Benefits of Belt Grinders For Knife Making

Belt grinders are the perfect tool for any knife maker. With a belt grinder, you can easily and quickly grind your sharp blade edges, ensuring they are perfectly symmetrical and ready for use. Here we discuss the benefits of belt grinders for knife making.

One of the most significant benefits of belt grinders is speed. Belt grinders have a faster grinding speed than many other types of grinders, making them an ideal tool for any knife maker. With a belt grinder, you can easily grind your blade edges with precision and speed, resulting in a high-quality, polished finish.

Another benefit of belt grinders is versatility. A belt grinder can be used to grind different types of materials like steel, brass, and even wood, as long as you use the right type of belt. Because of this, belt grinders are not just handy for knife making but also for other projects.

Belt grinders also allow for better control of the grinding process. Knife making requires precision work, and belt grinders offer the kind of control necessary to produce high-quality knives. With a belt grinder, you can easily adjust the angle of the blade and apply just the right amount of pressure to produce a perfect edge.

Finally, belt grinders are long-lasting, making them an excellent investment for any knife maker. With proper use, a belt grinder can last for years or even decades. It pays to invest in a high-quality machine from a reliable manufacturer.

In conclusion, a belt grinder is a must-have tool for professional and amateur knife makers alike. With speed, versatility, precision control, and longevity, belt grinders offer a range of benefits that make them the best choice for grinding the perfect edge on your knives.

Features of Belt Grinders For Knife Making

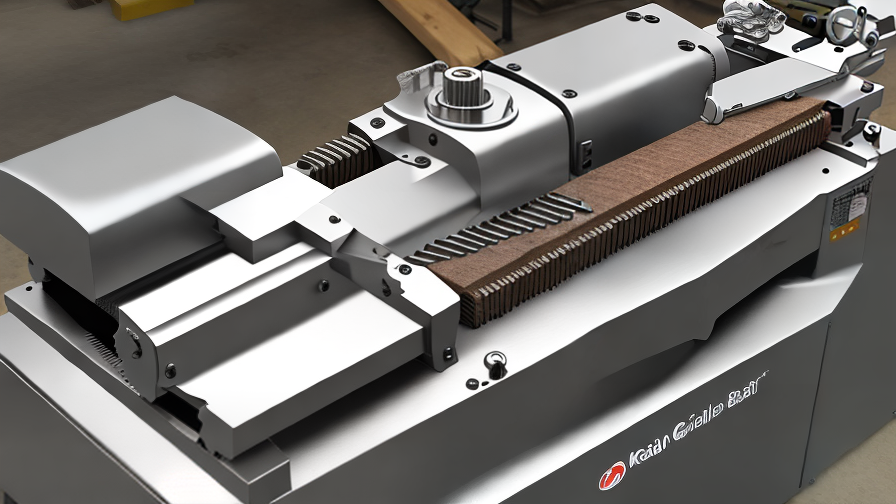

Belt grinders are an essential tool for knife makers. They allow knife makers to shape and polish their blades quickly and easily. These grinders come in a variety of sizes and shapes, but all have several key features that make them ideal for knife making.

One of the most important features of a belt grinder is the speed of the belt. High-speed belts are ideal for shaping metal quickly, while slower belts are better for polishing and finishing. A good belt grinder will have adjustable speeds, allowing knife makers to fine-tune the speed to their specific needs.

Another important feature is the size of the belt. Most belt grinders come with a 2-inch wide belt, but some models feature wider belts. Wider belts are better for faster material removal, but they can be more expensive.

A good belt grinder also needs a powerful motor. The motor should be powerful enough to drive the belt at high speeds without bogging down. A motor with at least 1.5 horsepower is ideal for most knife makers.

The construction of the belt grinder is also important. The grinder should be made of heavy-duty materials that can withstand the rigors of knife making. Look for grinders made of steel, aluminum, or cast iron.

Finally, a good belt grinder should be easy to use and maintain. Look for grinders that are easy to adjust, with clear instructions for changing belts and making other adjustments. Some models even come with built-in tool rests that make it easy to find the right angle for your knife.

In conclusion, a belt grinder is an essential tool for knife makers. Look for models with powerful motors, adjustable speeds, and sturdy construction. With a good belt grinder, you’ll be able to shape and polish your blades quickly and easily, making your knife making process more efficient and enjoyable.

Various Types of Belt Grinders For Knife Making

When it comes to knife making, a belt grinder is an essential tool for any craftsman. A belt grinder is a tool that is used to grind and sand metals, wood, and plastics. Belt grinders can be used to sharpen knives, blades or any other raw material.

Here are some of the various types of belt grinders that are used for knife making:

1. Benchtop Belt Grinders:

These belt grinders are great for smaller shops or home-based business. They are typically mounted on a bench for easy operation and access. They are also relatively inexpensive, making them a great choice for those just starting out.

2. Portable Belt Grinders:

As the name implies, these belt grinders are portable and ideal for those who need to move their tools around frequently. These belt grinders are great for sharpening and grinding knives on the go.

3. Wet Belt Grinders:

Wet belt grinders are perfect for those who need to maintain a cool temperature during the grinding process. These belt grinders use water to cool down the metal and prevent overheating during the grinding process.

4. 2×72 Belt Grinders:

The 2×72 belt grinder is a popular tool among knife makers. It is versatile and makes sanding and grinding extremely easy. It is a great choice for those who need to sand large pieces of metal quickly and efficiently.

5. Variable Speed Belt Grinders:

Variable speed belt grinders are perfect for those who need to adjust the speed of their grinding to match their material. By adjusting the speed of the belt, you can ensure that your metals or blades are being ground at the appropriate speed.

In conclusion, there are many different types of belt grinders on the market, with a variety of features and options available. When choosing a belt grinder for knife making, it is important to consider your specific needs and budget. The right belt grinder can make all the difference in the quality of your finished product, so take the time to choose one that will best suit your needs.

Applications of Belt Grinders For Knife Making

Belt grinders are versatile tools that are used in a wide range of industries, including knife making. Belt grinders offer a quick and efficient way to create clean, sharp edges on blades, making them an essential tool for any knife maker.

One of the most common applications of belt grinders in knife making is the beveling process. Beveling is the process of grinding the edge of a blade to create a sharp, angled edge. Belt grinders are the preferred tool for this process due to their speed, consistency, and ability to remove large amounts of material quickly.

Another application of belt grinders in knife making is the grinding and sanding of handles. Many knife makers use belt grinders to shape and sand handles made from a variety of materials, including wood, bone, and synthetic materials. Belt grinders allow for precision shaping and sanding, resulting in a perfectly shaped and smooth handle.

Belt grinders can also be used for finishing work on blades. After the blade has been beveled and sharpened, belt grinders can be used to create a polished, mirror-like finish on the blade. This process, known as buffing or polishing, can be done quickly and efficiently with the use of a belt grinder.

In addition to knife making, belt grinders have many other applications, including metalworking, woodworking, and automotive work. Belt grinders can be used to grind and shape metal and wood, as well as remove rust and other surface imperfections.

Overall, belt grinders are essential tools for any knife maker. They offer a quick, efficient, and precise way to create clean, sharp edges on blades, as well as shape and finish handles. With their versatility and customizable features, belt grinders are a popular choice for knife makers looking to improve their craft.

The Process of Belt Grinders For Knife Making

Belt grinders are essential tools for knife makers who want to create high-quality, sharp blades. These machines use an abrasive belt to remove metal and shape the blade. The process involves several steps, including selecting the right belt, adjusting the machine’s settings, and using proper techniques to achieve the desired results.

The first step in the process is selecting the right belt for the job. Belt grinders come in various sizes, and the belt’s grit is crucial to getting the results you want. For knife making, a medium-grit belt is usually the best choice. It will remove material quickly but leaves a good finish. You could also use fine-grit belts for achieving a smooth finish.

Once you’ve chosen the right belt, it’s time to adjust the machine’s settings. To get the right results, you need to adjust the speed and angle of the grinding head. The speed should be set to a level that allows you to remove material efficiently without overheating the blade. The angle should be set at a degree that allows you to work efficiently and achieve your desired results.

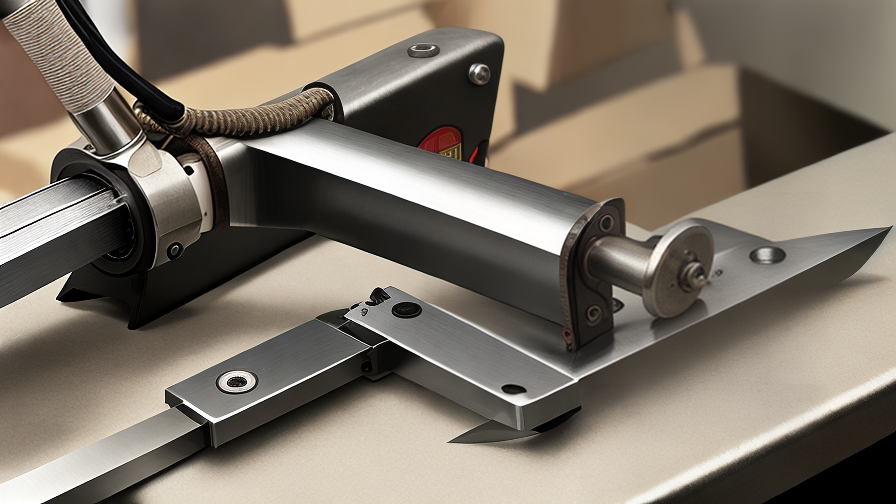

The grinding process begins by holding the blade against the belt and moving it slowly across the surface. You need to use a steady hand to prevent the blade from slipping or getting caught in the belt. Work slowly and patiently, making sure to cover the entire blade surface evenly.

After every pass over the belt, you should flip the blade over and repeat the process on the other side. This ensures that both sides of the blade are ground evenly. Continue this process, changing to finer grit belts as you go, to achieve the desired sharpness and finish.

In conclusion, belt grinders are an essential tool for knife makers, and the process requires precision and patience. Choose the right belt and adjust the machine’s settings before starting the grind. Use a steady hand and work patiently, and you’ll be able to create sharp, high-quality blades that will last a long time.

How to use Belt Grinders For Knife Making

Belt grinders are specially designed tools for heavy-duty material removal, precision sharpening, and finishing of metal products. If you’re a knife-making hobbyist, using a belt grinder can help you achieve smooth, straight edges, and optimal blade geometry. Here’s a beginner’s guide on how to use a belt grinder for knife making.

1. Get the right machine: Look for a belt grinder with a heavy-duty motor that runs at 1,800 RPM or higher, has multiple speed settings, and comes with variable belt positions for versatility. Some features to consider include adjustable tool rests, dust collection ports, and quick-release systems.

2. Choose the right belts: Select the right belt grit for the type of knife you’re making. Coarse belts are good for grinding rough surfaces, while fine belts can be used for sharpening and polishing blades. Durability is also essential, so consider investing in high-quality belts that can withstand heavy use.

3. Prepare the workspace: Make sure you work in a well-ventilated area with proper illumination. Clear out any debris, clutter, and flammable materials as sparks and hot metal bits can fly off during the grinding process. Put on personal protective gear such as safety glasses, gloves, and durable clothing.

4. Set up the grinders: Start by attaching the right belt to your grinder and aligning the tracking system to keep the belt centered. Adjust the tool rest angle and height based on the type of grind you want to achieve. Set the speed to low until you get comfortable with the handling.

5. Start the grinding process: Hold the blade against the grinding belt at the proper angle, applying gentle pressure against the direction of the belt’s rotation. Move the blade along the length of the belt in straight lines, using both hands to control its angle and position.

6. Check the progress: After a few passes, check the blade’s progress by wiping off any debris and checking for the right shape, thickness, and consistency.

7. Finishing touches: Once you’re happy with the blade’s grind, move to a finer belt grit for polishing and sharpening. Continue until you achieve the desired edge angle and surface finish.

8. Clean up: Turn off the belt grinder and use a wire brush to remove any debris or metal shavings from the machine. Use compressed air or a cleaning brush to clear dust and debris from the air vents, tracking system, and other components.

In conclusion, mastering how to use a belt grinder for knife making can be rewarding and profitable. With practice, patience, and the right tools, you can create high-quality knives that will impress even the most discerning customers.

Selecting the Ideal Manufacturer Belt Grinders For Knife Making

When it comes to knife making, a belt grinder is an essential tool. It allows for precision and speed when shaping and finishing blades. The market is flooded with various belt grinder manufacturers, and selecting the ideal one can be overwhelming. Here are some factors to consider when choosing the best manufacturer belt grinders for knife making.

1. Quality of the Grinder – Quality is essential in knife making. Therefore, it is essential to consider the quality of the grinder. When selecting a grinder, look for robust construction, efficient motor and high-quality materials.

2. Belt Size – Belt size is also an important factor to consider when choosing a grinder. If you are working on bigger blades, then you may need a bigger belt size. However, if you are working on smaller blades, then a smaller belt grinder may be ideal.

3. Motor Power – The motor power determines the speed and efficiency of the grinder. Select a grinder that has a powerful motor that can handle tough projects. The motor should also have enough torque to handle heavy workloads.

4. Belt Speed – Depending on the blade, you may need a different belt speed. Some blades require high speeds, while others need slower speeds. Therefore, choose a grinder that has different belt speed options.

5. Warranty – A warranty is an essential factor to consider when purchasing a belt grinder. A good warranty will cover any repair or replacement costs that may arise during the warranty period.

In conclusion, selecting the ideal manufacturer belt grinders for knife making requires careful consideration. Look for a high-quality, robust, efficient motor, and high-quality materials. Choose a belt grinder with the correct belt size, motor power, belt speed, and warranty. With the right belt grinder, knife making becomes an enjoyable and efficient process.

list FAQ with answer about Belt Grinders For Knife Making

Belt grinders for knife making have become increasingly popular among knife enthusiasts and hobbyists. However, for those new to the craft, there may be some common questions and concerns. Here are some frequently asked questions and answers about belt grinders for knife making:

1. What is a belt grinder?

A belt grinder is a power tool that uses a belt to grind and polish various materials. For knife making, it is used to sharpen, shape, and texture the blade.

2. What types of belt grinders are suitable for knife making?

There are several types of belt grinders available, but the most suitable for knife making are the 2×72 belt grinders featuring a large contact wheel and a flat platen.

3. What grit should I use when grinding knives?

The grit used depends on the purpose of the grind. For rough shaping and removing material, a lower grit such as 36 or 60 is ideal. For finer shaping and finishing, a higher grit such as 220 or 400 is recommended.

4. What type of belt should I use for knife making?

Zirconia abrasive belts are ideal for knife making as they are durable and long-lasting. Other options include ceramic, aluminum oxide, and silicon carbide.

5. How do I maintain and care for my belt grinder?

It is important to keep the machine clean and free from debris. Lubricating the moving parts and regularly changing the belts is also essential for the longevity of the machine.

6. Can a belt grinder be used to make a full knife?

While a belt grinder is useful for shaping and sharpening the blade, it is not recommended for making the entire knife. Other tools such as a bandsaw, drill press, and bench grinder are necessary for the full construction of a knife.

In conclusion, a belt grinder is an essential tool for any knife maker, but choosing the right type of grinder and grit for the job is crucial. Maintaining the machine and using appropriate safety equipment such as gloves and eye protection is also important for safe and successful knife making.

Things to Consider When Purchasing Belt Grinders For Knife Making

When it comes to knife making, a belt grinder can make all the difference in the final result. When considering purchasing a belt grinder for your knife making endeavors, there are a few key things to keep in mind.

Firstly, you’ll want to think about the size and power of the belt grinder. If you’ll be working on larger blades or pieces of metal, you’ll want a larger and more powerful grinder. Smaller grinders may have trouble with larger jobs or may take longer to complete them.

Another important factor to consider is the type of belt grinder. There are several different types, including horizontal, vertical, and combination grinders. Each has its own advantages and disadvantages, so you’ll want to choose the one that best fits your needs and preferences.

You’ll also want to consider the belt size and speed. Certain belt sizes and speeds may be better suited to certain tasks, so think about the type of work you’ll be doing when making your selection.

Durability is another key factor. Look for a belt grinder that is made from high-quality materials and built to last. This will ensure that you can use it for many years to come without needing to replace it.

Lastly, consider the price. Higher-end belt grinders may come with more features and be of higher quality, but they will also come with a higher price tag. Decide on a budget before making your purchase and stick to it.

Overall, when purchasing a belt grinder for knife making, it’s important to consider the size, type, belt size and speed, durability, and price. With these factors in mind, you can choose a grinder that will help you create the perfect knife every time.

Properties of Belt Grinders For Knife Making

Belt grinders are essential tools for knife making, and the right qualities can make all the difference between excellent and mediocre results. One of the most important properties of a belt grinder is its motor size. A motor with high horsepower ensures that even the toughest materials are ground without grinding to a halt.

The belt speed of a grinder is another critical feature. Faster belt speeds can reduce the time it takes to finish a knife, while slower speeds are ideal for fine work. Another vital aspect to consider when choosing a belt grinder is the type of belt used. Zirconia belts manage to grind away steel much faster, while belts made of ceramic materials are better for polishing.

The platen of a belt grinder is also something to consider. The platen is essentially a flat surface that holds the belt in place. Some belt grinders allow the platen to be adjusted, while others are fixed in position. An adjustable platen allows for more control over the grinding process.

Lastly, a belt grinder’s wheel size should factor into your decision. A larger wheel size provides a larger grinding area, making it easier to maneuver the workpiece, and also lasts longer.

In conclusion, a belt grinder is a crucial tool for every knife maker, and choosing the right one is essential to obtain the best possible results. The horsepower of the motor, belt speed, belt type, platen adjustment, and wheel size are all critical factors to consider when selecting the perfect belt grinder for your needs. Getting all these factors right can help you achieve precise and professional results, making your knife making efforts both easier and more successful.

Technical Parameters Terms for Belt Grinders For Knife Making

Belt grinders for knife making are an essential tool for any knife maker, whether you are a professional or a hobbyist. Before purchasing a belt grinder, it’s important to know the technical parameters and what they mean to ensure that you get the right tool for your specific needs.

One of the most important technical parameters is the belt size, which refers to the length and width of the belt. Belt sizes for knife making typically range from 1×30 inches to 2×72 inches. The bigger the belt size, the more surface area there is for grinding, which means that the workpiece can be ground more quickly and efficiently.

Another important parameter is the motor power. Most belt grinders for knife making have motors that range from 1/2 horsepower to 2 horsepower. Higher horsepower means more power and faster grinding, which can save time and increase productivity.

The speed of the belt is also an important consideration. Belt speeds for knife making can range from 2,000 to 7,000 feet per minute. The faster the belt speed, the more aggressively the grinder will grind. However, a faster speed can also create more heat, which can damage the workpiece.

Tensioning mechanisms are also an important consideration. A good tensioning mechanism should be easy to adjust and maintain constant tension on the belt during operation.

Other important technical parameters include the size of the grinding table, the type of platen, and the overall construction of the grinder.

In conclusion, when looking for a belt grinder for knife making, it’s important to take into account these technical parameters to ensure that you get the right tool for your specific needs. With the right belt grinder, creating high-quality knives is much easier and more efficient.

Belt Grinders For Knife Making Price

Belt grinders are a vital tool for knife making, providing precision and efficiency in the grinding process. However, the cost of a belt grinder can vary depending on the size and features of the machine.

Basic belt grinders suitable for home knife-making projects typically start around $250 and can go up to $600. These grinders usually have a single-speed motor and a small belt, making them ideal for DIY projects and small-scale knife making.

Mid-range belt grinders range from $600 to $1,000 and typically offer a larger motor and a larger belt. These grinders are more powerful and can handle larger and tougher materials. Additionally, they often come with more advanced features, such as adjustable speed control, tilt tables, and dust collection ports.

Professional-grade belt grinders with higher HP motors, variable speed controls, and larger belts can cost upwards of $1,000. These grinders are designed for heavy-duty tasks and are typically used in industrial settings. They offer precision and speed, making them an excellent choice for professional knife makers.

It is crucial to consider the size and power of the belt grinder when choosing one for your knife-making projects. If you are a beginner or working on small projects, a basic belt grinder may be sufficient. However, if you are a professional or working on larger projects, investing in a mid-range or professional-grade belt grinder may provide greater efficiency and productivity.

In conclusion, belt grinders are essential for knife making, and their cost varies depending on the size and features of the machine. It is important to consider your needs and budget when choosing a belt grinder for your knife-making projects.