food items such as snacks, confectionery, bakery items, and frozen foods. Automatic packing machines are equipped with sensors and software that ensure that the packaging process is accurate and consistent. This not only improves the quality of the packaged product but also increases the efficiency of the packaging process.

Pharmaceutical Industry

The pharmaceutical industry is another major user of automatic packing machines. These machines are used to package a range of pharmaceutical products such as tablets, capsules, and powders. Automatic packing machines are designed to meet the strict quality standards of the pharmaceutical industry. They are equipped with advanced features such as dust control systems and air filtration systems, which ensure that the packaged products are free from contamination.

Cosmetics Industry

The cosmetics industry is another industry that has seen a significant increase in the use of automatic packing machines. These machines are used to package a variety of cosmetic products such as creams, lotions, and shampoos. Automatic packing machines are designed to handle a wide range of packaging materials such as plastic, glass, and metal. They are also equipped with features such as label applicators, date coders, and cartoners, which make the packaging process more efficient.

Consumer Goods Industry

The consumer goods industry is another industry that has embraced the use of automatic packing machines. These machines are used to package a range of consumer goods such as toiletries, cleaning products, and pet foods. Automatic packing machines are designed to handle a variety of packaging formats such as pouches, sachets, and bottles. They are also equipped with features such as multi-head weighers, volumetric fillers, and baggers, which make the packaging process more efficient.

In conclusion, automatic packing machines have revolutionized the packaging industry by making the packaging process more efficient, reliable, and cost-effective. The industries that use automatic packing machines include the food and beverage industry, the pharmaceutical industry, the cosmetics industry, and the consumer goods industry. These industries have benefited from the use of automatic packing machines by improving the quality of their products and increasing the efficiency of their packaging process.

Manufactured Products made of automatic packing machine

In today’s fast-paced world, the demand for automation is increasing at an unprecedented rate. The manufacturing industry is no exception to this trend. With advancements in technology, automated packing machines are becoming increasingly popular in the manufacturing of various products.

Automatic packing machines are designed to perform tasks such as counting, bagging, and sealing products. They are widely used in the food, pharmaceutical, and cosmetic industries, among others. These machines have a high level of accuracy, which ensures that the products are packaged correctly and consistently.

One of the significant advantages of using automated packing machines is their ability to improve efficiency in the manufacturing process. These machines can handle large volumes of products in a shorter amount of time than manual packaging. This allows manufacturers to increase their production rates without compromising on the quality of the product.

Another advantage of using automated packing machines is the reduction in labor costs. With manual packaging, manufacturers need to hire a considerable workforce to perform the task. However, with automated packing machines, the need for a large workforce is eliminated, reducing labor costs, and increasing profit margins.

Automated packing machines are also beneficial in ensuring product safety and hygiene. These machines are designed to operate in a clean environment, which minimizes the risk of contamination. They also have features such as metal detectors and X-ray machines to ensure that the packaged products are free from any foreign objects.

The use of automated packing machines has also led to the development of new and innovative packaging designs. These machines can handle a wide range of product shapes and sizes, allowing manufacturers to experiment with different packaging designs. This can help to improve the product’s shelf appeal, making it more attractive to consumers.

In conclusion, automated packing machines have revolutionized the manufacturing industry, providing numerous benefits to manufacturers. They are efficient, cost-effective, and ensure product safety and hygiene. As technology continues to advance, we can expect to see more innovative features added to these machines, further improving the manufacturing process.

The Evolution history of automatic packing machine

The packing process is one of the most important and time-consuming tasks in the manufacturing industry. In the past, manual packing was the only option for manufacturers. However, with the technological advancements, the automatic packing machine was introduced, which revolutionized the packing process. The evolution of the automatic packing machine has come a long way since its inception. In this article, we will take a look at the history of the automatic packing machine and its evolution.

The first automatic packing machine was invented in the 1920s by a German engineer named Karl-Heinz Brandenburg. This machine was designed to pack cigarettes automatically, which helped to reduce labor costs and increased production efficiency. However, the machine was not suitable for packing other products as it was designed specifically for cigarettes.

In the 1950s, automatic packing machines were introduced that could pack various products such as biscuits, candies, and other food items. These machines were designed to pack products in different shapes and sizes, which made them versatile and useful for different industries.

In the 1960s and 1970s, the automatic packing machine evolved further with the introduction of computer technology. The computer-controlled machines were more efficient and accurate in packing products. These machines could also be programmed to pack products in different formats, which made them even more versatile.

In the 1980s and 1990s, the automatic packing machine became even more advanced with the introduction of robotics technology. The robotic packing machines were designed to pack products at a faster rate with more accuracy. These machines could also handle fragile products, which was difficult for the earlier machines.

In the 21st century, the automatic packing machine has evolved even further with the introduction of artificial intelligence (AI) technology. The AI-powered machines are designed to pack products at a faster rate with high accuracy. These machines can also recognize and sort products automatically, which saves a lot of time and labor costs.

Today, the automatic packing machine is one of the most important machines in the manufacturing industry. It has revolutionized the packing process and has made it more efficient, accurate, and cost-effective. The evolution of the automatic packing machine has come a long way, and it will continue to evolve with the advancement of technology.

In conclusion, the evolution of the automatic packing machine has been a remarkable journey. From its humble beginnings in the 1920s to the AI-powered machines of today, the automatic packing machine has come a long way. It has revolutionized the packing process and has made it more efficient, accurate, and cost-effective. The future of the automatic packing machine looks bright, and it will continue to evolve with the advancement of technology.

The Process of automatic packing machine

The process of automatic packing machine is a revolutionary innovation in the packaging industry. This machine is capable of packing a wide range of products, including food items, pharmaceuticals, and household products, with precision and speed.

The process of the automatic packing machine starts by placing the product on the conveyor belt. The machine then automatically detects the product’s size, shape, and weight to ensure that the appropriate packing material is used. The packing material is then fed into the machine, and the product is securely packed.

The automatic packing machine uses various packaging materials, including plastic, paper, and cardboard. The machine can also seal the packages using heat or ultrasonic waves to ensure that the product is kept fresh and secure during transportation.

One of the significant advantages of the automatic packing machine is that it reduces the need for manual labor. This machine is designed to handle large volumes of products, reducing the need for human intervention. This, in turn, reduces the risk of error and increases the efficiency of the packaging process.

The automatic packing machine is also capable of printing barcodes, product information, and expiry dates on the packages. This ensures that customers can easily identify the product and its contents, reducing the risk of confusion and errors.

Moreover, the automatic packing machine is designed to be energy-efficient, reducing the environmental impact of the packaging process. The machine can also be customized to meet the specific needs of the product, ensuring that it is packed securely and efficiently.

In conclusion, the process of the automatic packing machine is a game-changer in the packaging industry. It offers a range of benefits that include increased efficiency, reduced labor costs, and improved product security. As the demand for packaged products continues to grow, the automatic packing machine is expected to become an essential tool for businesses worldwide.

Benefits Advantages of Utilizing automatic packing machine

In today’s fast-paced world, every business is looking for ways to increase their productivity and efficiency. One of the best ways to do this is by investing in an automatic packing machine. These machines have revolutionized the packaging industry, making it possible for businesses to process products faster, more efficiently, and with less waste. Here are some of the benefits and advantages of utilizing automatic packing machines.

1. Increased Efficiency and Productivity

One of the main benefits of using an automatic packing machine is the increased efficiency and productivity that it provides. With an automatic packing machine, businesses can process products at a faster rate, reducing the time it takes to package products manually. This, in turn, increases productivity, allowing businesses to process more products in a shorter amount of time.

2. Cost Savings

Another advantage of utilizing an automatic packing machine is the cost savings that come with it. Automated packaging machines can reduce labor costs, as they require fewer workers to operate. Additionally, with an automatic packing machine, there’s less risk of packaging errors, which can save businesses money in the long run by minimizing waste and reducing returns.

3. Improved Product Quality

Automatic packing machines provide a more consistent packaging process, which can help improve product quality. With an automated machine, packaging is done with precision and accuracy, without the risk of human error. This ensures that products are packaged in a way that meets the desired standards, improving overall customer satisfaction.

4. Increased Flexibility

Automated packing machines are highly customizable, allowing businesses to tailor the packaging process to their specific needs. This makes it possible to package a wider range of products, from small items to larger ones, without having to invest in multiple machines. This increased flexibility is especially important for businesses that need to package different products at different times of the year.

5. Enhanced Safety

Manual packaging can be a hazardous task, especially when dealing with heavy or sharp objects. Automatic packing machines provide a safer packaging process, reducing the risk of injuries to workers. This can help businesses reduce liability costs and provide a safer working environment for their employees.

In conclusion, automatic packing machines offer numerous benefits and advantages for businesses looking to increase their efficiency, productivity, and profitability. With cost savings, improved product quality, increased flexibility, and enhanced safety, investing in an automatic packing machine is a smart decision for any business looking to stay ahead of the competition.

Disadvantages automatic packing machine

Automatic packing machines have become increasingly popular in today’s manufacturing industry, as they offer several benefits such as increased efficiency, accuracy, and reduced labor costs. However, despite the many advantages, there are also some disadvantages associated with these machines.

One of the major drawbacks of automatic packing machines is their high cost. These machines are expensive to purchase, install and maintain. In addition to the initial investment, there are also ongoing costs associated with the regular maintenance, repairs, and replacement of parts. This can be a significant financial burden for small businesses or those with limited budgets.

Another disadvantage of automatic packing machines is that they require a high level of expertise to operate and maintain. This means that businesses must invest in specialized training for their employees to ensure that they are able to operate and maintain the machines effectively. This can also be a challenge for small businesses, which may not have the resources to invest in such training.

Automatic packing machines also have limitations in terms of the products they can handle. These machines are designed for specific types of products and may not be suitable for handling a wide range of products. This can be a problem for businesses that produce a variety of products or those that need to adapt quickly to changes in market demand.

Another disadvantage of automatic packing machines is that they can be less flexible than manual packing methods. While these machines are designed to operate efficiently, they may not be able to handle unexpected changes in product or packaging requirements. This can result in delays and additional costs for businesses.

In conclusion, while automatic packing machines offer many benefits, they also have several disadvantages that businesses must consider before investing in them. These machines are expensive to purchase and maintain, require specialized expertise to operate and maintain, and may have limitations in terms of the products they can handle. Additionally, they may not be as flexible as manual packing methods, which can be a challenge for businesses that need to adapt quickly to changes in market demand.

Selecting the Ideal automatic packing machine Manufacturer

Selecting the ideal automatic packing machine manufacturer is a crucial decision for any business that wants to automate its packaging process. Automated packaging machines offer numerous benefits, including increased efficiency, reduced labor costs, and consistent product quality. However, choosing the right manufacturer is essential to ensure that the machine meets your specific requirements and delivers the expected results.

Here are some factors to consider when selecting the ideal automatic packing machine manufacturer:

1. Experience and Expertise

The first thing to consider when choosing an automatic packing machine manufacturer is their experience and expertise in the field. Look for a manufacturer that has been in the industry for a considerable amount of time and has a proven track record of delivering high-quality machines. You can also check their reviews and testimonials from previous customers to get an idea of their performance.

2. Machine Customization

Not all businesses have the same packaging needs, so it’s essential to look for a manufacturer that offers customization options. A reliable manufacturer should be able to tailor the machine to your specific requirements, including packaging materials, product dimensions, and production capacity. This will ensure that the machine can handle your unique packaging needs and deliver optimal performance.

3. Technical Support and Maintenance

Automated packaging machines are complex systems that require regular maintenance and technical support to operate efficiently. Therefore, it’s crucial to choose a manufacturer that offers reliable technical support and maintenance services. Look for a company that provides training to your staff on how to operate the machine and troubleshoot common issues. This will help you avoid downtime and maximize the machine’s lifespan.

4. Quality and Safety Standards

Packing machines are an essential part of the production process, so it’s vital to ensure that they meet the necessary quality and safety standards. Choose a manufacturer that adheres to industry standards and regulations, such as ISO and CE certifications. This will ensure that the machine is safe to operate and will deliver consistent quality results.

5. Cost and ROI

Finally, consider the cost of the machine and the return on investment (ROI) it will deliver. Choose a manufacturer that offers competitive pricing without compromising on quality. Also, consider the long-term benefits of investing in an automated packaging machine, such as increased efficiency, reduced labor costs, and improved product quality. This will help you determine the ROI of the machine and make an informed decision.

In conclusion, selecting the ideal automatic packing machine manufacturer is a critical decision that requires careful consideration. By choosing a reliable manufacturer that offers customization, technical support, and adheres to quality and safety standards, you can ensure that the machine meets your specific requirements and delivers optimal performance.

Things to Consider When Purchasing automatic packing machine

Automatic packing machines have revolutionized the packaging industry by providing efficient and cost-effective solutions to pack a wide range of products. These machines come in different types, sizes, and configurations, making it challenging to choose the right one for your business. In this article, we will discuss the things to consider when purchasing an automatic packing machine.

1. Product characteristics

The first thing you need to consider is the type of product you want to pack. The product’s size, shape, weight, and fragility will determine the type of machine you need. For example, if you are packing fragile items like glass bottles, you will need a machine that can handle them with care. On the other hand, if you are packing heavy products like cement bags, you will need a robust machine that can handle the weight.

2. Production capacity

The production capacity of the machine is another critical factor to consider when choosing an automatic packing machine. You need to know the number of products you need to pack per minute or hour to determine the machine’s capacity. The capacity of the machine will depend on the type of product you want to pack and the production volume of your business. Make sure you choose a machine that can handle your production needs.

3. Type of packaging

The type of packaging you want to use is another factor to consider when choosing an automatic packing machine. There are different types of packaging, such as bottles, pouches, bags, and boxes. You need to choose a machine that can handle the type of packaging you want to use. For example, if you want to use pouches, you will need a pouch packing machine.

4. Machine features

Automatic packing machines come with different features that make them more efficient and effective. Some of the features to consider include:

– Automatic feeding system

– Automatic bag forming and filling

– Bag sealing and closing

– Multi-lane packaging

– Automatic labeling

– Touchscreen control panel

– Remote monitoring

You need to choose a machine with features that are relevant to your business needs.

5. Maintenance and support

The maintenance and support of the machine are crucial factors to consider when making a purchase. You need to choose a machine from a reputable manufacturer that offers maintenance and support services. You also need to ensure that the machine comes with a warranty to cover any defects or malfunctions.

In conclusion, choosing the right automatic packing machine requires careful consideration of the product characteristics, production capacity, type of packaging, machine features, and maintenance and support. Make sure you do your research and choose a machine that will meet your business needs and improve your packaging process.

Properties automatic packing machine

Automatic packing machines are devices used to pack products in airtight containers, bags, or cartons. They are widely used in various industries, including food, pharmaceuticals, cosmetics, and chemicals. These machines are designed to increase efficiency, accuracy, and productivity in packaging operations.

Properties of automatic packing machines vary depending on the application and the type of machine. Here are some of the common properties of automatic packing machines:

1. Speed: The speed of automatic packing machines is one of the most important properties. It determines the number of products that can be packed in a given time. High-speed machines can pack hundreds of products per minute, while slower machines may pack only a few dozen.

2. Accuracy: Automatic packing machines are designed to pack products with high accuracy. The machines can be programmed to pack products in precise quantities, ensuring that each package contains the same amount of product.

3. Flexibility: Automatic packing machines can be customized to pack different types of products. They can be adjusted to pack products of different sizes, shapes, and weights. This flexibility makes them ideal for packaging a wide range of products.

4. Reliability: Automatic packing machines are designed to be reliable and durable. They are built with high-quality components that can withstand the demands of continuous operation. This ensures that the machines can operate efficiently with minimal downtime.

5. Ease of use: Automatic packing machines are designed to be user-friendly. They are equipped with intuitive interfaces that make them easy to operate. The machines can be programmed to perform specific tasks, and operators can easily adjust the settings to suit their needs.

6. Safety: Automatic packing machines are designed with safety in mind. They are equipped with safety features such as emergency stop buttons, safety guards, and sensors that can detect abnormalities and shut down the machine to prevent accidents.

In conclusion, automatic packing machines are essential tools for modern packaging operations. They offer a range of properties that make them ideal for packaging a wide range of products. These properties include speed, accuracy, flexibility, reliability, ease of use, and safety. Investing in an automatic packing machine can help businesses increase efficiency, reduce costs, and improve product quality.

How to use automatic packing machine

Automatic packing machines have revolutionized the packaging industry by making the packaging process faster, more efficient, and more accurate. These machines are designed to automate the packaging process by automatically filling and sealing packages with products.

If you are new to using an automatic packing machine, it can be daunting to know how to use it for the first time. Here is a step-by-step guide on how to use an automatic packing machine:

1. Prepare the machine

Before using the automatic packing machine, you need to prepare it by checking the machine’s settings and ensuring that the machine’s components are working correctly.

2. Set the desired package size

Next, set the desired package size. This includes the length, width, and depth of the package. The machine will then adjust its settings to ensure that the package is filled and sealed correctly.

3. Load the products

Once the machine is set up, load the products that you want to pack into the machine’s hopper. The hopper feeds the products into the machine, which then automatically fills the package.

4. Start the machine

After loading the products, start the machine. The machine will automatically fill the package with the product, seal the package, and cut it to the desired size.

5. Collect the packages

Once the machine has finished packaging the products, collect the packages from the output chute. Check the packages to ensure that they are correctly filled, sealed, and cut.

6. Clean the machine

After using the machine, it is essential to clean it thoroughly. This ensures that the machine is hygienic and ready for the next use.

In conclusion, using an automatic packing machine is relatively easy once you understand the process. By following the steps above, you can use the machine to package your products faster, more efficiently, and more accurately. Automatic packing machines can help businesses save time and money while improving the productivity of their packaging process.

Glossary Terminology Terms automatic packing machine

An automatic packing machine is a device used in modern manufacturing processes to pack products automatically. It is designed to save time and increase productivity by reducing the need for manual labor in the packaging process. This type of machine is used in various industries, including food, pharmaceuticals, and consumer goods, to pack products such as candies, pills, and bottles.

The automatic packing machine operates by feeding products into the machine, which then sorts, counts, and packages them according to a pre-set program. The machine can package products in various forms such as bags, boxes, or bottles. It uses sensors and cameras to detect the products and ensure that they are packaged correctly.

The automatic packing machine can be customized to fit the specific needs of a manufacturing company. Some machines are designed to handle a specific type of product or packaging material, while others can handle multiple types of products and packaging. The machine can also be programmed to handle different packaging sizes and configurations.

The benefits of using an automatic packing machine include increased productivity, reduced labor costs, and improved efficiency. The machine can operate continuously without the need for breaks, reducing the amount of time required to package products. It also reduces the risk of human error in the packaging process, resulting in a higher quality of product packaging.

There are different types of automatic packing machines available in the market, including horizontal and vertical form-fill-seal machines, cartoning machines, and case packing machines. Each machine has its specific features and capabilities, so it is essential to choose a machine that meets the specific requirements of the manufacturing process.

In conclusion, the automatic packing machine is a valuable tool for modern manufacturing processes. It offers many benefits, including increased productivity, improved efficiency, and reduced labor costs. With the ability to customize the machine to fit specific needs, it is an essential investment for any manufacturing company looking to improve their packaging process.