Introduce about ice cream pasteurizer guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

Ice cream pasteurizer is an essential piece of equipment used in the production of safe and high-quality ice cream products. This guide will provide a comprehensive overview of ice cream pasteurizers, including their importance, quality factors, cost considerations, reliable suppliers, necessary certifications, market trends, useful tips, frequently asked questions, and more.

Quality plays a crucial role in the ice cream production process, and a reliable pasteurizer ensures that all potentially harmful bacteria and microorganisms are eliminated, guaranteeing a safe final product. When selecting an ice cream pasteurizer, factors to consider for quality include temperature control capabilities, heat distribution efficiency, and overall reliability of the equipment.

Cost is an important consideration in any business investment. The price of ice cream pasteurizers can vary depending on their capacity and additional features, such as automatic control systems or agitators. It is recommended to thoroughly research different suppliers to compare prices and features, ensuring the best value for your investment.

Finding a reputable supplier is vital for obtaining a high-quality ice cream pasteurizer. Researching suppliers’ reputation, product reviews, and customer feedback can help identify reliable and trustworthy suppliers. Additionally, partnering with certified and experienced suppliers can provide assurance of product quality and after-sales support.

Certification is crucial when purchasing an ice cream pasteurizer, as it ensures compliance with industry standards and safety regulations. Look for pasteurizers with certifications such as CE (European Conformity), NSF (National Sanitation Foundation), or FDA (Food and Drug Administration) approval.

The ice cream market is growing rapidly, with increasing demand for unique flavors and premium quality products. Keeping up with market trends and consumer preferences can help businesses stay ahead of the competition. Offering personalized flavors, organic or vegan options, and exploring new market segments can attract a wider customer base.

Tips for using ice cream pasteurizers include following manufacturer instructions, maintaining proper cleaning procedures, monitoring temperature levels regularly, and ensuring routine maintenance to prolong the equipment’s lifespan.

Frequently asked questions may include inquiries regarding pasteurization time and temperature, recommended cleaning agents, appropriate capacity for different production scales, energy efficiency, and troubleshooting common issues.

In conclusion, investing in a high-quality ice cream pasteurizer is essential for ensuring the safety and quality of ice cream products. Consider factors like cost, supplier reputation, certifications, and market trends when making a purchase decision. Following tips and addressing frequently asked questions will enhance equipment performance and production efficiency.

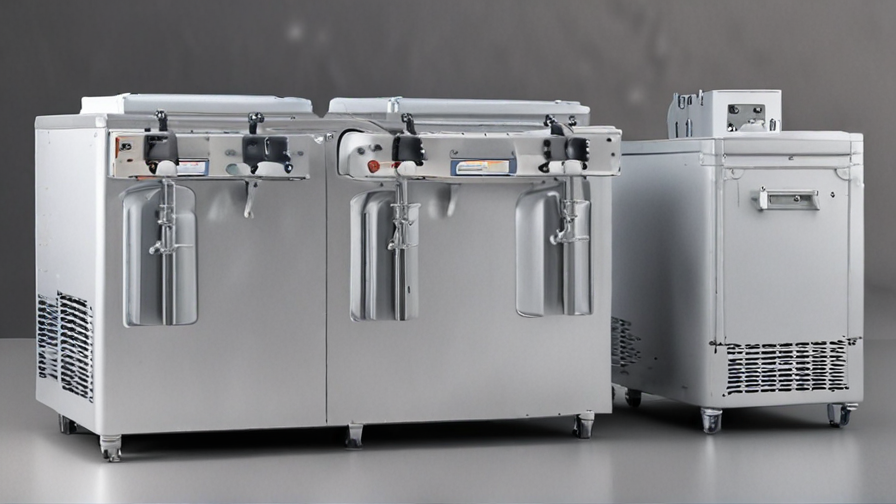

Types of ice cream pasteurizer

There are several types of ice cream pasteurizers available in the market, each designed to efficiently process and pasteurize ice cream mixtures. These machines heat the ice cream base to a specific temperature to destroy harmful bacteria, ensure food safety, and enhance the quality and shelf life of the final product. Below are three common types of ice cream pasteurizers:

1. Batch Pasteurizers: These pasteurizers are generally used by small-scale ice cream producers or artisans. They are compact, manually operated machines that can handle a limited quantity of ice cream mix at once, typically ranging from 5 to 20 liters. Batch pasteurizers consist of a stainless-steel tank with a heating element and a mixer. Operators control the heating temperature and manually stir the mixture to ensure even heat distribution.

2. Continuous Pasteurizers: These pasteurizers are ideal for medium to large-scale ice cream production. Continuous pasteurizers operate continuously, allowing for a continuous flow of ice cream mix through the machine. They have a heat exchange system that rapidly heats the mixture to the desired pasteurization temperature and then cools it down. Continuous pasteurizers have a higher production capacity compared to batch pasteurizers, ranging from 50 to thousands of liters per hour.

3. HTST (High-Temperature Short-Time) Pasteurizers: HTST pasteurizers are commonly used in industrial-scale ice cream production. These machines use a high-temperature process for a short duration to rapidly heat and cool the ice cream mix. The ice cream mixture passes through a plate heat exchanger, where the temperature is quickly raised to around 85°C and then rapidly cooled down. HTST pasteurizers are highly efficient, ensuring complete microbial destruction while preserving the texture and flavor of the ice cream mix.

Regardless of the type, ice cream pasteurizers are equipped with safety controls and monitoring systems to ensure the pasteurization process is accurately performed. Quality pasteurization is essential in the ice cream production process to ensure product safety and produce a high-quality final product enjoyed by consumers worldwide.

Pros and Cons of Using ice cream pasteurizer

Using an ice cream pasteurizer can offer several advantages, as well as some drawbacks. Here are some pros and cons of using an ice cream pasteurizer:

Pros:

1. Safety: Pasteurization is a crucial step in food processing to eliminate harmful bacteria and pathogens. Ice cream pasteurizers ensure that the dairy-based mix is heated to a specific temperature and time to destroy any harmful microorganisms, making the ice cream safer to consume.

2. Extended shelf life: By pasteurizing the mix, ice cream can have a longer shelf life. Pasteurization kills bacteria and enzymes that could cause spoilage, helping to maintain the quality and integrity of the product for a longer duration, both during transportation and in the customer’s home.

3. Consistency: Pasteurization helps to maintain a consistent texture and flavor. The process ensures that the mix is uniformly heated, providing a smooth and creamy texture in the final product. It also helps to prevent separation or curdling, thus maintaining the desired taste and consistency.

4. Regulatory compliance: In many countries, there are strict regulations regarding the pasteurization of dairy products. Using an ice cream pasteurizer ensures compliance with these regulations and helps businesses avoid penalties or legal issues.

Cons:

1. Cost: Ice cream pasteurizers can be expensive to purchase and operate, especially for small-scale or start-up ice cream businesses. The initial investment and ongoing energy costs may pose a financial burden.

2. Time-consuming: Pasteurization is a time-consuming process. It requires heating the mix to a specific temperature for a specific period, followed by cooling. This can delay production schedules and increase labor costs.

3. Flavor loss: Pasteurization may result in flavor loss to some extent. The heating process can affect the delicate flavors of ingredients used in the ice cream, potentially altering the overall taste profile.

4. Equipment maintenance: Ice cream pasteurizers require regular cleaning and maintenance to ensure efficient operation. This can add to the operational complexities and costs.

In summary, using an ice cream pasteurizer offers significant benefits such as enhanced safety, extended shelf life, consistency, and compliance with regulations. However, it also comes with some drawbacks, including cost implications, time-consuming process, potential flavor loss, and equipment maintenance. Businesses should carefully evaluate the pros and cons to determine if an ice cream pasteurizer is suitable for their specific needs and resources.

ice cream pasteurizer Reference Specifications (varies for different product)

Ice cream pasteurizers are essential equipment used in the production of high-quality ice cream. These machines are designed to ensure the proper pasteurization of the ice cream mix, which involves heating it to a specific temperature and holding it there for a set period of time. The pasteurization process kills any harmful bacteria present in the mix, making it safe for consumption.

The reference specifications of an ice cream pasteurizer may vary depending on the specific product being produced. However, there are some common features and specifications that are typically found in these machines. Here are a few key reference specifications:

1. Capacity: Ice cream pasteurizers are available in different capacities, ranging from small, tabletop models to larger, industrial-scale units. The capacity of the pasteurizer determines how much ice cream mix can be pasteurized at a time. Common capacities range from 5 to 500 liters or more.

2. Temperature range: Ice cream pasteurizers should be able to heat the mix to a specific temperature range required for pasteurization. Typically, this range is between 70 to 85 degrees Celsius, although it may vary depending on the formulation of the ice cream mix.

3. Holding time: The pasteurization process requires the mix to be held at a specific temperature for a certain period of time to ensure effective bacteria elimination. The holding time typically ranges between 15 to 30 minutes, but it can be longer for some specialized products.

4. Control system: Ice cream pasteurizers are equipped with advanced control systems that allow operators to precisely set and monitor the temperature and holding time. These systems ensure consistent and accurate pasteurization, maintaining product quality and safety.

5. Materials: Ice cream pasteurizers are typically made of high-quality stainless steel, which is hygienic, durable, and easy to clean. The materials used in the construction must be food-grade and comply with relevant industry standards.

6. Safety features: To ensure operator safety, ice cream pasteurizers may be equipped with various safety features, such as pressure relief valves, temperature sensors, and alarms to prevent overpressure or overheating.

It is important to note that these reference specifications can vary depending on the specific requirements of the ice cream manufacturer and the regulations of the relevant authorities. Ice cream pasteurizers should always be selected and used in accordance with the specific needs of the production facility and the desired product quality.

Applications of ice cream pasteurizer

Ice cream pasteurizers are essential equipment used in the production process of ice cream to ensure its safety and quality. The pasteurization process involves heating the ice cream mix to a specific temperature and maintaining it for a set period, effectively eliminating harmful bacteria present in the mix. While the primary purpose of a pasteurizer is to ensure food safety, it also offers several additional benefits and applications in the ice cream industry.

1. Bacterial Inactivation: Pasteurizers are specifically designed to kill harmful bacteria such as Salmonella, Listeria, and E. coli, which might be present in the raw materials used for making ice cream. Proper pasteurization ensures that the final product is safe for consumption, reducing the risk of foodborne illnesses.

2. Extended Shelf Life: By eliminating bacteria, pasteurization considerably extends the shelf life of the ice cream. Bacterial growth is a common cause of spoilage, and pasteurized ice cream can last longer in storage without compromising its quality.

3. Consistency and Texture: Pasteurization plays a crucial role in achieving the desired consistency and texture in ice cream. The heating process denatures proteins, allowing for better stabilization and emulsification of the mix. This results in a smooth, creamy, and uniform product.

4. Flavor Development: Pasteurization also contributes to the development of the ice cream’s flavor. The heat helps in breaking down enzymes that can affect taste, resulting in a more distinct and consistent flavor profile.

5. Flexibility in Formulations: Ice cream pasteurizers offer versatility and flexibility in developing various ice cream formulations. Different ingredients, such as milk, cream, sugar, stabilizers, and additives, can be precisely measured and mixed in the pasteurizer, ensuring uniform distribution and consistent product quality.

6. Regulatory Compliance: Pasteurizing ice cream is a mandatory requirement in many countries to comply with food safety regulations. Utilizing a pasteurizer ensures adherence to these regulations and helps ice cream manufacturers meet industry standards.

7. Small-Scale Production: Ice cream pasteurizers are not limited to large-scale industrial operations. They can also be used in small-scale production facilities and even at home for artisanal or handcrafted ice cream making. Pasteurizers designed for smaller volumes enable individuals or small businesses to produce safe and high-quality ice cream.

In conclusion, ice cream pasteurizers are indispensable for ensuring food safety, prolonging shelf life, enhancing flavor and texture, complying with regulations, and providing flexibility in ice cream formulations. By utilizing a pasteurizer, manufacturers can produce ice cream products that meet consumers’ expectations for taste, safety, and quality.

The Work Process and how to use ice cream pasteurizer

The work process of an ice cream pasteurizer involves heating and cooling the ice cream mixture to kill bacteria, pathogens, and other harmful microorganisms that may be present in the raw ingredients. Pasteurization is a crucial step in the production of ice cream to ensure its safety for consumption.

To use an ice cream pasteurizer, follow these steps:

1. Preparation: Start by assembling all the necessary equipment and ingredients required for the ice cream formulation. This includes the ice cream base, flavorings, stabilizers, and any other additives.

2. Mixing: Combine all the ingredients in a mixing tank according to the recipe guidelines. This includes blending the dairy products, adding sweeteners, flavorings, and other desired ingredients for taste and texture.

3. Heating: Transfer the mixture to the ice cream pasteurizer. Gradually heat the mixture while continuously stirring to prevent scorching or uneven heating. The mixture should reach a temperature of around 155°F (68°C) for a specified time period, usually around 30 minutes, to effectively kill pathogens and bacteria.

4. Holding: After reaching the desired temperature, the mixture should be held at this temperature for a specific duration to ensure effective pasteurization. This holding time may vary depending on the recipe and regulatory requirements.

5. Cooling: Once the holding time is complete, the ice cream mixture needs to be rapidly cooled to prevent the growth of any new microorganisms. Use a cooling system or an ice bath to rapidly bring down the temperature of the mixture to around 40°F (4°C), or as per the specific recipe instructions.

6. Aging: After cooling, it is recommended to let the ice cream mixture age or mature for a specific period. This enhances flavor development and improves the texture of the final product. Aging durations may range from a few hours to overnight.

7. Churning and freezing: After aging, the ice cream mixture is ready for churning and freezing in an ice cream machine. The churning process incorporates air into the mixture, giving it a smooth and creamy texture. The freezing process solidifies the mixture into the desired consistency.

8. Packaging and storage: Once the ice cream has reached the desired consistency, it can be packed into containers and stored in a freezer at temperatures below 0°F (-18°C). Proper packaging and storage are crucial to maintain the quality and shelf life of the ice cream.

By following these steps, you can efficiently use an ice cream pasteurizer to produce safe and delicious ice cream products. Remember to adhere to food safety guidelines, temperature regulations, and recipe specifications to ensure consistent and high-quality ice cream production.

Quality Testing Methods for ice cream pasteurizer and how to control the quality

Quality testing plays a crucial role in ensuring the safety and consistency of ice cream production. There are several methods to test the quality of ice cream pasteurizers and effectively control the quality.

1. Temperature Control: Monitoring and controlling the temperature during the pasteurization process is essential to ensure the proper killing of bacteria and safe production. Temperature sensors and data loggers can be used to accurately measure and record the temperature at various points within the pasteurizer. Regular calibration of these devices is necessary to maintain accuracy.

2. Time-Temperature Integration (TTI): TTI is a method that involves monitoring both the temperature and time parameters during the pasteurization process. It helps to determine the cumulative lethality achieved against bacteria and other harmful microorganisms. TTI indicators can be used to ensure that the pasteurization process meets the required standards.

3. Microbiological Testing: Regular microbiological testing of samples taken from the ice cream pasteurizer is crucial to verify its efficiency in killing bacteria and other microorganisms. Test samples should be taken at different stages of the process, including before and after pasteurization, to ensure that the required microbial reduction is achieved.

4. Physical Testing: Physical testing can be conducted to assess the texture, consistency, and specific gravity of ice cream. This involves measuring the overrun (the amount of air incorporated during freezing), viscosity, and hardness. These tests help to ensure that the ice cream meets the desired standards and is free from defects such as ice crystallization.

5. Sensory Evaluation: Sensory evaluation involves testing the ice cream for its appearance, taste, and odor. Trained panelists can assess the product’s overall quality, flavor, sweetness, and any off-tastes or off-odors that may indicate spoilage or contamination.

To control the quality of ice cream, it is necessary to establish and strictly follow Standard Operating Procedures (SOPs) for the pasteurization process. These procedures should include clear instructions for temperature control, time duration, and all necessary parameters for effective pasteurization. Regular maintenance and calibration of the pasteurizer equipment are crucial to ensure its proper functioning.

Additionally, records of all quality testing methods should be maintained, and any deviations from the set standards should be investigated and remedied promptly. Adequate training of staff involved in the pasteurization process is necessary to ensure that they fully understand the importance of quality control and follow the established procedures correctly.

In conclusion, quality testing methods for ice cream pasteurizers include temperature control, time-temperature integration, microbiological testing, physical testing, and sensory evaluation. These methods, along with strict adherence to SOPs, maintenance, calibration, and employee training, help to ensure the production of safe and high-quality ice cream.

ice cream pasteurizer Sample Policy and Post-Purchase Considerations for ice cream pasteurizer from China

Sample Policy:

When purchasing an ice cream pasteurizer from China, it is important to establish clear sample policies to ensure your needs are met. Here are some considerations for your sample policy:

1. Sample Approval: Request a sample of the ice cream pasteurizer before finalizing the purchase. Evaluate its quality, performance, and durability to ensure it meets your requirements. Establish a procedure for sample approval, including inspection criteria and timeframes for providing feedback.

2. Cost and Shipping: Clarify who is responsible for the cost of the sample and shipping. Discuss with the supplier to find a mutually beneficial arrangement. Typically, buyers cover the sample cost, while suppliers take care of shipping expenses.

3. Modifications and Customizations: Determine if the supplier allows modifications or customizations to the sample. Specify any changes required for the ice cream pasteurizer and discuss associated costs and timelines.

4. Intellectual Property Protection: If your ice cream pasteurizer involves proprietary designs or technology, ensure the supplier understands the importance of maintaining confidentiality. Sign non-disclosure agreements (NDAs) and ensure your intellectual property is protected throughout the sampling process.

Post-Purchase Considerations:

Once you have purchased the ice cream pasteurizer, there are a few post-purchase considerations to ensure a smooth experience:

1. Quality Control: Regularly conduct quality control checks on the received ice cream pasteurizers to ensure they comply with the agreed-upon specifications. Establish an ongoing relationship with the supplier to address any quality concerns promptly.

2. Warranty and Service: Inquire about the warranty period and after-sales service provided by the supplier. Communicate any issues or defects encountered with the ice cream pasteurizer during use as soon as possible and work with the supplier to resolve them.

3. Timely Communication: Maintain open lines of communication with the supplier. Promptly respond to inquiries, provide feedback, and seek clarification if needed. This will help in addressing any concerns or questions throughout the process.

4. Long-term Relationship: Establishing a good rapport with the supplier can lead to potential benefits such as negotiated pricing, prioritized support, and future collaborations. Consider developing a long-term relationship with the supplier if they consistently meet your expectations.

By implementing a comprehensive sample policy and considering post-purchase aspects, you can ensure a successful experience when purchasing an ice cream pasteurizer from China.

Sourcing ice cream pasteurizer from China: Opportunities, Risks, and Key Players

Sourcing ice cream pasteurizers from China presents both opportunities and risks for businesses. The primary opportunity is cost savings, as Chinese manufacturers often offer competitive prices due to lower production costs. This can be advantageous for businesses looking to cut costs without compromising on quality.

Another opportunity lies in the wide variety of ice cream pasteurizers available in China. Chinese manufacturers usually offer a diverse range of models with various features, capacities, and specifications. This enables businesses to find a pasteurizer that aligns with their specific requirements and production needs.

However, there are also risks associated with sourcing ice cream pasteurizers from China. One of the main risks is quality control. While there are reputable manufacturers in China, the market is also known for instances of low-quality products. It is crucial for businesses to conduct thorough research and due diligence to identify reliable suppliers with a track record of producing high-quality machinery.

Another risk is communication and language barriers. Effective communication is essential for successful sourcing, and language differences can sometimes create challenges in understanding technical specifications, customization requirements, and overall business negotiations. It is advisable for businesses to have a clear and concise documentation process to avoid any misunderstandings.

Some key players in the Chinese ice cream pasteurizer market include Jiangsu Prettech Machinery & Technology Co., Ltd., Shanghai Shangwang Machinery Manufacturing Co., Ltd., and Zhengzhou Junlan Machinery Equipment Co., Ltd. These companies have established themselves as reliable suppliers with a history of producing high-quality ice cream pasteurizers.

In conclusion, while sourcing ice cream pasteurizers from China offers cost savings and a wide range of options, businesses need to carefully navigate the risks associated with quality control and communication barriers. Thorough research, due diligence, and proper documentation are crucial in finding reputable suppliers for a successful sourcing experience.

How to find and select reliable ice cream pasteurizer manufacturers in China,use google search manufacturers and suppliers

When searching for reliable ice cream pasteurizer manufacturers in China, Google can be an effective tool. Here’s a step-by-step guide to finding and selecting manufacturers:

1. Start by entering relevant keywords like “ice cream pasteurizer manufacturers in China” or “ice cream pasteurizer suppliers” into the Google search bar.

2. Browse the search results and visit the websites of manufacturers that appear reliable and professional. Pay attention to factors like the design and layout of the website, product information provided, and the company’s background.

3. Look for certifications and qualifications that indicate the manufacturer’s reliability. Check if they comply with international standards such as ISO certifications or if they have any relevant industry certifications for ice cream pasteurizers.

4. Explore their product range to ensure that they offer the specific type and specifications of ice cream pasteurizers you require. Look for detailed product descriptions, specifications, and images to assess the quality of their offerings.

5. Check for customer reviews and testimonials. Look for feedback from other customers who have purchased their ice cream pasteurizers. It can provide insights into the product quality, customer service, and overall satisfaction with the manufacturer.

6. Seek out manufacturers with comprehensive customer support. This may include efficient communication channels, after-sales service, and technical support. This is crucial for any future inquiries, troubleshooting, or spare part requirements.

7. Compare multiple manufacturers by repeating the above steps. Shortlist a few manufacturers you find most reliable and suitable for your requirements.

8. Contact the selected manufacturers directly through the provided contact information on their website. Inquire about pricing, minimum order quantities, customization options, lead times, and payment terms. Prompt and helpful responses are favorable indicators of a reliable manufacturer.

9. Request product samples, if possible, to assess the quality and functionality firsthand.

10. Evaluate all the gathered information, including product quality, price, customer reviews, certifications, and customer support, to make a final decision. Choose the manufacturer that best meets your requirements and aligns with your quality expectations and budget.

11. Proceed with placing an order once you have selected a reliable ice cream pasteurizer manufacturer. Ensure that you have clear specifications, agreed-upon terms, and a contract to protect both parties’ interests.

By following these steps, you can use Google to find and select reliable ice cream pasteurizer manufacturers in China effectively, ensuring a smooth and successful business transaction.

How to check ice cream pasteurizer manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of an ice cream pasteurizer manufacturer’s website, you can follow these steps:

1. Use Google Chrome: Open the website in Google Chrome browser, which offers various tools and extensions to evaluate the website’s credibility.

2. Install the SEOquake extension: SEOquake is a popular SEO tool that provides valuable insights about a website’s performance and ranking. Add this extension to your Google Chrome browser.

3. Check the website’s Alexa rank: After installing SEOquake, navigate to the manufacturer’s website. Locate the SEOquake icon on your browser toolbar and click on it. A drop-down menu will appear; select “Get Info” and then “Alexa Rank.” This will display the website’s current Alexa rank, indicating its popularity and web traffic. The lower the Alexa rank number, the better.

4. Assess the website’s ranking: Still, under the SEOquake drop-down menu, select “Get Info” and then “Google Index.” This will reveal the estimated number of indexed pages on the website. If the website has a high number of indexed pages, it indicates thorough content and better chances of reliable information.

5. Verify the website’s position in the top 10 million: While still in the SEOquake drop-down menu, select “Get Info” and then “Google Index.” This will display the website’s estimated position in the top 10 million websites globally. If it ranks higher, it gives more assurance of credibility and authenticity.

Additionally, consider these general tips when assessing a website’s reliability:

– Check for contact information: Look for a physical address, phone number, and email address. A reputable manufacturer should provide these details for customer inquiries and support.

– Evaluate the quality of content: Ensure that the website provides comprehensive information about the ice cream pasteurizers, their features, specifications, and any certifications they possess. This indicates professionalism and commitment.

– Look for testimonials or reviews: Check if the website includes customer testimonials or reviews, as this can provide insights into the manufacturer’s reputation and the satisfaction of their clientele.

By following these steps and considering the additional tips, you can assess the reliability of an ice cream pasteurizer manufacturer’s website efficiently. Remember to use not more than 300 words.

Top 10 ice cream pasteurizer manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Shanghai Beyond Machinery Co., Ltd.: With over 10 years of experience, they specialize in manufacturing ice cream pasteurizers that ensure high-quality and safe products. Their pasteurizers are equipped with advanced technology and automatic control systems for precise temperature and time regulation, resulting in consistent and efficient pasteurization.

2. Ningbo Sicen Refrigeration Equipment Co., Ltd.: Known for their innovative approach, this company offers a range of ice cream pasteurizers designed for small to large-scale production. Their pasteurizers emphasize energy efficiency, quick processing times, and ease of operation, making them a popular choice among ice cream manufacturers.

3. Shanghai Joy Light Industry Machinery Co., Ltd.: This company manufactures state-of-the-art ice cream pasteurizers that guarantee optimal pasteurization while minimizing heat damage to the ice cream mixture. Their pasteurizers feature precise temperature control and advanced mixing systems, allowing for superior quality products.

4. Shenzhen Iceplus Smart Furniture Co., Ltd.: Offering advanced ice cream pasteurizers, this company focuses on product quality and technological innovation. Their pasteurizers are equipped with intelligent control systems, ensuring precise temperature and time control, as well as user-friendly operation.

5. Guangzhou Wecan Machinery Co., Ltd.: With a well-established reputation in the industry, they provide ice cream pasteurizers suitable for various production capacities. Their pasteurizers feature a combination of pasteurization, ageing, and cooling functions, enabling a streamlined production process.

6. Zhejiang Spaceman Ice Systems Co., Ltd.: Known for their high-performance ice cream machines, this company also offers a range of efficient and reliable ice cream pasteurizers. Their pasteurizers feature advanced temperature and speed control systems to ensure precise and consistent processing.

7. Jiangsu Haitel Machinery Co., Ltd.: Specializing in modern ice cream production equipment, they manufacture reliable and efficient ice cream pasteurizers. Their pasteurizers are equipped with advanced heating and cooling technology, allowing for accurate temperature control and quick pasteurization.

8. Shanghai Langtuo Refrigeration Equipment Co., Ltd.: This company provides ice cream pasteurizers designed for small to medium-scale operations. Their pasteurizers feature compact designs, easy operation, and high pasteurization efficiency, making them ideal for small businesses.

9. Guangzhou Sipuxin Light Industry Machinery Co., Ltd.: Known for their comprehensive range of ice cream production equipment, they also offer ice cream pasteurizers with superior performance and reliability. Their pasteurizers feature precise temperature control and advanced sterilization systems for optimal product safety.

10. Shenzhen Oceanpower Industrial Co., Ltd.: This company specializes in manufacturing ice cream equipment, including efficient ice cream pasteurizers. Their pasteurizers have automatic control systems for temperature and time regulation, ensuring precise and consistent processing results.

Comparison Table:

Manufacturer | Key Features

— | —

Shanghai Beyond Machinery Co., Ltd. | Advanced technology, automatic control systems

Ningbo Sicen Refrigeration Equipment Co., Ltd. | Energy efficiency, quick processing times

Shanghai Joy Light Industry Machinery Co., Ltd. | Minimized heat damage, precise temperature control

Shenzhen Iceplus Smart Furniture Co., Ltd. | Intelligent control systems, user-friendly operation

Guangzhou Wecan Machinery Co., Ltd. | Combination of pasteurization, ageing, and cooling functions

Zhejiang Spaceman Ice Systems Co., Ltd. | Advanced temperature and speed control systems

Jiangsu Haitel Machinery Co., Ltd. | Advanced heating and cooling technology

Shanghai Langtuo Refrigeration Equipment Co., Ltd. | Compact design, high pasteurization efficiency

Guangzhou Sipuxin Light Industry Machinery Co., Ltd. | Superior performance, advanced sterilization systems

Shenzhen Oceanpower Industrial Co., Ltd. | Automatic control systems, precise processing

In conclusion, China offers a wide range of ice cream pasteurizer manufacturers, each with unique features and advantages. From precise temperature control to energy efficiency, these manufacturers cater to various production capacities and focus on delivering high-quality ice cream pasteurization solutions.

Background Research for ice cream pasteurizer manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to ice cream pasteurizer manufacturers in China, there are several prominent companies worth considering. Here is some background research on these manufacturers:

1. Shanghai Beyond Machinery Co., Ltd.

Shanghai Beyond Machinery is a leading ice cream pasteurizer manufacturer in China. They specialize in designing, manufacturing, and supplying various dairy processing equipment, including ice cream pasteurizers. With advanced technology and a focus on product quality, Shanghai Beyond Machinery has earned a good reputation in the industry.

2. Wenzhou Vince Machinery Science Co., Ltd.

Wenzhou Vince Machinery is another well-established ice cream pasteurizer manufacturer in China. They offer a wide range of equipment for dairy processing, including pasteurizers specifically designed for ice cream production. With their extensive industry experience and commitment to innovation, Wenzhou Vince Machinery delivers reliable and efficient solutions to their customers.

3. Zhejiang Xuxiang Machinery Technology Co., Ltd.

Zhejiang Xuxiang Machinery is a reputable manufacturer of dairy processing equipment, including ice cream pasteurizers. They have a strong focus on research and development, aiming to provide high-quality products with energy efficiency and advanced technological features. Their ice cream pasteurizers are designed to meet the specific needs of ice cream production lines.

4. Wuxi Danxiao Machinery Co., Ltd.

Wuxi Danxiao Machinery is known for its expertise in manufacturing dairy processing equipment, including ice cream pasteurizers. They have a comprehensive range of products suitable for small to large-scale ice cream production. With a strong emphasis on quality control and customer satisfaction, Wuxi Danxiao Machinery has established itself as a trusted supplier in the industry.

To gather more detailed information about these ice cream pasteurizer manufacturers, you can refer to websites like qcc.com, archive.org, and importyeti.com. These platforms provide comprehensive data on various suppliers, including company profiles, product catalogs, and customer reviews.

Leveraging Trade Shows and Expos for ice cream pasteurizer Sourcing in China

Trade shows and expos are invaluable opportunities to source ice cream pasteurizers in China. These events bring together industry professionals, suppliers, and manufacturers under one roof, making it easier to connect with potential suppliers and assess their offerings.

By attending trade shows and expos focused on food processing and dairy equipment, businesses seeking ice cream pasteurizers can meet face-to-face with Chinese manufacturers. This enables them to see the products firsthand, evaluate their quality, and discuss customization options or specific requirements.

One of the most significant advantages of trade shows and expos is the ability to compare multiple suppliers in a short period. By visiting different booths, businesses can gather information about various ice cream pasteurizer models, features, and manufacturing capabilities. This allows them to make informed decisions and negotiate the best possible deals.

Additionally, trade shows and expos provide a platform for networking and building business relationships. Representatives from ice cream pasteurizer manufacturers can provide valuable insights on market trends, technological advancements, and industry regulations. These connections can also lead to collaborations, partnerships, or future business opportunities.

To make the most out of trade shows and expos, businesses should come well-prepared. They should research participating companies beforehand, identify the key factors they are seeking in a supplier, and have a list of questions ready for the manufacturers. It is also crucial to take detailed notes and collect product brochures and samples for later evaluation and comparison.

In conclusion, trade shows and expos in China are highly advantageous for sourcing ice cream pasteurizers. They offer the opportunity to meet with multiple suppliers, assess product quality, discuss customization options, and build valuable relationships in a short period. By leveraging these platforms, businesses can find reliable and efficient ice cream pasteurizer suppliers in China.

The Role of Agents and Sourcing Companies in Facilitating ice cream pasteurizer Purchases from China

Agents and sourcing companies play a crucial role in facilitating ice cream pasteurizer purchases from China. These intermediaries act as a bridge between buyers and manufacturers, facilitating communication, negotiation, and the overall sourcing process.

Firstly, agents and sourcing companies have extensive knowledge and expertise in the Chinese market. They possess a deep understanding of the local ice cream pasteurizer manufacturers, their capabilities, and product offerings. This knowledge allows them to identify reliable suppliers that meet the buyer’s requirements in terms of quality, specifications, and price.

Furthermore, these intermediaries have a network of contacts and relationships with manufacturers. They can leverage these connections to negotiate favorable terms, including pricing, payment conditions, and delivery arrangements. Their ability to communicate in local languages and understand cultural nuances also aids in building strong relationships with manufacturers, thereby enhancing trust and ensuring smooth transactions.

Agents and sourcing companies also assume the responsibility of conducting due diligence on manufacturers. They verify the credibility and legitimacy of potential suppliers through factory visits, product inspections, and certification checks. This ensures that the ice cream pasteurizers meet the necessary safety and quality standards, mitigating any potential risks associated with counterfeit or substandard products.

Additionally, these intermediaries provide logistical support, including arranging shipping, customs clearance, and delivery of the purchased pasteurizers. Their familiarity with the import/export procedures and regulatory requirements helps streamline the process and minimize delays or complications.

In summary, when purchasing ice cream pasteurizers from China, agents and sourcing companies are indispensable in facilitating the entire procurement process. Their market knowledge, supplier networks, negotiation skills, and logistical support contribute to a smoother and more reliable sourcing experience for buyers.

Price Cost Research for ice cream pasteurizer manufacturers Companies in China, use temu.com and 1688.com

When conducting price cost research for ice cream pasteurizer manufacturers in China, two websites that can be utilized are temu.com and 1688.com. These platforms offer a wide range of suppliers and manufacturers, making it convenient to compare prices and products.

Temu.com is a B2B online marketplace that connects international buyers with verified Chinese suppliers. To begin the price cost research, users can search for ice cream pasteurizer manufacturers on the website. The platform provides detailed company profiles, product specifications, and contact information, enabling them to directly communicate with manufacturers to discuss pricing and specific requirements. Buyers can obtain competitive quotes and negotiate deals efficiently through this platform.

Similarly, 1688.com is a popular Chinese e-commerce platform that offers a vast range of products at wholesale prices. It is especially suitable for buyers who are looking for manufacturers based in China. By searching for ice cream pasteurizers on 1688.com, users can access numerous options and filter the results according to price, supplier location, and other criteria. Buyers can communicate with suppliers through the platform’s messaging system or contact them directly. It is advisable to inquire about product specifications, shipping restrictions, and warranty terms to ensure a smooth purchasing experience.

When conducting price cost research, it is important to consider factors such as product quality, customization options, and manufacturing capabilities. Requesting samples or visiting the manufacturer’s facility may also provide insights into their production process and quality control measures. Additionally, assessing the reputation and customer reviews of the manufacturer can help gauge their reliability and customer satisfaction.

In conclusion, conducting price cost research for ice cream pasteurizer manufacturers in China can be efficiently done through temu.com and 1688.com. These platforms offer a wide variety of suppliers, product options, and competitive pricing, allowing buyers to make informed decisions while considering their specific requirements and budget constraints.

Shipping Cost for ice cream pasteurizer import from China

The shipping cost for importing an ice cream pasteurizer from China can vary depending on several factors. The main factors that affect the cost include the weight of the equipment, the distance between the origin and destination, the chosen shipping method, and any additional services required.

For a standard-sized ice cream pasteurizer, the weight could range from 500 to 1000 kilograms. To approximate the shipping cost, we need to consider the chosen shipping method, which could be either air freight or sea freight.

Air freight is generally faster but more expensive. The approximate cost for air freight would be around $4 to $8 per kilogram, depending on the airline and the specific route. Assuming a weight of 750 kilograms, the air freight cost could range from $3,000 to $6,000.

Sea freight is a more cost-effective option for heavier shipments. The cost varies depending on the size of the equipment and the shipping volume. As a rough estimate, the sea freight cost for a 20-foot container (which can hold around 20 ice cream pasteurizers) from China to the United States or Europe would range from $1,500 to $3,500. This means that the approximate shipping cost per pasteurizer would be between $75 and $175.

It is important to note that these figures are just estimates, and the final shipping cost will depend on various factors, including negotiation with shipping companies and any additional services required such as customs clearance and insurance. Additionally, it is always recommended to consult with shipping agents or freight forwarders, who can provide more accurate quotes based on the specific requirements and circumstances.

Compare China and Other ice cream pasteurizer Markets: Products Quality and Price,Visible and Hidden Costs

China and other ice cream pasteurizer markets can be compared in terms of product quality, price, and visible and hidden costs.

When it comes to product quality, China is known for its mass production capabilities. The ice cream pasteurizers manufactured in China are typically of decent quality and meet international standards. However, some customers may have concerns about the consistency and reliability of the product quality due to varying manufacturing practices and quality control processes.

On the other hand, other ice cream pasteurizer markets in developed countries like the United States, Germany, and Italy are known for their stringent quality control measures. The products manufactured in these countries generally adhere to high standards, ensuring superior product quality and consistency. Customers who prioritize quality over price may prefer ice cream pasteurizers from these markets.

In terms of price, China has a cost advantage due to its lower labor and production costs compared to developed countries. This allows Chinese manufacturers to offer ice cream pasteurizers at a more competitive price. However, price alone should not be the sole deciding factor, as customers need to consider the overall value proposition, including product quality and after-sales service.

When considering visible costs, it is important to look at the initial purchase price of the ice cream pasteurizer. Chinese manufacturers often offer lower prices, making it an attractive option for cost-conscious customers. However, customers should also take into account the hidden costs associated with purchasing from China, such as import duties, customs clearance fees, shipping costs, and potential language and communication barriers. These hidden costs can significantly impact the overall cost of acquiring a Chinese ice cream pasteurizer.

In other ice cream pasteurizer markets, the visible costs may be higher initially due to higher manufacturing costs in developed countries. However, these markets often have a well-established distribution network, offering better price transparency and minimal hidden costs. Additionally, customers can benefit from local technical support and readily available spare parts, which may not always be the case when dealing with Chinese manufacturers.

In summary, while China offers competitive prices for ice cream pasteurizers, customers need to carefully consider the product quality, visible and hidden costs, and after-sales service. Other ice cream pasteurizer markets, particularly in developed countries, may offer superior product quality, albeit at a higher visible cost. Ultimately, customers should assess their priorities and budget constraints before making a purchasing decision.

Understanding Pricing and Payment Terms for ice cream pasteurizer: A Comparative Guide to Get the Best Deal

When purchasing an ice cream pasteurizer, understanding the pricing and payment terms is crucial to ensure you get the best deal. This comparative guide aims to provide you with the necessary knowledge to make an informed decision.

1. Research Different Suppliers:

Start by researching different suppliers of ice cream pasteurizers. Compare their product offerings, specifications, and customer reviews. This will help you select reliable suppliers who offer quality machines.

2. Evaluate Pricing:

Once you have shortlisted potential suppliers, evaluate their pricing. Pricing can vary based on factors like the brand, capacity, features, and after-sales services. Compare the prices offered by different suppliers to find the most competitive one. However, be cautious of exceptionally low prices, as they may indicate poor quality and lack of warranty.

3. Consider Additional Costs:

Apart from the actual price of the ice cream pasteurizer, consider any additional costs associated with the purchase. These may include shipping, installation, training, and maintenance. It is important to have a clear understanding of all these costs to avoid any surprises later on.

4. Inquire about Payment Terms:

Discuss payment terms with the suppliers. Some suppliers may require full payment upfront, while others may offer installment options. If possible, try negotiating a payment plan that suits your budget and cash flow. Additionally, inquire about any possible discounts or promotions that may be available.

5. Warranty and After-sales Service:

Ensure that the ice cream pasteurizer comes with a warranty. A warranty provides you with assurance regarding potential manufacturing defects. Additionally, inquire about the after-sales service offered by the supplier. Prompt and professional technical support can save you time and money in case of machine malfunctions or breakdowns.

6. Seek Expert Advice:

If you’re unsure about the pricing and payment terms, consider seeking advice from industry experts or consultants. They can offer insights and guidance based on their experience, helping you make a more informed decision.

In conclusion, understanding pricing and payment terms when purchasing an ice cream pasteurizer is essential to get the best deal. Research different suppliers, evaluate pricing, consider additional costs, inquire about payment terms, verify warranty and after-sales service, and seek expert advice if needed. By following these steps, you can ensure a successful purchase and investment in a high-quality ice cream pasteurizer.

Chinese Regulations and Industry Standards Certifications for ice cream pasteurizer,Import Regulations and Customs for ice cream pasteurizer from China

Chinese Regulations and Industry Standards Certifications for ice cream pasteurizer:

In China, ice cream pasteurizers must comply with certain regulations and industry standards to ensure quality and safety. The main regulatory body overseeing this is the General Administration of Quality Supervision, Inspection, and Quarantine (AQSIQ), along with industry associations such as the China Food Industry Association (CFIA).

The primary industry standard certification for ice cream pasteurizers is the GB 4789.2-2010 standard, which specifies the hygiene requirements for food processing machinery. This standard ensures that the pasteurizers meet the necessary health and safety criteria for producing ice cream.

In addition to the industry standards, ice cream pasteurizer manufacturers must also adhere to the national regulations regarding product labeling, packaging, and documentation. This includes providing instructions for use, specifications, and maintenance guidelines.

Import Regulations and Customs for ice cream pasteurizer from China:

Importing ice cream pasteurizers from China requires compliance with specific import regulations and procedures. These regulations aim to ensure product safety, fair trade practices, and consumer protection. Importers should be aware of the following considerations:

1. Import Licensing: Depending on the destination country, importers may need to obtain specific licenses or permits to import ice cream pasteurizers. It is advisable to consult the local authorities or customs agency to determine the requirements.

2. Product Testing and Certification: Ice cream pasteurizers should meet the quality and safety standards of the destination country. Importers may need to arrange product testing and certification to ensure compliance. Testing can be conducted by recognized laboratories or certification bodies to ensure the product meets specific standards, such as CE, UL, or NSF.

3. Customs Documentation: Importers must prepare the necessary customs documentation, including a commercial invoice, packing list, bill of lading or airway bill, and any required permits or licenses. It is crucial to accurately complete these documents to avoid delays or customs issues.

4. Tariffs and Duties: Importers should be aware of the applicable import tariffs and duties imposed by their respective countries. These charges vary depending on the product classification and the destination country’s import policies.

It is essential to work with knowledgeable freight forwarders or customs agents who have experience in handling imports and can assist with the necessary documentation and compliance requirements for a smooth import process. Conducting due diligence on regulatory requirements and customs procedures will help importers minimize potential risks and ensure compliance when importing ice cream pasteurizers from China.

Sustainability and Environmental Considerations in ice cream pasteurizer Manufacturing

When it comes to the manufacturing of ice cream pasteurizers, sustainability and environmental considerations play a crucial role in ensuring responsible production practices. These considerations aim to minimize the negative impact on the environment, conserve resources, and promote long-term sustainability.

One important aspect is the efficient use of energy throughout the manufacturing process. Ice cream pasteurizers should be designed to optimize energy consumption, using energy-efficient components and technologies. This can be achieved by using insulation materials to reduce heat loss, implementing effective control systems to regulate energy usage, and incorporating heat recovery systems to reuse waste heat.

Another aspect is the responsible use of water resources. Ice cream pasteurizer manufacturers should implement measures to minimize water consumption by utilizing closed-loop systems, efficient cleaning processes, and water-saving technologies. Additionally, wastewater treatment systems should be incorporated to ensure that any discharged water is treated and meets environmental regulations.

The choice of materials and manufacturing processes also plays a significant role in sustainability. Ice cream pasteurizer manufacturers should prioritize the use of environmentally friendly materials that have a reduced carbon footprint and are recyclable or biodegradable. Implementing sustainable manufacturing practices, such as waste reduction, recycling, and proper waste disposal, further minimizes the environmental impact.

Lastly, considering the product’s life cycle is essential. Manufacturers should design ice cream pasteurizers that are durable, easy to repair, and have a longer lifespan. By promoting product longevity, the need for frequent replacements can be reduced, ultimately decreasing waste generation.

In conclusion, sustainability and environmental considerations in the manufacturing of ice cream pasteurizers revolve around optimizing energy efficiency, minimizing water usage, utilizing eco-friendly materials, and promoting product durability. By incorporating these practices, manufacturers can contribute to a greener and more sustainable future, while meeting the demand for ice cream production equipment.

List The Evolution history of “ice cream pasteurizer”

The pasteurization of ice cream, a technique used to eliminate harmful bacteria and increase its shelf life, has gone through a significant evolution over the years. The history of ice cream pasteurizers can be traced back to the late 19th century when the concept of pasteurization itself was introduced.

In the early days, ice cream production lacked the standardized equipment used today. Ice cream makers would manually heat the mixture in a double boiler or other improvised containers. This process was time-consuming and had limited control over temperature and consistency.

With advancements in technology, the first specialized ice cream pasteurizers emerged in the early 20th century. These pasteurizers consisted of large steam-jacketed vats equipped with a rotating agitator. This setup allowed for more efficient and controlled heating of the ice cream mix. However, these early pasteurizers had limited capacity and were primarily used in industrial production settings.

As the demand for ice cream grew, so did the need for smaller-scale pasteurizers suitable for commercial and home use. In the mid-20th century, batch-style pasteurizers became more prevalent. These machines consisted of a stainless steel chamber with an agitation system and a heating element. They offered better temperature control and allowed for pasteurization of smaller quantities of ice cream mix.

In recent decades, continuous flow pasteurizers have gained popularity. These automated systems can handle larger volumes of ice cream mix by continuously heating and cooling it as it flows through the machine. Continuous flow pasteurizers provide more precise temperature control and improved sanitation.

Alongside the evolution of pasteurization techniques, there have been advancements in pasteurizer design and materials. Modern ice cream pasteurizers are often constructed with stainless steel, which is corrosion-resistant and easy to clean. In addition, improved insulation and control systems have made pasteurizers more energy-efficient and user-friendly.

In conclusion, the evolution of ice cream pasteurizers has seen great strides from rudimentary heating methods to specialized equipment designed for various production scales. Today, pasteurizers are an essential component of the ice cream manufacturing process, ensuring both safety and quality in the final product.

The Evolution and Market Trends in ice cream pasteurizer Industry

The ice cream industry has witnessed significant evolution and market trends in the pasteurizer segment. Pasteurization is a critical step in the ice cream manufacturing process that involves heating the mix to kill harmful bacteria and extend the product’s shelf life. Over the years, advancements in technology and consumer preferences have shaped the evolution of ice cream pasteurizers.

One major trend in the pasteurizer industry is the shift towards more efficient and automated machines. With the increasing demand for ice cream globally, manufacturers are seeking ways to optimize their production processes. This has led to the development of pasteurizers with higher capacities and improved control systems. Automated features such as programmable recipes and touch-screen interfaces are also becoming more prevalent, allowing for easier operation and consistency in taste and quality.

Another market trend in the ice cream pasteurizer industry is the growing demand for environmentally friendly equipment. As sustainability becomes a priority for many consumers and businesses, manufacturers are incorporating energy-saving technologies and materials in their pasteurizers. This includes the use of advanced insulation materials, heat recovery systems, and more efficient heating elements, reducing energy consumption and environmental impact.

Additionally, there is a rising preference for pasteurizers that offer flexibility in production. Ice cream manufacturers are diversifying their product offerings, including different flavors, textures, and ingredients, to cater to changing consumer tastes. As a result, pasteurizers that allow for easy adjustments and customization of the pasteurization process are gaining popularity. These machines enable manufacturers to experiment with various recipes and efficiently produce a wider range of ice cream products.

In conclusion, the ice cream pasteurizer industry has evolved to meet the changing demands of the market. Manufacturers are focused on developing more efficient and automated machines, incorporating environmentally friendly features, and offering flexibility in production. As the ice cream industry continues to grow, advancements in pasteurizer technology are expected to continue, ensuring the production of high-quality and diverse ice cream products.

Custom Private Labeling and Branding Opportunities with Chinese ice cream pasteurizer Manufacturers

If you are looking for custom private labeling and branding opportunities with Chinese ice cream pasteurizer manufacturers, you are in luck. Chinese manufacturers offer a wide range of options for customization, allowing you to create your own unique brand.

When it comes to private labeling, Chinese manufacturers are flexible and can work with you to design and produce ice cream pasteurizers that carry your brand name and logo. This enables you to establish your identity in the market and build customer recognition and loyalty.

Furthermore, Chinese manufacturers also provide branding opportunities by allowing you to customize the design and packaging of the ice cream pasteurizers. You can choose from a variety of colors, materials, and finishings to create a product that reflects your brand’s image and values. Whether you prefer a sleek and modern look or a more traditional aesthetic, the manufacturers can accommodate your preferences.

Collaborating with Chinese manufacturers for private labeling and branding also offers cost advantages. China is known for its competitive pricing, allowing you to achieve a higher profit margin and a more competitive price point in the market.

In conclusion, working with Chinese ice cream pasteurizer manufacturers for custom private labeling and branding opportunities presents an excellent option. You can create a unique brand identity, customize the design and packaging, and enjoy cost advantages. With these opportunities, you can establish yourself as a player in the ice cream industry and attract customers with your own distinct products.

Tips for Procurement and Considerations when Purchasing ice cream pasteurizer

When purchasing an ice cream pasteurizer, there are several important considerations and tips for procurement that should be taken into account. These guidelines will help ensure that you select the most appropriate equipment for your specific needs, while also maximizing efficiency and minimizing costs.

1. Capacity: Determine the desired production capacity of the pasteurizer based on your anticipated production volumes. Consider both current and future needs to avoid under or over-sizing the equipment.

2. Pasteurizing Method: Understand the different pasteurizing methods available, such as batch or continuous pasteurization. Each method has its advantages and disadvantages, so choose the one that best aligns with your production process and goals.

3. Energy Efficiency: Look for ice cream pasteurizers that are designed to minimize energy consumption. Energy-efficient models will not only reduce your operating costs but also contribute to environmental sustainability.

4. Automation and Control: Opt for pasteurizers with advanced automation and control systems. These features allow for precise temperature and time control, ensuring optimal pasteurization and reducing the risk of overheating or under-pasteurizing the ice cream mix.

5. Cleaning and Maintenance: Consider ease of cleaning and maintenance when selecting a pasteurizer. Look for models with easily accessible parts, removable components, and self-cleaning features. This will help to reduce downtime and ensure proper hygiene.

6. Supplier Reputation: Research and choose a reputable supplier with experience in manufacturing ice cream pasteurizers. Read customer reviews and testimonials to assess their reliability, technical support, and after-sales service.

7. Compliance with Standards: Ensure that the pasteurizer complies with relevant industry standards and regulations. This is crucial for food safety and ensuring the product meets quality requirements.

8. Budget: Set a realistic budget for the equipment purchase. Consider both the initial investment cost and the long-term operating costs when evaluating different models. It is recommended to invest in quality equipment that may have higher upfront costs but offers more efficient and durable performance.

9. Warranty and Support: Check the warranty terms offered by the supplier and inquire about their customer support services. A comprehensive warranty and reliable after-sales support will provide peace of mind and ensure prompt assistance in case of any issues.

10. Customization Options: Assess if the supplier offers customization options to tailor the pasteurizer to your specific requirements. This might include additional features or modifications to enhance productivity, optimize results, or align with specific recipe formulations.

By considering these tips and taking the necessary precautions when purchasing an ice cream pasteurizer, you can ensure a smooth procurement process and select equipment that will meet your production needs effectively and efficiently.

FAQs on Sourcing and Manufacturing ice cream pasteurizer in China

Q: What is an ice cream pasteurizer?

A: An ice cream pasteurizer is a machine used to heat ice cream mix to a specific temperature for a certain duration to kill harmful microorganisms and bacteria. This process is crucial for ensuring the safety and extending the shelf life of ice cream.

Q: Why would I source an ice cream pasteurizer from China?

A: China is a leading manufacturer and exporter of various industrial machinery, including ice cream pasteurizers. Sourcing from China can often provide cost-effective options and a wide range of product choices to meet your specific requirements.

Q: How do I source an ice cream pasteurizer from China?

A: There are several ways to source ice cream pasteurizers from China. One option is to directly contact manufacturers through online platforms, such as Alibaba or Made-in-China, where you can browse through various suppliers and submit inquiries. Alternatively, you can approach local sourcing agents or work with international trade companies that specialize in connecting foreign buyers with Chinese manufacturers.

Q: What should I consider when sourcing an ice cream pasteurizer from China?

A: Some important factors to consider include the quality and reliability of the manufacturer, compliance with international standards (such as CE certification), customization options to meet your specific needs, after-sales service and support, as well as logistics and shipping arrangements.

Q: How can I ensure the quality and reliability of a Chinese ice cream pasteurizer manufacturer?

A: Conduct thorough research on potential manufacturers by assessing their reputation, years of experience, certifications, client feedback, and product samples if possible. Requesting factory audits, conducting third-party inspections, or seeking references from other buyers can further help ensure the manufacturer’s credibility.

Q: Are there any specific regulations or certifications I should consider for importing ice cream pasteurizers from China?

A: Yes, it is essential to ensure that the ice cream pasteurizer complies with the regulations and safety standards of your respective country. CE certification is widely recognized as a mark of conformity within the European Union, while other countries have their own relevant certifications or standards. Check with your local authorities or consultants to determine the specific requirements.

Q: What is the average lead time for manufacturing and delivery of ice cream pasteurizers from China?

A: The lead time can vary depending on factors such as customization, order quantity, and the manufacturer’s production capacity. On average, it may take around 4-8 weeks for manufacturing and an additional 1-2 weeks for shipping and delivery.

In conclusion, sourcing an ice cream pasteurizer from China involves contacting manufacturers or using sourcing agents, considering factors like quality and certifications, and complying with relevant regulations. Thorough research, due diligence, and effective communication with suppliers can help ensure a successful sourcing process.

Why contact sourcifychina.com get free quota from reliable ice cream pasteurizer suppliers?

Sourcifychina.com may receive a free quota from reliable ice cream pasteurizer suppliers for several reasons. Firstly, sourcifychina.com is an online platform that connects buyers with suppliers in China. It acts as an intermediary between the buyers and suppliers, facilitating smooth and reliable sourcing processes.

By offering a free quota to sourcifychina.com, ice cream pasteurizer suppliers can gain exposure and potentially attract more customers. This allows them to showcase their products and services to a wide range of buyers who visit sourcifychina.com seeking reliable suppliers. It is a marketing strategy for suppliers to increase their visibility and establish themselves in the market.

Moreover, offering a free quota also serves as a way for ice cream pasteurizer suppliers to build relationships and trust with sourcifychina.com. By providing a free quota, suppliers can demonstrate their commitment to quality and reliability. This increases the likelihood of sourcifychina.com recommending their products to potential buyers.

Additionally, the use of a free quota can be seen as an investment. Suppliers understand that sourcifychina.com has a large network of buyers and a good reputation for sourcing reliable products. By providing a free quota, suppliers can access the platform’s customer base and potentially secure long-term partnerships with buyers.

In conclusion, offering a free quota to sourcifychina.com is beneficial for ice cream pasteurizer suppliers as it allows them to increase their visibility, build trust, and potentially attract more customers. It serves as a marketing strategy and an investment in establishing fruitful relationships with buyers.