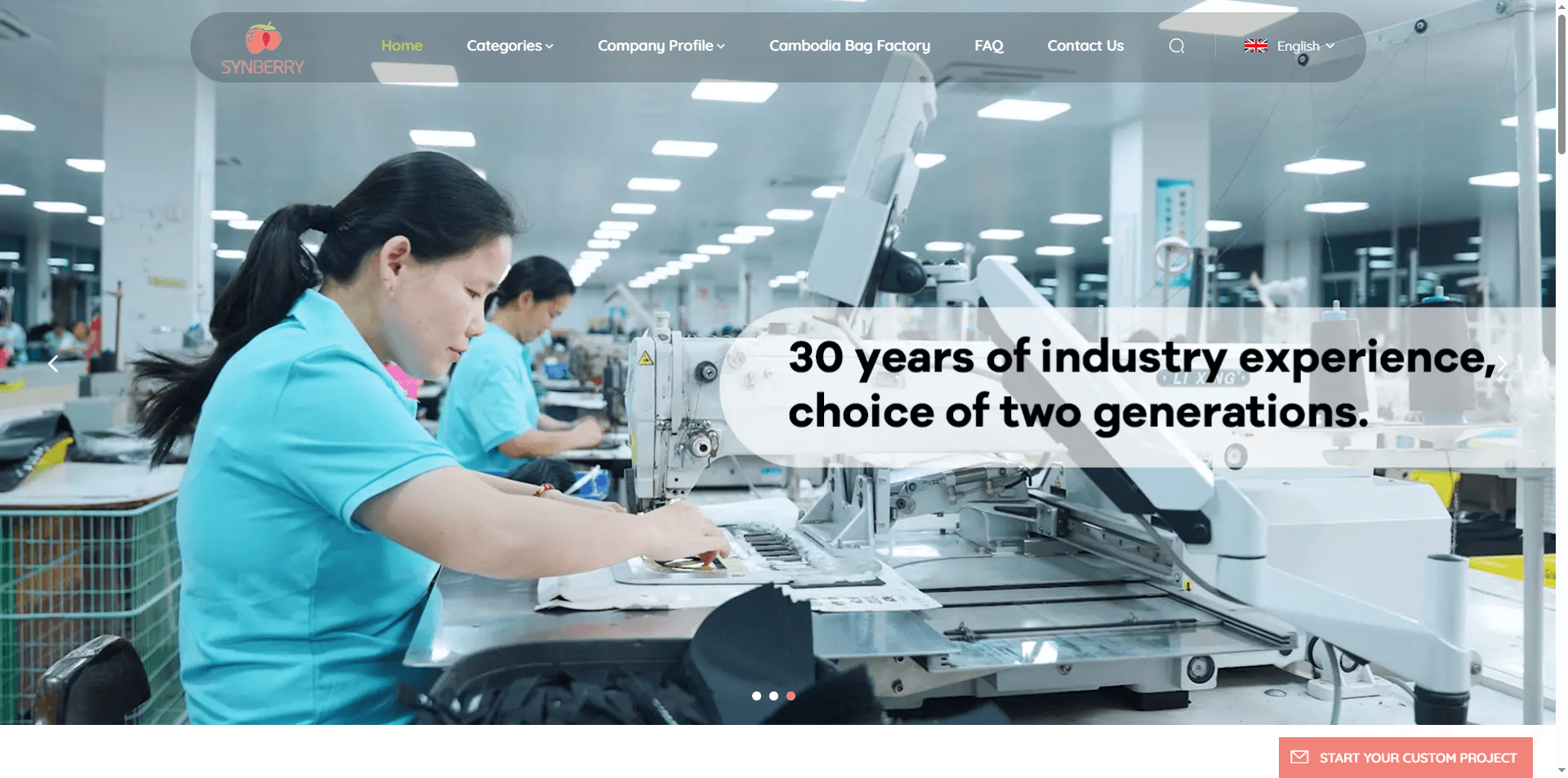

Experienced Bag Manufacturer Since 1993: Quality You Can Trust

Founded in 1993, Synberry is one of the earliest bag manufacturers in China. With high-quality standards and professional production practices, the company has earned the trust of international clients and stood out in a highly competitive market. As the company has grown and the global trade landscape has evolved, Synberry established a branch factory in Cambodia, offering international customers a new option to mitigate the impact of high tariffs.

The manufacturing capabilities cover a wide range of categories, including school bags, backpacks, travel bags, duffel bags, tote bags, handbags, and other custom-designed products. Every stage of production — from material sourcing to final inspection — follows strict quality control processes to ensure durability and customer satisfaction.

As an old bag factory in China, Synberry has served a wide range of clients, offering solutions suitable for both small-batch purchases and large-scale procurement needs.

For businesses seeking a reliable bag manufacturer with decades of experience and proven expertise, Synberry stands out as a trusted partner in the supply chain — combining quality, efficiency, and customizability across a variety of product categories.

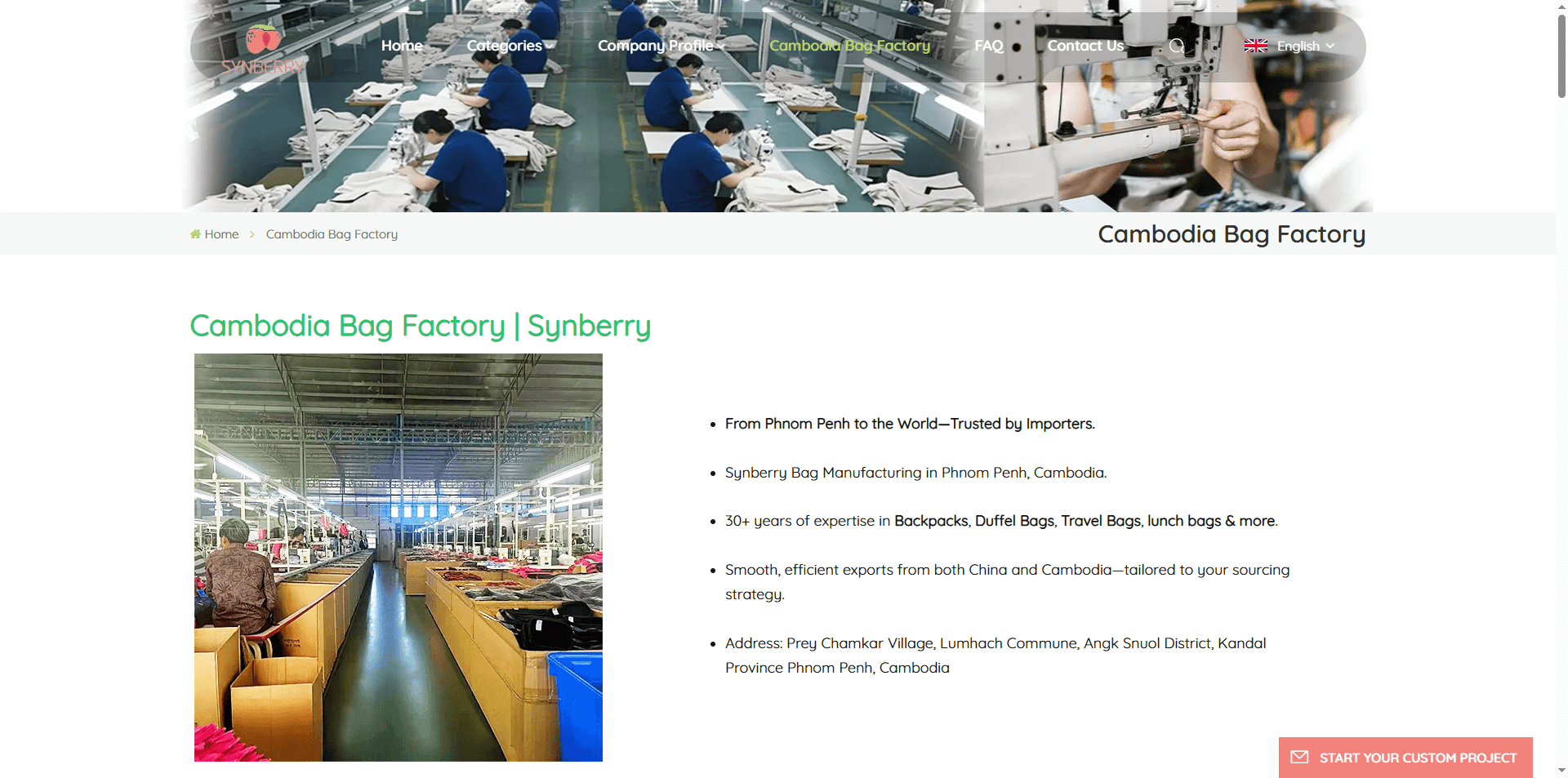

Cost-Efficient Bag Production from Synberry Cambodia Factory

With Synberry’s growth and the increasing demand from clients for production outside of China, Synberry established a bag OEM factory in Phnom Penh, Cambodia, to address concerns about high export tariffs from China. The Cambodia Bag Factory imports raw materials from China, replicates the production lines, manufacturing processes, and standardized management model used in the China facility. This ensures that exports from Cambodia maintain high quality and high standards while also being cost-effective, providing many international clients with a premium alternative outside of China.

Custom Bag Manufacturer for Brands That Need a Unique Edge

Finding a custom bag manufacturer that truly understands branding needs can make all the difference. Synberry specializes in producing tailored bag solutions that align with each client’s unique design, function, and identity goals. From material selection to logo placement and packaging, every detail is handled with precision. Whether it’s for retail, promotional campaigns, or private label collections, customized bags offer brands a distinct edge in a competitive market. With advanced production capabilities and flexible manufacturing options, Synberry supports both emerging labels and established names seeking to stand out through high-quality, custom-made bag products.

Advantages of Synberry

- Dual Production Locations: Choose between factories in China and Cambodia to optimize lead time and reduce import tariffs.

- In-House Testing Lab: Each product is tested for strength, durability, and safety to ensure consistent high quality.

- 30+ Years of Industry Experience: Trusted by global brands for professional manufacturing and smart sourcing solutions, built on the foundation of an old bag factory with decades of craftsmanship and production expertise.

- Flexible Customization: Wide range of materials, printing, and packaging options to meet diverse brand needs.

- Stable Capacity & On-Time Delivery: Reliable production systems built for both small and large volume orders.

What is the minimum order quantity (MOQ) for Synberry’s products?

To support clients at different stages of development, Synberry offers relatively low MOQs (typically starting from 500 pieces). The exact MOQ depends on factors such as bag type, materials, and customization requirements. Clients are welcome to discuss their needs with Synberry to find the most suitable MOQ, helping them reduce initial investment costs and successfully launch their ideal products.

What certifications does the Synberry old bag factory in China and Cambodia have?

The Synberry bag factory holds a comprehensive set of certifications to meet international standards for ethical production, quality, and sustainability. These include WRAP (Worldwide Responsible Accredited Production), BSCI (Business Social Compliance Initiative), and SCAN for supply chain security. In addition, the factory is certified by ICAS for quality assurance and testing compliance. For eco-conscious buyers, Synberry also complies with the Global Recycled Standard (GRS), ensuring transparency and traceability in the use of recycled materials.

What are the cost differences between production in China and Cambodia? How do I choose the best location?

The cost differences between production in China and Cambodia depend on factors such as order size, materials, and shipping requirements. We will provide personalized advice based on your specific needs to help you choose the best location.