Types of aluminum laser cutter

Aluminum laser cutters are specifically designed to cut aluminum materials quickly and precisely using a high-powered laser beam. These machines are widely used in various industries such as automotive, aerospace, electronics, and signage.

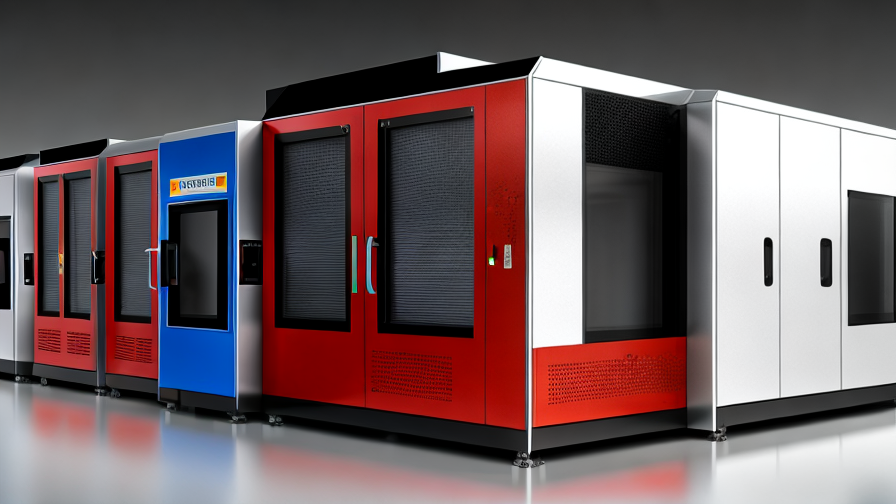

There are several types of aluminum laser cutters available on the market, each offering different features and capabilities to meet specific cutting needs. Some of the common types include:

1. Fiber laser cutter: Fiber laser technology is the most popular choice for aluminum cutting due to its high cutting speed and accuracy. It utilizes a fiber laser source that generates an intense laser beam, which is delivered through a fiber optic cable to the cutting head. Fiber lasers are energy-efficient and offer excellent beam quality, making them ideal for thin to medium aluminum sheet cutting applications.

2. CO2 laser cutter: Although not as commonly used for aluminum cutting as fiber lasers, CO2 laser cutters can still be used effectively for this purpose. They utilize a carbon dioxide laser source that produces a high-powered laser beam. CO2 laser cutters are capable of cutting thicker aluminum materials but are generally slower compared to fiber lasers.

3. YAG laser cutter: Yttrium-Aluminum-Garnet (YAG) lasers are solid-state lasers commonly used for aluminum cutting. YAG laser cutters are capable of cutting thicker aluminum materials up to 10mm and are suitable for various applications, including jewelry, electronics, and automotive parts manufacturing.

4. Diode laser cutter: Diode lasers are compact and versatile laser cutters suitable for aluminum cutting on a smaller scale. Diode lasers provide high-speed cutting for thin aluminum sheets and are often used in the hobbyist and small manufacturing industries.

When choosing the right aluminum laser cutter, it is essential to consider specific factors such as desired cutting thickness, cutting speed requirements, budget, and the type of aluminum material being cut. It is recommended to consult with experts in the field to ensure the chosen laser cutter meets the specific requirements of the application.

Pros and Cons of Using aluminum laser cutter

Pros:

1. Versatility: Aluminum laser cutters are capable of cutting through various thicknesses of aluminum, enabling the creation of intricate and precise designs. They can cut aluminum sheets with thicknesses ranging from thin foils to thick plates.

2. Speed: Aluminum laser cutting is a quick process that reduces production time. This is especially beneficial for industries that require fast turnaround times, such as automotive, aerospace, and electronics.

3. High precision: Laser cutting provides a high level of accuracy, ensuring clean, smooth, and burr-free edges. This is crucial for industries that require tight tolerances and precise measurements.

4. Minimum heat affected zone (HAZ): Aluminum laser cutting minimizes the HAZ, or the area of material affected by heat during the cutting process. This reduces the chances of warping or distorting the aluminum, preserving its structural integrity.

5. Automation: Aluminum laser cutting machines can be fully automated, enabling continuous and unattended operation, increasing production efficiency and reducing labor costs.

Cons:

1. Initial cost: The initial investment required for an aluminum laser cutting machine can be high. This may deter small businesses or startups with limited financial resources.

2. Maintenance and operating costs: Laser cutting machines require regular maintenance and servicing, which can be expensive. Additionally, the cost of operating a laser cutter, including electricity and consumables, should be considered when assessing the overall cost-effectiveness.

3. Limited material compatibility: Aluminum laser cutters are specifically designed for cutting aluminum, limiting their utility to other materials. If a business requires cutting different materials, separate laser cutting machines may be required.

4. Safety precautions: Working with laser cutters requires adherence to strict safety guidelines. Operators must wear the appropriate protective goggles and follow safety protocols to prevent accidents and injuries.

5. Material limitations: While aluminum laser cutters are efficient for cutting aluminum, they may not be as effective for other non-ferrous metals or materials with reflective surfaces. In these cases, alternative cutting methods may need to be employed.

aluminum laser cutter Reference Specifications (varies for different product)

An aluminum laser cutter is a versatile and precise machine used for cutting aluminum sheets, plates, and components with great accuracy. The primary purpose of an aluminum laser cutter is to provide a clean and smooth cut to aluminum materials.

The reference specifications of an aluminum laser cutter may vary depending on the specific product, but some common specifications are as follows:

1. Laser power: The laser power of an aluminum laser cutter ranges from 500 watts to 6000 watts. Higher laser power is suitable for thicker aluminum materials.

2. Cutting speed: The cutting speed of an aluminum laser cutter typically ranges from 0.1 m/min to 150 m/min. The speed can be adjusted based on the thickness and type of aluminum being cut.

3. Cutting thickness: An aluminum laser cutter can usually handle aluminum sheets and plates with thicknesses varying from 0.5 mm to 25 mm. The maximum cutting thickness depends on the specific model.

4. Laser wavelength: The laser wavelength used in aluminum laser cutters is commonly around 1.06 micrometers. This wavelength ensures efficient absorption of the laser energy by aluminum for effective cutting.

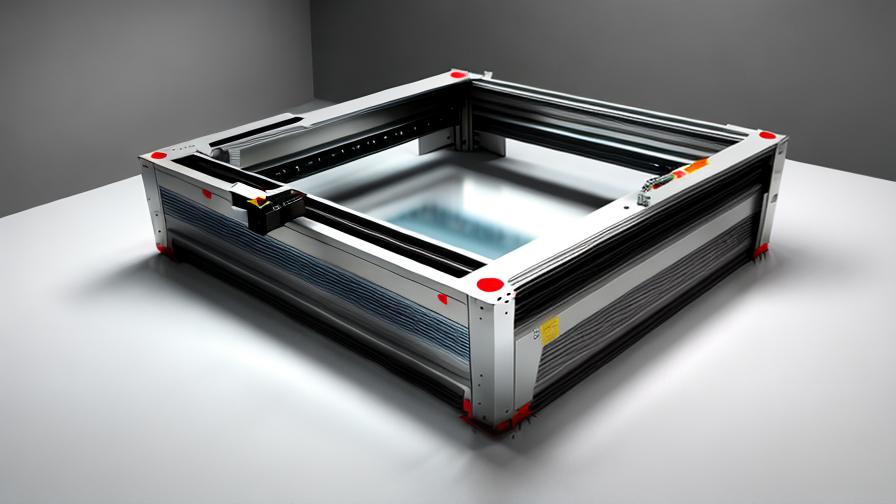

5. Cutting area: The cutting area, or working table, of an aluminum laser cutter can range from small sizes of a few square meters to large sizes exceeding 10 square meters. The size of the cutting area determines the maximum dimensions of aluminum sheets that can be processed.

6. Accuracy and precision: Aluminum laser cutters are known for their high accuracy and precision. The positioning accuracy can be as low as ±0.03 mm, ensuring that intricate and detailed designs are accurately realized.

7. Auxiliary functions: Some aluminum laser cutters include additional features such as automatic focus adjustment, material recognition, and real-time monitoring systems. These functions enhance the efficiency and ease of operation.

8. Software compatibility: Aluminum laser cutters are typically compatible with various software programs for designing and generating cutting paths. Common formats include DXF and DWG. Compatibility with CAD and CAM software is essential for seamless integration into manufacturing workflows.

It is important to note that the specifications mentioned above are for reference only and can vary based on the specific manufacturer and model of the aluminum laser cutter.

Top 10 aluminum laser cutter manufacturers in China

1. Trumpf: Trumpf is a world-renowned German company with a strong presence in China. They offer high-precision aluminum laser cutting machines with advanced technologies and excellent performance.

2. Bystronic: Bystronic is a leading international manufacturer of sheet metal processing equipment, including aluminum laser cutting machines. They have a wide range of machines catering to various customer needs.

3. Amada: Amada is a global leader in the sheet metal fabrication industry and offers a range of aluminum laser cutting machines with high-speed and precision capabilities.

4. Han’s Laser: Han’s Laser is a Chinese company that specializes in laser equipment manufacturing. They offer a variety of aluminum laser cutting machines that are known for their reliability and cost-effectiveness.

5. Bodor: Bodor is a Chinese manufacturer known for its innovative laser cutting solutions. They provide a range of aluminum laser cutting machines that offer high efficiency and precision.

6. HSG Laser: HSG Laser is a leading manufacturer of laser cutting machines in China. They have a range of aluminum laser cutting machines that provide fast and accurate cutting for various applications.

7. Jinan Bodor CNC Machine Co., Ltd: Bodor CNC Machine is a specialized manufacturer of laser cutting machines, including aluminum laser cutting machines. They offer high-quality machines with advanced features.

8. Golden Laser: Golden Laser is a Chinese manufacturer with extensive experience in the laser industry. They offer aluminum laser cutting machines that are known for their stability, high cutting speed, and precision.

9. Feiyue Laser: Feiyue Laser is a Chinese manufacturer that focuses on the research and development of laser cutting machines. They offer aluminum laser cutting machines with advanced technologies and efficient cutting capabilities.

10. Morn Laser: Morn Laser is a Chinese manufacturer that offers a range of laser cutting machines, including those designed for aluminum cutting. Their machines are known for their high precision and affordability.

These manufacturers represent some of the top players in the Chinese market for aluminum laser cutting machines. Each provides a range of options to cater to different customer requirements, ensuring high-quality cutting solutions for the aluminum industry.

Create table compare top 10 aluminum laser cutter manufacturers in China

Aluminum laser cutters are widely used in various industries, and China is one of the leading manufacturers of these machines. Here’s a table comparing the top 10 aluminum laser cutter manufacturers in China:

| Manufacturer | Location | Founded | Website | Notable Features |

|—————–|—————|———|——————————|——————————————————|

| Bodor Laser | Jinan, Shandong | 2004 | www.bodor.com | High cutting accuracy, fast speed, and stable performance. |

| Han’s Laser | Shenzhen, Guangdong | 1996 | www.hanslaser.com | Wide range of laser cutters, including specialized aluminum cutting machines. |

| Bystronic China | Shanghai | 1989 | www.bystronic.cn | Advanced technology and intelligent automation for precise aluminum cutting. |

| HSG Laser | Foshan, Guangdong | 2006 | www.hsglaser.com | Offers a comprehensive range of laser cutters for aluminum processing. |

| HGTECH | Wuhan, Hubei | 2008 | www.hglaser.com.cn | High-speed and high-precision aluminum laser cutters with low maintenance requirements. |

| Wuhan Golden Laser| Wuhan, Hubei| 2005 | www.goldenlaser.cc | Specializes in customizing laser cutters for aluminum sheet, tube, and profiles. |

| Jinan Senfeng | Jinan, Shandong | 2004 | www.sfcnclaser.com | Offers cost-effective aluminum laser cutters with reliable performance. |

| ZHEJIANG SHUANGLIN JIATE METAL TECHNOLOGY CO., LTD | Hangzhou, Zhejiang | 2002 | www.sltz-aluminium.com | Specialized in producing aluminum laser cutting machines for industrial applications. |

| Wuhan Hans Goldensky | Wuhan, Hubei | 2002 | www.goldensky.cc | Known for its high-power fiber laser cutting machines used in aluminum fabrication. |

| Ma’anshan Prima | Ma’anshan, Anhui | 2007 | www.primapress.com | Cutting-edge aluminum laser cutters designed for precision cutting and efficient production. |

These manufacturers have established themselves in the aluminum laser cutter market by offering cutting-edge technology, precise cutting capabilities, and excellent customer support. Customers can choose among a variety of models based on their specific requirements, such as sheet thickness, cutting speed, and automation features.

It is important to note that this table provides basic information about the top 10 aluminum laser cutter manufacturers in China. To make an informed decision, potential buyers should conduct further research, compare specifications, and consider factors like after-sales service, warranty, and customer reviews before making a purchase.

Applications of aluminum laser cutter

Aluminum laser cutters have a wide range of applications across various industries due to their precise and efficient cutting capabilities. Here are some of the key applications where aluminum laser cutters are essential:

1. Automotive Industry: Aluminum laser cutters are extensively used in the automotive industry for cutting aluminum components and sheets. They are utilized for precision cutting of parts such as car body frames, doors, engine parts, and heat shields. The accuracy and speed of the laser cutting process provide high-quality finishes and allow for complex designs.

2. Aerospace Industry: Aluminum is widely used in aerospace applications due to its lightweight property. Laser cutters are employed to process aluminum alloys for manufacturing components like aircraft wings, fuselage panels, frames, brackets, and engine parts. The precise cutting ability of lasers ensures the accuracy and fit of these critical aerospace components.

3. Electronics Industry: Aluminum laser cutters are used in the electronics industry to cut aluminum sheets and panels for manufacturing electronic enclosures, computer chassis, and heat sinks. The cutters can create intricate designs and perforations in thin aluminum layers, ensuring proper ventilation and heat dissipation.

4. Signage and Display Industry: Aluminum laser cutting is extensively utilized in the signage and display industry for creating customized signage, channel letters, and logos. The high precision and intricate cutting capability of lasers allow for the production of intricate designs quickly, enabling signage companies to meet client demands efficiently.

5. Architecture and Interior Design: Aluminum laser cutters are commonly used in architectural applications for producing decorative screens, window frames, sunshades, and cladding panels. They enable architects and interior designers to create unique and customized designs that add aesthetic appeal to buildings and interiors. The versatility of aluminum laser cutting opens up possibilities for creative and intricate patterns.

6. Furniture and Decor Industry: Aluminum laser cutters are utilized in the furniture and decor industry for cutting aluminum sheets and profiles for the production of customized furniture pieces and decorative items. They provide designers with the flexibility to create intricate designs and patterns on aluminum surfaces for unique furniture and decor pieces.

In summary, aluminum laser cutters find applications in a wide range of industries, including automotive, aerospace, electronics, signage, architecture, furniture, and decor. The precise cutting capabilities, speed, and versatility of aluminum laser cutters make them an essential tool for achieving high-quality and customized products in these industries.

Type of Companies use aluminum laser cutter

Aluminum laser cutters are widely used in a variety of industries and by various types of companies. Here are a few examples:

1. Aerospace Industry: Aluminum laser cutting is extensively used in the aerospace sector for cutting aluminum sheets, panels, and intricate parts for aircraft and spacecraft manufacturing. These companies require precise and accurate cutting to meet high safety standards and maintain lightweight components.

2. Automotive Industry: Many automotive companies utilize aluminum laser cutters to fabricate components such as body panels, chassis parts, and intricate designs for custom vehicles. Aluminum’s lightweight nature, combined with laser cutting precision, allows for improved fuel efficiency and performance.

3. Electronics Industry: Manufacturers of electronic devices often use aluminum laser cutters to create intricate casings, frames, heat sinks, and brackets. Laser cutting ensures precise dimensions for the assembly of circuitry, components, and housing.

4. Architecture and Construction: Companies in the architecture and construction sector employ aluminum laser cutters for various applications. It is used to craft decorative panels, wall claddings, screens, façades, and architectural elements that incorporate intricate designs or patterns.

5. Furniture and Interior Design: Many companies in the furniture and interior design industry utilize aluminum laser cutters for creating unique and aesthetically appealing components. These may include decorative panels, room dividers, signs, lighting fixtures, and custom furniture pieces.

6. Packaging Industry: Aluminum laser cutting finds its usage in the packaging industry for cutting aluminum foils, trays, and containers. It ensures precise cuts, enabling seamless packaging processes and protecting the contents.

7. Medical Device Manufacturers: Medical equipment and device manufacturers often employ aluminum laser cutters for creating components used in surgical instruments, prosthetics, biomedical devices, or medical equipment casings. Laser cutting helps achieve accurate dimensions and intricate shapes for precise medical procedures.

These are just a few examples of the types of companies that use aluminum laser cutters. Considering the versatility and precision of this technology, its applications continue to expand across various industries, making it an essential tool for efficient and precise aluminum cutting operations.

List The Evolution history of “aluminum laser cutter”

The evolution history of the aluminum laser cutter dates back to the early 1970s when the concept of laser cutting was first introduced. During this time, lasers were primarily used for scientific research and industrial applications. However, it was not until the 1980s that laser cutting technology began to advance and became commercially viable.

In the 1980s, the first aluminum laser cutters were introduced, utilizing CO2 lasers. These early models had limited power and could only cut thin sheets of aluminum. However, they paved the way for future advancements in the field.

Throughout the 1990s, research and development efforts focused on enhancing laser cutting technology. New techniques emerged, such as high-power lasers and improved beam quality, which allowed for more precise and efficient aluminum cutting. This led to the development of more powerful aluminum laser cutters capable of handling thicker materials.

In the 2000s, advancements in computer-aided design (CAD) and computer-aided manufacturing (CAM) software further revolutionized aluminum laser cutting. These advancements enabled designers to create intricate and complex patterns, increasing the versatility of aluminum laser cutters. Additionally, the integration of automation systems and robotic technology improved productivity and efficiency.

The 2010s saw significant improvements in laser technology, specifically the introduction of fiber lasers for aluminum cutting. Fiber lasers offered higher power densities and improved cutting speeds, making them ideal for industrial applications. These lasers also consumed less energy and had a longer lifespan, reducing operational costs.

Furthermore, the adoption of advanced cooling mechanisms, such as air and water cooling, eliminated the need for expensive and bulky cooling systems, making aluminum laser cutters more compact and affordable. The integration of additional safety features, such as automatic shutdown systems and protective enclosures, also enhanced operator safety.

Looking ahead, the future of aluminum laser cutters lies in continued technological advancements. Researchers are exploring the potential of ultrafast lasers, which can further increase cutting speeds and precision. Additionally, the integration of artificial intelligence and machine learning algorithms may optimize cutting processes, reducing human error and enhancing productivity.

In conclusion, the evolution of the aluminum laser cutter has seen significant progress over the years, leading to improved cutting capabilities, increased automation, and enhanced safety features. With ongoing advancements in laser technology and software integration, the aluminum laser cutter is expected to continue shaping various industries, from automotive manufacturing to aerospace engineering.

List Top 10 FAQ about “aluminum laser cutter”

1. What is an aluminum laser cutter?

An aluminum laser cutter is a machine that uses a laser beam to cut or engrave aluminum sheets, profiles, or other aluminum materials with precision and efficiency.

2. How does an aluminum laser cutter work?

The cutter uses a high-powered laser beam to melt, burn, or vaporize the aluminum material along a predetermined cutting path. This process creates a precise and clean cut.

3. What are the advantages of using an aluminum laser cutter?

Some advantages include high cutting speed, accuracy, minimal material waste, versatility in cutting complex shapes, and the ability to automate processes.

4. What thickness of aluminum can an aluminum laser cutter handle?

The cutting capabilities of an aluminum laser cutter depend on the power and quality of the machine. However, most industrial laser cutters can easily cut aluminum sheets up to 25mm (1 inch) in thickness.

5. Can an aluminum laser cutter cut other materials?

Yes, aluminum laser cutters are versatile and can also cut other metals such as stainless steel, mild steel, and brass, along with various non-metal materials like acrylic, wood, and plastics.

6. Are there any safety precautions when using an aluminum laser cutter?

Yes, safety measures must be followed, including wearing appropriate protective gear, proper ventilation to remove fumes, and ensuring the machine is properly maintained to prevent accidents.

7. How much does an aluminum laser cutter cost?

The cost of an aluminum laser cutter can vary depending on its power, size, features, and brand. Generally, entry-level desktop models could cost around $3,000, while industrial-grade machines can range from $10,000 to $100,000+.

8. What maintenance does an aluminum laser cutter require?

Regular maintenance includes cleaning the lens and mirrors, checking and adjusting beam alignment, cleaning and replacing filters, and ensuring proper ventilation and cooling of the machine.

9. Can an aluminum laser cutter engrave logos or designs on aluminum surfaces?

Yes, aluminum laser cutters are capable of engraving intricate designs or logos onto aluminum surfaces, providing a high-quality and permanent result.

10. Is training required to operate an aluminum laser cutter?

Yes, proper training is crucial to operate an aluminum laser cutter efficiently and safely. Training may include software operation, machine handling, maintenance, and safety guidelines to ensure smooth operation and prevent accidents.

The Work Process and how to use aluminum laser cutter

The work process of an aluminum laser cutter involves a few steps to ensure the accurate and efficient cutting of the material.

Firstly, the aluminum sheet or workpiece is placed on the cutting platform of the laser cutter. It is important to secure the sheet firmly to prevent any movement during the cutting process. Once the material is properly positioned, the laser cutter is turned on, and the machine is prepared for operation.

Next, the appropriate cutting parameters need to be set on the laser cutter. This includes selecting the desired laser power, adjusting the speed of the cutting head, and determining the focus of the laser beam. These parameters are crucial as they directly impact the quality and precision of the cutting process.

After the parameters are finalized, the laser cutter is ready to start cutting. The cutting head moves along the pre-programmed path, directed by computer numerical control (CNC) instructions, while the laser beam accurately melts and vaporizes the aluminum sheet. The high temperature of the laser beam results in a clean and precise cut.

During the cutting process, it is essential to monitor the machine and ensure that everything is functioning correctly. Regular inspections of the cutting quality and measurements of the dimensions are important to maintain accuracy.

Once the cutting is complete, the workpiece is removed from the cutting platform. If necessary, the edges may be smoothed or finished to achieve the desired final product. Proper cleaning of the machine and regular maintenance are necessary to ensure its longevity and optimal performance.

To use an aluminum laser cutter effectively, it is vital to understand the machine’s capabilities and limitations. Familiarize yourself with its control panel, software, and safety features. Adequate training and knowledge of aluminum properties are also important for optimal cutting results.

In summary, the work process of an aluminum laser cutter includes careful setup and positioning of the workpiece, setting the appropriate cutting parameters, executing the cutting process, monitoring the machine, and post-cutting finishing. By following these steps and understanding the machine’s operation, one can successfully utilize an aluminum laser cutter for precise and efficient cutting.

Quality Testing Methods for aluminum laser cutter

When it comes to quality testing methods for an aluminum laser cutter, there are several important techniques that can be employed. These methods ensure that the cutter is performing at its optimal level and producing accurate and precise cuts.

One of the most common testing methods is dimensional accuracy testing. This involves measuring the dimensions of the cut pieces and comparing them to the intended specifications. Any deviations from the desired measurements can indicate a problem with the cutter’s accuracy and may require adjustments or maintenance.

Another crucial testing method is material inspection. It involves examining the cut pieces for any signs of material defects, such as cracks, rough edges, or uneven surfaces. This inspection ensures that the cutter is cutting through the aluminum smoothly and without damaging the material.

Additionally, testing the cutter’s speed and efficiency is vital. This can be done by measuring the time it takes for the laser cutter to complete a specific task or by calculating the amount of material that can be processed within a given time frame. This evaluation helps determine the cutter’s productivity and its ability to meet production demands effectively.

Furthermore, examining the laser beam quality is essential. This involves testing the beam’s focus, power density, and stability. A well-focused and stable laser beam ensures consistent and accurate cuts, while any issues with beam quality can result in irregular or erroneous cuts.

To ensure the cutter’s safety, testing methods such as interlock testing can be utilized. This involves checking that all safety features, such as emergency stop buttons and safety interlocks, are fully functional. Additionally, testing the exhaust and filtration systems can help ensure that the cutter is operating in a safe and clean environment.

In conclusion, quality testing methods for an aluminum laser cutter include dimensional accuracy testing, material inspection, speed and efficiency evaluation, laser beam quality examination, and safety testing. Employing these methods helps maintain the cutter’s performance, accuracy, and safety, ensuring high-quality cuts and optimal productivity.

Chinese Regulations and Industry Standards Certifications for aluminum laser cutter

In China, the regulations and industry standards certifications for aluminum laser cutters mainly focus on product safety, quality control, and environmental protection. These certifications ensure that manufacturers comply with specific guidelines, specifications, and requirements to meet industry standards and provide reliable and trustworthy products to consumers.

One of the crucial certifications is the China Compulsory Certification (CCC), also known as the 3C certification. It is a mandatory certification that covers various product categories, including industrial equipment like laser cutters. The certification verifies that the product meets national safety and quality standards, ensuring it does not pose any risk to human health or property.

Another important certification is the ISO 9001, which specifies the requirements for a quality management system. Manufacturers need to adhere to strict quality control processes, including documentation, record keeping, and continuous improvement, to obtain this certification. ISO 9001 ensures consistent production and delivery of high-quality aluminum laser cutters.

Environmental certifications such as the Restriction of Hazardous Substances (RoHS) also play a significant role. This certification restricts the use of specific hazardous substances in electrical and electronic equipment to minimize environmental impact and health hazards. Manufacturers need to comply with the RoHS directive to ensure their aluminum laser cutters are environmentally friendly.

Furthermore, the International Electrotechnical Commission (IEC) standards are widely recognized in the industry. These standards cover various aspects like electrical safety, performance, and electromagnetic compatibility of electrical equipment, including laser cutters. Compliance with IEC standards ensures that aluminum laser cutters meet international safety and performance requirements.

In summary, Chinese regulations and industry standards certifications for aluminum laser cutters primarily aim to ensure product safety, quality control, and environmental protection. The China Compulsory Certification (CCC), ISO 9001, RoHS, and IEC standards are critical certifications that manufacturers need to obtain to provide reliable and compliant products in the market.

Comprehensive Analysis of aluminum laser cutter Costs: Including Visible and Hidden Costs

An aluminum laser cutter is a valuable tool in various industries that require precise metal cutting. When considering the costs of an aluminum laser cutter, both visible and hidden costs should be taken into account.

Visible costs include the initial purchase price of the laser cutter, which can vary based on the brand, model, and specifications. Additionally, there may be costs associated with delivery, installation, and training for operating the machine. These visible costs are relatively straightforward and can be estimated upfront.

Hidden costs, on the other hand, are often overlooked but can significantly impact the overall cost of owning an aluminum laser cutter. One important hidden cost is the maintenance and repair expenses. Laser cutters require regular upkeep, such as replacing laser tubes, lenses, and other consumables, as well as periodic calibration. These maintenance costs should be factored into the budget for owning and operating the machine.

Electricity consumption is another hidden cost to consider. Aluminum laser cutters usually require a significant amount of power to operate, and electricity costs can accumulate over time. It is essential to analyze the energy efficiency specifications of the laser cutter before purchasing to estimate the potential electricity expenses accurately.

Furthermore, there are ongoing costs associated with materials and gases used in the cutting process. Aluminum sheets or other metallic materials required for laser cutting can contribute to the overall expenses. Similarly, certain laser cutting processes may require specific gases, such as nitrogen or oxygen, which need to be purchased regularly.

It is also crucial to evaluate the potential downtime of the machine due to repairs, servicing, or any unexpected issues. During downtime, productivity and revenue can be affected, resulting in additional hidden costs.

In conclusion, when analyzing the costs of an aluminum laser cutter, it is essential to consider both visible and hidden costs. The visible costs encompass the purchase price, delivery, installation, and training. Meanwhile, hidden costs consist of maintenance and repair expenses, electricity consumption, materials, gases required, and potential downtime. Properly accounting for these costs allows for a comprehensive assessment of the total cost of ownership of an aluminum laser cutter.

Pricing Strategies for aluminum laser cutter

When it comes to pricing strategies for an aluminum laser cutter, there are several factors to consider. These include understanding the market, assessing the competition, evaluating the cost of production, determining the value proposition, and considering the desired profit margin.

To start, it is important to research the market thoroughly to understand the demand and supply dynamics. This can help in identifying the target market segment and estimating the potential customer base. Analyzing the competition is crucial to determine how the pricing strategy should be positioned in comparison to similar products in the market.

Calculating the cost of production is essential to establish a baseline for pricing. This should include the cost of materials, labor, overhead expenses, and any other associated costs. It is important to ensure that the selling price covers these costs and provides a reasonable profit margin.

Determining the value proposition is a crucial aspect of pricing the aluminum laser cutter. This involves understanding the unique features and benefits of the product and how it solves the customer’s problems or meets their needs. Pricing should align with the perceived value customers receive from using the product.

Choosing an appropriate pricing strategy can be based on various factors. Some common strategies are cost-based pricing, market-based pricing, value-based pricing, and penetration pricing. Cost-based pricing sets the price by adding a desired profit margin to the cost of production. Market-based pricing takes into account the current market price and competitor prices to set the price. Value-based pricing focuses on the value customers place on the product and sets the price accordingly. Penetration pricing involves setting a low initial price to gain market share and increase sales volume.

In conclusion, pricing an aluminum laser cutter requires a comprehensive analysis of the market, competition, cost of production, value proposition, and desired profit margin. Choosing an appropriate pricing strategy that aligns with these factors is crucial for success in the market.

Compare China and Other aluminum laser cutter Markets: Products Quality and Price

China is a major player in the global aluminum laser cutter market, with a strong presence in both the domestic and international markets. When it comes to product quality, China has made significant advancements over the years. Many Chinese manufacturers have invested heavily in research and development, leading to the production of high-quality aluminum laser cutters. These machines are equipped with advanced technology and precision components, offering excellent cutting accuracy and reliability.

However, China does face some challenges in terms of product quality. The domestic market is highly competitive, resulting in a wide range of manufacturers with varying levels of quality control. Some low-cost suppliers may compromise on the quality of materials used or cut corners in production to keep prices low. As a result, it is important for buyers to carefully research and select reputable Chinese manufacturers known for their quality standards.

In terms of price, China is known for offering highly competitive prices compared to other aluminum laser cutter markets. The country benefits from economies of scale due to its large manufacturing base and lower production costs. This allows Chinese manufacturers to offer aluminum laser cutters at more affordable prices compared to some Western counterparts.

Other markets, such as Europe and the United States, also offer high-quality aluminum laser cutters. Manufacturers in these regions often prioritize quality and precision, and their products are known for their durability and reliability. However, these aluminum laser cutters are typically more expensive compared to those from China. The higher labor and manufacturing costs in these regions contribute to the overall higher prices.

In conclusion, China has become a significant player in the aluminum laser cutter market, offering a wide range of products with varying levels of quality. While there are concerns about product quality due to competition and varying standards, many Chinese manufacturers produce high-quality machines. Additionally, China’s advantage lies in its competitive pricing, thanks to economies of scale and lower production costs. Other markets, such as Europe and the United States, may offer higher-quality aluminum laser cutters, but at a higher price point.

Understanding Pricing and Payment Terms for aluminum laser cutter: A Comparative Guide to Get the Best Deal

When purchasing an aluminum laser cutter, it is important to understand the pricing and payment terms to get the best deal possible. This comparative guide aims to provide a brief overview within the word limit.

The pricing for aluminum laser cutters can vary significantly based on several factors such as the machine’s power, cutting speed, and overall quality. Higher-powered machines and those with faster cutting speeds tend to be more expensive. Additionally, the brand and reputation of the manufacturer can also influence the price.

It is essential to compare prices from different suppliers to ensure you are getting the most competitive offer. Consider reaching out to multiple manufacturers or distributors to receive quotes for aluminum laser cutters that meet your requirements. This will help you identify any significant price differences and negotiate a better deal.

When reviewing payment terms, consider the upfront cost and any additional charges. Some suppliers may offer financing options or lease agreements, allowing you to pay for the machine in installments. Evaluate these options carefully, ensuring the interest rates and overall costs are reasonable.

Additionally, check if there are any ongoing maintenance or service fees associated with the laser cutter. Understanding these costs upfront will help you assess the overall investment required for the machine.

Warranty and after-sales support should also be considered. Find out the duration of the warranty and what it covers. Determine if the supplier provides technical assistance, training, or spare parts. These services can be valuable in ensuring the smooth operation of your aluminum laser cutter in the long run.

To get the best deal, it is recommended to reach out to reputable suppliers, attend industry trade shows, or consult with experienced professionals who can provide guidance and recommendations based on their expertise.

In conclusion, when purchasing an aluminum laser cutter, take time to research and compare prices from multiple suppliers, consider financing options, evaluate ongoing maintenance costs, and assess the warranty and after-sales support provided. By doing thorough research and negotiations, you can make an informed decision and secure the best pricing and payment terms for your aluminum laser cutter investment.

Strategies for Lowering aluminum laser cutter Expenses: Bulk Purchase Discounts and Price Variances Among Suppliers

Lowering aluminum laser cutter expenses can be achieved through several key strategies. Two effective approaches include taking advantage of bulk purchase discounts and comparing price variances among different suppliers. By implementing these strategies, businesses can optimize their cost savings and potentially reduce overhead expenses associated with aluminum laser cutting.

One strategy to lower expenses is to leverage bulk purchase discounts offered by suppliers. Purchasing a large quantity of aluminum laser cutters can often result in significant price reductions. Suppliers typically incentivize bulk orders by offering discounted prices, as it allows them to sell a larger volume of their products. By taking advantage of these discounts, businesses can save a substantial amount of money in the long run.

Additionally, comparing price variances among different suppliers is crucial. Prices for aluminum laser cutters can vary significantly depending on the supplier. It is important to conduct research and obtain quotes from multiple suppliers to evaluate the best available options. By analyzing price differences, businesses can identify suppliers offering the most competitive rates without compromising on quality. This approach can help to secure the best possible deal, ultimately reducing expenses associated with aluminum laser cutting.

In conclusion, it is important to implement effective strategies for lowering aluminum laser cutter expenses. Taking advantage of bulk purchase discounts and comparing price variances among different suppliers are two key approaches. By utilizing these strategies, businesses can maximize cost savings and potentially reduce overhead expenses. Ultimately, careful consideration of these strategies can contribute to the overall success and profitability of businesses utilizing aluminum laser cutting technology.

Procurement and Considerations when Purchasing aluminum laser cutter

When considering purchasing an aluminum laser cutter, there are several key procurement factors that need to be carefully evaluated. These considerations will ensure the right investment is made and will help optimize the machine’s performance and efficiency.

One primary consideration is the power of the laser cutter. It is crucial to select a machine with adequate power to efficiently cut aluminum. Aluminum is a highly reflective metal, which requires a laser cutter with high power density to effectively perform the task. It is recommended to opt for a laser cutter with at least 300W power for efficient aluminum cutting.

Another important aspect is the size and bed capacity of the laser cutter. The size of the machine should align with the intended applications and fulfill the production requirements. Consider the maximum sheet size and thickness of aluminum that the laser cutter can handle. It is crucial to ensure the machine has a large enough cutting area to accommodate the desired projects.

The laser source is another vital consideration. Fiber laser sources are most commonly used for cutting aluminum as they offer high energy efficiency and superior beam quality. They are also known for their long operational life and low maintenance requirements. Selecting a laser cutter with a reliable and advanced fiber laser source is the key to achieving precise and high-quality aluminum cutting.

Additionally, the software and control system of the laser cutter should be user-friendly and intuitive. A well-designed interface and compatible software will not only enhance productivity but also provide ease of use for operators.

Furthermore, factors such as after-sales service, technical support, and warranty should be taken into account. It is essential to purchase from a reputable supplier who can offer reliable service and support in case of any issues with the machine.

To summarize, when procuring an aluminum laser cutter, one must consider the power of the machine, size and bed capacity, laser source, software and control system, as well as after-sales service and support. By carefully evaluating these factors, one can make an informed decision and choose the right aluminum laser cutter that meets their specific requirements.

Sourcing aluminum laser cutter from China: Opportunities, Risks, and Key Players

Sourcing an aluminum laser cutter from China can provide several opportunities for businesses. Firstly, China is known for its robust manufacturing capabilities, and there are numerous suppliers that offer a wide range of aluminum laser cutting machines at competitive prices. Additionally, Chinese manufacturers often have access to advanced technology and equipment, allowing them to produce high-quality laser cutters.

One of the key opportunities is cost savings. Chinese suppliers typically offer lower prices compared to manufacturers in other countries. This cost advantage can be beneficial for businesses, especially smaller ones operating on a limited budget.

Another opportunity lies in the variety of options available. China has a vast network of suppliers offering different types and models of aluminum laser cutters. This allows businesses to select a machine that aligns with their specific requirements, ensuring maximum efficiency and productivity.

However, there are also risks associated with sourcing from China. Quality control can be a concern, as not all suppliers maintain consistent product quality. Weaker quality control measures may lead to lower durability, accuracy, or reliability of the laser cutter. It is crucial to research and choose a reputable supplier with a proven track record in manufacturing high-quality machines.

Another risk is intellectual property (IP) protection. China has faced criticisms regarding IP infringement in the past. Businesses should conduct thorough due diligence and work with suppliers that have strong IP protection measures in place. This can help safeguard the company’s designs and prevent potential legal issues.

When it comes to key players in the industry, there are several well-established manufacturers of aluminum laser cutters in China. Some prominent ones include Han’s Laser, Bodor Laser, and HSG Laser. These manufacturers have gained recognition for their technological advancements, product reliability, and comprehensive customer support.

In conclusion, sourcing an aluminum laser cutter from China offers opportunities for cost savings, a wide range of options, and access to advanced technology. However, businesses should be aware of the risks related to quality control and intellectual property protection. Thorough research and due diligence are essential in choosing a reliable supplier. Han’s Laser, Bodor Laser, and HSG Laser are notable key players in the Chinese market.

Navigating Import Regulations and Customs for aluminum laser cutter from China

Importing any product from China, including an aluminum laser cutter, involves complying with import regulations and customs requirements. Here are some key steps to navigate this process:

1. Research Import Regulations: Begin by understanding the import regulations imposed by your country’s customs authorities. Check if there are any specific requirements for importing aluminum laser cutters, such as certifications, product safety standards, or labeling requirements.

2. Determine HS Code: Identify the Harmonized System (HS) code for the aluminum laser cutter. This code classifies the product and determines the applicable import duties, taxes, and any restrictions or preferences related to its import. Consult the official HS code directory or seek assistance from customs agents or import experts.

3. Engage Customs Broker: Consider hiring a licensed customs broker or freight forwarder who specializes in importing goods from China. They can assist with documentation, customs clearance, and compliance with import regulations, thus ensuring a smooth import process.

4. Choose Incoterms: Agree with the supplier on the Incoterms (International Commercial Terms) that define the responsibilities and costs between the buyer and seller during transportation. Common Incoterms for Chinese exports are EXW (Ex Works), FOB (Free on Board), or CIF (Cost, Insurance, and Freight).

5. Arrange Shipping and Insurance: Coordinate with a reputable shipping company to transport the aluminum laser cutter from China to your location. Be sure to arrange appropriate insurance coverage to protect against any damages or losses during transit.

6. Complete Documentation: Prepare the necessary documentation, including the commercial invoice, packing list, bill of lading/airway bill, and any additional certificates or permits required by your country’s customs authorities.

7. Customs Declaration and Duties: Provide your customs broker with all relevant documentation for the customs declaration process. They will calculate and advise you on the applicable import duties, taxes, and fees, such as value-added tax (VAT) or customs duties.

8. Customs Clearance: Submit the required documentation to customs authorities for clearance. They will inspect the shipment and verify its conformity with regulations. Pay any applicable duties and taxes to release the aluminum laser cutter from the customs custody.

9. Compliance and Safety Standards: Ensure that the imported aluminum laser cutter meets all safety and compliance requirements mandated by your country’s regulatory bodies. This may include electrical, product safety, and emissions standards.

10. Delivery and Installation: Once the customs clearance is completed, arrange for the delivery and installation of the aluminum laser cutter at your preferred location.

By following these steps, you can navigate the import regulations and customs procedures involved in importing an aluminum laser cutter from China. Seeking professional assistance, such as a customs broker, can help streamline the process and ensure compliance with all relevant requirements.

Cultivating Successful Business Relationships with Chinese aluminum laser cutter Suppliers

Cultivating successful business relationships with Chinese aluminum laser cutter suppliers requires a strategic approach. Here are some key factors to consider:

1. Communication: Efficient and clear communication is essential when dealing with suppliers in China. Effective communication can help establish mutual understanding and build trust. It is recommended to invest in translators or hire bilingual staff to ensure smooth communication.

2. Building Trust: Chinese suppliers value long-term business relationships based on trust. To build trust, it is essential to follow through on commitments, maintain transparency, and always be honest in your dealings. Suppliers appreciate loyalty and consistent business transactions.

3. Face-to-Face Meetings: In Chinese culture, face-to-face interactions are highly valued. Scheduling visits to your suppliers in China can help establish rapport and trust. It also provides an opportunity to understand their production processes, inspect their facilities, and showcase your commitment to the partnership.

4. Relationship Development: Personal relationships are crucial in Chinese business culture. Taking the time to get to know your suppliers, such as their family, hobbies, or interests, can strengthen the bond and lead to more harmonious business transactions. Regular visits and attending social events can foster relationship development.

5. Negotiation and Stability: Chinese suppliers often prefer stability and long-term partnerships. Negotiating fair prices and terms is vital, but it is equally important to maintain some stability in terms of product quantities and frequency of orders. Consistency in business transactions helps build trust and demonstrates commitment.

6. Cultural Sensitivity: Understanding and respecting Chinese culture is essential. Familiarize yourself with cultural norms, taboos, and customs. Show appreciation for their culture and traditions, which will be highly regarded and help strengthen the relationship.

By focusing on effective communication, trust-building, personal relationships, negotiation, stability, and cultural sensitivity, businesses can cultivate successful and mutually beneficial relationships with Chinese aluminum laser cutter suppliers.

The Evolution and Market Trends in aluminum laser cutter Industry

The aluminum laser cutter industry has witnessed significant advancements and changes in recent years, driven by technological evolution and market trends. The adoption of laser cutting technology in aluminum fabrication processes has allowed for greater precision, efficiency, and cost-effectiveness.

One notable evolution in the industry is the development of fiber laser technology, which has revolutionized aluminum laser cutting. Fiber lasers offer advantages such as higher cutting speeds, improved energy efficiency, and reduced maintenance requirements compared to traditional CO2 lasers. This technological advancement has greatly contributed to the growth of the aluminum laser cutter industry.

Market trends have also played a crucial role in shaping the industry. The growing demand for lightweight, durable, and cost-effective aluminum components across various sectors such as automotive, aerospace, and construction has fueled the need for efficient and accurate aluminum laser cutting solutions. This increased demand has encouraged manufacturers to invest in advanced laser cutting systems to meet customer requirements.

Furthermore, sustainability and environmental considerations have become significant market trends. Aluminum laser cutting is known for its minimal material wastage, low energy consumption, and reduced carbon footprint compared to traditional cutting methods. As industries strive to reduce their environmental impact, the adoption of aluminum laser cutting has seen a sharp rise.

Automation and integration have also become prevalent market trends in the aluminum laser cutter industry. Manufacturers are increasingly incorporating automation technologies such as robotics and advanced software systems to enhance productivity, reduce labor costs, and improve overall operational efficiency. The integration of laser cutting machines with computer-aided design (CAD) software allows for seamless digitization of product designs and quick adaptation to changes in customer requirements.

In conclusion, the aluminum laser cutter industry has experienced notable advancements and market trends. The adoption of fiber laser technology, increasing demand for aluminum components, sustainability considerations, and automation have all contributed to the evolution and growth of the industry. As technology continues to advance and market demands evolve, the aluminum laser cutter industry is expected to further expand and adapt to emerging trends.

Sustainability and Environmental Considerations in aluminum laser cutter Manufacturing

In the manufacturing of aluminum laser cutters, sustainability and environmental considerations play a crucial role. Several aspects need to be considered to ensure sustainable practices are implemented throughout the manufacturing process.

Firstly, the selection of materials is important in minimizing the environmental impact. Aluminum is a sustainable choice due to its abundance, recyclability, and energy efficiency. It can be recycled multiple times without losing its properties, reducing the need for virgin aluminum extraction. Additionally, selecting aluminum from sustainable sources, such as those certified by the Aluminum Stewardship Initiative, ensures responsible sourcing practices.

Efficient energy consumption during manufacturing is another essential aspect of sustainability. Optimizing the design and production processes of aluminum laser cutters can help reduce energy consumption. Implementing energy-efficient technologies, such as using high-efficiency lasers and improving insulation, can minimize energy waste and lower the carbon footprint associated with manufacturing.

Furthermore, reducing waste generation and promoting recycling are significant environmental considerations. Implementing lean manufacturing principles, such as just-in-time production and waste minimization strategies, can help minimize material waste. Proper disposal and recycling of any leftover aluminum or other waste materials can further reduce the environmental impact of manufacturing.

Transportation and logistics also contribute to the overall sustainability of aluminum laser cutter manufacturing. Choosing local suppliers and optimizing the supply chain can help reduce emissions from transportation. Additionally, packaging materials should be eco-friendly and recyclable to minimize waste.

Finally, considering the end-of-life stage of aluminum laser cutters is essential for sustainability. Designing products for disassembly and recyclability can facilitate the recovery of valuable materials and minimize landfill waste. Implementing a product take-back program or partnering with recycling facilities can ensure responsible disposal, avoiding environmental harm.

In conclusion, sustainability and environmental considerations are crucial in aluminum laser cutter manufacturing. By selecting sustainable materials, optimizing energy consumption, reducing waste generation, considering logistics, and planning for end-of-life disposal, manufacturers can minimize their environmental footprint and contribute to a more sustainable future.

Custom Private Labeling and Branding Opportunities with Chinese aluminum laser cutter Manufacturers

Chinese aluminum laser cutter manufacturers offer excellent options for custom private labeling and branding opportunities. With their expertise and advanced technology, these manufacturers can meet the specific requirements of businesses looking to incorporate their own branding and labeling onto aluminum laser cutters.

One of the key advantages of working with Chinese manufacturers is their ability to provide custom solutions tailored to individual business needs. They offer a wide range of options for private labeling and branding, allowing businesses to showcase their logos, colors, and other branding elements on the laser cutters.

Chinese manufacturers have extensive experience in OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) services. This means that they can produce laser cutters with custom features and design elements, specifically tailored to the brand requirements of businesses. They use high-quality materials, advanced laser cutting technology, and precise manufacturing processes to ensure the production of top-notch branded laser cutters.

Additionally, Chinese manufacturers offer flexible order quantities, enabling businesses to order small batches or large volumes according to their specific needs. This allows businesses to start with a smaller order to test the market, minimize upfront investment, and scale up production as demand increases.

Furthermore, Chinese manufacturers often provide comprehensive support throughout the entire branding and labeling process. They work closely with businesses to understand their branding requirements and provide advice on design, packaging, and marketing strategies, ensuring that the final product aligns perfectly with the brand image.

In conclusion, Chinese aluminum laser cutter manufacturers present lucrative opportunities for businesses to incorporate custom private labeling and branding onto laser cutting machines. Their expertise, advanced technology, flexible order quantities, and comprehensive support make them ideal partners for businesses seeking to personalize their laser cutters and promote their brand.

Leveraging Trade Shows and Expos for aluminum laser cutter Sourcing in China

Trade shows and expos are excellent platforms for sourcing aluminum laser cutters in China. By attending these events, businesses can effectively leverage the advantages they offer in terms of networking, product discovery, and building relationships with suppliers.

Firstly, trade shows and expos provide a wide range of opportunities to connect with suppliers. These events attract numerous manufacturers, distributors, and industry experts, offering a consolidated platform to explore different options. The presence of multiple suppliers allows businesses to compare product offerings, negotiate prices, and understand the latest trends and advancements in the market.

Moreover, attending these events promotes face-to-face interactions, which are crucial for building trust and developing long-term partnerships. Engaging in direct conversations with suppliers helps obtain more detailed information about their capabilities, manufacturing processes, and quality control measures. It also provides an opportunity to assess their credibility and reliability, which is crucial when sourcing equipment such as aluminum laser cutters.

Additionally, trade shows and expos offer the advantage of on-site product demonstrations. Seeing the aluminum laser cutters in action allows buyers to evaluate their performance, quality, and efficiency firsthand. It also enables businesses to request customizations or modifications according to their specific requirements.

Lastly, these events serve as a platform for gaining valuable industry insights. Seminars, workshops, and presentations are often held alongside trade shows, providing educational opportunities and the chance to stay updated on the latest industry trends. Staying ahead of competitors in terms of knowledge and awareness of new technologies and techniques is crucial when sourcing equipment like aluminum laser cutters.

In conclusion, trade shows and expos significantly enhance the aluminum laser cutter sourcing process in China. They facilitate networking, enable direct communication with potential suppliers, allow for product demonstrations, and provide valuable industry insights. By actively participating in these events, businesses can effectively leverage the opportunities available to find the most suitable suppliers and make informed decisions.

Protecting Business Interests and Managing Risks When Sourcing aluminum laser cutter from China

When sourcing an aluminum laser cutter from China, it is important to take steps to protect your business interests and manage potential risks. Here are a few key considerations to keep in mind:

1. Thoroughly research suppliers: Take the time to find reputable and reliable suppliers with a proven track record in producing high-quality aluminum laser cutters. Look for manufacturers with certifications, positive customer reviews, and a history of exporting to international markets.

2. Conduct due diligence: Before finalizing any deal, thoroughly vet the supplier by conducting background checks, visiting their facilities, and requesting product samples. This will help confirm their ability to meet your specifications and maintain quality standards.

3. Clearly define your requirements: Provide detailed specifications for the aluminum laser cutter and ensure that the supplier understands your expectations. Document these requirements in a formal agreement or contract to protect yourself if any disputes arise.

4. Intellectual property protection: If you have unique designs or technology associated with the aluminum laser cutter, consider registering patents or trademarks to protect your intellectual property rights. Consult legal experts to understand the legal framework for intellectual property protection in China.

5. Quality control: Implement a comprehensive quality control process that includes product inspections at various stages of production. Regularly communicate with the supplier to address any issues and ensure that the final product meets your quality standards.

6. Risk management: Develop a risk management plan that includes strategies for handling potential disruptions in the supply chain, such as delays in production or shipping. Consider diversifying your supplier base to reduce dependency on a single source.

7. Payment terms and methods: Negotiate favorable payment terms and methods that protect your interests. Consider using secure payment methods, such as escrow services, to minimize the risk of fraud or non-delivery.

8. Communication and relationship-building: Regularly communicate with the supplier to maintain a good working relationship. Establish clear channels of communication and build trust over time, as this can help resolve issues and mitigate risks effectively.

By taking these precautionary measures, you can protect your business interests and minimize risks when sourcing an aluminum laser cutter from China.

Post-Purchase Considerations for aluminum laser cutter from China

When considering purchasing an aluminum laser cutter from China, there are several post-purchase considerations that should be taken into account. These considerations are crucial to ensure a smooth and successful acquisition of the equipment. Here are some important factors to consider:

1. Warranty and Technical Support: It is essential to understand the warranty coverage offered by the manufacturer. Be aware of the duration and terms of the warranty. Additionally, inquire about the availability and accessibility of technical support for troubleshooting and maintenance issues.

2. Spare Parts Availability: Check if the manufacturer provides spare parts for the laser cutter. It is crucial to inquire about the availability and lead time for acquiring spare parts, as this will impact potential downtime if any parts need to be replaced.

3. Training and Documentation: Ensure that the manufacturer provides comprehensive training and documentation for operating and maintaining the laser cutter. It is essential to have access to user manuals, software guides, and safety procedures to optimize machine performance and ensure user safety.

4. Shipping and Customs: Understand the logistics and shipping details for transporting the laser cutter from China. Consider any additional costs, such as import duties or taxes, and ensure compliance with relevant import regulations and certifications.

5. Installation and Setup: Clarify whether the manufacturer offers installation services or provides detailed instructions for setting up the machine. It is crucial to have a clear understanding of the requirements for power, ventilation, and workspace to facilitate a smooth installation process.

6. Quality Control and Testing: Request information about the manufacturer’s quality control processes. Inquire about pre-delivery testing of the machine to ensure that it meets specifications and performs as expected upon arrival.

7. User Feedback and Reviews: Research user feedback and reviews from other buyers who have purchased similar laser cutters from the same manufacturer. This can provide valuable insights into the equipment’s performance, reliability, and overall customer satisfaction.

By carefully considering these post-purchase factors, one can minimize potential risks and ensure a successful acquisition of an aluminum laser cutter from China. Thorough research and clear communication with the manufacturer will contribute to a smooth installation, efficient operation, and satisfactory overall experience.

Marketing and Business Expansion Strategies for aluminum laser cutter

Marketing and Business Expansion Strategies for Aluminum Laser Cutter

1. Identify and target specific industries: Conduct market research to identify industries that heavily rely on aluminum cutting services, such as automotive, aerospace, and construction. Develop targeted marketing campaigns highlighting the benefits and cost-effectiveness of aluminum laser cutting for each industry.

2. Leverage online platforms: Create a user-friendly website and optimize it for search engines to increase organic traffic. Utilize targeted online advertising on platforms like Google Ads and social media platforms where potential clients are active. Showcase the advantages of aluminum laser cutting through visually appealing images and videos.

3. Participate in industry trade shows and exhibitions: Attend relevant trade shows and exhibitions that attract professionals from industries using aluminum extensively. Set up a booth displaying samples of aluminum cutting projects to demonstrate the precision and versatility of the laser cutter. Network with potential clients and collect contact information for follow-up.

4. Collaborate with industry influencers: Identify influencers within the industries targeted and approach them for partnerships or collaborations. This could involve sponsoring their content or offering them free access to the aluminum laser cutter in exchange for promoting the services to their followers.

5. Offer competitive pricing and flexibility: Conduct a thorough cost analysis and optimize the pricing structure to remain competitive in the market. Consider offering flexible pricing options like bulk discounts, long-term contracts, or special rates for new clients to attract and retain customers.

6. Provide exceptional customer service: Focus on building strong relationships with clients by delivering excellent customer service. Offer prompt responses to inquiries, provide detailed technical support, and ensure timely completion of aluminum cutting projects. Satisfied customers are likely to recommend the services to others, helping to expand the client base.

7. Explore strategic partnerships: Identify manufacturers or subcontractors in the aluminum supply chain who could benefit from having an aluminum laser cutter on-site. Offer partnerships that allow them to outsource their aluminum cutting needs to reduce costs and increase efficiency.

8. Expand geographical reach: Explore opportunities to expand the business beyond the local market by offering shipping services or partnerships with logistics companies to serve clients globally. Target regions or countries known for their significant demand for aluminum-based products and services.

9. Continuous improvement and innovation: Invest in research and development to stay at the forefront of technological advancements in laser cutting. Continuously improve the cutting precision, speed, and software capabilities of the aluminum laser cutter to stay competitive and attract customers seeking cutting-edge technology.

By implementing these marketing and business expansion strategies, a company providing aluminum laser cutting services can effectively reach its target audience, expand its customer base, and increase its market share in this growing industry.

How to create aluminum laser cutter business website

Creating an aluminum laser cutter business website is an essential step in establishing a strong online presence and attracting potential customers. Here’s a simple guide to help you create a website for your aluminum laser cutter business in less than 300 words:

1. Planning: Begin by defining your website’s goals, target audience, and key features. Consider what information your potential customers would be looking for and what sets your business apart from the competition.

2. Domain and Hosting: Choose a domain name that is catchy, relevant, and easy to remember. Find a reliable hosting provider to ensure that your website is accessible at all times.

3. Design: Opt for a clean and professional design that reflects the nature of your business. Use a responsive layout, ensuring your website looks great on various devices. Keep your color scheme in line with your branding.

4. Homepage: Create an engaging homepage that highlights the core aspects of your aluminum laser cutter business. Include a clear call-to-action, encouraging visitors to explore further.

5. Services: Dedicate a page to showcase your services, providing detailed descriptions of the aluminum laser cutting solutions you offer. Incorporate high-quality images and videos to illustrate your capabilities.

6. About Us: Share your company’s story, mission, and values on the About Us page. Mention your expertise, experience, and why customers should choose your aluminum laser cutter services over others.

7. Portfolio: Display a gallery featuring finished projects and examples of aluminum laser cutting work you have done. This will allow potential customers to assess your skills and capabilities.

8. Testimonials: Include testimonials from satisfied customers to build trust and credibility. Positive reviews can help potential clients feel confident in choosing your aluminum laser cutter services.

9. Contact: Provide a clear and accessible contact page with a contact form, phone number, and email address. Consider integrating live chat functionality for instant communication.

10. SEO and Analytics: Optimize your website for search engines by incorporating relevant keywords throughout your content. Install Google Analytics to monitor website traffic and user behavior, allowing you to make data-driven decisions.

11. Social Media Integration: Include social media buttons on your website to allow visitors to share your content and connect with your brand on platforms like Facebook, Instagram, LinkedIn, or Twitter.

12. Regular Updates: Keep your website updated with the latest information, news, and upcoming events to keep visitors engaged and encourage repeat visits.

By following these guidelines, you can create a professional and informative aluminum laser cutter business website that effectively showcases your capabilities and attracts potential customers.

aluminum laser cutter Sample Policy

Our company is pleased to offer samples of our aluminum laser cutting service to potential customers who wish to evaluate the quality and capabilities of our equipment. Our sample policy aims to ensure a fair and efficient process for both parties involved.

1. Requesting a Sample:

Customers interested in obtaining an aluminum laser cutting sample can submit a request through our website or by contacting our sales team directly. Provide the desired specifications and dimensions of the sample, including the type and thickness of the aluminum sheet.

2. Sample Preparation:

Once we receive the sample request, our team will review the specifications and assess if the desired outcome is achievable with our laser cutting equipment. In some cases, we may suggest modifications to ensure the best results. We will then provide a quote for the sample and confirm the estimated delivery time.

3. Sample Cost:

To cover material costs, machine setup, and labor, we charge a nominal fee for producing laser cutting samples. The exact cost will be provided in the quote and must be paid in advance.

4. Sample Delivery:

Upon receipt of payment, our team will promptly start the production process. The laser cutting sample will be manufactured according to the provided specifications and dimensions. Please note that the sample will not undergo any additional surface treatment unless specifically requested.

5. Sample Dispatch:

The finished sample will be carefully packaged to protect it during delivery. We work with reliable shipping carriers to ensure the product reaches you in the best condition and within the estimated timeframe. A tracking number will be provided for easy monitoring.

6. Sample Evaluation:

Once the sample is received, we kindly request the customer to evaluate its quality and suitability for their intended applications. If there are any concerns or questions, our team will be happy to address them promptly.

We believe that our aluminum laser cutting samples will provide you with a clear understanding of our capabilities and the quality that our equipment can deliver. Contact us today to request your sample and experience our cutting-edge services firsthand.

The Role of Agents and Sourcing Companies in Facilitating aluminum laser cutter Purchases from China

Agents and sourcing companies play a crucial role in facilitating aluminum laser cutter purchases from China. With their expertise and knowledge of the Chinese market, they act as intermediaries between buyers and manufacturers, ensuring a smooth and efficient purchasing process.

Firstly, agents and sourcing companies are well-connected to a vast network of manufacturers in China. They have in-depth knowledge about the best suppliers, their capabilities, and the quality of their products. This enables them to identify suitable manufacturers that specialize in aluminum laser cutters, based on the buyer’s specific requirements.

Moreover, agents and sourcing companies have a thorough understanding of the Chinese market and its regulations. They are familiar with import/export procedures, customs requirements, and local laws. This expertise allows them to navigate the complex logistics involved in shipping goods from China to the buyer’s destination country, ensuring compliance and minimizing delays.

Furthermore, agents and sourcing companies assist with quality control. They have a team of experts who can visit the manufacturing facilities and inspect the aluminum laser cutters to ensure they meet the buyer’s quality standards. This mitigates the risk of receiving substandard products and provides buyers with confidence in their purchase.

In addition, agents and sourcing companies are skilled negotiators. They can negotiate the best prices, terms, and conditions with manufacturers on behalf of the buyer. By leveraging their relationships and bulk purchasing power, they can help secure competitive pricing and favorable payment terms, ultimately saving the buyer money and maximizing value.

Lastly, agents and sourcing companies provide valuable assistance with communication and language barriers. They act as translators, ensuring effective communication between the buyer and the manufacturer. This helps to bridge any cultural or linguistic gaps, minimizing misunderstandings and ensuring smooth negotiations.

In summary, agents and sourcing companies play a pivotal role in facilitating aluminum laser cutter purchases from China. Their expertise in supplier identification, quality control, logistics, negotiation, and communication provide buyers with a seamless and efficient purchasing experience, ultimately facilitating successful transactions.

How to use import and export data website importyeti.com to search the company and aluminum laser cutter

To use the import and export data website importyeti.com to search for a company and an aluminum laser cutter, follow the steps below:

1. Visit importyeti.com and navigate to the search bar on the homepage.

2. Enter the name of the company you want to search for in the search bar.

3. Click the “Search” button to initiate the search.

4. The website will provide you with a list of results related to the company you searched for, including details like company name, address, contact information, and import/export data.