Introduce about bending machine for sale guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

When it comes to finding a bending machine for sale, it is essential to consider various factors such as quality, cost, suppliers, certification, market demand, tips, and frequently asked questions (FAQs). This guide aims to provide a concise overview of these aspects in less than 300 words.

Quality is paramount when selecting a bending machine. Look for reputable manufacturers that offer machines built with durable materials, advanced technology, and precise bending capabilities. Checking customer reviews and testimonials can help gauge the quality of the machine.

Cost is another crucial aspect to consider. Compare the prices of different suppliers and determine if the machine’s features and capabilities justify the cost. Additionally, examine the long-term cost of ownership, including maintenance, spare parts availability, and energy consumption.

Choosing the right supplier is crucial to ensure a smooth purchasing process and reliable after-sales support. Select suppliers with extensive experience, good track record, and excellent customer service. Evaluate their warranty policies, technical support, and delivery options.

Certification is an essential factor to ensure safety and compliance with regulations. Look for machines that meet international standards such as ISO certification, CE marking, or other regional certifications depending on your country or region.

Market demand plays a significant role in the selection process. Research the current market trends, industry requirements, and specific bending needs to identify the most suitable machine. Consider factors such as the range of materials the machine can handle, bending capacities, and versatility.

Tips for buying a bending machine include assessing your production volume, considering future scalability, and consulting with industry experts for recommendations. Moreover, consider the machine’s automation features, ease of use, and compatibility with other equipment in your production line.

Frequently asked questions (FAQs) provide valuable insights into common concerns buyers may have. FAQs may cover topics such as machine capabilities, maintenance requirements, troubleshooting tips, and warranty coverage.

In conclusion, when seeking a bending machine for sale, prioritize the quality, compare costs, choose reliable suppliers, consider certifications, evaluate market demands, follow helpful tips, and review FAQs. By considering these aspects, one can make an informed decision and find a bending machine that suits their needs efficiently.

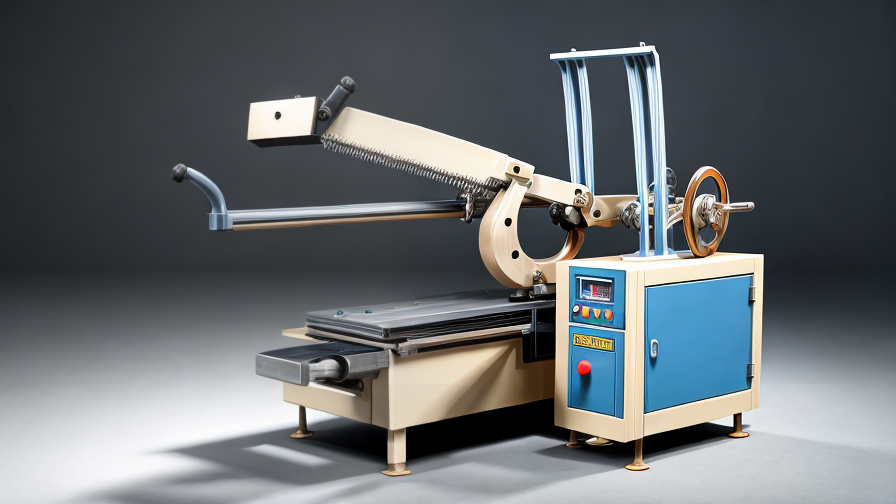

Types of bending machine for sale

There are several types of bending machines available for sale, each designed for specific purposes and tasks. These machines are commonly used in industries such as metalworking, construction, and manufacturing. Below, we will discuss some of the most common types of bending machines that you can find on the market.

1. Manual Sheet Metal Bending Machine:

This type of bending machine consists of a clamping mechanism and a pivoting bending beam. It is operated manually by the user, who positions the metal sheet between the clamping mechanism and bends it using the bending beam. This machine is suitable for small-scale bending tasks and is cost-effective, but requires physical effort.

2. Hydraulic Press Brake:

A hydraulic press brake is a more advanced bending machine that utilizes hydraulic power to bend metal sheets. It features a hydraulic ram that applies force on the metal, which is placed on a V-shaped die. This machine offers high precision and can handle heavy-duty bending tasks. It is commonly used for bending thick metal sheets and plates.

3. CNC Press Brake:

CNC (Computer Numerical Control) press brakes are automated bending machines that are controlled by a computerized system. They offer high accuracy and repeatability in bending operations. CNC press brakes can be programmed to bend metal sheets with complex shapes using specific bending angles and lengths. They are widely used in industries requiring high productivity and precision.

4. Roll Bending Machine:

A roll bending machine, also known as a plate rolling machine, is used to bend metal sheets into curved or cylindrical shapes. It consists of three rollers, where the top roller and two bottom rollers apply pressure to the metal sheet, causing it to bend. This machine is commonly used in manufacturing processes that require cylindrical or conical components, such as pipes and tanks.

5. Tube and Pipe Bending Machine:

This type of bending machine is specifically designed to bend tubes and pipes into various shapes and angles. It uses mandrels and bending dies to form tubes or pipes accurately without collapsing or deforming them. Tube and pipe bending machines are widely used in industries such as automotive, aerospace, and HVAC.

These are just a few examples of bending machines available for sale. The choice of machine depends on the specific bending requirements, such as the material being bent, thickness, shape, and desired accuracy. It is essential to assess your needs and consult with experts before purchasing a bending machine to ensure you select the most suitable option for your application.

Pros and Cons of Using bending machine for sale

Using a bending machine for sale offers several advantages, along with a few drawbacks. Here, we will explore the pros and cons of utilizing such equipment within a business or manufacturing setting.

Pros:

1. Cost-effectiveness: Purchasing a used bending machine for sale can be a cost-effective solution compared to buying a brand-new one. It allows businesses to save money on their initial investment, which is particularly beneficial for small or start-up companies operating on limited budgets.

2. Increased productivity: Bending machines automate the bending process, reducing the need for manual labor. This not only saves time but also boosts overall productivity. With faster production speeds and less downtime, businesses can meet project deadlines and fulfill customer orders more efficiently.

3. Enhanced precision: Bending machines offer high precision and accuracy, ensuring that each bend is consistent and of the desired quality. This results in a higher-quality end product, which can increase customer satisfaction and foster a positive reputation for the business.

4. Versatility: Bending machines come with adjustable features, allowing users to bend various materials, shapes, and sizes. This versatility provides businesses with the flexibility to handle different projects and cater to diverse customer demands.

5. Reduced risk of injuries: By automating the bending process, bending machines minimize the risk of operator injuries associated with manual bending techniques. This can contribute to a safer working environment and reduce workers’ compensation claims.

Cons:

1. Limited warranty: Used bending machines for sale may have expired or limited warranties, leaving the buyer responsible for any repairs or replacements needed. This can result in additional costs and potential maintenance hassles.

2. Potential wear and tear: Since it is a used machine, there is a risk of greater wear and tear. The condition of the equipment might not be optimal, and there could be a need for frequent repairs or part replacements, resulting in additional expenses.

3. Technology limitations: Older models of bending machines may lack advanced technologies and features found in newer versions. These might include enhanced programmability, automated adjustments, or digital interfaces. Businesses seeking state-of-the-art capabilities may need to invest in a new machine rather than a used one.

4. Limited supplier support: Older or discontinued models might have limited availability of spare parts and support from the original equipment manufacturer. This can prolong downtime during breakdowns, making it challenging to maintain consistent production without delays.

5. Outdated safety features: Older bending machines may not meet the latest safety standards and regulations. This could pose potential risks to operators if adequate safety precautions are not in place.

In conclusion, using a bending machine for sale offers cost-effectiveness, increased productivity, enhanced precision, versatility, and reduced risk of injuries. However, potential drawbacks include limited warranty, wear and tear, technology limitations, limited supplier support, and outdated safety features. Businesses should weigh these pros and cons to make an informed decision on whether investing in a used bending machine aligns with their specific needs and circumstances.

bending machine for sale Reference Specifications (varies for different product)

We have a variety of bending machines available for sale, each with its own unique specifications. Below, we provide a reference guide with a brief overview of these specifications to help you make an informed decision.

1. Model: BM-100

– Maximum Bending Capacity: 12mm

– Bending Angle Range: 0-180 degrees

– Power Supply: 220V, 50Hz

– Weight: 50kg

– Size: 800mm x 500mm x 900mm

2. Model: BM-200

– Maximum Bending Capacity: 25mm

– Bending Angle Range: 0-120 degrees

– Power Supply: 380V, 60Hz

– Weight: 120kg

– Size: 1000mm x 700mm x 1200mm

3. Model: BM-300

– Maximum Bending Capacity: 40mm

– Bending Angle Range: 0-90 degrees

– Power Supply: 440V, 50Hz

– Weight: 200kg

– Size: 1500mm x 900mm x 1300mm

4. Model: BM-400

– Maximum Bending Capacity: 50mm

– Bending Angle Range: 0-135 degrees

– Power Supply: 380V, 50Hz

– Weight: 350kg

– Size: 1800mm x 1000mm x 1500mm

5. Model: BM-500

– Maximum Bending Capacity: 75mm

– Bending Angle Range: 0-180 degrees

– Power Supply: 440V, 60Hz

– Weight: 500kg

– Size: 2000mm x 1200mm x 1700mm

Please note that these specifications may vary depending on the specific product and model. It is recommended to consult the individual product listings for detailed information and any additional features or accessories included with each bending machine.

With a wide range of bending capacities, angle ranges, and power supply options, our bending machines are designed to meet various bending needs. From smaller applications to heavy-duty tasks, you can find the right machine to suit your requirements.

For further information or assistance in selecting the ideal bending machine for your specific needs, please don’t hesitate to contact our sales team.

Applications of bending machine for sale

A bending machine is a versatile tool that finds applications in various industries. With its ability to shape a wide range of materials, such as metal, plastic, and glass, it serves as an essential equipment in manufacturing processes. Here are some key applications where a bending machine for sale can be highly beneficial:

1. Metal Fabrication: Bending machines are extensively used in metal fabrication industries to bend and shape metal sheets into desired forms. They enable precise bending of metal components, such as brackets, angles, channels, and pipes. This is vital in industries like automotive, aerospace, construction, and furniture manufacturing.

2. HVAC Ducting: Bending machines play a crucial role in the fabrication of heating, ventilation, and air conditioning (HVAC) systems. They help bend sheet metal into various shapes and sizes required for ductwork, ensuring efficient air distribution throughout buildings. Bending machines ensure accurate bending angles, reducing installation time and ensuring proper airflow.

3. Signage and Advertising: Bending machines are widely used in the signage and advertising industry to create 3D letters, logos, and decorative elements. By bending materials like acrylic, aluminum, and stainless steel, they facilitate the production of eye-catching and durable signage.

4. Electronics and Appliances: Bending machines are employed during the manufacturing of electrical enclosures, control panels, and appliance components. They provide precise bending of sheet metal parts used in these products, ensuring proper fitment and functionality.

5. Furniture and Interior Design: Bending machines enable the creation of curved components, such as chair frames, tables, and architectural structures. This is particularly useful in furniture manufacturing and interior design, where curved elements add aesthetic appeal to products and spaces.

6. Glass Manufacturing: Bending machines equipped with heated rollers are utilized to bend glass sheets, creating curved glass panels used in architecture, automotive, and furniture industries. They enable the production of curved windows, doors, and display cases.

In conclusion, a bending machine for sale is indispensable in numerous industries, including metal fabrication, HVAC, signage, electronics, furniture, and glass manufacturing. With their ability to bend various materials accurately, they enhance production efficiency, product quality, and design possibilities.

The Work Process and how to use bending machine for sale

The work process of a bending machine involves several steps to ensure accurate and efficient bending of materials. Here is a general overview of how to use a bending machine for sale:

1. Setup: Start by selecting the appropriate tooling and forming die based on the desired bend angle and material thickness. Secure the tooling and ensure it is aligned properly with the machine. Adjust the machine’s settings, such as bending speed and pressure, according to the material being used.

2. Material preparation: Measure and mark the material to indicate the desired bend points. Ensure the material is clean and free from any debris or imperfections that may affect the bending process.

3. Loading the material: Place the material carefully on the machine’s bending table, aligning it with the marked bend points. Adjust the material’s position to ensure it is securely held in place, either by manual clamping or with the help of pneumatic or hydraulic clamps.

4. Bending operation: Activate the bending machine by pressing the appropriate buttons or foot pedal, depending on the machine’s control system. The bending machine will apply force to the material, gradually bending it to the desired angle. Monitor the process closely to ensure correct alignment and prevent any slipping or distortion of the material.

5. Unloading and inspection: Once the bending process is complete, release the clamps and carefully remove the bent material from the machine’s table. Inspect the bend for any defects, such as cracks or uneven curves. If required, use additional tools like a deburring machine to smooth out any sharp edges or burrs.

6. Repeat and adjust: If multiple bends are needed, repeat the process by repositioning the material on the bending table and adjusting the machine settings accordingly. If adjustments are required for better results, fine-tune the settings and repeat the bending process until the desired outcome is achieved.

It is essential to follow all safety guidelines provided by the manufacturer while using a bending machine. Proper training and experience are also crucial to ensure the machine’s efficient and safe operation.

In conclusion, using a bending machine involves setting up the machine, preparing the material, loading it onto the machine, performing the bending process with careful monitoring, inspecting the results, and repeating the process if necessary. By understanding and following these steps, one can effectively utilize a bending machine for sale.

Quality Testing Methods for bending machine for sale and how to control the quality

When it comes to ensuring the quality of bending machines for sale, there are several testing methods that can be employed. These methods aim to identify any potential defects, malfunctions, or deficiencies in the machine’s performance. Quality control measures are also crucial in ensuring that the machines meet the required standards and specifications. Here are some commonly employed testing methods and quality control practices:

1. Visual Inspection: Conduct a thorough examination of the bending machine for any visible defects, such as irregularities in components, loose or broken parts, or improper welding.

2. Functional Testing: Test the machine’s functionality by running trial operations to ensure that it performs the intended bending tasks accurately and efficiently. This includes evaluating how the machine responds to various parameters such as speed, thickness, and material.

3. Tolerance Checks: Carry out measurements and checks to ensure that the machine maintains precise tolerances during the bending process. This involves measuring the angles, lengths, and dimensions of the bent materials and comparing them against the required specifications.

4. Material Compatibility: Verify that the bending machine can handle various materials effectively, including different metal alloys, plastics, or composite materials. This is essential to guarantee its adaptability in different industrial settings.

5. Safety Testing: Assess the machine’s safety features and mechanisms to make sure they comply with relevant safety standards. This includes checking emergency stop buttons, protective guards, and safety sensors to prevent accidents or injuries during operation.

To control and maintain quality, it is essential to implement a robust quality management system. This includes:

a. Establishing clear quality control guidelines, standard operating procedures, and work instructions for operating, maintaining, and inspecting the bending machines.

b. Regular calibration and maintenance of measuring instruments to ensure accurate measurements and consistent quality.

c. Conducting periodic audits and inspections to monitor compliance with quality standards, identify areas for improvement, and take corrective actions if needed.

d. Implementing failure analysis techniques to investigate any defects or malfunctions, analyze their root causes, and implement preventive measures.

e. Training and skill development programs for machine operators and quality control personnel to enhance their understanding of quality requirements and testing methods.

By integrating these testing methods and quality control practices, manufacturers can ensure that the bending machines for sale meet the highest standards of quality, performance, and reliability in various industrial applications.

bending machine for sale Sample Policy and Post-Purchase Considerations for bending machine for sale from China

Sample Policy:

1. Price: The price of the bending machine will be quoted with FOB terms. It includes the cost of the machine, packaging, and loading into containers. Any additional charges like customs duties and taxes will be the responsibility of the buyer.

2. Payment terms: A standard payment method for the purchase of the bending machine from China will be through a confirmed irrevocable letter of credit (L/C) or by wire transfer. The payment will be divided into several milestones, including an initial deposit upon order confirmation, progress payments, and final payment upon completion of manufacturing. The payment terms can be negotiated based on mutual agreement.

3. Quality assurance: The bending machine will be manufactured and tested according to international quality standards. The manufacturer will provide the necessary certificates and documents to ensure compliance with the agreed-upon specifications, operation manuals, and maintenance guidelines. Warranty terms, typically covering a specified period, will be discussed and agreed upon.

4. Shipment and delivery: The manufacturer will arrange transportation of the bending machine to the nearest port of export in China. The buyer is responsible for the importation process, including customs clearance, transportation, and any associated costs. The delivery time will be provided upon order confirmation and may vary based on production capacity and other factors.

Post-Purchase Considerations:

1. Installation and training: The buyer should arrange for professional technicians to handle the installation and commissioning of the bending machine. The manufacturer can provide technical guidance and support remotely or, if agreed, on-site assistance at an additional cost. Proper training should be given to the operators on the usage, maintenance, and safety precautions to ensure optimal performance.

2. Spare parts availability: It is important to discuss the availability of spare parts and after-sales support with the manufacturer. A reliable supply of essential components is crucial for the longevity and efficient operation of the bending machine. The buyer should ensure that there is a clear communication channel for ordering spare parts and resolving any technical issues that may arise.

3. Maintenance and service agreements: Consider negotiating a maintenance and service agreement with the manufacturer or a local authorized service provider. Regular maintenance visits, inspections, and preventive measures will help prolong the lifespan and functionality of the bending machine. Clear terms, including response time, service charges, and warranty coverage, should be established in the agreement.

4. Feedback and warranty claims: Establish a procedure for providing feedback or raising warranty claims to address any performance or operational issues that may occur with the bending machine. The manufacturer should be prompt in acknowledging and resolving valid warranty claims, which may include repairs, replacements, or refunds, as agreed upon in the warranty terms.

In summary, when considering a bending machine for sale from China, it is important to establish clear policies regarding pricing, payment terms, quality assurance, and shipment. Post-purchase considerations should include proper installation and training, spare parts availability, maintenance and service agreements, and a process for providing feedback or warranty claims.

Sourcing bending machine for sale from China: Opportunities, Risks, and Key Players

Sourcing a bending machine for sale from China presents both opportunities and risks. China is known for its manufacturing capabilities, offering a wide range of bending machines at competitive prices. The country is a leading exporter of industrial machinery and enjoys economies of scale, allowing for cost-effective production. This presents an opportunity for buyers to find high-quality bending machines at affordable prices.

One of the key advantages of sourcing from China is the availability of a vast selection of bending machines. Manufacturers in China offer various types of machines including hydraulic, CNC, and manual bending machines, catering to different needs and requirements. This variety enables buyers to find a bending machine that suits their specific applications.

However, there are also risks associated with sourcing from China. One of the primary concerns is the quality of products. While there are reputable manufacturers in China, there is also the risk of encountering low-quality or counterfeit products. It is crucial for buyers to conduct thorough research, read reviews, and verify the credentials and certifications of the seller before making a purchase. This helps in reducing the risk of receiving substandard machines.

Another risk is related to communication and language barriers. Dealing with manufacturers in China may require effective communication to ensure the specifications, customization, and delivery details are clearly understood. Overcoming language barriers may necessitate hiring a translator or working with a reliable agent who can manage the communication effectively.

When it comes to key players in the Chinese bending machine industry, there are several renowned manufacturers that have built a strong reputation both domestically and internationally. Some of the leading companies manufacturing bending machines in China include HACO, Yangli, LVD Group, and Amada. These companies are known for their expertise, quality assurance, and after-sales support.

In conclusion, sourcing a bending machine for sale from China offers opportunities in terms of a wide selection and competitive pricing. However, buyers must also be cautious of the risks related to product quality and communication barriers. By conducting thorough research, verifying credentials, and working with reliable manufacturers or agents, individuals can mitigate these risks and find a suitable bending machine from China.

How to find and select reliable bending machine for sale manufacturers in China,use google search manufacturers and suppliers

When looking for reliable bending machine manufacturers for sale in China, it is advisable to use Google search to find suitable manufacturers and suppliers. Here are some steps you can follow to ensure a successful search:

1. Begin your search by typing relevant keywords into the Google search bar, such as “bending machine manufacturers in China” or “bending machine suppliers in China.” This will provide you with a list of potential manufacturers to explore.

2. It is crucial to carefully review each manufacturer’s website. Look for important information such as their experience in the industry, certifications, products offered, and any customer reviews or testimonials.

3. While going through the manufacturers’ websites, pay attention to their production capabilities, product quality assurance, and the range of bending machines they offer. This will help you understand if they have the specific machine you need.

4. Look for manufacturers that provide detailed product specifications, including materials used, technical details, and performance capabilities. This information is crucial for selecting a reliable supplier.

5. Check if the manufacturer has a professional sales team or customer service representatives who are responsive and can provide timely assistance. Good communication is essential for a smooth transaction.

6. Go through the manufacturer’s export experience, ensuring they have successfully exported products in the past. This indicates their familiarity with the international market and their ability to handle logistics and shipping efficiently.

7. If possible, ask for samples or visit the manufacturer’s factory to evaluate their production process and quality control measures. This will give you firsthand experience on the reliability and quality of their bending machines.

8. Finally, consider the price and compare it with other manufacturers in the market. While price plays a significant role, it should not be the sole determining factor. The focus must be on finding a reliable and reputable manufacturer rather than the cheapest option.

By following these steps, you can effectively use Google search to find and select reliable bending machine manufacturers for sale in China. Remember to choose a manufacturer with a good reputation, quality products, and excellent customer service to ensure a successful business partnership.

How to check bending machine for sale manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

When looking to verify the reliability of a bending machine manufacturer’s website, there are a few steps you can take to ensure its credibility. Here is a brief guide primarily using Google Chrome and the SEOquake tool:

1. Open Google Chrome: Use this web browser as it integrates well with SEOquake, allowing you to access additional information about the website.

2. Search for the manufacturer: Enter the name of the bending machine manufacturer in the Google search bar. Look for the official website within the search results.

3. Install SEOquake: Go to the Chrome Web Store and search for the SEOquake extension. Install it on your Google Chrome browser to leverage its features during the evaluation process.

4. Visit the manufacturer’s website: Click on the link to the manufacturer’s website from the search results. Take note of the website’s design, user-friendliness, and professional appearance. A well-designed website generally indicates a reliable manufacturer.

5. Check SEOquake metrics: Once on the website, activate the SEOquake extension by clicking on its icon in the top-right corner of your browser. A side panel will appear, displaying various metrics. Look for the estimated number of visitors (found under ‘SEMrush Traffic’) and ensure it ranks within the top 10 million websites. This ranking suggests a decent level of traffic and online presence.

6. Evaluate the content: Pay attention to the content provided on the website. Reliable manufacturers have clear, detailed, and accurate information about their bending machines, including technical specifications, operation guides, and frequently asked questions. Poorly written or lack of informative content may be a red flag.

7. Look for contact information and customer reviews: Check if the manufacturer provides contact details such as phone numbers or email addresses. Additionally, search for customer reviews on external websites or forums to gain insights into their reputation.

By following these steps, you can assess the reliability of a bending machine manufacturer’s website, identify their online presence, and make an informed decision about purchasing their products.

Top 10 bending machine for sale manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Yueqing Ruihua Cabinet & Whole Set Equipment Co., Ltd. specializes in manufacturing high-quality bending machines that are widely used in various industries such as automotive, construction, and manufacturing. Their bending machines feature advanced technology, precise bending capabilities, and user-friendly operation. The company’s range includes hydraulic press bending machines, CNC bending machines, and pipe bending machines.

2. Nanjing Jinqiu CNC Machine Tool Co., Ltd. is a leading manufacturer of bending machines in China. They offer a comprehensive range of bending machines, including CNC hydraulic press brakes, torsion bar press brakes, and sheet metal bending machines. With high precision and efficiency, these machines are popular for their durability and reliability.

3. Shanghai Huantu Technical Industry Co., Ltd. is known for its innovative bending machines. Their product line includes pipe bending machines, metal sheet bending machines, and hydraulic press brakes. These machines are designed to deliver outstanding performance, accuracy, and flexibility in bending various materials such as steel, aluminum, and copper.

4. Zhangjiagang Liye Machinery Co., Ltd. is a trusted manufacturer of bending machines that cater to diverse industrial requirements. Their range covers hydraulic pipe bending machines, CNC tube bending machines, and profile bending machines. These machines offer excellent flexibility, easy operation, and high productivity.

5. Jiangsu Hefeng Mechanical Making Co., Ltd. specializes in the production of bending machines suitable for different applications. Their range includes hydraulic profile bending machines, pipe bending machines, and section bending machines. These machines are highly efficient, precise, and durable.

6. Anhui Hualing CNC Machine Technology Co., Ltd. focuses on producing high-quality CNC bending machines. Their product lineup includes hydraulic press brakes, plate bending machines, and tube bending machines. These machines feature advanced technology, superior performance, and excellent precision.

| Manufacturer | Products |

| ————————————————————- | —————————————————————– |

| Yueqing Ruihua Cabinet & Whole Set Equipment Co., Ltd. | Hydraulic press bending machines, CNC bending machines, pipe bending machines |

| Nanjing Jinqiu CNC Machine Tool Co., Ltd. | CNC hydraulic press brakes, torsion bar press brakes, sheet metal bending machines |

| Shanghai Huantu Technical Industry Co., Ltd. | Pipe bending machines, metal sheet bending machines, hydraulic press brakes |

| Zhangjiagang Liye Machinery Co., Ltd. | Hydraulic pipe bending machines, CNC tube bending machines, profile bending machines |

| Jiangsu Hefeng Mechanical Making Co., Ltd. | Hydraulic profile bending machines, pipe bending machines, section bending machines |

| Anhui Hualing CNC Machine Technology Co., Ltd. | Hydraulic press brakes, plate bending machines, tube bending machines |

These manufacturers offer a wide range of bending machines that cater to different industrial needs. Key factors to consider when choosing a bending machine include the type of material you will be bending, the required precision, and production volume. By comparing the products offered by these manufacturers, buyers can make informed decisions based on their specific requirements.

Background Research for bending machine for sale manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to finding bending machine manufacturers in China, several online platforms can provide valuable information. Here, we will explore the background research on three popular websites: qcc.com, archive.org, and importyeti.com.

Qcc.com is a Chinese business information platform that offers comprehensive company profiles and business data. Using this website, one can search for bending machine manufacturers in China. The platform provides details about the companies, such as their registered address, legal representatives, business scope, and contact information. One can also find other relevant information like company financials and certifications. With qcc.com, potential buyers can verify the authenticity of manufacturers and evaluate their suitability for business partnerships.

Archive.org is a digital library that allows users to access archived versions of websites. This platform can be helpful in understanding the historical background of bending machine manufacturers. By accessing older versions of a manufacturer’s website, one can trace its past products, services, and capabilities. This can provide valuable insights into the manufacturer’s experience, product development, and technology advancements over time.

Importyeti.com is an international trade search engine that provides information on suppliers and buyers across the globe. It can be utilized to search for bending machine manufacturers in China and obtain relevant details such as company profiles, product listings, and contact information. Importyeti.com also offers information on suppliers’ export and import histories, allowing potential buyers to assess manufacturers’ market presence and experience in international trade.

In conclusion, qcc.com, archive.org, and importyeti.com are valuable platforms for conducting background research on bending machine manufacturers in China. Through qcc.com, one can obtain comprehensive company profiles; archive.org allows users to explore the historical background of manufacturers, and importyeti.com provides information on suppliers’ international trade history. By leveraging these platforms, potential buyers can make informed decisions and identify reliable bending machine manufacturers in China.

Leveraging Trade Shows and Expos for bending machine for sale Sourcing in China

Trade shows and expos offer a valuable opportunity for sourcing bending machines for sale in China. By leveraging these events, businesses can effectively connect with suppliers, explore the latest market trends, and negotiate favorable deals.

One key advantage of trade shows and expos is the concentration of suppliers in a single location. These events bring together a wide range of bending machine manufacturers, giving businesses access to a diverse pool of potential suppliers. This saves time and effort compared to individually searching for suppliers online or through other means.

Attending trade shows and expos also allows businesses to interact directly with suppliers. Through face-to-face conversations, businesses can assess the credibility, professionalism, and reliability of potential suppliers. This helps build trust and establish a solid business relationship, which is crucial when sourcing products from overseas.

Furthermore, trade shows and expos offer an opportunity to compare different bending machine models and technologies. By observing live demonstrations and examining the machines up close, businesses can gain a deeper understanding of the quality, features, and capabilities of the available options. This knowledge is essential in making an informed purchasing decision.

In addition to sourcing suppliers and evaluating products, trade shows and expos provide a platform for networking with industry professionals. Attending seminars, workshops, and networking events allows businesses to exchange ideas, gain insights, and stay updated on the latest industry developments. Connecting with other businesses in the same industry can also create potential collaboration opportunities or partnerships.

To effectively leverage trade shows and expos for sourcing bending machines in China, businesses should thoroughly research and select relevant events. Preparing a list of specific requirements and questions to ask potential suppliers is also essential. Additionally, businesses should allocate sufficient time and resources to attend these events, making the most out of their investment and enhancing their chances of success.

By strategically leveraging trade shows and expos, businesses can efficiently source bending machines for sale in China, access a wide variety of suppliers, stay up-to-date with the latest industry trends, and establish strong business relationships.

The Role of Agents and Sourcing Companies in Facilitating bending machine for sale Purchases from China

Agents and sourcing companies play a crucial role in facilitating the purchase of bending machines from China. These entities act as intermediaries between buyers and Chinese manufacturers, providing a range of services to streamline the sourcing process. By leveraging their expertise and local knowledge, agents and sourcing companies help mitigate the risks and challenges associated with purchasing machinery from overseas markets.

Firstly, agents and sourcing companies in China possess extensive knowledge about the local market and its manufacturing landscape. They have established relationships with reputable manufacturers who specialize in producing bending machines. Agents can guide buyers in selecting reliable suppliers, ensuring that they meet quality standards and are capable of delivering the desired product.

Furthermore, agents act as effective mediators in negotiations between buyers and manufacturers. They have a deep understanding of Chinese business culture, language, and customs, which helps to bridge any communication gaps and facilitate smooth interactions. Agents can facilitate effective communication, ensuring that both parties understand each other’s requirements and expectations. This reduces the chances of miscommunication and promotes a more successful business relationship.

Agents and sourcing companies also provide valuable logistical support. They assist with tasks such as arranging factory visits, conducting quality inspections, managing shipping logistics, and handling import/export documentation. These services ensure that the purchasing process is efficient and that the products are delivered on time and in good condition.

Moreover, agents offer valuable expertise in navigating the complexities of international trade and compliance. They are well-versed in import/export regulations, customs requirements, and documentation procedures. This knowledge helps buyers comply with legal and regulatory requirements and avoid potential pitfalls or delays in the importing process.

Overall, agents and sourcing companies act as a vital link between buyers and Chinese manufacturers in the purchase of bending machines. Their experience, knowledge, and range of services facilitate a smoother sourcing process, reduce risks, and increase the chances of a successful purchase from China.

Price Cost Research for bending machine for sale manufacturers Companies in China, use temu.com and 1688.com

When it comes to finding a bending machine for sale, China is known for its extensive manufacturing industry and competitive prices. Two popular online platforms for researching and purchasing machinery in China are temu.com and 1688.com.

Temu.com is known for its wide range of machinery and equipment options. By searching for “bending machine” on temu.com, you will find numerous manufacturers and suppliers offering different types of bending machines. The prices vary depending on factors such as machine specifications, brand reputation, and additional features. It is advisable to carefully compare the prices and specifications of different machines before making a decision.

1688.com is another reliable platform for sourcing machinery from China. It is a business-to-business (B2B) platform, connecting buyers with manufacturers and suppliers directly. Using keywords such as “bending machine” on 1688.com will give you a list of suppliers offering these machines. Similar to Temu.com, it is essential to thoroughly compare different options in terms of price, quality, and customer reviews.

When conducting the price cost research, it is recommended to utilize the search filters to narrow down options that fit your specific requirements. These filters include machine type, price range, certification, location, and more. It is also advisable to directly communicate with the manufacturers or suppliers to inquire about additional costs, such as shipping and customs duties.

In summary, when researching bending machines for sale in China, Temu.com and 1688.com are two reliable platforms to consider. By utilizing their search functions and filters, you can find numerous manufacturers and suppliers offering bending machines at various price points. It is crucial to carefully compare different options and communicate with the sellers to ensure you make an informed decision.

Shipping Cost for bending machine for sale import from China

The shipping cost for importing a bending machine for sale from China will depend on various factors such as the size and weight of the machine, the distance between the origin and destination, and the chosen shipping method.

Generally, the two main shipping methods are by air and by sea. Shipping by air is usually faster but more expensive, while shipping by sea is slower but more cost-effective for large or heavy machinery.

If the bending machine is relatively small and lightweight, shipping it by air might be a viable option. Air freight rates typically range from $4 to $8 per kilogram, and additional charges may apply for customs clearance, insurance, and handling fees. However, shipping costs can vary significantly depending on the airline, volume discounts, and the specific route.

On the other hand, if the bending machine is large and heavy, shipping it by sea would be more economical. The total shipping cost will generally include various fees such as handling charges, customs duties, container fees, and port-related charges. Altogether, the sea freight cost can range from $500 to $3000, depending on factors like the distance, the type of container used, and any additional services required.

It is crucial to consider additional costs such as customs duties, import taxes, and brokerage fees that may apply upon arrival in the destination country. Proper documentation, such as a bill of lading, commercial invoice, and customs declaration, will also be needed to facilitate smooth customs clearance.

To obtain accurate shipping cost estimates, it is advisable to consult with shipping companies or freight forwarders experienced in international trade. They can provide detailed information and guidance tailored to specific requirements, ensuring a cost-effective and efficient import of the bending machine from China.

Compare China and Other bending machine for sale Markets: Products Quality and Price,Visible and Hidden Costs

China is known for being one of the largest and most competitive bending machine markets in the world. When comparing it to other bending machine markets, several factors can be considered: product quality, price, visible costs, hidden costs, and total cost of ownership.

In terms of product quality, China offers a wide range of bending machines. While the quality may vary depending on the manufacturer, Chinese machines are often regarded as reliable and well-built. However, in comparison to some Western markets, Chinese machines may not always meet the same stringent quality standards and may have a shorter lifespan.

Regarding price, China tends to offer highly competitive prices for bending machines. The low production costs, large manufacturing base, and high competition in the Chinese market contribute to lower prices. When compared to other markets, such as Europe or North America, Chinese machines are often more affordable, allowing businesses with tighter budgets to purchase the equipment.

Visible costs include the initial purchase price, taxes, and shipping fees. In this aspect, China holds a clear advantage. Due to its large-scale manufacturing capabilities and proximity to global shipping routes, the visible costs of purchasing a bending machine from China are generally lower than in other markets. However, it is essential to consider the additional hidden costs associated with the purchase.

Hidden costs include import duties, customs fees, and potential language barriers when communicating with Chinese manufacturers. These costs may not be immediately apparent and can significantly impact the overall price of purchasing a bending machine from China. Additionally, warranty and after-sales support can sometimes be lacking compared to more established markets, leading to additional expenses and potential complications.

Finally, the total cost of ownership should be considered. While China offers competitive prices, it is crucial to assess the long-term costs associated with maintenance, spare parts, and potential downtime. Chinese machines may require more frequent maintenance and replacement of components, which can increase the total cost of ownership over time.

In conclusion, China’s bending machine market provides a wide selection of products at competitive prices. However, buyers should carefully consider product quality, hidden costs, and total cost of ownership before making a purchase decision. Other markets may offer higher quality products, better after-sales support, and fewer hidden costs, but at a higher price. Ultimately, the choice between the Chinese market and other markets will depend on a buyer’s specific needs, budget, and preferences.

Understanding Pricing and Payment Terms for bending machine for sale: A Comparative Guide to Get the Best Deal

When looking to purchase a bending machine, it is essential to understand pricing and payment terms to ensure you get the best deal. This comparative guide aims to provide insights into the factors to consider when evaluating the cost and payment options for a bending machine for sale.

Firstly, it is important to research and compare prices from different suppliers. Bending machine prices can vary significantly depending on the brand, size, functionality, and additional features included. Thus, obtaining quotes from multiple suppliers will help you identify the average market price and determine whether a specific offer is reasonable or overpriced.

While comparing prices, also consider the quality and reliability of the bending machine. Opting for a lower-priced machine may seem tempting, but if it compromises on quality and performance, you may experience more significant expenses in the long run due to repairs or replacement.

Apart from the initial cost, payment terms play a crucial role in determining the overall value. Many suppliers offer various payment options, including upfront payment, installment plans, or leasing. Each option has its own advantages and considerations.

If you have sufficient funds and want to avoid additional financial burdens, paying the full amount upfront may be the best choice. This option often comes with benefits like discounts or extended warranties.

However, if the full payment is not feasible, installment plans can be a viable option. Ensure you evaluate the interest rates and any additional fees associated with this payment option. Calculating the total amount paid over the installment period will help you determine the actual cost of the machine and make an informed decision.

Leasing is another option that allows you to use the bending machine without making a significant upfront investment. This option can be advantageous for businesses looking to conserve capital or those with uncertain long-term needs. However, carefully review the leasing agreement to understand the terms, conditions, and obligations involved.

Finally, always consider the supplier’s reputation, customer service, and warranty information when assessing pricing and payment terms. A reputable supplier with excellent after-sales support can provide added value and peace of mind.

In conclusion, understanding pricing and payment terms is crucial when seeking the best deal for a bending machine. Compare prices, assess the machine’s quality, and consider payment options to make an informed decision. By taking these factors into account, you can secure a bending machine that fits your requirements and budget, ensuring a successful and cost-effective purchase.

Chinese Regulations and Industry Standards Certifications for bending machine for sale,Import Regulations and Customs for bending machine for sale from China

China has a stringent set of regulations and industry standards certifications for the sale of bending machines. These regulations ensure the safety, quality, and performance of these machines, providing a guarantee to buyers.

The main industry standard certification in China for bending machines is called the CCC (China Compulsory Certification) mark. This mark demonstrates compliance with national standards and is mandatory for products sold in China. To obtain this certification, manufacturers must undergo rigorous testing and meet specific requirements related to product design, materials used, electrical safety, and performance.

Additionally, manufacturers may also obtain ISO 9001 certification, which signifies compliance with international quality management standards. This certification focuses on ensuring consistent quality control and continuous improvement in all aspects of the manufacturing process.

When importing bending machines from China, buyers must also adhere to import regulations and customs procedures. These procedures aim to ensure the legality and safety of the imported goods. Importers must provide necessary documentation, such as a commercial invoice, bill of lading, packing list, and any required permits or licenses.

Imported bending machines may be subject to import duties, value-added tax (VAT), and other customs charges. Importers are responsible for understanding and complying with these financial requirements.

To facilitate smooth customs clearance, buyers should also ensure that the bending machines meet the relevant safety and technical requirements in their own country. This may involve obtaining additional certifications or complying with specific regulations.

In summary, China has comprehensive regulations and certifications for the sale of bending machines, ensuring quality and safety. Importers must navigate import regulations and customs procedures, including paying import duties and complying with relevant safety requirements in their own country.

Sustainability and Environmental Considerations in bending machine for sale Manufacturing

When it comes to manufacturing bending machines for sale, sustainability and environmental considerations play a vital role in ensuring responsible and eco-friendly production processes. By integrating sustainable practices into the manufacturing process, companies can reduce their carbon footprint, conserve energy and resources, and minimize waste generation.

One aspect to consider is the sourcing of raw materials. Opting for sustainable materials, such as recycled or renewable resources, can significantly reduce environmental impact. Additionally, ensuring the ethical sourcing of materials can help minimize social and environmental issues associated with extraction and processing.

The production process itself should be optimized for energy efficiency. Implementing energy-saving technologies, such as efficient machinery and lighting systems, can minimize energy consumption and greenhouse gas emissions. Moreover, adopting renewable energy sources, such as solar or wind power, can further reduce the carbon footprint of the manufacturing process.

Waste management is another crucial aspect. Implementing strategies to reduce, reuse, and recycle waste generated during the manufacturing process is essential. This can involve implementing lean manufacturing practices, optimizing material usage, and segregating and recycling waste materials whenever feasible. Additionally, companies can explore partnerships with recycling facilities to ensure proper disposal and recovery of materials.

Transportation plays a significant role in the sustainability of the manufacturing process. Minimizing transportation distances and choosing eco-friendly transportation methods can reduce carbon emissions. Additionally, optimizing packaging materials to reduce weight and utilizing recyclable or biodegradable packaging can further contribute to sustainable manufacturing.

Finally, end-of-life consideration is essential to ensure circularity and minimize the environmental impact of the products. Designing bending machines for easy disassembly and promoting reuse or recycling of components can help decrease waste generation and promote a circular economy.

In conclusion, sustainability and environmental considerations are paramount when manufacturing bending machines for sale. By integrating sustainable practices in material sourcing, production processes, waste management, transportation, and end-of-life considerations, companies can mitigate environmental impacts, reduce their carbon footprint, and contribute to a greener and more sustainable future.

List The Evolution history of “bending machine for sale”

The evolution of the bending machine for sale can be traced back to the early 20th century when manual bending machines were first introduced. These machines required a significant amount of physical effort and skill to operate, as they involved manually bending and shaping metal or other materials.

In the 1950s, advancements in technology led to the development of hydraulic bending machines. These machines utilized hydraulics to generate the necessary force for bending, reducing the physical strain on the operator and improving efficiency. Hydraulic bending machines quickly became popular in industrial settings, where they were used for bending various metals like steel and aluminum.

In the 1970s, electronic bending machines emerged, incorporating computerized controls and motorized mechanisms for precise and automated bending processes. These machines offered greater accuracy, repeatability, and speed, making them ideal for mass production and high-volume operations. With the advent of electronic bending machines, operators could input specific bending angles and dimensions, and the machine would execute the desired bends automatically.

The 21st century witnessed the rise of CNC (Computer Numerical Control) bending machines, which further revolutionized the bending industry. These machines rely on computer programming and numerical control to precisely control the bending process. CNC bending machines can handle complex bending tasks with ease, enabling manufacturers to produce intricate and custom-shaped components. Furthermore, these machines often incorporate advanced features such as automatic tool changes, material handling systems, and real-time monitoring for efficient and streamlined operations.

Moreover, technological advancements have led to the development of hybrid bending machines that combine the benefits of multiple bending methods. These machines integrate both hydraulic and electric drives, allowing for greater flexibility and improved energy efficiency. Hybrid bending machines are designed to provide optimal performance while minimizing operating costs.

In recent years, the bending machine industry has also witnessed the integration of artificial intelligence and machine learning technologies. These advancements have enabled machines to learn, adapt, and optimize bending processes based on real-time data, leading to enhanced production efficiency and reduced waste.

In conclusion, the evolution of bending machines for sale has seen a transition from manual to hydraulic, electronic, and CNC machines. These advancements have brought significant improvements in accuracy, speed, and overall productivity, enabling manufacturers to meet the ever-increasing demands of the market efficiently.

The Evolution and Market Trends in bending machine for sale Industry

The bending machine industry has experienced significant evolution and market trends over the years. Bending machines are essential equipment used in various industries, including automotive, manufacturing, construction, and aerospace, among others. They are commonly used for bending metal sheets and profiles to create various shapes and designs.

One significant evolution in the bending machine industry is the adoption of computer numerical control (CNC) technology. CNC bending machines provide higher accuracy, precision, and flexibility in bending operations compared to traditional manual bending machines. This advancement has led to increased productivity, reduced human errors, and improved product quality.

Another evolution is the development of automated bending machines. These machines incorporate robotic arms and artificial intelligence, further enhancing productivity and reducing labor costs. Automated bending machines can perform complex bending tasks with minimal human intervention, improving efficiency and throughput.

Market trends in the bending machine industry indicate a growing demand for customized bending solutions. As industries become more specialized and diverse, there is a need for bending machines that can handle unique bending requirements. Manufacturers are now offering customizable bending machines that can be tailored to meet specific customer needs, such as handling different materials, shapes, and thicknesses.

The market also shows a rising demand for energy-efficient bending machines. Environmental concerns and the need for cost savings have driven manufacturers to develop bending machines that consume less energy without compromising their performance. Energy-efficient bending machines not only reduce operational costs but also contribute to sustainability efforts.

Additionally, there is a growing trend towards compact and portable bending machines. These machines are designed to be lightweight and easily transported, making them suitable for on-site bending tasks. Industries such as construction and repair services find portable bending machines beneficial as they can be easily moved to different job sites, increasing flexibility and reducing downtime.

In conclusion, the bending machine industry has evolved significantly with the introduction of CNC technology, automation, customization, energy efficiency, and portability. These advancements and market trends have transformed the industry by improving productivity, product quality, and flexibility while reducing labor costs and environmental impact.

Custom Private Labeling and Branding Opportunities with Chinese bending machine for sale Manufacturers

If you are considering private labeling and branding opportunities with Chinese bending machine manufacturers, you have made a wise decision. Chinese manufacturers offer a wide range of bending machines that are not only high in quality but also cost-effective. By taking advantage of private labeling and branding, you can establish your own unique identity in the market while benefiting from the expertise and experience of Chinese manufacturers.

Private labeling allows you to customize the product with your own branding, logo, and packaging. Chinese manufacturers understand the importance of branding and can offer flexible options to meet your specific requirements. This enables you to create a product that stands out from the competition and appeals to your target audience.

Moreover, Chinese manufacturers are known for their ability to produce a diverse range of bending machines. From manual models to CNC-controlled machines, you can find a variety of options that cater to different industry needs. By collaborating with Chinese manufacturers, you can choose the most suitable bending machine for your specific application and have it customized to meet your branding requirements.

Apart from the extensive product range and customization options, Chinese manufacturers also offer competitive pricing. The cost of labor and manufacturing in China is generally lower compared to other countries, resulting in more affordable prices for their products. This affordability allows you to maximize your profit margins while offering a competitive price range to your customers.

When engaging with Chinese manufacturers, it is crucial to conduct thorough research and due diligence. Assess their track record, reputation, and certifications to ensure that they meet the necessary quality standards. Communicate clearly with the manufacturer about your private labeling and branding requirements to avoid any misunderstandings.

In conclusion, partnering with Chinese bending machine manufacturers for private labeling and branding opportunities can be highly advantageous. With their wide product range, customization options, competitive pricing, and manufacturing expertise, you can confidently establish your own unique identity in the market.

Tips for Procurement and Considerations when Purchasing bending machine for sale

When purchasing a bending machine for sale, there are several important considerations that you should keep in mind to ensure that you make a wise investment. Here are some tips and factors to consider when procuring a bending machine:

1. Determine your specific bending needs: Assess your requirements and understand the types of materials, shapes, and thicknesses you will be working with. This will help you choose a bending machine that is suitable for your applications.

2. Quality and durability: Look for a bending machine that is made of high-quality materials and built to last. Check the reputation and history of the manufacturer to ensure that they produce reliable and durable machines.

3. Ease of use: Consider the level of expertise required to operate the bending machine. Look for features like an intuitive user interface, clear instructions, and easy adjustments. This will reduce the learning curve and optimize productivity.

4. Flexibility and versatility: Ensure that the bending machine can handle a variety of bending tasks, including different angles and radii. Look for adjustable settings and tooling options that offer versatility in your bending operations.

5. Accuracy and precision: The bending machine should be capable of producing accurate and consistent bends. Look for machines that have precise controls and indicators to ensure that you achieve the desired bending angles and dimensions.

6. Maintenance and support: Consider the availability of spare parts, technical support, and maintenance requirements for the bending machine. Opt for manufacturers that offer good customer support and have a reliable supply chain for spare parts.

7. Safety features: Prioritize machines with proper safety guards, emergency stop buttons, and other safety mechanisms. Ensure that the bending machine complies with safety standards and regulations to minimize the risk of accidents.

8. Price and value for money: Compare prices from different manufacturers and suppliers, but avoid sacrificing quality for a lower price. Balance the initial investment cost with the machine’s features, warranty, durability, and reputation to ensure value for money.

9. User reviews and recommendations: Read customer reviews and seek recommendations from professionals who have experience with the particular bending machine you are interested in. Their insights can provide useful information about the machine’s performance, reliability, and overall satisfaction.

10. Warranty and after-sales service: Check the warranty period provided by the manufacturer and the after-sales support they offer. A comprehensive warranty and reliable service can give you peace of mind in case of any issues or repairs.

By considering these tips and factors, you can make an informed decision when purchasing a bending machine for sale that is well-suited to your needs, reliable, and durable.

FAQs on Sourcing and Manufacturing bending machine for sale in China

1. What types of bending machines are available for sale in China?

China offers a wide range of bending machines for sale, including hydraulic press brakes, CNC press brakes, tube and pipe bending machines, plate bending rolls, and profile bending machines.

2. How can I find reliable bending machine manufacturers in China?

To source reliable manufacturers, one can start by conducting online research, exploring industrial directories, and attending trade shows in China. Additionally, seeking recommendations from industry experts and utilizing professional sourcing services can help identify trustworthy manufacturers.

3. What factors should I consider when choosing a bending machine manufacturer in China?

When selecting a manufacturer, important factors include their experience and reputation in the industry, certifications and quality control measures, technical capabilities and customization options, after-sales service and support, and their ability to meet specific requirements such as production capacity, delivery time, and price considerations.

4. How can I ensure the quality of the bending machine manufactured in China?

To ensure quality, it is essential to work with manufacturers who have established quality control processes in place. Conducting factory audits, requesting product samples, or visiting them in person can help evaluate the manufacturer’s production facilities and quality standards.

5. What are the typical lead times for manufacturing bending machines in China?

Lead times can vary depending on the type and complexity of the bending machine, as well as the manufacturer’s production capacity and current workload. It is advisable to discuss lead times directly with potential manufacturers, taking into account factors such as customization requirements and shipping timeframes.

6. Can I request customizations or modifications to the bending machine design in China?

Yes, many manufacturers in China offer customization options to meet specific requirements. It is important to communicate your customization needs clearly and confirm that the manufacturer has the technical capabilities to accommodate those modifications.

7. How can I arrange shipping and logistics for the purchased bending machine from China?

Most manufacturers in China offer assistance in arranging shipping and logistics, including packaging, documentation, and delivery to the desired destination. It is recommended to discuss shipping arrangements, costs, and insurance coverage with the manufacturer or a trusted freight forwarder.

8. What are the payment terms usually accepted by bending machine manufacturers in China?

Manufacturers in China often accept payment terms such as T/T (telegraphic transfer) or L/C (letter of credit). It is important to establish clear payment terms and conditions with the manufacturer and ensure that they are in agreement with your company’s financial policies.

9. Are there any warranty and after-sales support provided by bending machine manufacturers in China?

Most reputable bending machine manufacturers in China offer warranties and after-sales support. The duration and coverage of warranties may vary, so it is advisable to discuss this with the manufacturer beforehand and understand the terms of warranty, technical support, and spare parts availability.

10. How can I minimize the risks associated with sourcing and manufacturing bending machines in China?

To minimize risks, it is recommended to conduct thorough due diligence on potential manufacturers, establish clear communication channels, request and review samples or prototypes, and consider using legal contracts and quality control inspections during the manufacturing process. Collaborating with sourcing agents or consultants with expertise in Chinese manufacturing can also help mitigate risks and ensure a successful sourcing experience.

Why contact sourcifychina.com get free quota from reliable bending machine for sale suppliers?

Sourcifychina.com may receive a free quota from reliable bending machine for sale suppliers for several reasons. Firstly, by offering a free quota, suppliers can attract potential customers and generate leads. By partnering with Sourcifychina.com, suppliers can expand their customer base and increase the chances of making sales. Secondly, providing a free quota allows suppliers to showcase their products and services to a wider audience. It serves as a marketing tool to highlight the quality, features, and competitive pricing of their bending machines, attracting customers who may be interested in purchasing such equipment. Additionally, offering a free quota enables suppliers to establish a relationship with Sourcifychina.com and potentially collaborate on future business endeavors. This partnership can lead to mutual benefits and a long-term, productive relationship. Moreover, the free quota serves as an opportunity for suppliers to gauge the demand and interest for their bending machines in the market. By receiving inquiries and requests for quotes, suppliers can gain insights into the potential market size and tailor their strategies accordingly. Ultimately, providing a free quota is a strategic move by suppliers to gain visibility, attract customers, build relationships, and gather market intelligence, all of which contribute to their overall business growth and success.