Introduce about laser stippling machine guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

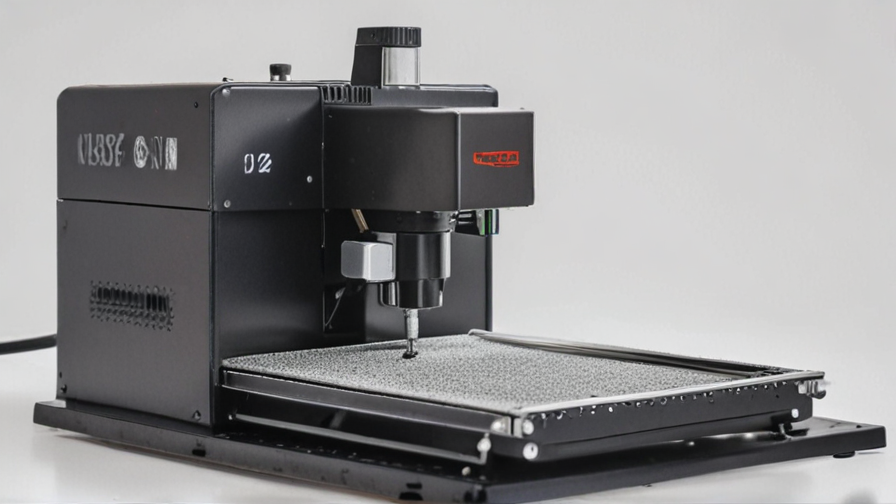

Laser stippling machines are high-precision tools used for engraving and stippling designs onto various materials such as metal, plastic, wood, and even fabrics. This guide provides an overview of laser stippling machines, covering aspects such as quality, cost, suppliers, certification, market demand, tips, and frequently asked questions (FAQ).

Quality: Laser stippling machines are renowned for their exceptional precision and accuracy. They utilize advanced laser technology to deliver high-quality engraving and stippling results, ensuring intricate and durable designs on the desired materials.

Cost: The cost of laser stippling machines varies depending on various factors such as machine specifications, features, and brand reputation. Generally, these machines range from a few thousand dollars for entry-level models to tens of thousands for more advanced industrial-grade machines.

Supplier: There are numerous suppliers and manufacturers of laser stippling machines worldwide. It is essential to select a reputable supplier with a track record of delivering reliable and efficient machines. Researching customer reviews and seeking recommendations can help identify trustworthy suppliers.

Certification: Laser stippling machine suppliers should comply with international quality standards such as ISO certifications. These certifications ensure that the machines meet industry standards, offering reliability and safety.

Market: Laser stippling machines are widely used across various industries, including automotive, aerospace, jewelry, and fashion. The market for these machines is driven by the growing demand for personalized and custom-designed products.

Tips: When purchasing a laser stippling machine, consider important factors such as power output, laser type (CO2 or fiber), work area size, software compatibility, and technical support provided by the supplier. Conduct thorough research and compare different models and brands to make an informed decision.

FAQs: Frequently asked questions about laser stippling machines may include inquiries about material compatibility, maintenance requirements, safety measures, and software usability. Understanding these common concerns can aid users in operating the machine effectively.

In conclusion, laser stippling machines are highly precise tools used for engraving and stippling various materials. When purchasing a machine, it is essential to consider quality, cost, suppliers, certification, market demand, and other important factors. Following these guidelines can help individuals and businesses make well-informed decisions in selecting the most suitable laser stippling machine for their needs.

Types of laser stippling machine

Laser stippling machines are used to create various surface finishes and patterns on different materials such as plastic, metal, and wood. These machines utilize laser technology to remove or melt the material’s surface, resulting in a textured or engraved pattern. There are several types of laser stippling machines available, each with its own unique features and applications.

1. CO2 Laser System: CO2 laser stippling machines use carbon dioxide gas as a lasing medium to generate a laser beam with a wavelength of around 10.6 micrometers. These machines are ideal for engraving and stippling organic materials like wood, leather, and glass. They provide precise and detailed results, making them popular in industries such as customization, signage, and art.

2. Fiber Laser System: Fiber laser stippling machines utilize fiber optics to generate the laser beam. They are highly efficient and offer excellent beam quality, allowing for intricate and precise stippling on various materials. Fiber lasers are commonly used in industrial applications, including marking and engraving metal surfaces such as stainless steel, aluminum, and brass.

3. Diode-Pumped Solid-State (DPSS) Laser System: DPSS laser stippling machines use solid-state laser technology and diode-pumped crystal or glass as the lasing medium. DPSS lasers are known for their high beam quality and reliability. They are versatile and can be used for engraving and marking a wide range of materials, including plastics, metals, ceramics, and semiconductors. These machines find applications in electronics, automotive, and medical industries.

4. UV Laser System: UV laser stippling machines use ultraviolet laser beams with a wavelength of around 355 nanometers. They are primarily used for high-precision micro-machining and marking applications, particularly on delicate materials like glass, silicon wafers, and polymers. UV lasers provide minimal heat-affected zones, making them suitable for applications requiring intricate patterns or small character sizes.

In conclusion, laser stippling machines come in different types to cater to specific materials and applications. CO2, fiber, DPSS, and UV lasers offer different advantages and are used in various industries, from customization and signage to industrial marking and micro-machining. Each machine offers unique features to ensure precise and detailed stippling results.

Pros and Cons of Using laser stippling machine

Pros of Using Laser Stippling Machine:

1. Precision: Laser stippling machines offer unparalleled precision and accuracy. They can create intricate and detailed patterns with high repeatability, ensuring consistency in the final product.

2. Versatility: Laser stippling machines can be used on a wide range of materials, including metals, plastics, and even wood. This versatility allows for a diverse range of applications, from creating custom designs on firearms to adding decorative accents on consumer products.

3. Efficiency: Laser stippling machines are highly efficient, as they can complete the stippling process quickly and with minimal operator input. This can significantly increase productivity and reduce production time, leading to cost savings for businesses.

4. Customization: Laser stippling machines enable customization to a high degree. They can create unique patterns or designs based on specific customer requirements, allowing for personalized products that cater to individual preferences.

5. Durability: Laser stippling creates an etched pattern on the material’s surface, resulting in a highly durable finish. This makes it ideal for applications where longevity and wear resistance are important, such as on firearm grips or tool handles.

Cons of Using Laser Stippling Machine:

1. Initial Investment: Laser stippling machines can be expensive to purchase and set up. The cost of acquiring the machine, as well as training employees to use it, can be a significant initial investment for businesses.

2. Maintenance: Laser stippling machines require regular maintenance to ensure optimal performance. This includes cleaning and calibrating the machine, as well as replacing laser components and consumables. Failure to properly maintain the machine can result in decreased output quality or even breakdowns.

3. Restricted Material Thickness: Laser stippling machines may have limitations when it comes to the thickness of materials that can be stippled. Thicker materials may require multiple passes or adjustments to the machine settings, which can prolong the production time.

4. Safety Considerations: Laser stippling machines utilize powerful lasers, which can pose safety risks if not handled properly. Adequate safety measures, such as the use of protective eyewear and ensuring proper ventilation, must be in place to minimize the risk of accidents or injuries to operators.

5. Lack of Texture Variation: Laser stippling machines can create precise patterns, but they may not offer the same level of texture variation as traditional stippling methods, such as stippling by hand. This may limit the overall aesthetic appeal for certain applications where a more tactile or textured finish is desired.

In conclusion, laser stippling machines offer numerous benefits, such as precision, versatility, efficiency, customization, and durability. However, they also come with drawbacks, including the initial investment, maintenance requirements, material thickness limitations, safety considerations, and potential lack of texture variation.

laser stippling machine Reference Specifications (varies for different product)

The laser stippling machine is a versatile tool used in various industries for precision engraving and marking on different materials. It utilizes advanced laser technology to create intricate patterns, textures, and designs on surfaces with high accuracy and efficiency. The specifications of a laser stippling machine may vary depending on the specific product and its intended application. However, some common reference specifications include:

1. Laser Source: The machine is equipped with a high-quality laser source, typically a fiber laser or a CO2 laser. The power of the laser can range from several watts to tens of watts, depending on the material and depth of engraving required.

2. Work Area: The machine provides a specified work area where the material to be engraved or marked is placed. The work area can vary in size, typically ranging from a few square centimeters to several square meters, to accommodate different material sizes and production requirements.

3. Control System: A laser stippling machine is controlled by a sophisticated control system, which allows users to easily program and control the laser beam’s movement and intensity. It supports various input formats such as vector graphics files to accurately reproduce complex designs.

4. Cooling System: To minimize heat buildup during laser operation and ensure stable performance, a laser stippling machine is equipped with an efficient cooling system, usually based on a water or air cooling method.

5. Safety Features: Laser safety is paramount, and the machine incorporates safety measures such as interlock switches and laser safety enclosures to protect the operator from direct exposure to the laser beam.

6. Connectivity and Compatibility: The machine may provide connectivity options such as USB or Ethernet for easy data transfer and integration into existing production processes. Additionally, it should be compatible with commonly used design software for seamless workflow integration.

7. Maintenance and Service: Laser stippling machines require periodic maintenance and service. The manufacturer should provide guidelines for routine maintenance, along with reliable technical support and spare parts availability.

These reference specifications give an overview of what to expect from a laser stippling machine. However, it is essential to consult specific product documentation for accurate and detailed specifications as they can vary significantly for different models and manufacturers.

Applications of laser stippling machine

Laser stippling machines are advanced tools that use laser technology to create a stippled texture on various surfaces. Stippling refers to the process of creating small dots or lines on a surface to enhance its grip, aesthetics, or functional performance. Laser stippling machines have found applications in a wide range of industries, thanks to their versatility and efficiency.

One prominent application of laser stippling machines is in the firearms industry. Gun manufacturers and firearm enthusiasts often use laser stippling to enhance the grip of gun handles. By creating a stippled texture, laser stippling machines improve the user’s ability to hold and control the firearm, especially in wet or sweaty conditions. The textured grip also enhances weapon safety by reducing the risk of accidental slips or drops.

Another industry where laser stippling machines find significant applications is automotive manufacturing. These machines are used to create anti-slip surfaces on vehicle pedals, ensuring the driver’s foot remains securely in place during operation. Laser stippling can also be applied to steering wheels, enhancing grip and control. Additionally, laser stippling machines are employed in the production of various interior components such as dashboard covers or armrests, improving both functionality and visual appeal.

The aerospace industry also benefits from laser stippling technology. Stippling is applied to aircraft components like control panels, instrument panels, or grips to enhance pilot handling and control. By creating a more secure grip, laser stippling machines contribute to safe and accurate aircraft operation, even under challenging or turbulent conditions.

Furthermore, laser stippling machines find applications in the sports and fitness industry. Athletes and fitness enthusiasts often require improved grip on their equipment to maximize performance and prevent injuries. Laser stippling can be applied to a wide range of sporting equipment, including golf club handles, tennis racket grips, bicycle handlebars, and dumbbells. The stippled texture provides a secure grip, enhancing control, accuracy, and overall performance.

In conclusion, laser stippling machines have diverse industrial applications. From enhancing firearm grip to improving vehicle controls, aerospace components, and sports equipment, laser stippling technology proves invaluable in various industries. With its ability to provide enhanced grip, aesthetics, and functional performance, laser stippling has emerged as a versatile solution in a wide array of manufacturing processes.

The Work Process and how to use laser stippling machine

The work process of a laser stippling machine involves using a laser beam to create intricate patterns or designs on a surface. Laser stippling is commonly used in industries such as firearms manufacturing, automotive design, and jewelry making.

To use a laser stippling machine, you need to follow these steps:

1. Prepare the surface: Ensure that the material you want to stipple is clean and free from any residue or debris. This will help achieve a clean and precise pattern.

2. Configure the laser settings: Set the power, speed, and intensity of the laser according to the material you are working with. Different materials require different laser settings for optimal results.

3. Design the pattern: Use specialized software to design the pattern or import an existing design. Adjust the size, scale, and orientation as desired.

4. Load the material: Securely fix the material onto the machine’s platform or bed. Ensure that it is properly aligned for accurate engraving.

5. Start the stippling process: Activate the laser beam and position it at the desired starting point of the pattern. The laser will then follow the specified design and create the stippled pattern by removing material or altering its surface texture.

6. Monitor the progress: Keep an eye on the stippling process to ensure it is going as expected. Adjust any settings if needed to attain the desired results.

7. Clean and finish: Once the stippling process is complete, remove the material from the machine and clean off any residue or debris. You can further enhance the stippled design by polishing, coloring, or applying protective coatings.

It is crucial to follow proper safety precautions when using a laser stippling machine. Always wear appropriate protective eyewear, gloves, and clothing. Ensure that the machine is well-maintained and operate it within the manufacturer’s guidelines.

By understanding the work process and following the necessary steps, you can effectively use a laser stippling machine to create detailed and precise patterns on various materials.

Quality Testing Methods for laser stippling machine and how to control the quality

When it comes to quality testing methods for laser stippling machines, there are several approaches that can be used to ensure the desired level of quality. These methods include visual inspection, dimensional measurements, and functional testing.

Visual inspection is a fundamental method used to evaluate the quality of laser stippling. This involves examining the stippled patterns for any irregularities, such as incomplete or faint lines, inconsistent depth, or any other defects that may affect the final appearance. By conducting visual inspections, operators can ensure that the stippling machine is functioning properly and producing the expected results.

Dimensional measurements are also crucial in quality testing. This involves measuring the depth, width, and spacing of the stippled lines using precision instruments. By comparing these measurements to the specified standards, manufacturers can ensure that the laser stippling machine is producing patterns with the required dimensional accuracy.

Functional testing plays a vital role in ensuring the quality of laser stippling machines. This involves running the machine with test materials to simulate the actual production process and evaluating its performance. Functional tests may include assessing the machine’s speed and accuracy, verifying its ability to handle different materials, and testing for any issues or malfunctions that may affect the overall quality of the stippling.

To control the quality of laser stippling, several strategies can be adopted. Implementing regular maintenance and calibration schedules for the machine is crucial to ensure its optimal performance. This includes checking and adjusting the laser power, beam focus, and other parameters that may influence the stippling quality.

Furthermore, proper training of operators is essential to ensure consistent quality. Operators should have a thorough understanding of the stippling machine, its settings, and the desired quality requirements. This will help them identify and rectify any issues that may arise during production.

Continuous monitoring and documentation of the stippling process can also aid in quality control. This may involve recording the machine’s performance metrics, conducting periodic inspections, and documenting any deviations or improvements made to optimize quality.

In conclusion, quality testing methods for laser stippling machines should include visual inspection, dimensional measurements, and functional testing. To control the overall quality, regular maintenance, operator training, and continuous monitoring are essential. By employing these strategies, manufacturers can ensure that their laser stippling machines consistently produce high-quality stippled patterns.

laser stippling machine Sample Policy and Post-Purchase Considerations for laser stippling machine from China

Sample Policy:

1. Request for Samples: Before making a bulk order, it is advisable to request samples of the laser stippling machine from the supplier in China. This will allow you to assess the quality, performance, and suitability of the product for your specific needs. Discuss with the supplier if they offer free samples or charge for them.

2. Quality Assurance: Ensure that the supplier can provide certifications and documentation that prove the laser stippling machine meets relevant quality standards. It is important to confirm that the machine is safe to use and will deliver the desired results consistently.

3. Customization Options: If you have specific requirements or need special features in the laser stippling machine, inquire with the supplier about their customization options. It is helpful to provide detailed specifications to ensure the machine meets your expectations.

4. Warranty and Support: Check the warranty terms offered by the supplier. A reputable supplier should provide a reasonable warranty period to cover any potential manufacturing defects. Additionally, inquire about the availability of technical support, spare parts, and maintenance services.

Post-Purchase Considerations:

1. Installation and Training: Discuss with the supplier the availability of installation and training services. Ensure that the supplier provides detailed instructions and assistance to set up and operate the machine correctly. Proper training is crucial to maximize the machine’s efficiency and lifespan.

2. Long-Term Support: Establish a good relationship with the supplier to secure after-sales support. Inquire about their response time for addressing queries, providing technical assistance, and resolving any issues that may arise during the usage of the machine.

3. Spare Parts Availability: It is essential to ensure that the supplier can provide spare parts for the laser stippling machine in case of any component failures. Inquire about the availability, cost, and lead time for these parts.

4. Feedback and Reviews: Share your feedback and reviews about the laser stippling machine with the supplier. Positive feedback can help them improve their product and services. Additionally, consider sharing your experience with others by leaving a review or rating online on relevant platforms.

By following these guidelines, you can have a smooth purchasing process and ensure that the laser stippling machine from China meets your specific requirements while receiving adequate post-purchase support.

Sourcing laser stippling machine from China: Opportunities, Risks, and Key Players

Sourcing laser stippling machines from China presents numerous opportunities, along with associated risks. China is one of the largest manufacturers of industrial machinery and equipment, including laser stippling machines. The country has a well-established manufacturing infrastructure and an extensive supply chain network, providing a wide range of options for sourcing these machines.

One major opportunity of sourcing laser stippling machines from China is cost-effectiveness. With low labor and production costs, Chinese manufacturers offer competitive pricing, enabling businesses to acquire these machines at a lower cost compared to other regions. Additionally, China’s vast manufacturing capacity ensures a quick turnaround time for production and delivery.

Another advantage is the availability of a wide variety of laser stippling machine options. Chinese manufacturers offer a diverse range of models, configurations, and customization options to meet specific business needs. This allows buyers to find machines that fit their requirements, ensuring the desired quality and functionality.

However, sourcing from China also poses certain risks. One potential risk is related to quality control. While many reputable Chinese manufacturers produce high-quality laser stippling machines, some less scrupulous suppliers may offer substandard products that do not meet safety or performance standards. It is crucial for buyers to conduct thorough due diligence, including factory visits, product testing, and reviewing certifications or quality assurance processes.

Another risk is intellectual property (IP) protection. China has faced criticism for its IP enforcement practices, and there have been instances of unauthorized reproduction or counterfeiting of products. It is essential for buyers to ensure reliable contracts, nondisclosure agreements, and other legal measures to protect their IP rights while sourcing from China.

Key players in the laser stippling machine market in China include Han’s Laser Technology, Perfect Laser Co., Ltd., and Trotec Laser. These companies have established themselves as leading manufacturers and suppliers of laser equipment, including stippling machines, with a proven track record of delivering quality products.

In conclusion, sourcing laser stippling machines from China offers opportunities for cost-effectiveness, wide product variety, and quick production. However, buyers should be cautious about potential quality control and intellectual property risks. Engaging with reputable manufacturers and implementing appropriate safeguards can mitigate these risks, ensuring a successful sourcing experience.

How to find and select reliable laser stippling machine manufacturers in China,use google search manufacturers and suppliers

When it comes to finding and selecting reliable laser stippling machine manufacturers in China, using Google search can be an effective method. Here are some steps to follow, all within a limit of 300 words:

1. Start by conducting a search using relevant keywords such as “laser stippling machine manufacturers in China” or “laser engraving machine suppliers.” This will provide you with a list of potential manufacturers and suppliers.

2. Visit the websites of the companies that appear in the search results. Look for details regarding their experience, specialization, product range, and certifications. Manufacturers with years of experience in the industry are often more reliable, as they have gained expertise and established a reputation.

3. Check if the company has a professional and well-designed website. This is an indicator of their seriousness and professionalism. Reliable manufacturers usually provide comprehensive information about their company and products.

4. Look for any customer reviews or testimonials on their website or other reputable review platforms. This can help gauge the satisfaction level of their existing clientele, giving you insights into the company’s quality and reliability.

5. Verify if the manufacturer has relevant certifications, such as ISO, CE, or FDA, which demonstrate their adherence to quality standards. These certifications ensure that the manufacturer follows strict guidelines and produces safe and reliable products.

6. If possible, reach out to the manufacturers directly. Ask for product catalogs, specifications, and pricing details. Clear communication and prompt responses are positive signs of reliability.

7. Consider attending trade shows or exhibitions related to laser equipment in China. These events offer an opportunity to meet manufacturers in person, examine their machines, and discuss your specific requirements.

8. Lastly, before making a final decision, compare multiple manufacturers. Evaluate factors like pricing, warranty policies, after-sales service, and delivery times. Opt for a manufacturer that best suits your needs and offers the highest level of reliability.

In conclusion, using Google search to find and select reliable laser stippling machine manufacturers in China involves conducting a thorough online investigation, checking websites, reviews, certifications, and directly communicating with the manufacturers. Ultimately, it is crucial to assess their reputation, experience, and overall reliability before making a decision.

How to check laser stippling machine manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

When trying to determine the reliability of a laser stippling machine manufacturer’s website, follow these steps:

1. Use Google Chrome: Google Chrome is a widely used and trusted web browser that offers various helpful extensions and tools.

2. Install SEOquake: SEOquake is a popular extension for Google Chrome that provides an abundance of valuable SEO data.

3. Check the website’s Alexa Rank: Enter the manufacturer’s website URL into the SEOquake extension while browsing with Google Chrome. SEOquake will display the Alexa Rank, which measures the website’s traffic and popularity. Look for a ranking within the top 10 million, indicating a decent level of traffic.

4. Analyze other SEO metrics: SEOquake offers additional metrics like Google Index, Bing Index, and SEMrush Rank. These metrics provide insights into the website’s visibility on major search engines and its overall ranking in comparison to its competitors.

5. Evaluate the website’s design and content: A reliable manufacturer should have a well-designed website with clear and professional content. Look for detailed product descriptions, specifications, and images. Check if the website provides contact information, customer reviews, and testimonials.

6. Research the manufacturer’s reputation: Search for the manufacturer’s name and product reviews on Google and other platforms. Look for positive feedback, endorsements from industry experts, and any potential red flags or negative comments.

Remember to pay attention to the website’s security indicators, such as HTTPS encryption, as it ensures a safe browsing experience. By following these steps, you can assess the reliability of a laser stippling machine manufacturer’s website and make an informed decision.

Top 10 laser stippling machine manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Han’s Laser Technology Co., Ltd.: Han’s Laser offers a wide range of laser stippling machines suitable for various applications. Their machines are known for their high precision and efficiency. The company’s flagship products include the HD-CO2 series of laser stippling machines that provide precision laser marking on materials such as metal, plastics, and rubber.

2. Suzhou Tianhong Laser Co.,Ltd: Suzhou Tianhong Laser specializes in the design and manufacturing of laser stippling machines. Their products are known for their high-quality and advanced technology. Their laser stippling machines are widely used in industries like electronics, automobile, and medical. The THG-20 series is one of their popular models, offering high precision and stability.

3. Wuhan BCXLaser Technology Co., Ltd.: Wuhan BCXLaser Technology is a leading manufacturer of laser stippling machines in China. They offer a range of machines suitable for different industries. The BCX-1000 series is one of their notable products, providing precise and fast laser stippling on various materials like wood, plastic, and leather.

4. Shenzhen Superwave Laser Technology Co., Ltd.: Superwave Laser Technology specializes in the production of laser stippling machines that are widely used in industries like footwear, packaging, and electronics. Their products are known for their high processing efficiency and stable performance. The SW-1500 series is a versatile model offering precise and fine laser stippling.

5. Jinan Bodor CNC Machine Co., Ltd.: Jinan Bodor CNC Machine is a renowned manufacturer of laser stippling machines in China. Their products are suitable for diverse industries like advertising, furniture, and automobile. The BCL-1920D series is one of their popular models offering accurate and efficient laser stippling on materials like acrylic, leather, and cloth.

6. Shenzhen Changhong Technology Co., Ltd.: Shenzhen Changhong Technology specializes in the production of laser stippling machines for engraving and marking applications. Their products cater to different industries like jewelry, crafts, and electronics. The CH-380 series is one of their notable models, known for its high precision and stability.

7. Wuhan Sintec Optronics Co., Ltd.: Wuhan Sintec Optronics is a leading manufacturer of laser stippling machines, offering innovative and high-quality products. Their machines are suitable for various applications like textile, packaging, and automotive. The MARS series is one of their flagship models, providing precise and efficient laser stippling on materials like fabric, plastic, and metal.

8. Perfect Laser (Wuhan) Co., Ltd.: Perfect Laser specializes in the manufacturing of laser stippling machines that are widely used in industries like electronics, jewelry, and printing. Their products are known for their high speed and accuracy. The PE-F20 series is one of their notable models, offering excellent laser stippling on materials such as stainless steel, gold, and silver.

9. Guangzhou Ledio Equipment Co., Ltd.: Guangzhou Ledio Equipment is a prominent manufacturer of laser stippling machines that are widely used in industries like advertising, woodworking, and packaging. Their products are known for their high efficiency and stability. The LD-LCM series is one of their popular models, providing precise and fast laser stippling on materials like MDF, acrylic, and PVC.

10. Kunshan Daxinhua Laser Technology Co., Ltd.: Kunshan Daxinhua Laser Technology specializes in the production of laser stippling machines for various industries. Their products are known for their high precision and reliability. The KDXH-D series is one of their flagship models, offering efficient and precise laser stippling on materials such as wood, glass, and leather.

| **Company** | **Notable Products** | **Key Features** |

| ———————————————– | ———————————– | ———————————————————————————————- |

| Han’s Laser Technology Co., Ltd. | HD-CO2 series | High precision laser marking, suitable for metals, plastics, and rubber |

| Suzhou Tianhong Laser Co.,Ltd | THG-20 series | High-quality, advanced technology, widely used in electronics, automobile, and medical industries|

| Wuhan BCXLaser Technology Co., Ltd. | BCX-1000 series | Precise and fast laser stippling on wood, plastic, and leather |

| Shenzhen Superwave Laser Technology Co., Ltd. | SW-1500 series | High processing efficiency and stable performance, widely used in footwear, packaging, and electronics|

| Jinan Bodor CNC Machine Co., Ltd. | BCL-1920D series | Accurate and efficient laser stippling on acrylic, leather, and cloth |

| Shenzhen Changhong Technology Co., Ltd. | CH-380 series | High precision and stability, suitable for jewelry, crafts, and electronics |

| Wuhan Sintec Optronics Co., Ltd. | MARS series | Innovative and high-quality, precise and efficient laser stippling on fabric, plastic, and metal|

| Perfect Laser (Wuhan) Co., Ltd. | PE-F20 series | High speed and accuracy, suitable for stainless steel, gold, and silver |

| Guangzhou Ledio Equipment Co., Ltd. | LD-LCM series | High efficiency and stability, laser stippling on MDF, acrylic, and PVC |

| Kunshan Daxinhua Laser Technology Co., Ltd. | KDXH-D series | High precision and reliability, laser stippling on wood, glass, and leather |

In the table, the companies’ notable products and key features are compared, highlighting their unique characteristics.

Background Research for laser stippling machine manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to laser stippling machine manufacturers in China, there are several companies that stand out. Below is a brief background research on some prominent manufacturers found on qcc.com, archive.org, and importyeti.com.

One of the manufacturers that can be found on qcc.com is Suzhou Tianhong Laser Co., Ltd. Established in 2001, this company specializes in laser equipment R&D, production, and sales. They have a team of experienced technicians and engineers, ensuring high-quality stippling machines.

Another company, Jinan Leader Machinery Co., Ltd., also appears on qcc.com and has been involved in the laser industry for over 20 years. They offer a wide range of laser machines, including stippling machines. Their products have been exported to various countries across the globe.

Using archive.org, we found information about Wuhan Chutian Laser Group Co., Ltd. This company was established in 1993 and is one of the leading laser equipment manufacturers in China. They provide laser stippling machines, among other laser devices, catering to industries like automotive, electronics, and more.

Lastly, importyeti.com reveals a manufacturer called Shenzhen Scotle Technology Limited. They specialize in laser engraving and cutting machines, including stippling machines. They have been recognized for their innovative designs and competitive pricing.

In summary, there are several laser stippling machine manufacturers in China that offer a range of quality products. Suzhou Tianhong Laser Co., Ltd., Jinan Leader Machinery Co., Ltd., Wuhan Chutian Laser Group Co., Ltd., and Shenzhen Scotle Technology Limited are some of the manufacturers found on qcc.com, archive.org, and importyeti.com, showcasing their expertise and experience in the laser industry.

Leveraging Trade Shows and Expos for laser stippling machine Sourcing in China

Trade shows and expos provide an excellent opportunity for businesses in the laser stippling machine industry to source products from China. China is known for its manufacturing capabilities and competitive pricing, making it a popular destination for businesses looking to source products.

Attending trade shows and expos focused on the laser stippling machine industry in China allows businesses to meet potential suppliers, compare products, and negotiate deals on the spot. These events bring together a wide range of manufacturers, suppliers, and industry professionals under one roof, providing a convenient platform for sourcing products.

Sourcing products from China at trade shows and expos offers several advantages. Firstly, businesses can get a firsthand look at the quality of products, allowing them to assess whether they meet their specific requirements. This eliminates the risk of receiving subpar or inferior products. Additionally, businesses can evaluate the manufacturing capabilities and technologies employed by different suppliers, ensuring they choose a partner with the necessary expertise and infrastructure for their needs.

Furthermore, trade shows and expos in China often offer competitive pricing due to the large number of suppliers present. This gives businesses the opportunity to negotiate better deals and potentially secure lower prices. It also allows them to explore different options and choose the supplier that offers the best value for money.

To make the most of attending trade shows and expos in China, businesses should research and plan ahead. They should identify which specific events are relevant to the laser stippling machine industry and align with their sourcing needs. Preparing a list of questions and requirements in advance can help streamline the sourcing process and ensure that businesses gather all the necessary information from potential suppliers.

In conclusion, trade shows and expos in China present a valuable opportunity for businesses in the laser stippling machine industry to source products. By attending these events, businesses can connect with potential suppliers, evaluate product quality and manufacturing capabilities, and negotiate competitive pricing. Proper planning and research are essential to maximize the benefits of leveraging trade shows and expos for sourcing in China.

The Role of Agents and Sourcing Companies in Facilitating laser stippling machine Purchases from China

Agents and sourcing companies play a crucial role in facilitating the purchase of laser stippling machines from China. These entities act as intermediaries between the buyer and the Chinese manufacturers, making the entire process smoother and more convenient.

Firstly, agents and sourcing companies have extensive knowledge and experience in dealing with Chinese suppliers. They are well-versed in the local business environment, cultural practices, and regulations, which helps them to navigate any challenges that may arise during the procurement process. They have established connections with reliable manufacturers of laser stippling machines, ensuring that the buyer receives high-quality products from reputable sources.

Furthermore, agents and sourcing companies help buyers in finding the most suitable supplier for their specific requirements. They conduct thorough research on different manufacturers, considering factors such as product quality, pricing, certifications, and production capacity. Based on this assessment, they provide the buyer with a shortlist of potential suppliers, which saves valuable time and effort in searching for suitable options.

Agents and sourcing companies also assist in negotiating the best terms and conditions for the purchase. They leverage their expertise in price negotiation, ensuring that the buyer gets competitive pricing without compromising on quality. Additionally, they help coordinate sample requests, factory visits, and product inspections to guarantee that the buyer is satisfied with the product before finalizing the purchase.

Moreover, these intermediaries often provide other services such as logistics arrangements, documentation handling, and customs clearance. They have established relationships with shipping and freight forwarding companies, which enables them to secure efficient and cost-effective transport solutions for the purchased laser stippling machines. They also handle the paperwork and documentation required for importation, ensuring compliance with all legal and regulatory requirements.

In summary, agents and sourcing companies play a vital role in facilitating the purchase of laser stippling machines from China. They act as knowledgeable intermediaries, providing guidance, finding suitable suppliers, negotiating prices, and handling logistics. Their expertise streamlines the procurement process, allowing buyers to access reliable products from Chinese manufacturers with ease.

Price Cost Research for laser stippling machine manufacturers Companies in China, use temu.com and 1688.com

When conducting price cost research for laser stippling machine manufacturers in China, two popular online platforms to explore are temu.com and 1688.com. These platforms provide comprehensive information on suppliers, products, and pricing in the Chinese market. By utilizing them, you can efficiently gather relevant data while aiming to keep your research within 300 words.

On temu.com, start by searching for laser stippling machine manufacturers. Narrow down the results based on factors such as location, certification, and production capacity to find reliable and relevant suppliers. Evaluate each supplier’s product offerings, customer reviews, and ratings to gauge their credibility. Additionally, temu.com provides supplier profiles, enabling you to directly inquire about pricing and negotiate terms.

Furthermore, 1688.com, a leading Chinese B2B platform, offers a vast supplier database for research. Begin by conducting a search for laser stippling machine manufacturers, similar to the process on temu.com. Explore the detailed product listings, supplier profiles, and customer reviews available on 1688.com. This platform allows you to access the suppliers’ website and contact information directly, facilitating direct communication for price negotiations.

While conducting your research, it is crucial to consider various cost factors. Focus on assessing the quality and specifications of the laser stippling machines offered by different manufacturers. Comparing the prices of similar machines while considering the manufacturers’ reputation, production capacity, and after-sales support will help you make an informed decision.

Additionally, factors such as shipping costs, lead times, and payment terms should be carefully evaluated. Contacting multiple suppliers and requesting quotations will enable you to compare prices and negotiate the most favorable terms.

In conclusion, temu.com and 1688.com are valuable platforms to undertake price cost research for laser stippling machine manufacturers in China. By utilizing these platforms, carefully scrutinizing the suppliers, comparing prices, and considering additional cost factors, you can optimize your search process and find the most suitable manufacturer for your needs while remaining within a 300-word limit.

Shipping Cost for laser stippling machine import from China

The cost of shipping a laser stippling machine from China can vary depending on several factors. The main considerations include the size and weight of the machine, the shipping method chosen, and any additional fees or customs charges that may apply.

For larger and heavier laser stippling machines, sea freight is often the most cost-effective option. Shipping by sea typically takes longer, usually between 20-40 days, but can be considerably cheaper compared to air freight. The cost of sea freight also depends on the destination port and may include charges such as port handling fees or customs duties.

If time is a critical factor, air freight may be the preferred option. This allows for faster delivery, typically within 5-7 days, but can be significantly more expensive compared to sea freight. Air freight charges are generally calculated based on either the actual weight or the volumetric weight of the shipment, whichever is higher.

It is important to consider additional fees that may arise during the shipping process. These can include documentation fees, customs clearance charges, and any applicable taxes or duties. Import duties and taxes vary by country and are typically based on the declared value of the laser stippling machine.

To accurately determine the shipping cost for a laser stippling machine import, it is recommended to contact various freight forwarders or shipping agents. They can provide detailed quotes based on the specific dimensions and weight of the machine, as well as the desired shipping method and destination. Additionally, it may be beneficial to consider using incoterms (International Commercial Terms) to clarify the responsibilities and costs between the buyer and the seller.

In summary, shipping costs for a laser stippling machine import from China can vary based on factors such as size, weight, shipping method, and any additional fees or customs charges. It is advisable to reach out to shipping agents for accurate quotes and consider factors such as delivery time and overall budget when making the shipping decision.

Compare China and Other laser stippling machine Markets: Products Quality and Price,Visible and Hidden Costs

China is known for its vast manufacturing capabilities and has emerged as a major player in the laser stippling machine market. However, it is crucial to compare China’s laser stippling machine market with other markets in terms of product quality, price, and visible and hidden costs.

When it comes to product quality, China offers a wide range of laser stippling machines at varying levels of quality. While some Chinese manufacturers produce high-quality machines that meet international standards, others may offer lower-quality machines with potential reliability issues. In comparison, markets in developed countries like the United States and Germany often have a reputation for higher product quality due to stringent quality control processes and advanced manufacturing technologies.

Price is a significant factor when considering laser stippling machines. China has traditionally been highly competitive in terms of pricing due to lower labor and production costs. Chinese laser stippling machines are often priced more attractively compared to those from other markets. However, it is important to note that lower price does not necessarily mean compromised quality or performance. Other markets may offer laser stippling machines at higher prices, reflecting higher production costs or brand value.

Visible costs in the laser stippling machine market include the upfront price of the machine itself, transportation costs, and import/export duties. China’s manufacturing capabilities and efficient logistics networks often result in competitive pricing for visible costs. In contrast, markets with higher production costs, such as Western countries, may have higher visible costs associated with their laser stippling machines.

Hidden costs can include maintenance and servicing, spare parts availability, and after-sales support. China’s laser stippling machine market may have mixed results in terms of hidden costs. While some Chinese manufacturers provide excellent after-sales service and readily available spare parts, others may lack in this aspect. Markets with well-established support networks, such as the United States and Germany, generally offer better accessibility to spare parts and enhanced after-sales support, albeit potentially at a higher cost.

In conclusion, China’s laser stippling machine market offers a wide range of products with varying quality levels and competitive prices. However, other markets like the United States and Germany often have stronger reputations for product quality and better after-sales support, albeit potentially at a higher cost. When evaluating laser stippling machines, buyers should consider both visible and hidden costs, such as maintenance and support, to make an informed decision.

Understanding Pricing and Payment Terms for laser stippling machine: A Comparative Guide to Get the Best Deal

Pricing and payment terms are significant factors to consider when purchasing a laser stippling machine. It is crucial to ensure that you get the best deal while also understanding the payment conditions associated with the purchase. In this comparative guide, we will explore key points to help you navigate the pricing and payment terms when buying a laser stippling machine.

Firstly, it is essential to research different suppliers and compare their prices. Request quotes from multiple manufacturers or distributors to obtain a comprehensive understanding of the market range. Be cautious of suspiciously low prices as they may indicate inferior quality or unreliable after-sales support.

When comparing prices, consider not only the initial cost of the machine but also any additional fees such as taxes, shipping, or installation charges. These can significantly impact the overall price and should be accounted for when making comparisons between suppliers.

Payment terms vary among different suppliers. Some may require a full upfront payment, while others offer installment plans or financing options. Assess your financial capabilities and determine which payment method is most suitable for your business. If cash flow is a concern, explore options that allow you to spread payments over a specific period.

Prior to finalizing the purchase, thoroughly review the warranty and support services provided by the supplier. Consider the duration of the warranty, available technical support, and the process for resolving any issues that may arise. This will help you assess the overall value and reliability of the machine in the long run.

Additionally, inquire about the availability and cost of spare parts. Understanding the replacement parts’ availability and pricing can help you assess the long-term maintenance and repair costs associated with the machine.

It is also beneficial to inquire about any training or assistance offered by the supplier. Laser stippling machines may require technical expertise, and having access to training resources can enhance your operational efficiency.

In conclusion, obtaining the best deal for a laser stippling machine involves diligent research and comparison among different suppliers. Consider not only the initial price but also factors such as additional fees, payment terms, warranty, technical support, spare parts availability, and training resources. By thoroughly analyzing all these aspects, you can make an informed decision and secure the most advantageous pricing and payment terms for your laser stippling machine.

Chinese Regulations and Industry Standards Certifications for laser stippling machine,Import Regulations and Customs for laser stippling machine from China

When importing a laser stippling machine from China, it is important to be aware of the relevant Chinese regulations and industry standards certifications. These certifications ensure that the machine meets the necessary safety and quality requirements. The most important certifications for laser stippling machines include the China Compulsory Certification (CCC) and the International Organization for Standardization (ISO) certification.

The CCC certification is mandatory for certain products, including laser stippling machines, to enter the Chinese market. It ensures that the product meets the safety and quality standards set by the Chinese government. To obtain the CCC certification, the manufacturer must undergo testing and provide relevant documentation to prove compliance.

Additionally, the ISO certification verifies that the manufacturer follows international standards for quality management systems and processes. It is not mandatory, but having this certification demonstrates the manufacturer’s commitment to quality and can increase trust in the product.

When it comes to importing laser stippling machines, importers must comply with Chinese import regulations and customs procedures. Firstly, it is necessary to gather all the required documents, including the purchase agreement, shipping documents, and certificates of compliance, such as the CCC and ISO certifications.

Importers should also account for customs duties and taxes, including import duties, value-added taxes (VAT), and consumption taxes. These charges depend on the customs classification of the laser stippling machine and its declared value. Importers should accurately declare this information to avoid customs issues.

It is recommended to work with a qualified freight forwarder or customs broker who can assist with the customs clearance process and ensure compliance with all regulations. They can help handle the necessary paperwork, tariff classifications, and arrange transportation from the supplier to the importer’s destination.

In summary, when importing a laser stippling machine from China, importers should verify that the manufacturer holds the necessary certifications, such as CCC and ISO. They must also follow Chinese import regulations and customs procedures, correctly declare the machine’s value, and consider the associated customs duties and taxes. Collaborating with a knowledgeable freight forwarder or customs broker can simplify the import process and ensure compliance with all requirements.

Sustainability and Environmental Considerations in laser stippling machine Manufacturing

In the manufacturing of laser stippling machines, sustainability and environmental considerations play a crucial role in reducing the negative impact on the environment and promoting responsible manufacturing practices.

One important aspect of sustainability in laser stippling machine manufacturing is the use of energy-efficient processes. Manufacturers can aim to minimize energy consumption by optimizing the production layout, implementing energy-saving technologies, and ensuring proper insulation and ventilation systems. By reducing energy consumption, manufacturers can decrease their carbon footprint and contribute to environmental preservation.

Another vital consideration is the choice of materials used in the manufacturing process. Opting for eco-friendly and recyclable materials helps to minimize waste generation and reduce the overall environmental impact. Manufacturers can also aim to source materials from suppliers that follow sustainable practices, such as using renewable resources and reducing the use of harmful chemicals.

Waste management is another area to focus on in laser stippling machine manufacturing. Implementing proper waste segregation and recycling processes can significantly reduce the environmental impact of manufacturing operations. By reusing and recycling materials within the production process, manufacturers can minimize the amount of waste sent to landfills and contribute to a circular economy.

Furthermore, manufacturers can strive for sustainable logistics and transportation practices. By optimizing transportation routes, reducing packaging waste, and choosing low-emission vehicles, companies can minimize their contribution to air and noise pollution. Collaborating with suppliers and implementing green procurement practices can also help promote sustainable practices throughout the supply chain.

Lastly, manufacturers should consider the end-of-life phase of laser stippling machines. Designing products that are easily disassembled and recyclable can encourage proper disposal and reduce the accumulation of electronic waste. Encouraging customers to participate in take-back programs or offering repair and upgrade services can extend the lifespan of the product, reducing the overall environmental impact.

Overall, incorporating sustainability and environmental considerations in laser stippling machine manufacturing can lead to reduced energy consumption, waste generation, and greenhouse gas emissions. By adopting these practices, manufacturers can contribute to a more sustainable and environmentally responsible future.

List The Evolution history of “laser stippling machine”

The evolution of laser stippling machines dates back to the early 1990s when laser technology began to be explored for various industrial applications. Initially, laser marking machines were developed to engrave or label surfaces with high precision using a focused laser beam.

In the mid-1990s, the concept of stippling, a method of creating textured patterns on surfaces, gained popularity in the firearms industry. Gunsmiths started experimenting with various techniques to add grip and improve handling on firearm frames. This led to the birth of manual stippling using soldering irons or other heated tools, which proved to be time-consuming and inconsistent.

Recognizing the need for a more efficient solution, laser manufacturers began innovating and integrating stippling functionalities into their laser marking systems. By the late 1990s, laser stippling machines were introduced as a revolutionary way to automate the stippling process.

These early laser stippling machines utilized galvanometer scanners to rapidly move the laser beam across the target surface. This allowed for precise control over the stippling pattern, depth, and density. However, these machines often required manual programming and adjustments, limiting their widespread adoption.

As technology advanced in the 2000s, laser stippling machines became more user-friendly and efficient. Manufacturers introduced graphical user interfaces and pre-programmed patterns, making it easier for users to select and customize stippling designs. Enhanced software allowed for quick adjustments to parameters like pattern size, spacing, and depth, further improving flexibility.

In recent years, laser stippling machines have continued to evolve, incorporating cutting-edge features such as 3D scanning capabilities. This enables the reproduction of intricate patterns or even personalized designs on curved surfaces with utmost precision.

Furthermore, the introduction of fiber laser technology in stippling machines has revolutionized the process, offering improved speed, versatility, and energy efficiency. Fiber lasers deliver higher power density while consuming less energy, resulting in faster stippling speeds and reduced operating costs.

In conclusion, the evolution of laser stippling machines has brought significant advancements to the firearms industry. From manual stippling to the integration of laser marking systems and the adoption of fiber laser technology, these machines continue to enhance grip customization and firearm aesthetics while saving time and providing consistent results.

The Evolution and Market Trends in laser stippling machine Industry

The laser stippling machine industry has seen significant evolution and market trends over the years, driven by advancements in technology and the increasing demand for precision and customization. Laser stippling is a process that involves using a laser to create patterns or textures on various surfaces, such as metals, plastics, and fabrics.

One prominent evolution in this industry is the development of more advanced laser stippling machines. Earlier versions of these machines were primarily limited to basic pattern designs. However, with advancements in laser technology, modern machines now offer enhanced flexibility and precision. They can create intricate and detailed patterns that were previously not possible. This evolution has opened up new opportunities in various industries, including automotive, fashion, and packaging.

Another significant evolution is the integration of laser stippling machines with computer-aided design (CAD) systems. CAD systems enable designers to create complex patterns and transfer them directly to the laser stippling machines. This integration has streamlined the manufacturing process and reduced human error. It has also allowed for greater customization, as designers can easily modify and experiment with different patterns.

In terms of market trends, there is a growing demand for laser stippling machines in industries such as automotive and consumer goods. Automotive manufacturers are increasingly using laser stippling to create aesthetically pleasing and functional textures on dashboards, steering wheels, and interior trims. This not only enhances the overall look of the vehicle but also improves grip and haptic feedback for better user experience.

In the consumer goods sector, laser stippling machines are being used to add unique designs and textures to products such as cell phone cases, jewelry, and home décor items. Consumers are increasingly seeking personalized and customized products, and laser stippling offers a cost-effective solution for manufacturers to meet this demand.

Furthermore, there is a growing focus on sustainability and environmental-friendly practices in various industries. Laser stippling machines use minimal energy and produce minimal waste compared to traditional manufacturing methods, making them a more sustainable choice.

Overall, the evolution of laser stippling machines has brought about more advanced capabilities and integration with CAD systems, while the market trends point to increased demand in automotive, consumer goods, and a focus on sustainability. These factors are expected to drive further growth and innovation in the laser stippling machine industry.

Custom Private Labeling and Branding Opportunities with Chinese laser stippling machine Manufacturers

If you are looking for custom private labeling and branding opportunities with Chinese laser stippling machine manufacturers, you are in luck. China is renowned for its vast production capabilities and cost-effectiveness, making it an ideal destination for sourcing these machines.

Chinese manufacturers offer a wide range of laser stippling machines that can be customized according to your specifications. This customization allows you to add your logo, branding elements, and distinctive features to the machines, thus creating a unique product that represents your brand identity.

By collaborating with Chinese manufacturers, you gain access to their expertise in laser stippling technology and advanced manufacturing processes. They are experienced in producing high-quality machines that meet international standards and regulations. Furthermore, these manufacturers often invest in research and development, ensuring that their machines are equipped with the latest features and technologies.

Not only do Chinese manufacturers provide private labeling opportunities, but they also offer branding services. They can assist you in designing packaging, user manuals, and promotional materials that reflect your brand aesthetic. This comprehensive approach helps create a consistent brand experience for your customers.

In terms of cost-effectiveness, Chinese manufacturers often offer competitive pricing due to lower production costs. This enables you to maintain a healthy profit margin while staying competitive in the market.

To ensure a successful collaboration, it is advisable to conduct thorough due diligence on potential manufacturers, including verifying their certifications, quality control processes, and reputation. Additionally, communication plays a crucial role in conveying your requirements accurately and fostering a long-term partnership.

In conclusion, Chinese laser stippling machine manufacturers offer custom private labeling and branding opportunities that allow you to create unique products reflecting your brand identity. With their expertise, advanced technologies, and cost-effectiveness, collaborating with Chinese manufacturers can be a strategic move for your business.

Tips for Procurement and Considerations when Purchasing laser stippling machine

When purchasing a laser stippling machine for your procurement needs, there are several considerations to keep in mind:

1. Machine Quality: Look for a reliable and reputable supplier that offers high-quality machines. Consider the construction materials, durability, and overall performance of the machine.

2. Laser Power and Capability: Evaluate the laser power and capability of the machine. Different applications require different power levels, so ensure that the machine you choose meets your specific requirements.

3. Precision and Speed: Consider the precision and speed of the laser stippling machine. Look for features such as adjustable frequency and pulse duration, as well as high-speed scanning systems, to achieve the desired results efficiently.

4. Software and User Interface: Check the software and user interface of the machine. Look for easy-to-use software with intuitive controls that allow for customization and flexibility in the laser stippling process.

5. Safety Features: Ensure that the machine has safety features such as a protective housing, emergency stop buttons, and interlocks to prevent accidents and protect the operator from laser exposure.

6. Maintenance and Support: Consider the maintenance requirements and availability of technical support for the machine. Check if the supplier offers training, spare parts, and reliable after-sales service to minimize downtime and ensure smooth operation.

7. Compatibility and Integration: If you plan to integrate the laser stippling machine into an existing production line, make sure it is compatible with your current equipment and systems.

8. Cost and Return on Investment (ROI): Consider the initial purchase cost, as well as the long-term ROI. Evaluate the machine’s efficiency, productivity, and potential for business growth.

9. User Feedback and Reviews: Research customer reviews and feedback on the machine you are considering. This can provide insights into the experiences of other users and help you make an informed decision.

10. Compliance and Regulations: Ensure that the laser stippling machine complies with local regulations and safety standards related to laser equipment.

By considering these factors and conducting thorough research, you can make an informed decision when purchasing a laser stippling machine that fits your procurement needs effectively.

FAQs on Sourcing and Manufacturing laser stippling machine in China

Q: Where can I source a laser stippling machine in China?

A: There are several options to source a laser stippling machine in China. You can directly contact manufacturers or suppliers, explore online marketplaces like Alibaba, or attend trade exhibitions and fairs related to laser equipment. It is advisable to conduct thorough research and due diligence before finalizing a supplier.

Q: What factors should I consider when sourcing a laser stippling machine in China?

A: Some key factors to consider include the reputation and credibility of the supplier, manufacturing capabilities, quality control processes, technical support, after-sales service, and pricing. It is crucial to request samples, review product specifications, and inquire about certifications to ensure compliance with safety standards and industry requirements.

Q: Can I customize the laser stippling machine according to my specific needs?

A: Many suppliers offer customization options for laser stippling machines in China. You can discuss your requirements with the manufacturer or supplier, such as laser power, work area size, control system, and additional features. Ensure to communicate your specifications clearly and verify the supplier’s ability to meet them.

Q: How can I ensure the quality of the laser stippling machine manufactured in China?

A: To ensure quality, it is important to select a reputable supplier with a track record of manufacturing reliable laser equipment. Requesting product samples, checking for ISO certifications, and conducting factory audits can help assess the supplier’s quality control processes. Additionally, reading customer reviews and testimonials can provide insights into the reliability and performance of the machine.

Q: What is the typical lead time for manufacturing a laser stippling machine in China?

A: The lead time for manufacturing a laser stippling machine in China can vary depending on factors such as customization requirements, order quantity, and the supplier’s production capacity. On average, it can take around 4-6 weeks or more for production, excluding shipping time.

Q: How can I arrange shipping of the laser stippling machine from China to my location?

A: Suppliers in China can arrange shipping services as per your preference. They can provide quotes for different shipping methods, such as air freight or sea freight, based on your order size and urgency. It is advisable to consider factors like shipping costs, delivery time, and customs clearance procedures when choosing the most suitable shipping option.

Q: What kind of warranty and after-sales support can I expect when purchasing a laser stippling machine from China?

A: Different suppliers offer varying warranty terms and after-sales support. It is recommended to clarify all warranty details, including the duration and coverage, before making a purchase. Furthermore, inquire about the availability of technical support, spare parts, training, and troubleshooting assistance to ensure a smooth operation of the machine.

In conclusion, when sourcing and manufacturing a laser stippling machine in China, it is essential to thoroughly research and evaluate suppliers, consider customization options, assess quality control processes, and clarify warranty and after-sales support.

Why contact sourcifychina.com get free quota from reliable laser stippling machine suppliers?

SourcifyChina.com, a reputed online sourcing platform for businesses, may get free quota from reliable laser stippling machine suppliers for a variety of reasons. Here are a few possible explanations within the 300-word limit:

1. Mutual benefit: Offering a free quota to SourcifyChina.com can be seen as a marketing strategy by laser stippling machine suppliers. By allowing SourcifyChina.com to access their services without charge, suppliers can gain exposure and potentially attract new customers through the platform. This mutually beneficial arrangement helps both parties expand their reach and enhance their business prospects.

2. Increased visibility: By providing a free quota, laser stippling machine suppliers can attract more attention and generate heightened visibility among SourcifyChina.com users. This exposure can lead to increased inquiries, potential partnerships, and more opportunities to showcase the quality and reliability of their products. It can be an effective way for suppliers to stand out in a competitive market.

3. Building partnerships: Laser stippling machine suppliers may view offering a free quota to SourcifyChina.com as a means to establish long-term partnerships. By providing access to their services at no cost, suppliers can build trust and rapport with SourcifyChina.com, potentially leading to a closer collaboration. Suppliers might anticipate that this gesture will pave the way for future collaborations and a mutually beneficial business relationship.

4. Quality assurance: Laser stippling machine suppliers who offer a free quota to SourcifyChina.com may use this opportunity to demonstrate the quality and reliability of their products. By providing free access to SourcifyChina.com, suppliers can showcase the superiority of their laser stippling machines and ensure that potential customers have the chance to experience their products firsthand. This can instill confidence in buyers, making them more likely to choose the supplier’s products over competitors.

5. Market testing: Another reason for offering free quotas could be for suppliers to test demand and gauge market interest. By providing complimentary access to SourcifyChina.com, suppliers can observe the level of attention their laser stippling machines receive and evaluate the response of potential customers. This market testing can help suppliers understand customer preferences, optimize their offerings, and make informed business decisions.

In conclusion, laser stippling machine suppliers may offer free quotas to SourcifyChina.com as a strategic marketing approach to increase visibility, build partnerships, showcase quality, and test the market. This collaboration benefits both suppliers and SourcifyChina.com by expanding their business opportunities and potentially leading to fruitful, long-term relationships.