auto parts china

Auto parts china companies and suppliers

Hunan Woojin Autoparts is a professional enterprise specializing in exporting automotive parts, particularly car cooling system accessories like water flanges, thermostats, sensors, rubber hoses and tubes, and engine mountings.

RUIFAN is a leading manufacturer in China specializing in auto parts, specifically oil pans/sumps. With a focus on innovation and customer satisfaction for the past 15 years, RUIFAN has built a good reputation domestically and overseas.

Sailing Auto Parts is a company that produces and exports auto spare parts, specializing in body parts for Japanese and European cars. Their main products include head lamps, tail lamps, mirrors, grilles, bumpers, hoods, fenders, radiator supports, and other body parts.

Guangzhou Hong Modi Co.,Ltd specializes in air suspension parts, including shocks, springs, compressor pumps, turbochargers, power steering pumps, control arms, and tie rod ends for various car brands. Established in 2015, the company has gained a good reputation for providing high-quality products, competitive prices, and excellent service, earning support from customers worldwide.

Linyi RongYuan Auto Parts is a supplier of auto parts in Linyi City, Shandong Province, China. They offer brake pad sensors, ABS wheel speed sensors, brake accessories, and oxygen sensors. Their products are mainly for European passenger vehicles such as BMW, Mercedes-Benz, Land Rover, Mini, Porsche, Audi, and some China local cars.

Suzhou Kingrun Auto Parts Co., Ltd. is a leading manufacturer and trader of automotive spare parts in China, specializing in the industry for over ten years. They offer various products such as suspension parts, brake parts, engine parts, transmission parts, throttle body, power steering pump, etc., which are mainly exported to over 30 countries in Europe, USA, Canada, and South America.

Knowleage about auto parts china

Auto parts are an important component of the automotive industry, and China has emerged as a major player in the global auto parts market. Chinese auto parts manufacturers have been known for their quality, reliability, and affordability, making them a popular choice for auto manufacturers and consumers alike.

China’s auto parts industry has seen significant growth over the years, thanks to the country’s booming automotive industry. According to the China Association of Automobile Manufacturers, China produced over 25 million vehicles in 2020, making it the largest automotive market in the world. This has led to a surge in demand for auto parts, both domestically and internationally.

Chinese auto parts manufacturers have been able to capitalize on this demand by offering a wide range of products, from engine parts and brake systems to electronics and accessories. They have also invested heavily in research and development, constantly improving their products to meet the evolving needs of the automotive industry. As a result, many Chinese auto parts manufacturers have earned certifications and quality standards from international organizations such as ISO and TUV.

One of the main advantages of sourcing auto parts from China is the cost-effectiveness. Chinese auto parts are often priced lower than their counterparts from other countries, making them a popular choice for budget-conscious consumers. However, it is important to note that the low cost does not necessarily mean low quality. Chinese auto parts manufacturers have been able to maintain high quality standards while keeping their prices competitive.

Another advantage of sourcing auto parts from China is the availability of a wide range of products. Chinese manufacturers offer a diverse range of auto parts, catering to the needs of different types of vehicles and consumers. This makes it easier for buyers to find the specific parts they need, without having to look for them from multiple sources.

However, there are also some challenges associated with sourcing auto parts from China. One of the main challenges is the language barrier, as many Chinese manufacturers may not be proficient in English. This can make communication difficult, especially when it comes to technical specifications and requirements.

Another challenge is the issue of counterfeit products. As the demand for Chinese auto parts has grown, so has the market for counterfeit products. Buyers need to be cautious when sourcing auto parts from China, and ensure that they are dealing with reputable manufacturers who have a track record of delivering high-quality products.

In conclusion, China’s auto parts industry has emerged as a major player in the global market, offering a wide range of quality products at competitive prices. However, buyers need to be aware of the challenges associated with sourcing auto parts from China, and take steps to ensure that they are dealing with reputable manufacturers. With the right precautions, sourcing auto parts from China can be a cost-effective and convenient option for auto manufacturers and consumers alike.

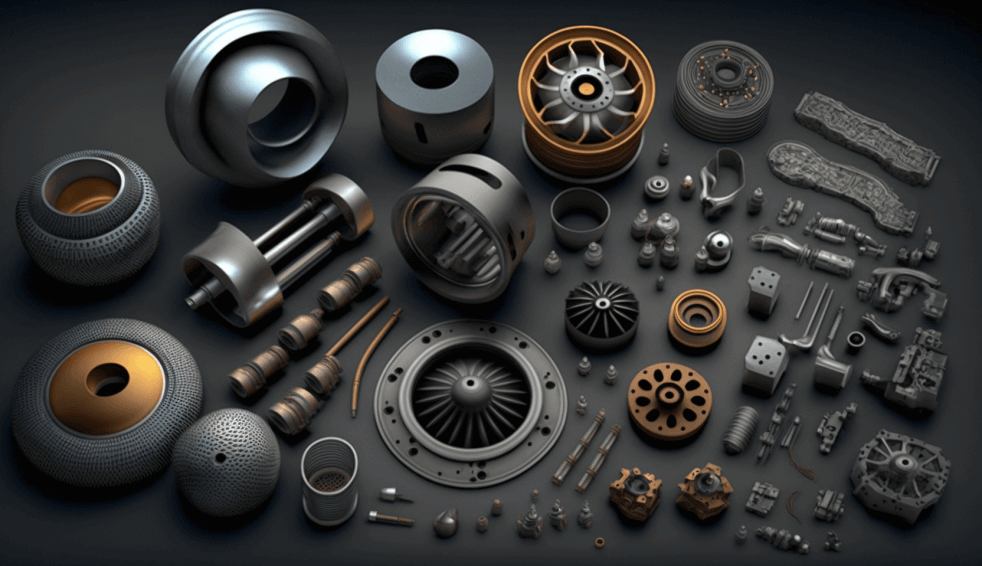

Various Types auto parts china

When it comes to auto parts, China is a leading supplier of different types of auto parts. These auto parts are essential for the functioning of a vehicle and include components such as brakes, suspension, engines, and transmissions. There are several types of auto parts available in China, and this article will discuss some of the most common ones.

1. Brakes

Brakes are one of the most critical components of a vehicle. They are responsible for stopping the car, and their failure can lead to dangerous accidents. China produces different types of brakes, including drum brakes, disc brakes, and hydraulic brakes. The drum brakes are the most common type and are popular due to their low cost and durability. Disc brakes are more expensive but provide better braking performance, especially in high-speed situations.

2. Suspension

The suspension system is responsible for providing a smooth ride and keeping the vehicle stable while driving. China produces various types of suspension systems, including coil springs, leaf springs, and air suspension systems. Coil springs are the most common type and are used in most vehicles. Leaf springs are used in trucks and heavy-duty vehicles as they provide more stability and can carry heavier loads. Air suspension systems are more expensive but provide better ride quality and can adjust the vehicle’s height based on the load.

3. Engines

China produces various types of engines, including diesel and gasoline engines. These engines are used in cars, trucks, and other vehicles. The diesel engines are more fuel-efficient and are used in heavy-duty vehicles, while gasoline engines are more common in cars and light-duty vehicles. China is also a leading producer of electric motors used in electric vehicles.

4. Transmissions

Transmissions are responsible for transferring power from the engine to the wheels. China produces various types of transmissions, including manual and automatic transmissions. Manual transmissions are more common in vehicles with smaller engines, while automatic transmissions are more common in larger vehicles. China also produces continuously variable transmissions (CVT), which provide smoother shifting and better fuel efficiency.

In conclusion, China is a leading supplier of different types of auto parts. These auto parts are essential for the proper functioning of a vehicle and include brakes, suspension, engines, and transmissions. China produces various types of these auto parts, including drum brakes, coil springs, diesel engines, and automatic transmissions. These auto parts are exported worldwide and are popular due to their affordability and quality.

FAQ sourcing auto parts from China manufacturer

Sourcing auto parts from China manufacturers can be a cost-effective way for businesses to acquire the parts they need. However, there are several frequently asked questions about this process that need to be addressed in order for companies to make informed decisions about sourcing from China.

Q: Is it safe to source auto parts from China manufacturers?

A: Yes, it is safe to source auto parts from China manufacturers as long as proper due diligence is done before making any purchases. It is important to research the manufacturer and to ask for references and product samples before placing any orders.

Q: What are the advantages of sourcing auto parts from China manufacturers?

A: The main advantage of sourcing auto parts from China manufacturers is cost savings. China is known for its low labor costs, which allows manufacturers to offer their products at a lower price than competitors in other countries. Additionally, China has a large manufacturing industry, which means there are many options for businesses to choose from.

Q: What are the disadvantages of sourcing auto parts from China manufacturers?

A: The main disadvantage of sourcing auto parts from China manufacturers is the potential for quality issues. While there are many reputable manufacturers in China, there are also some that may produce low-quality or counterfeit products. It is important to do proper research and to work with a trusted supplier to avoid these issues.

Q: How can I ensure the quality of the auto parts I source from China manufacturers?

A: To ensure the quality of the auto parts sourced from China manufacturers, it is important to work with a trusted supplier who has a proven track record of delivering high-quality products. Additionally, businesses should request product samples before making any large purchases and should conduct quality control inspections before shipping the products.

Q: What is the lead time for sourcing auto parts from China manufacturers?

A: The lead time for sourcing auto parts from China manufacturers can vary depending on the manufacturer and the specific product being sourced. Typically, lead times can range from a few weeks to several months. It is important to factor in lead time when planning orders and to work with a supplier who can provide accurate delivery estimates.

In conclusion, sourcing auto parts from China manufacturers can be a cost-effective way for businesses to acquire the parts they need. However, it is important to do proper due diligence, work with trusted suppliers, and ensure the quality of the products being sourced. By addressing these frequently asked questions, companies can make informed decisions about whether sourcing from China is the right choice for them.

Applications of auto parts

Auto parts are the building blocks of automobiles. They are essential components that are used to construct and maintain vehicles. From engines to brakes, auto parts come in various shapes and sizes, and they are designed to perform specific functions in a car. While many people may not realize it, auto parts are not just limited to their use in cars. They have a wide range of applications in other industries as well. In this article, we will explore some of the applications of auto parts beyond the automotive industry.

Industrial Machinery

Auto parts such as gears, bearings, and pulleys are essential components in industrial machinery. They are used to move heavy loads, transmit power, and control the movement of machinery. For instance, gearboxes used in industrial machinery are similar to those found in cars. They are used to control the speed and torque of rotating equipment.

Agriculture

Auto parts are also used in the agriculture industry. Tractors, harvesters, and other farm machinery rely on auto parts such as hydraulic pumps, belts, and bearings to function correctly. For example, hydraulic pumps are used to control the movement of the equipment, while belts are used to transfer power from the engine to the machinery.

Construction

The construction industry also relies on auto parts. Heavy machinery such as bulldozers, excavators, and cranes use auto parts such as engines, transmissions, and hydraulic systems to operate. These parts are designed to withstand heavy loads and harsh environments, making them ideal for use in construction machinery.

Medical Equipment

Auto parts are also used in medical equipment. For example, linear actuators, which are used to control the movement of hospital beds and other medical equipment, are similar to the ones used in car seats. Similarly, hydraulic systems used in wheelchairs and other medical equipment are similar to those used in cars.

Conclusion

In conclusion, auto parts have a wide range of applications beyond the automotive industry. They are essential components in industrial machinery, agriculture, construction, and medical equipment. Their durability and reliability make them ideal for use in other industries where heavy loads and harsh environments are common. As such, the importance of auto parts in our daily lives cannot be overstated.

Industries That Use auto parts

The auto parts industry plays a crucial role in the global economy, providing essential components to various sectors, including the automotive, aerospace, and transportation industries. These industries rely on auto parts for their daily operations and maintaining their machinery to ensure maximum efficiency.

The automotive industry is the primary consumer of auto parts, accounting for a significant portion of the global market. Auto parts are used to manufacture cars, trucks, and other vehicles, including motorcycles, buses, and boats. These parts may include engines, transmissions, brakes, steering systems, electrical and electronic components, and other critical parts.

The aerospace industry also relies on auto parts for its operations. The industry uses auto parts in the production of military and commercial aircraft, helicopters, and space shuttles. These parts include engine components, hydraulic systems, landing gears, and other essential components.

The transportation industry is another significant consumer of auto parts. This industry uses auto parts in the production of trains, ships, and other heavy equipment. Auto parts such as engines, transmissions, and brakes are crucial in ensuring the smooth operation of these machines.

The construction industry also uses auto parts in the production of heavy machinery, including bulldozers, cranes, and excavators. These machines require durable and reliable auto parts to operate efficiently.

Furthermore, the medical industry also uses auto parts in the production of medical equipment, such as MRI machines, X-ray machines, and other medical devices. These machines require high-quality auto parts to ensure their accuracy and precision.

In conclusion, the auto parts industry plays a critical role in various sectors, including the automotive, aerospace, transportation, construction, and medical industries. The demand for auto parts is expected to increase as these industries continue to grow and expand. Therefore, the auto parts industry must continue to innovate and produce high-quality components that meet the ever-changing needs of these sectors.

Manufactured Products made of auto parts

In recent years, there has been a growing trend of using auto parts to create various manufactured products. From furniture to home decor and even fashion accessories, auto parts have found new life beyond their original purpose of being used in cars.

One of the most popular ways that auto parts are being repurposed is by using them to create unique furniture pieces. Old car seats and steering wheels have been transformed into chairs, while engine blocks have been turned into coffee tables. These one-of-a-kind pieces not only add a touch of industrial style to any space, but they also serve as a conversation starter.

Auto parts have also found their way into the world of home decor. Old license plates have been fashioned into wall art, while headlights and taillights have been used as lighting fixtures. These creative uses of auto parts can add a quirky and personalized touch to any living space.

Beyond furniture and decor, auto parts have even been incorporated into fashion accessories. Using old seat belts, designers have created belts and bags that are both stylish and sustainable. Car emblems have also been used as decorative accents on jewelry, adding a unique touch to any outfit.

The use of auto parts in these manufactured products not only offers a creative outlet for designers and artists, but it also promotes sustainability. By repurposing old parts that would otherwise end up in a landfill, these products help reduce waste and conserve resources.

Overall, the versatility of auto parts has proven to be a valuable resource in the world of design and manufacturing. From furniture to fashion, the possibilities are endless when it comes to incorporating auto parts into unique and sustainable products.

The Evolution history of auto parts china

Auto parts have played a significant role in the evolution of the automobile industry. The Chinese auto parts industry has experienced a remarkable evolution throughout the years. The sector has grown to become one of the largest in the world, supplying a significant amount of auto parts to various car manufacturers worldwide. In this article, we will take a look at the evolution history of auto parts in China.

The Chinese auto parts industry started in the 1950s when the country began manufacturing its first automobiles. During this period, the auto parts industry was underdeveloped, and most of the parts were imported from other countries. The industry began to take shape in the 1980s when the Chinese government began the process of opening up the economy through economic reforms. The reforms allowed foreign investors to invest in the country’s auto parts industry.

The 1990s marked a significant milestone in the evolution of the Chinese auto parts industry. During this period, the industry experienced an exponential growth rate, and many foreign investors began to invest in the sector. The growth was attributed to the favorable government policies that were put in place to encourage foreign investment. The government also provided incentives to encourage the establishment of joint ventures between foreign and domestic companies.

By the early 2000s, the Chinese auto parts industry had become one of the largest in the world. The industry had grown to become a major supplier of auto parts to various car manufacturers worldwide. The growth was fueled by the country’s large population, which created a huge demand for automobiles. The industry also benefited from the cheap labor and low production costs in the country.

The Chinese auto parts industry continued to grow in the 2010s, with the government rolling out more favorable policies to encourage the sector’s growth. The policies included tax incentives, subsidies, and other measures aimed at encouraging innovation and the development of new technologies. The government also encouraged the establishment of research and development centers in the country to help the industry keep up with the latest technological advancements.

Today, the Chinese auto parts industry continues to thrive, with many companies investing heavily in research and development to improve the quality of their products. The industry has also shifted its focus from low-cost production to the development of high-quality, innovative products. The industry’s growth has also been fueled by the country’s increasing demand for electric vehicles, which has created a new market for auto parts manufacturers.

In conclusion, the evolution of the Chinese auto parts industry has been remarkable. The industry has grown from a small underdeveloped sector to become one of the largest in the world. The sector’s growth has been attributed to favorable government policies, cheap labor, and the country’s large population. The industry’s focus on innovation and the development of high-quality products has also contributed significantly to its growth. With the increasing demand for electric vehicles, the industry is set to continue growing, and we can expect to see more innovative products coming out of China in the future.

The Process of auto parts china

Auto parts China has become a significant player in the global automotive industry. The country has a thriving auto parts sector that produces a wide range of components to meet the needs of both domestic and international markets. The process of auto parts manufacturing in China has evolved over the years, with the country now being a leader in the production of high-quality and affordable auto parts.

The process of auto parts manufacturing in China begins with sourcing raw materials. China has a rich supply of raw materials that are used in the production of auto parts, including steel, aluminum, rubber, and plastic. These raw materials are sourced from local suppliers, and in some cases, from international markets.

Once the raw materials are sourced, the next step is the production of the auto parts. China has invested heavily in its manufacturing infrastructure, with modern factories equipped with state-of-the-art machinery and technology. These manufacturing facilities are staffed by skilled workers who are trained in the latest production techniques.

The auto parts manufacturing process involves a series of stages, including design, prototyping, testing, and production. The design stage involves the creation of 3D models and blueprints that are used to guide the production process. The prototyping stage involves the creation of physical models that are used to test the design and functionality of the auto parts.

The testing stage is crucial in ensuring that the auto parts meet the required standards of quality and safety. China has a robust quality control system that ensures that all auto parts are tested and inspected before they are released into the market. This includes testing for durability, performance, and safety.

The final stage is the production of the auto parts, which involves the use of high-tech machinery and equipment to manufacture the components. The production process is closely monitored to ensure that the auto parts meet the required specifications and standards.

Once the auto parts are produced, they are shipped to local and international markets. China has a robust logistics system that enables the efficient transportation of auto parts to different parts of the world. This has made China a preferred destination for auto parts buyers who are looking for high-quality and affordable components.

In conclusion, the process of auto parts manufacturing in China has evolved over the years to become a leader in the global automotive industry. The country’s investment in modern manufacturing facilities, skilled workers, and a robust quality control system has enabled it to produce high-quality and affordable auto parts that meet the needs of both domestic and international markets. With a continued focus on innovation and technology, China’s auto parts sector is poised for even greater growth in the future.

Benefits Advantages of Utilizing auto parts china

Auto parts China has been gaining popularity in the global market due to its ability to provide high-quality auto parts at an affordable price. The country has become a hub for the production of auto parts, with many international car manufacturers relying on Chinese-made components. There are several benefits of utilizing auto parts China, which we will discuss below.

Cost-effective

One of the most apparent benefits of using auto parts from China is the cost-effectiveness. The country’s manufacturing industry is well-known for its low labor costs, which translates to cheaper production costs. This allows Chinese manufacturers to offer their products at a lower price point than those produced elsewhere. As a result, businesses that utilize Chinese-made auto parts can save a considerable amount on their expenses.

High-quality products

Despite the low cost, Chinese auto parts are known for their high quality. This is because the Chinese government has implemented strict quality control measures to ensure that all products meet international standards. Additionally, many of the manufacturers in China have invested heavily in advanced technology and machinery to produce high-quality products.

Wide range of products

China is known for its vast manufacturing capabilities, and the auto parts industry is no exception. Chinese manufacturers produce a wide range of auto parts, including engine parts, suspension parts, brake parts, and much more. This means that businesses can source all the parts they need from one supplier, reducing the time and cost associated with sourcing from multiple suppliers.

Customization

Another benefit of utilizing auto parts China is that manufacturers can customize products to meet specific requirements. This is particularly useful for businesses that require unique parts or have specific design specifications. Chinese manufacturers can work with businesses to create custom parts that meet their requirements, ensuring that they receive the exact products they need.

Global distribution

Finally, Chinese manufacturers have a vast international distribution network, making it easy for businesses to source and distribute products globally. This means that businesses can easily access Chinese-made auto parts from anywhere in the world, making it easier to maintain their supply chain.

In conclusion, utilizing auto parts China can offer several benefits for businesses looking to reduce costs without compromising on quality. With the country’s vast manufacturing capabilities, businesses can source a wide range of high-quality auto parts at an affordable price. Additionally, the ability to customize products and the global distribution network makes it a convenient option for businesses operating in the global market.

Disadvantages auto parts china

Auto parts from China have become quite popular in recent years due to their affordability and easy availability. However, there are several disadvantages associated with using auto parts manufactured in China.

One of the primary concerns when it comes to Chinese auto parts is their quality. While there are many reputable manufacturers in China, there are also many cheap knockoffs that are of inferior quality. This can lead to safety issues, as faulty parts can cause accidents or fail at critical moments, such as when braking or steering.

Another issue with Chinese auto parts is the lack of standardization. The automotive industry is heavily regulated, with strict standards and regulations in place to ensure the safety and reliability of vehicles. However, there is no guarantee that Chinese auto parts will meet these standards, as they may be manufactured using cheaper materials or using outdated technology.

Additionally, there is also the issue of intellectual property theft. China has a reputation for producing counterfeit products, including auto parts. This not only hurts the original manufacturers but also puts consumers at risk by providing them with potentially unsafe and unreliable parts.

Furthermore, sourcing auto parts from China can lead to longer lead times and shipping costs. While the parts themselves may be cheaper, the logistics of importing them can be complicated and expensive. This can make it difficult for smaller businesses or individuals to access these parts, as they may not have the resources to navigate international shipping and customs protocols.

In conclusion, while there are certainly advantages to using auto parts from China, such as affordability and availability, there are also significant disadvantages that must be carefully considered. These include concerns about quality, standardization, intellectual property theft, and logistics. Ultimately, it is up to individual consumers and businesses to weigh the pros and cons and make an informed decision about whether or not to use auto parts from China.

Selecting the Ideal auto parts Manufacturer

When it comes to selecting the ideal auto parts manufacturer, there are several factors to consider. From the quality of the products to the level of customer support offered, each aspect plays a crucial role in determining whether a manufacturer is the right fit for your business. With so many options available in the market, it can be challenging to determine which one is the best for your needs. In this article, we will discuss the key aspects to consider when selecting an auto parts manufacturer.

Quality of Products

The quality of the products is undoubtedly the most critical factor to consider when selecting an auto parts manufacturer. It is essential to ensure that the manufacturer produces high-quality auto parts that meet your business’s standards. You can evaluate the quality of the products by inspecting the materials used, the manufacturing process, and the testing procedures performed by the manufacturer. It is also important to ensure that the manufacturer has a good reputation in the industry and has a track record of producing high-quality products.

Variety of Products

Another crucial factor to consider is the variety of products offered by the manufacturer. It is important to select a manufacturer that offers a wide range of auto parts that cater to your business’s needs. This will ensure that you can source all the required auto parts from a single manufacturer, which can save time and reduce costs. It is also essential to ensure that the manufacturer offers the latest and most innovative products in the market.

Price

Price is a critical factor to consider when selecting an auto parts manufacturer. It is important to select a manufacturer that offers competitive prices for their products. However, it is also important to ensure that the price does not compromise the quality of the products. It is essential to strike a balance between the price and quality of the products to ensure that you get the best value for your money.

Customer Support

Customer support is another important aspect to consider when selecting an auto parts manufacturer. It is important to select a manufacturer that offers excellent customer support to ensure that any issues or concerns are promptly addressed. This will ensure that you have a smooth and hassle-free experience when dealing with the manufacturer.

Delivery Time

Delivery time is another critical factor to consider when selecting an auto parts manufacturer. It is important to select a manufacturer that has a fast and reliable delivery system to ensure that you get the required auto parts in a timely manner. This will ensure that your business operations are not disrupted due to a delay in the delivery of auto parts.

In conclusion, selecting the ideal auto parts manufacturer requires careful consideration of several factors. The quality of the products, variety of products, price, customer support, and delivery time are some of the key aspects to consider when selecting a manufacturer. By evaluating each of these factors, you can select a manufacturer that meets your business’s needs and ensures that you get the best value for your money.

Things to Consider When Purchasing auto parts

When it comes to maintaining your vehicle, purchasing auto parts is an essential part of the process. However, buying auto parts can be a daunting task, especially if you’re not familiar with the process. To ensure that you’re getting the right parts for your vehicle, there are several things that you need to consider before making a purchase.

Compatibility

The first thing you need to consider when buying auto parts is compatibility. Not all parts are made to fit every make and model of car. You need to ensure that the part you’re purchasing is compatible with your vehicle. This means checking the part number, make, model, and year of your car to match the part you’re buying.

Quality

The quality of the auto parts is another factor that you need to consider. You want to ensure that you’re getting high-quality parts that will last longer and perform better. Low-quality parts may seem like a cheaper option at first, but they can be more expensive in the long run as they may need to be replaced more frequently.

Price

Price is also an essential factor to consider when purchasing auto parts. While you don’t want to break the bank, you also don’t want to sacrifice quality for a lower price. Do some research and compare prices from different suppliers to ensure that you’re getting the best deal without compromising on quality.

Warranty

The warranty is an essential factor that you should always consider when purchasing auto parts. A good warranty can provide you with peace of mind and protect you against any defects or faults in the parts. Always check the warranty before making a purchase and ensure that you understand the terms and conditions.

Brand

The brand of the auto parts is also something to consider. Some brands have a reputation for producing high-quality parts, while others are known for producing lower quality parts. Do some research on the brand you’re considering and read reviews from other customers to ensure that you’re getting the best quality parts.

Availability

The availability of the auto parts is another factor to consider. Some parts may be harder to find than others, and this can cause delays in the repair process. Always check the availability of the parts you need before making a purchase to ensure that you can get them when you need them.

Conclusion

Purchasing auto parts can be a daunting task, but by considering the factors above, you can ensure that you’re getting the right parts for your vehicle. Remember to always check compatibility, quality, price, warranty, brand, and availability before making a purchase. By doing so, you can ensure that your vehicle is running smoothly and efficiently.

Properties auto parts

When it comes to maintaining your vehicle, auto parts play a vital role in ensuring its smooth functioning. Auto parts are the components that make up a vehicle, including the engine, transmission, brakes, suspension, exhaust system, and more. Each of these parts has specific properties that contribute to the overall performance of the vehicle.

The engine is the heart of the vehicle, and it is responsible for producing power to move the car. The properties of engine parts vary depending on their function. For example, the pistons are designed to withstand high temperatures and pressure, while the crankshaft must be strong enough to withstand the force of the pistons.

Similarly, the transmission is responsible for transferring power from the engine to the wheels. Transmission parts must be able to withstand high torque and heat generated by the engine. The gears and bearings must be designed to handle the load and prevent wear and tear.

The brakes are responsible for stopping the vehicle, and they rely on various parts to function correctly. Brake pads must be able to withstand high temperatures and generate enough friction to slow down the vehicle. Brake discs or rotors must be able to dissipate heat quickly to prevent warping.

The suspension system is responsible for providing a comfortable ride and ensuring the vehicle’s stability. Suspension parts must be able to absorb shocks and vibrations and provide adequate support to the vehicle.

The exhaust system is responsible for removing exhaust gases from the engine and reducing emissions. Exhaust parts must be able to withstand high temperatures and pressure and prevent leaks.

In addition to these properties, auto parts must also be designed to fit specific makes and models of vehicles. This is why it is essential to use genuine parts or high-quality aftermarket parts when replacing or repairing components.

In conclusion, auto parts play a crucial role in the performance and safety of a vehicle. Each part has specific properties that contribute to the overall functioning of the vehicle. It is essential to use high-quality parts that fit your vehicle’s make and model to ensure its smooth functioning and longevity.

How to use auto parts

Auto parts are essential components that keep your vehicle running smoothly. Whether you are a mechanic or a car owner, knowing how to use auto parts can save you time and money. In this article, we will discuss some tips on how to use auto parts effectively.

1. Identify the problem

The first step in using auto parts is to identify the problem. If you are experiencing issues with your car, take the time to diagnose the problem. This will help you identify the parts that need to be replaced or repaired.

2. Choose the right part

Once you have identified the problem, you need to choose the right auto part. Make sure to choose a part that is compatible with your vehicle’s make and model. You can consult your vehicle manual or a mechanic to help you choose the right part.

3. Check for quality

Quality is essential when it comes to auto parts. Make sure to check for the quality of the part before purchasing it. A high-quality part will ensure that your vehicle runs smoothly and lasts longer.

4. Follow instructions

When installing the auto part, follow the instructions carefully. Make sure to use the right tools and follow the correct steps. This will prevent damage to the part and ensure that it is installed correctly.

5. Test the part

After installing the auto part, test it to ensure that it is working correctly. If you are not sure how to test the part, consult a mechanic or refer to your vehicle manual.

6. Maintain the part

Proper maintenance is essential to ensure that the auto part lasts longer. Make sure to clean and lubricate the part regularly. This will prevent wear and tear and extend the life of the part.

In conclusion, using auto parts is not rocket science. With the right knowledge and skills, you can easily install and maintain auto parts. Remember to identify the problem, choose the right part, check for quality, follow instructions, test the part, and maintain it properly. By following these tips, you can save money and ensure that your vehicle runs smoothly.

Glossary Terminology Terms auto parts china

Auto parts are a vital component in the manufacturing and maintenance of vehicles. With the increase in the number of vehicles on the road, the demand for auto parts has also risen. China has become one of the leading countries in the production and supply of auto parts worldwide.

To better understand the world of auto parts manufacturing, it is essential to know the terminology used in the industry. Here are some of the most common terms used in the auto parts industry in China:

1. OEM: Original Equipment Manufacturer refers to a company that produces parts for a vehicle manufacturer who then installs them on their vehicles.

2. Aftermarket: These are auto parts that are not made by the original equipment manufacturer but by other companies, often to replace worn-out or damaged parts.

3. Tier 1, 2, 3: These terms refer to the level of suppliers in the auto parts supply chain. Tier 1 suppliers provide parts directly to the vehicle manufacturer, while Tier 2 and 3 suppliers provide parts to Tier 1 suppliers.

4. Quality Control: The process of ensuring that the auto parts produced meet the required standards for safety, reliability, and performance.

5. Just-In-Time (JIT): A manufacturing strategy that involves producing and delivering auto parts to the manufacturer just in time for assembly, reducing inventory costs.

6. Capacity Utilization: The percentage of manufacturing capacity used to produce auto parts at any given time.

7. Lean Manufacturing: A manufacturing strategy that involves reducing waste and improving efficiency in the production process.

China has become a major player in the global auto parts industry due to its low labor costs and advanced manufacturing capabilities. The country has a vast network of suppliers, from Tier 1 to Tier 3, that produce a wide range of auto parts, from engines to electronics.

The demand for auto parts in China has also increased due to the growth of the domestic automotive industry. China is now the world’s largest market for vehicles, and this has led to an increase in the demand for auto parts.

In conclusion, understanding the terminology used in the auto parts industry is essential for anyone involved in the manufacturing or maintenance of vehicles. China has become a significant player in the global auto parts industry, and its vast network of suppliers and advanced manufacturing capabilities make it an attractive destination for auto parts production.