Introduce about cheap cnc mill guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

The Cheap CNC Mill Guide is an insightful resource that aims to provide valuable information about affordable Computer Numerical Control (CNC) mills. As the name suggests, it focuses on budget-friendly options, guiding readers through the selection process by considering important factors such as quality, cost, suppliers, and certifications.

Quality is a critical aspect to consider when purchasing a cheap CNC mill. The guide emphasizes the importance of finding a machine that delivers satisfactory performance at an affordable price. It offers tips on identifying reputable brands and models that offer good value for money.

Cost is, of course, a significant consideration for those seeking a cheap CNC mill. The guide helps readers understand the price ranges and factors that influence costs. Additionally, it provides insights on cost-saving measures and alternative options, enabling readers to make informed decisions that suit their budget requirements.

Finding reliable suppliers for affordable CNC mills can be challenging. The guide offers tips on sourcing reputable suppliers and suggests exploring both local and online platforms. It also advises readers to thoroughly research and review supplier credentials to ensure a smooth purchasing experience.

Certification is an important factor to consider when buying a CNC mill. The guide highlights the significance of looking for machines with appropriate certifications, which verify their quality and safety standards. It provides details on recognized certifications and explores their significance in the purchasing decision-making process.

Market trends and insights are also covered within the guide. It provides an overview of the current market landscape, outlining popular models and brands in the affordable CNC mill segment. By staying informed about the latest market developments, readers can make more informed decisions when choosing a suitable machine that meets their needs.

Finally, the guide concludes with a FAQ section that addresses common queries and concerns related to cheap CNC mills. It provides concise yet comprehensive answers to help readers navigate the buying process more effectively.

In conclusion, the Cheap CNC Mill Guide is a concise and informative resource that offers insightful information about affordable CNC mills. It covers essential topics such as quality, cost, suppliers, certifications, market trends, tips, and FAQs, aimed at assisting readers in making well-informed purchasing decisions without exceeding 300 words.

Types of cheap cnc mill

There are several types of cheap CNC mills available on the market that provide cost-effective solutions for individuals or small businesses looking to automate their machining processes. Here are three common types:

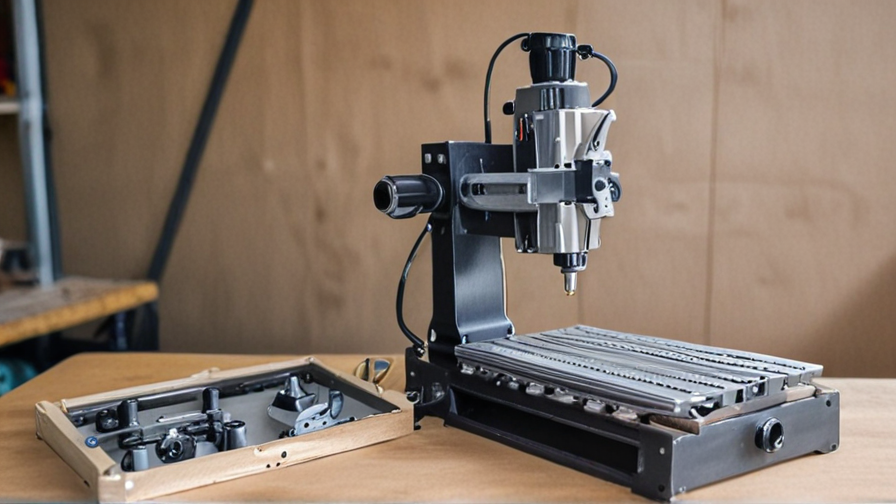

1. Desktop CNC mills: These are compact and affordable CNC machines designed for small-scale projects. They are popular among hobbyists, makers, and students. Typically, they have a smaller working area and can handle lighter materials like wood, plastics, and soft metals. Desktop CNC mills often come as DIY kits or pre-assembled machines that can be operated from a computer.

2. Benchtop CNC mills: Slightly larger and more robust than desktop mills, benchtop CNC mills offer greater stability and accuracy. They are suitable for intermediate level machining tasks on a variety of materials including metal, composites, and finer machining of wood or plastic. Benchtop CNC mills are often used in education, prototyping, or small-scale production as they provide good precision and versatility at an affordable price.

3. Mini CNC mills: Mini mills are typically compact, portable, and perfect for small machining tasks that do not require a large working area. They are budget-friendly and often come in DIY kits. Although mini mills may not have the same level of rigidity and power as larger machines, they are capable of producing precise parts in softer materials like wood, plastics, or aluminum.

When looking for a cheap CNC mill, factors to consider include the machine’s accuracy, rigidity, material compatibility, motor power, control system, and available software. It is important to assess the specific requirements of your projects and choose a machine that provides the right balance between cost and functionality.

Overall, desktop CNC mills, benchtop CNC mills, and mini CNC mills offer affordable options for different machining needs. By understanding their capabilities and limitations, individuals and small businesses can make an informed decision to enhance their productivity while staying within a limited budget.

Pros and Cons of Using cheap cnc mill

Using a cheap CNC mill can have both pros and cons. Let’s explore them in detail below.

Pros:

1. Cost-effective: One of the major advantages of using a cheap CNC mill is its low cost. These machines often come at a fraction of the price of high-end mills, making them more accessible to small businesses or individuals on a tight budget.

2. Entry-level learning: Cheap CNC mills can be an excellent tool for beginners who want to learn about CNC machining without investing a significant amount of money. They provide an opportunity to gain hands-on experience without the financial risk associated with expensive machinery.

3. Hobbyist-friendly: For hobbyists or DIY enthusiasts, a cheap CNC mill offers a cost-effective way to explore their creativity and bring their ideas to life. It allows them to experiment with various materials and designs without breaking the bank.

4. Versatile: While they may lack advanced features, cheap CNC mills often offer a good range of functionality suitable for a wide variety of applications. They can handle multiple materials such as wood, plastics, and soft metals, making them suitable for basic machining tasks.

Cons:

1. Limited capabilities: Cheap CNC mills are usually entry-level machines, and as such, they may have limitations in terms of precision, speed, and overall performance. These limitations can restrict the complexity and intricacy of the projects that can be accomplished.

2. Lower durability: Lower-cost machines are often made with less durable materials and components. This can result in issues such as decreased accuracy, reduced lifespan, and increased maintenance needs compared to higher-end CNC mills.

3. Limited support and upgrades: Cheap CNC mills may have limited or fragmented support in terms of documentation, software compatibility, and available upgrades. This can make it challenging to find resources or troubleshoot issues effectively, potentially affecting productivity and efficiency.

4. Productivity and efficiency constraints: Due to their lower performance capabilities, cheap CNC mills may have slower cutting speeds, limited tool capacity, and reduced automation options. This can impact productivity and efficiency, especially for larger or more complex projects.

In conclusion, using a cheap CNC mill can be a viable option for beginners, hobbyists, or those with budget constraints. However, it is important to consider the limitations and potential drawbacks these machines may have, and evaluate if they align with the intended usage and desired outcomes.

cheap cnc mill Reference Specifications (varies for different product)

A cheap CNC mill is typically a small-scale, entry-level machine that offers basic milling capabilities at an affordable price point. These machines are designed for hobbyists, small workshops, and budget-conscious buyers who require precision and versatility in their machining projects without breaking the bank.

One of the key specifications to look for in a cheap CNC mill is the machine’s working area or its table size. While this may vary across different products, a typical cheap CNC mill may offer a working area of around 12 x 8 inches to 24 x 12 inches. This size is usually sufficient for small to medium-sized projects.

Another important specification is the spindle speed. Cheap CNC mills usually have lower spindle speeds compared to their higher-end counterparts. A typical cheap CNC mill may have a spindle speed ranging from 3,000 to 10,000 RPM (rotations per minute). This speed range is suitable for machining various materials such as wood, plastic, and soft metals like aluminum.

The spindle motor power is also a crucial specification to consider. In the case of cheap CNC mills, the spindle motor power is typically between 0.5 to 3 horsepower. While this power range may not be suitable for heavy-duty machining tasks, it is sufficient for most hobbyist and light to medium milling applications.

Additionally, cheap CNC mills often come with a limited tool capacity. They may support between 3 to 6 tool positions, depending on the specific model. However, this is generally suitable for small-scale projects or beginners who don’t require complex tool changes frequently.

Moreover, cheap CNC mills may have lower positioning accuracy and repeatability compared to more expensive machines. They typically offer a positioning accuracy within a few thousandths of an inch and a repeatability of around 0.001 inches. Although not as precise as high-end models, these tolerances are generally sufficient for hobbyist applications.

Lastly, cheap CNC mills commonly include basic software for designing or generating G-code, the language that controls the machine. Additionally, they usually support standard communication protocols such as USB or parallel port, making it easy to connect the mill to a computer.

In summary, a cheap CNC mill usually offers a smaller working area, lower spindle speeds, limited tool capacity, moderate power, and slightly lower accuracy compared to more expensive counterparts. However, they still provide adequate functionality for hobbyists and small-scale machining projects, making them a cost-effective option for those seeking a basic CNC milling solution.

Applications of cheap cnc mill

A cheap CNC mill refers to a computer numerically controlled milling machine that is affordable and offers a cost-effective solution for various industries and applications. Despite its low price, a cheap CNC mill can still provide high precision and efficiency in machining processes. Here are some applications where a cheap CNC mill can be used:

1. Prototyping and Small-Scale Manufacturing: CNC mills are widely used in prototyping and small-scale manufacturing due to their ability to quickly and accurately produce complex parts. From creating prototypes for product development to producing custom components for small-scale production runs, a cheap CNC mill can significantly reduce lead times and costs.

2. Hobbyist and DIY Projects: With the availability of affordable CNC mills, hobbyists and do-it-yourself enthusiasts can easily venture into more advanced machining projects. Whether it’s engraving designs on various materials, creating custom parts and accessories, or even building their own CNC machines, the accessibility of a cheap CNC mill opens up a world of creative possibilities.

3. Education and Training: CNC mills are extensively used in technical schools, colleges, and vocational training centers to teach students the fundamentals of machining and manufacturing processes. Affordable CNC mills enable educational institutions to provide hands-on experience and practical knowledge to students, preparing them for careers in engineering, machining, and related fields.

4. Arts and Crafts: CNC mills can be utilized in artistic endeavors such as crafting intricate sculptures, decorative ornaments, and personalized jewelry. The precision and versatility of a cheap CNC mill allow artists and craftsmen to bring their creative designs to life with a high degree of accuracy and intricacy.

5. Model Making: Model makers, whether in the fields of architecture, automotive, or aerospace, can benefit from using a cheap CNC mill to produce highly detailed and precise models. Models can range from building mock-ups, vehicle prototypes, or scaled replicas. CNC technology allows for accurate replication of designs, ensuring the final model matches the desired specifications.

6. Wooden and Plastic Furniture Production: Affordable CNC mills are suitable for manufacturing custom wooden and plastic furniture. They enable precise cutting, drilling, and shaping of materials, resulting in high-quality finished products. From unique custom designs to small-scale batch production, a cheap CNC mill can offer furniture makers an efficient solution.

In conclusion, a cheap CNC mill can be employed in a variety of industries and applications, including prototyping, manufacturing, hobbyist projects, education, arts and crafts, model making, and furniture production. Despite its affordability, a cheap CNC mill offers high precision, efficiency, and endless possibilities for innovation and creativity.

The Work Process and how to use cheap cnc mill

The work process of a CNC mill involves several steps. Firstly, a design is created using CAD (Computer-Aided Design) software, which specifies the dimensions, shape, and features of the desired object. This design is then converted into a CNC program that the mill can understand. The program consists of a series of instructions that control the movements of the mill’s cutting tools.

Once the program is ready, it is loaded into the CNC mill’s control unit. The workpiece, typically a block of material such as metal or plastic, is secured on the mill’s worktable using clamps or fixtures. The mill’s cutting tools, such as drills, end mills, or routers, are mounted on a spindle that can move in multiple directions.

When the mill is started, the CNC program is executed, and the cutting tools begin to remove material from the workpiece based on the specified design. The tools move along the X, Y, and Z axes, cutting, drilling, or carving as required. The mill may also automatically change tools during the process to perform different operations.

Throughout the milling process, the CNC mill continuously monitors its position and makes adjustments to ensure accuracy. The milling speed and feed rate can also be controlled, depending on the material and desired finish. This allows for precise and efficient machining of complex shapes and structures.

Using a cheap CNC mill involves finding a machine that fits within a limited budget. There are various options available, including DIY kits, used machines, or entry-level models from different manufacturers. It is important to consider both the cost and the capabilities of the mill when making a decision.

Once a suitable CNC mill is acquired, it is important to familiarize oneself with the machine’s operation and programming. This can be done by referring to the user manual, online tutorials, or attending training sessions. It is also recommended to start with simpler projects and gradually advance to more complex designs.

To keep costs low, it is essential to optimize the milling process. This can be achieved by selecting appropriate cutting tools, speeds, and feeds for the material being machined. Making efficient use of material and minimizing wastage can also help reduce expenses.

In conclusion, the work process of a CNC mill involves designing a part, creating a CNC program, loading it onto the machine, securing the workpiece, and executing the program to achieve the desired shape. When using a cheap CNC mill, it is important to choose a machine within budget and optimize the milling process to control costs.

Quality Testing Methods for cheap cnc mill and how to control the quality

When it comes to quality testing methods for cheap CNC mills, there are several approaches that can help ensure the machine’s reliability and precision. Here are a few key methods:

1. Calibration: Regular calibration of critical components such as the spindle, axis drives, and tooling system is essential to maintain accuracy. Calibrating the machine at various operating conditions and verifying it against known standards can help identify any deviations or inaccuracies.

2. Accuracy Tests: Conducting accuracy tests, such as ball bar tests, can evaluate the CNC mill’s positioning and repeatability. These tests involve attaching a precision ball bar to the machine, which helps measure any deviations from the expected path. Analyzing the test results can indicate potential issues with the machine’s mechanical components, contributing to better quality control.

3. Surface Finish Check: Measuring the surface finish of the machined parts can provide insights into the CNC mill’s performance. Using a surface roughness gauge or a profilometer can assess the finish quality, detecting any irregularities or inconsistencies in the machining process.

4. Tool Monitoring: Implementing a tool monitoring system can help identify tool wear, breakage, or damage during the machining process. By continuously monitoring the cutting forces, vibration, or acoustic emissions, the system can detect deviations from normal machining conditions, preventing faulty parts and ensuring quality.

To control the quality of a cheap CNC mill effectively, it is important to establish a comprehensive quality management system. This includes:

1. Incoming Inspection: Conducting regular inspections of the machine’s components, such as lead screws, ball bearings, and controller boards, before assembly. This will help identify any defective parts and prevent their incorporation into the final product.

2. Process Control: Implementing effective process controls, including documented work instructions and standard operating procedures, can ensure consistency and repeatability. Enforcing strict adherence to these controls will help eliminate variations in the manufacturing process, ultimately improving the quality of the CNC mill.

3. Quality Assurance Checks: Performing regular quality checks throughout the manufacturing process, such as dimensional accuracy tests and surface finish inspections, can identify any deviations from the required specifications. This will enable timely adjustments and corrections, ensuring consistent quality output.

4. Post-Production Evaluation: Conducting thorough inspections and tests on the finished CNC mills before delivery to customers is crucial. This should include functional checks, accuracy verification, and surface finish assessments to confirm that the machine meets the desired quality standards.

By adopting these quality testing methods and establishing a strong quality management system, inexpensive CNC mills can offer reliable performance and meet customer expectations, all within a cost-effective framework.

cheap cnc mill Sample Policy and Post-Purchase Considerations for cheap cnc mill from China

Sample Policy:

When purchasing a cheap CNC mill from China, it is important to consider the sample policy provided by the supplier. Many suppliers offer the option to request samples before making a bulk purchase. This allows customers to evaluate the quality, performance, and suitability of the cheap CNC mill for their specific needs.

Prior to making a sample request, buyers should ensure that the supplier offers a reasonable sample policy. Some key considerations for the sample policy should include:

1. Sample Cost: Buyers should inquire about the cost of obtaining samples. Ideally, the cost should be reasonably priced and affordable for potential buyers.

2. Sample Delivery Time: It is essential to confirm the estimated delivery time for samples. This will give buyers an idea of how soon they can expect to receive and test the product.

3. Sample Quantity: Buyers should clarify the number of samples they can request. Often, suppliers have certain limitations on the number of samples that can be provided.

4. Sample Return Policy: In case the sample is not satisfactory, it is important to know the supplier’s return policy. Buyers should be aware of any return conditions, including whether they need to cover the return shipping costs.

Post-Purchase Considerations:

After purchasing a cheap CNC mill from China, there are several post-purchase considerations that buyers should keep in mind:

1. Quality Inspection: Conduct a thorough quality inspection upon receiving the CNC mill. Check for any defects or damage that may have occurred during shipping.

2. Testing and Calibration: Properly test and calibrate the machine to ensure it is functioning accurately and meeting the required performance standards.

3. User Manual and Support: Consider the availability and quality of the user manual provided. Additionally, inquire about the level of technical support offered by the supplier.

4. Spare Parts and Warranty: Check if the supplier offers spare parts for the CNC mill. Additionally, ask about the warranty coverage and duration provided by the supplier.

5. Maintenance and After-Sales Service: Understand the maintenance requirements of the CNC mill and the options for after-sales service provided by the supplier. This will ensure smooth operations and timely support if needed.

By following these sample policies and considering the post-purchase factors, buyers can make informed decisions when purchasing a cheap CNC mill from China, maximizing their chances of getting a reliable and cost-effective product.

Sourcing cheap cnc mill from China: Opportunities, Risks, and Key Players

Sourcing a cheap CNC mill from China can offer both opportunities and risks for businesses looking for affordable manufacturing options. China is known for its manufacturing capabilities and competitive pricing, making it an attractive destination for sourcing CNC mills. However, it is crucial to consider potential risks associated with quality control, intellectual property protection, and communication barriers.

One of the significant opportunities of sourcing from China is the cost advantage. Chinese manufacturers often offer lower prices due to lower labor and operational costs. This can be highly beneficial for small businesses or startups with budget constraints. In addition, China has a well-developed supply chain network, enabling easy sourcing of the required components and spare parts.

However, there are certain risks involved in sourcing CNC mills from China. Quality control is a significant concern, as not all manufacturers may deliver products meeting the expected standards. It is essential to thoroughly research potential suppliers, assess their certifications, and request samples before making a purchase. Intellectual property protection can be challenging, as China has had a history of counterfeit products and infringement issues. Proper due diligence and legal precautions are necessary to protect intellectual property rights.

Communication barriers arising from language differences can also pose challenges during the sourcing process. It is crucial to establish clear and effective communication channels with potential suppliers to avoid misunderstandings and ensure that product specifications and requirements are accurately communicated.

Some key players in the Chinese CNC mill market include Huazhong CNC, Jinan Quick CNC Router, and Shandong Mingmei CNC Machinery. These companies offer a range of CNC mills at competitive prices. However, it is vital to conduct thorough research, read customer reviews, and consider expert opinions before finalizing a supplier.

In conclusion, sourcing a cheap CNC mill from China can provide opportunities for businesses seeking cost-effective manufacturing options. However, careful consideration of risks related to quality control, intellectual property protection, and communication barriers is necessary. Researching potential suppliers and conducting due diligence is crucial to ensure a successful sourcing experience.

How to find and select reliable cheap cnc mill manufacturers in China,use google search manufacturers and suppliers

Finding reliable and affordable CNC mill manufacturers in China can be a daunting task. However, by utilizing Google search and following these strategies, you can increase your chances of finding the right manufacturer within limited words.

1. Use targeted search terms: Begin by conducting a Google search using specific keywords such as “reliable CNC mill manufacturers in China” or “affordable CNC mill suppliers in China.” This will help narrow down your search and lead to more relevant results.

2. Explore manufacturer directories: There are several online directories that specialize in connecting buyers with manufacturers in China. Websites like Alibaba, Global Sources, and Made-in-China.com provide a wide selection of CNC mill manufacturers. You can browse through these directories to find potential suppliers.

3. Check the manufacturer’s website: Once you have shortlisted a few potential manufacturers, visit their websites to gather more information. Look for details about their production capabilities, certifications, product specifications, and customer testimonials. A reliable manufacturer will have a professional and informative website.

4. Verify their certifications: Reliable manufacturers often possess certifications such as ISO 9001, CE, or RoHS, which indicate compliance with international quality standards. Make sure to check if the manufacturer holds any relevant certifications.

5. Contact the manufacturers: Reach out to the shortlisted manufacturers through email or phone to discuss your specific requirements. Ask for quotations, lead time, product customization options, and any other queries you may have. Timely and professional responses are indicative of a manufacturer’s reliability and customer service.

6. Request product samples: If possible, request product samples before making a final decision. This will allow you to assess the quality, functionality, and precision of their CNC milling machines firsthand.

7. Consider customer reviews and ratings: Look for customer reviews and ratings on platforms like Alibaba or other relevant review websites. Genuine feedback from previous customers can help you evaluate the manufacturer’s reliability, product quality, and after-sales service.

8. Evaluate communication and customer support: Pay attention to how the manufacturer communicates with you. A reliable manufacturer will be responsive, provide clear answers to your questions, and offer comprehensive customer support throughout the purchasing process.

Remember that finding a reliable and cheap CNC mill manufacturer is not solely determined by price – quality, reliability, and customer support should also be considered. Take your time, conduct thorough research, and compare different options to make an informed decision.

How to check cheap cnc mill manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

When looking for reliable and affordable CNC mill manufacturers, it’s essential to evaluate their websites. To ensure reliability, follow these steps using Google Chrome and the SEOquake extension:

1. Install SEOquake: Add SEOquake extension to your Google Chrome browser from the Chrome Web Store.

2. Search for CNC mill manufacturers: Open a new tab in Google Chrome and search for “cheap CNC mill manufacturers”.

3. Analyze search results: Scroll through the search results and click on the website URLs of potential manufacturers.

4. Check website credibility: When on the manufacturer’s website, look for signs of credibility, such as professional design, clear product information, customer testimonials, certifications, and contact information.

5. Use SEOquake for ranking analysis: Activate the SEOquake extension by clicking on the icon in your browser’s toolbar. It will display a variety of metrics related to the website.

6. Check Alexa Rank: SEOquake provides the Alexa Rank, which indicates a website’s popularity. Ensure the manufacturer’s website has a rank lower than 10 million, which signifies a decent level of traffic and trustworthiness.

7. Evaluate SEO metrics: Analyze other SEOquake metrics like the number of indexed pages, domain age, social shares, and backlinks. A high number of indexed pages, a well-established domain, and positive social signals indicate a reliable manufacturer.

8. Verify website security: Look for HTTPS encryption in the website URL and a lock icon on the left side. A secure connection assures the safety of your personal information.

9. Consider user-friendliness: Assess the website’s ease of navigation, mobile responsiveness, and accessibility. A user-friendly interface indicates a professional and reliable manufacturer.

10. Compare multiple manufacturers: Repeat the process for several potential manufacturers to make an informed decision. Alongside affordability, prioritize reliability and quality.

Remember, this method is not foolproof, but it can provide some initial insights into the credibility and popularity of the manufacturer’s website. Additionally, research further by reading reviews, reaching out to their customer support, and seeking recommendations from industry professionals to ensure a reliable and cost-effective CNC mill purchase.

Top 10 cheap cnc mill manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. VEVOR CNC – VEVOR CNC offers affordable and reliable CNC milling machines for various industries. Their products feature a sturdy structure, high precision, and efficient performance. The milling machines are equipped with advanced control systems and powerful spindles, enabling precise and smooth cutting operations. VEVOR CNC also provides excellent customer support and after-sales service.

2. Mophorn CNC – Mophorn CNC specializes in cost-effective CNC milling machines that cater to small and medium-sized businesses. Their products are easy to operate and designed for high accuracy and productivity. With rigid construction and stable performance, Mophorn CNC mills ensure efficient and consistent machining results.

3. SainSmart – SainSmart offers a range of affordable CNC mills suitable for hobbyists and small workshops. Their machines are designed with an easy-to-use interface and durable construction. SainSmart CNC mills deliver precise milling, engraving, and drilling operations on various materials, including wood, plastics, and aluminum.

4. Taishi – Taishi provides cost-effective CNC milling machines that are suitable for both industrial and home use. Their products boast high precision, stability, and durability. Taishi CNC mills feature user-friendly interfaces, robust spindles, and adjustable parameters, enabling users to achieve accurate and efficient machining.

5. SUNWIN – SUNWIN manufactures economical CNC milling machines suitable for beginners and DIY enthusiasts. Their products offer a balance between affordability and performance. SUNWIN CNC mills are equipped with high-quality components, ensuring smooth and accurate machining operations on materials like wood, acrylic, and soft metals.

6. Ten-High – Ten-High specializes in budget-friendly CNC milling machines that are perfect for home-based businesses and educational institutions. Their products feature compact designs, easy operation, and high precision. Ten-High CNC mills are compatible with various CAD/CAM software and deliver reliable performance for precision machining tasks.

7. Wisamic – Wisamic offers affordable CNC milling machines with an emphasis on user-friendly operation and versatility. Their products are equipped with powerful spindles, precise ball screws, and excellent control systems. Wisamic CNC mills deliver consistent and accurate results for cutting, engraving, and milling various materials.

8. BobsCNC – BobsCNC provides budget-friendly CNC milling machines suitable for beginners and hobbyists. Their products are known for their simplicity, ease of assembly, and cost-effectiveness. BobsCNC mills are capable of machining wood, plastics, and soft metals, making them ideal for carving, engraving, and light milling tasks.

9. Zen Toolworks – Zen Toolworks offers affordable CNC milling machines with durable frameworks and versatile design. Their products are designed to provide precision and reliability in a compact package. Zen Toolworks CNC mills are easy to assemble, operate, and maintain, making them suitable for hobbyists and small businesses.

10. Genmitsu – Genmitsu specializes in affordable CNC milling machines, particularly for woodworking applications. Their products feature a robust construction, high precision, and user-friendly interfaces. Genmitsu CNC mills deliver excellent performance for cutting, carving, and shaping wood, making them a popular choice among woodworking enthusiasts.

Markdown table comparison:

| Manufacturer | Specialties | Price Range | Features |

|—|—|—|—|

| VEVOR CNC | Various industries | Moderate | Sturdy structure, high precision |

| Mophorn CNC | Small to medium-sized businesses | Affordable | Easy operation, high accuracy |

| SainSmart | Hobbyists and small workshops | Budget-friendly | Easy-to-use interface, precise machining |

| Taishi | Industrial and home use | Cost-effective | User-friendly, stable performance |

| SUNWIN | Beginners and DIY enthusiasts | Low-cost | Smooth machining, compatibility |

| Ten-High | Home-based businesses and education | Affordable | Compact, easy operation |

| Wisamic | User-friendly operation | Economical | Powerful spindle, accurate results |

| BobsCNC | Beginners and hobbyists | Cost-effective | Simplicity, easy assembly |

| Zen Toolworks | Precision and reliability | Affordable | Durable framework, versatile design |

| Genmitsu | Woodworking applications | Budget-friendly | Robust construction, high precision |

In conclusion, these top 10 cheap CNC mill manufacturers in China offer a wide range of cost-effective options for various applications. They prioritize affordability while ensuring high precision, sturdy construction, and user-friendly operation. Whether you’re a hobbyist, small business, or educational institution, these manufacturers provide reliable CNC milling machines that deliver accurate and efficient results.

Background Research for cheap cnc mill manufacturers Companies in China, use qcc.com archive.org importyeti.com

When searching for cheap CNC mill manufacturers in China, there are several resources that can provide valuable background research. These include qcc.com, archive.org, and importyeti.com.

Qcc.com is a platform that offers business information and credit reports on Chinese companies. It provides data such as company profiles, registration information, financial statistics, and contact details. By searching for CNC mill manufacturers on qcc.com, one can gather information about the company’s background, including their establishment date, legal status, and registered capital. Additionally, qcc.com may also display the company’s production capacity, annual sales, and business scope. This information can help evaluate the credibility and reputation of the manufacturer.

Archive.org is an internet archive that stores historical snapshots of websites. By using this platform, one can access outdated versions of the manufacturer’s website, which can provide insights into its past operations, product offerings, and any changes made over time. This can be useful for assessing the manufacturer’s experience in producing CNC mills and their ability to adapt to market demands.

Importyeti.com is an import-export trade database that provides access to industry-specific data for businesses importing and exporting goods. By using this platform, one can gain insights into the import and export history of CNC mills by specific manufacturers. This includes details such as the countries they export to, the quantity of goods exported, and the value of these exports. Analyzing this data can help assess the manufacturer’s international presence, market competitiveness, and customer satisfaction.

In conclusion, qcc.com, archive.org, and importyeti.com are valuable resources for conducting background research on cheap CNC mill manufacturers in China. These platforms provide information on the company’s background, financials, historical website data, and import-export history. This data can assist in evaluating the credibility, experience, and market presence of the manufacturer.

Leveraging Trade Shows and Expos for cheap cnc mill Sourcing in China

Trade shows and expos provide a unique opportunity to source cheap CNC mills in China. These events bring together manufacturers, suppliers, and industry professionals in one place, making it easier to connect with potential suppliers and negotiate better deals. Here’s how to utilize trade shows and expos for sourcing CNC mills in China:

1. Research and identify trade shows: Research upcoming trade shows and expos in China that focus on manufacturing, machinery, and automation. Check reliable sources like industry magazines and online directories to identify relevant events.

2. Attend the trade shows: Plan your visit to the trade shows and expos to meet with potential suppliers face-to-face. Prepare a list of questions and specific requirements to discuss with exhibitors.

3. Engage with exhibitors: Visit the booths of CNC mill manufacturers and engage in meaningful conversations. Inquire about their manufacturing capabilities, product range, pricing, and customization options.

4. Assess product quality: Inspect the displayed CNC mills and evaluate their quality, precision, and durability. Request product samples or arrange for a factory visit to witness manufacturing processes firsthand.

5. Compare prices and negotiate: Engage with multiple exhibitors, compare prices, and negotiate for a better deal. Leverage the competition between vendors and ask for discounted prices, bulk discounts, or additional services.

6. Build relationships: Establish relationships with potential suppliers who meet your requirements. Exchange contact details and seek additional information about the supplier’s history, certifications, and after-sales support.

7. Seek referrals and recommendations: Network with industry professionals, fellow attendees, and even competitors to seek referrals and recommendations for reputable CNC mill suppliers in China.

8. Follow up after the event: Reach out to shortlisted suppliers after the trade show or expo to continue the conversation. Request formal quotes, technical specifications, and any necessary documentation before finalizing a purchase.

By leveraging trade shows and expos, you can find cost-effective CNC mill sourcing in China. Make the most of these events by conducting thorough research, networking, and negotiating to secure the best deals within your budget.

The Role of Agents and Sourcing Companies in Facilitating cheap cnc mill Purchases from China

Agents and sourcing companies play a crucial role in facilitating cheap CNC mill purchases from China. These entities act as intermediaries between the buyer and the Chinese manufacturers, navigating through language barriers, cultural differences, and complex supply chains to make the buying process effortless and efficient.

Firstly, agents and sourcing companies provide a deep understanding of the Chinese market and manufacturing industry. They have extensive knowledge about the various manufacturers, their capabilities, and product offerings. This expertise helps buyers identify the most suitable suppliers for their specific requirements, ensuring quality and cost-effectiveness.

In addition, agents and sourcing companies act as a bridge for communication between the buyer and the Chinese manufacturers. They possess bilingual capabilities, allowing them to effectively convey the buyer’s needs, expectations, and specifications to the manufacturers. This eliminates potential misunderstandings and ensures that the final product meets the buyer’s requirements.

Furthermore, agents and sourcing companies help in negotiating the best prices and terms for the CNC mill purchase. They have extensive networks and established relationships with Chinese manufacturers, allowing them to leverage their bargaining power to secure competitive pricing. By combining multiple buyers’ orders, these entities can also achieve economies of scale, further reducing the overall cost.

Moreover, agents and sourcing companies conduct regular quality control inspections throughout the manufacturing process. They ensure that the CNC mills meet the required quality standards and perform necessary checks such as factory audits, product inspections, and certifications. This minimizes the risk of receiving subpar or defective products.

Lastly, agents and sourcing companies handle all logistics and shipping arrangements. They are well-versed in export procedures, international shipping regulations, and customs documentation. This ensures a smooth and hassle-free delivery process, saving the buyer time and effort.

In conclusion, agents and sourcing companies play a vital role in facilitating cheap CNC mill purchases from China. Their expertise in the Chinese market, negotiation skills, quality control measures, and logistical support streamline the buying process and enable buyers to access cost-effective and reliable CNC mills.

Price Cost Research for cheap cnc mill manufacturers Companies in China, use temu.com and 1688.com

Doing price cost research for cheap CNC mill manufacturers in China can be efficiently carried out using two popular platforms – temu.com and 1688.com. These platforms provide a wide range of suppliers and manufacturers to choose from, making the process easier and more convenient.

Temu.com is a well-known online marketplace that connects global buyers with Chinese suppliers. It offers a wide range of products, including CNC mills, at competitive prices. To conduct research on temu.com, the following steps can be followed:

1. Visit temu.com and create an account to gain access to product information and contact details of suppliers.

2. Search for CNC mill manufacturers by using relevant keywords such as “cheap CNC mill” or “CNC mill manufacturer.”

3. Browse through different product listings and suppliers to compare prices, product specifications, and customer reviews.

4. Shortlist potential suppliers based on their pricing and other factors such as delivery time, after-sales service, and certifications.

1688.com, also known as Alibaba.cn, is a popular Chinese B2B platform that offers a vast selection of manufacturers and suppliers. To conduct research on 1688.com, the following steps can be followed:

1. Access 1688.com and register for an account to gain access to detailed product information and supplier contact details.

2. Use relevant keywords such as “cheap CNC mill” or “CNC mill manufacturer” to search for suitable suppliers.

3. Explore different supplier profiles and product listings to compare prices, product specifications, and customer reviews.

4. Shortlist potential suppliers based on their pricing as well as important factors like quality assurance processes, manufacturing capabilities, and customer feedback.

When conducting price cost research on temu.com and 1688.com, it is crucial to consider other factors in addition to the price alone. These factors include the supplier’s reputation, experience in CNC mill manufacturing, quality assurance processes, certifications, and after-sales service. Communicating with suppliers directly through these platforms can help gather further information and negotiate better deals.

In brief, conducting price cost research for cheap CNC mill manufacturers in China using temu.com and 1688.com can be highly effective due to the extensive supplier databases and comprehensive product information available on these platforms. However, it is important to consider additional factors beyond the price alone when selecting a suitable supplier.

Shipping Cost for cheap cnc mill import from China

The shipping cost for importing a cheap CNC mill from China can vary depending on several factors. Generally, there are two main options for shipping: air freight and sea freight.

Air freight is the quickest and most expensive option. It is suitable for smaller and lighter CNC mills. The cost typically ranges from $3 to $6 per kilogram. However, there may be additional charges such as customs clearance fees, handling fees, and fuel surcharges. Additionally, air freight often incurs higher insurance costs to protect the goods during transit.

Sea freight is a more cost-effective method for shipping larger and heavier CNC mills. The price depends on the volume and weight of the shipment, as well as the shipping destination. As a rough estimate, sea freight costs around $500 to $1500 for a 20-foot container, and $1000 to $3000 for a 40-foot container. These prices are subject to additional charges like customs clearance fees, handling fees, and port charges.

It is important to consider other potential expenses such as import duties, customs taxes, and customs brokers’ fees. These costs vary based on the country of import and the value of the CNC mill.

To get an accurate quote, it is recommended to contact shipping agents or freight forwarders who specialize in international trade. They will consider the weight, dimensions, delivery destination, and mode of transport to provide a precise shipping cost estimate.

In conclusion, while air freight is faster but expensive, sea freight is a more cost-effective method for shipping a cheap CNC mill from China. It is essential to factor in all associated costs to ensure a smooth and cost-efficient transportation process.

Compare China and Other cheap cnc mill Markets: Products Quality and Price,Visible and Hidden Costs

China has emerged as a leader in the cheap CNC mill market, offering a wide range of products at competitive prices. When comparing China’s cheap CNC mill market with other markets, several aspects need to be analyzed: product quality and price, visible and hidden costs.

In terms of product quality, China’s cheap CNC mills have made significant improvements in recent years. Many Chinese manufacturers have invested in research and development, leading to better quality control and precision engineering. However, it is important to note that the overall quality can still vary. Some Chinese manufacturers may offer low-priced CNC mills with subpar quality components. On the other hand, other markets may have established a reputation for better quality products, but at a higher price point.

Price is a crucial factor in the cheap CNC mill market. China has distinct advantages in terms of cost-effectiveness due to economies of scale and lower labor costs. Chinese manufacturers can produce CNC mills at significantly lower prices compared to other markets, making them highly attractive to budget-conscious buyers. This competitive pricing has played a significant role in the rise of China’s cheap CNC mill market.

Visible costs, such as the initial purchase price, are generally lower for Chinese CNC mills. However, other costs need to be considered as well. Hidden costs, including shipping fees, import duties, and taxes, may vary depending on the buyer’s location and the chosen supplier. It is important to carefully consider these factors, as they can significantly impact the overall cost and competitiveness of the CNC mill.

In conclusion, China’s cheap CNC mill market offers a wide range of products at competitive prices. Although product quality has improved, it can still vary among manufacturers. Price is a distinct advantage for China due to economies of scale and lower labor costs. However, buyers need to consider both visible and hidden costs when comparing the overall affordability of CNC mills from different markets.

Understanding Pricing and Payment Terms for cheap cnc mill: A Comparative Guide to Get the Best Deal

When looking to purchase a cheap CNC mill, understanding the pricing and payment terms can be crucial in finding the best deal. By comparing different options, buyers can make informed decisions and ensure they are getting the most value for their money. Here is a comparative guide to help in understanding pricing and payment terms for a cheap CNC mill.

Pricing for a cheap CNC mill can vary depending on various factors such as the machine’s specifications, brand reputation, and market demand. It is essential to research and compare prices from different suppliers to get an idea of the average market price. Online marketplaces, manufacturer websites, and local distributors can be valuable sources for price comparisons. Additionally, reaching out to other CNC mill users and forums can provide insights into common pricing trends.

Payment terms differ among suppliers, so understanding these terms is crucial to avoid any surprises or hidden costs. The most common payment terms include upfront full payment, partial upfront payment with the remainder upon delivery, or installment plans. It is important to carefully review payment terms to ensure they align with the buyer’s budget and preferences.

Considering extra costs when comparing prices is also crucial. These costs may include shipping fees, taxes, and potential customs duties, which can significantly impact the overall price. Some suppliers may offer free shipping or discounts on delivery, making them more cost-effective options.

Furthermore, evaluating warranty and after-sales service is important when assessing the value of a cheap CNC mill. Suppliers with comprehensive warranties and reliable after-sales support can save buyers from unexpected expenses in case of machine failure or malfunction.

Negotiating with suppliers can be an effective way to get the best deal. If buyers find similar models with different prices, they can leverage this information to negotiate a lower price or additional benefits such as extended warranties or discounted spare parts.

In conclusion, understanding pricing and payment terms is vital when purchasing a cheap CNC mill. Conducting thorough research, comparing prices, considering extra costs, evaluating warranties and after-sales support, and negotiating with suppliers can help buyers make informed decisions and secure the best deal within their budget constraints.

Chinese Regulations and Industry Standards Certifications for cheap cnc mill,Import Regulations and Customs for cheap cnc mill from China

Chinese Regulations and Industry Standards Certifications for cheap CNC mills play a vital role in ensuring product quality, safety, and compliance with relevant standards. One of the key regulations is the China Compulsory Certification (CCC), which is required for certain products, including electrical machines or equipment. Cheap CNC mills may fall under this category and need to obtain the CCC mark before entering the domestic or international market.

To obtain CCC certification, manufacturers must submit their CNC mill models for testing and evaluation in accredited testing laboratories in China. The tests ensure compliance with specific technical requirements and safety standards designed to protect consumers and prevent potential hazards. Upon successful completion of the testing process, the manufacturer will receive the CCC certification, allowing them to legally sell their CNC mills in China.

Additionally, industry standards certifications, such as ISO 9001 for quality management systems and ISO 14001 for environmental management systems, are highly recommended to enhance the credibility and competitiveness of cheap CNC mill manufacturers. These certifications demonstrate a commitment to quality control, customer satisfaction, and environmental responsibility.

When importing cheap CNC mills from China, import regulations and customs procedures must be followed to ensure a smooth clearance process. Importers need to provide the necessary documentation, such as invoices, packing lists, and bills of lading, to the customs authorities. The imported CNC mills may be subject to import duties, value-added tax (VAT), and other related fees based on the respective country’s customs regulations.

Importers should consult with customs brokers or trade experts to understand the specific import regulations and customs requirements applicable to their country. Properly declaring the value and origin of the CNC mills and ensuring compliance with the local regulations and quality standards is crucial to avoid customs delays or potential penalties.

In conclusion, meeting Chinese regulations and industry standards certifications, such as CCC, ISO 9001, and ISO 14001, is essential for cheap CNC mill manufacturers. Importers should carefully adhere to import regulations and customs procedures to guarantee a successful importation process.

Sustainability and Environmental Considerations in cheap cnc mill Manufacturing

Sustainability and environmental considerations are becoming increasingly important in the manufacturing industry, including the production of cheap CNC mills. While these mills offer affordability and efficiency, it is crucial to assess their impact on the environment and implement sustainable practices.

One key area to focus on is the materials used in the manufacturing process. Opting for sustainable and recyclable materials, such as aluminum, can significantly reduce the carbon footprint. Additionally, using recycled materials can lower the demand for virgin resources and minimize waste generation.

The energy consumption of CNC mills should also be addressed. Implementing energy-efficient technologies and practices, such as using LED lighting and optimizing motor efficiency, can minimize energy usage. Furthermore, exploring renewable energy sources, like solar or wind power, can contribute to a greener manufacturing process.

Another vital consideration is the reduction of waste and the implementation of proper disposal practices. Employing lean manufacturing techniques and implementing a strict recycling program can significantly reduce waste generation. Proper disposal of hazardous materials is crucial to prevent environmental contamination and should be in compliance with applicable regulations.

Transportation is another aspect to evaluate from an environmental perspective. Opting for local suppliers and manufacturing facilities can reduce emissions associated with long-distance transportation. Additionally, optimizing packaging design to minimize waste and using eco-friendly materials can further contribute to sustainability efforts.

Lastly, the product’s life cycle should be considered. Implementing a circular economy approach can extend the product’s lifespan and reduce the need for new mills, decreasing waste and resource consumption. Offering maintenance and repair services to encourage longevity and refurbishment can also contribute to sustainability.

Overall, cheap CNC mill manufacturing should integrate sustainability and environmental considerations at every stage, from material selection to disposal. By adopting eco-friendly practices, reducing waste, and minimizing energy consumption, the industry can contribute to a more sustainable future.

List The Evolution history of “cheap cnc mill”

The evolution of the “cheap CNC mill” has experienced significant milestones over the years, bringing this technology within reach of smaller businesses and hobbyists alike.

In the early years, CNC (Computer Numerical Control) milling machines were highly expensive and mainly limited to industrial applications. Manufacturers relied on specialized heavy-duty machines, which were prohibitively expensive for smaller operations. However, as technology advanced, CNC milling became more accessible and affordable.

The first breakthrough came in the 1990s with the introduction of desktop CNC mills. These machines were relatively affordable, compact, and suitable for light-duty tasks. While not cheap by today’s standards, they represented a major step towards making CNC technology more accessible.

The following decade witnessed the emergence of open-source CNC projects, notably the RepRap project. It aimed to develop low-cost 3D printers, but the underlying technology could be adapted for CNC milling as well. This open-source movement brought about a surge in DIY CNC mill designs, with users sharing their plans and modifications on online platforms. This enabled enthusiasts to build their own machines at considerably lower costs.

The early 2010s witnessed the rise of crowdfunding platforms, which played a pivotal role in the evolution of cheap CNC mills. Entrepreneurs and startups started launching campaigns to fund their affordable CNC mill designs. These campaigns gave birth to several successful companies, producing machines that were significantly more affordable than their industrial counterparts.

Further advancements in technology, such as the miniaturization of components and the availability of affordable off-the-shelf electronics, contributed to reducing costs. CNC mills became more accessible for individual hobbyists, small businesses, and educational institutions.

Today, cheap CNC mill options are widely available. There is a range of entry-level machines specifically designed for hobbyists and small-scale production. These machines often feature compact sizes, user-friendly software, and affordable pricing, democratizing the world of CNC milling.

In conclusion, the evolution of the “cheap CNC mill” has followed a trajectory from expensive industrial machines to more affordable desktop models, fueled by open-source projects, crowdfunding, and advancements in technology. This history has paved the way for smaller businesses and hobbyists to harness the benefits of CNC milling at a fraction of the cost.

The Evolution and Market Trends in cheap cnc mill Industry

The evolution of the cheap CNC mill industry has been greatly influenced by advancements in technology and changing market trends. Initially, CNC mills were expensive and limited to large manufacturing companies due to their high costs and complex operations. However, with the development of computer technology and the increasing demand for affordable machining solutions, cheap CNC mills have become more accessible to small and medium-sized businesses and even hobbyists.

One of the key factors driving the evolution of the cheap CNC mill industry is the affordability and availability of computer technology. As computers became more powerful and affordable, manufacturers started incorporating computer-controlled systems into their milling machines, making them easier to operate and more precise. This allowed for the production of cheaper CNC mills that could be operated by individuals with minimal training.

Another significant factor in the industry’s evolution is the changing market trends. As consumer demand shifted towards customization and small-batch production, manufacturers recognized the need for affordable CNC mills that could quickly and accurately produce smaller quantities of parts. This led to the development of compact and cost-effective CNC mills that catered to the needs of these market segments.

Additionally, advancements in automation and robotics have also had a profound impact on the cheap CNC mill industry. Integration of automated features such as tool changers and part loading/unloading systems has increased the efficiency and productivity of CNC mills, further reducing costs and making them more accessible to a wider range of users.

Furthermore, market trends such as the rise of e-commerce and the democratization of manufacturing have created new opportunities for cheap CNC mill manufacturers. Online platforms and marketplaces have made it easier for individuals and businesses to find and purchase affordable CNC mills, expanding the reach of manufacturers and driving innovation in the industry.

In conclusion, the evolution of the cheap CNC mill industry has been driven by advancements in technology, changing market trends, and the need for affordable machining solutions. The availability of computer technology, changing consumer demand, advancements in automation, and the rise of e-commerce have all played significant roles in shaping the industry. As technology continues to advance and market trends evolve, the cheap CNC mill industry is expected to further expand and innovate to meet the growing demand.

Custom Private Labeling and Branding Opportunities with Chinese cheap cnc mill Manufacturers

Chinese cheap CNC mill manufacturers offer great opportunities for custom private labeling and branding. With their cost-effective manufacturing capabilities, businesses can leverage these manufacturers to create their own branded CNC mills at competitive prices.

Private labeling allows businesses to put their own brand name and logo on the CNC mills they order. This creates a unique identity for the product and helps businesses establish their brand in the market. Chinese manufacturers can accommodate custom branding requests and ensure that the final product displays the desired branding elements.

Additionally, custom private labeling and branding can help businesses differentiate themselves from competitors by offering unique features, designs, and packaging. This not only attracts customers but also builds brand recognition and loyalty in the long run.

Chinese CNC mill manufacturers understand the importance of branding and offer flexible options to suit individual business needs. From personalized product colors to custom packaging with the brand’s logo and design, manufacturers can create a cohesive brand experience.

Moreover, Chinese manufacturers offer OEM (Original Equipment Manufacturer) services, allowing businesses to create their own CNC mills with the desired specifications and features. These manufacturers are equipped with advanced technology and expertise to customize the machines according to specific requirements. This enables businesses to meet the unique needs of their customers and stand out in the market.

In conclusion, Chinese cheap CNC mill manufacturers present lucrative opportunities for businesses to create custom private labeled and branded products. With their cost-effectiveness, flexibility, and advanced capabilities, these manufacturers can help businesses establish their brand identity, differentiate from competitors, and offer tailored solutions to their customers.

Tips for Procurement and Considerations when Purchasing cheap cnc mill

When considering purchasing a cheap CNC mill, it is important to keep a few key factors in mind to ensure you make a wise procurement decision. Here are some tips and considerations to help guide your purchase:

1. Define your requirements: Clearly identify your needs and intended use for the CNC mill. Understand the type of materials you will be working with, the complexity of the projects, and the desired accuracy and precision levels. This will help you select a machine that meets your specific requirements.

2. Research suppliers and models: Conduct thorough research on different suppliers and models available in the market. Read reviews, compare specifications, and check the reputation of the supplier. Look for a supplier that offers good customer support and has a track record of delivering quality machines.

3. Evaluate build quality and durability: Even with a limited budget, it is essential to focus on the build quality and durability of the CNC mill. Ensure that the machine is built with strong materials, has reliable components, and has a solid reputation for longevity. This will help you avoid costly repairs and replacements in the future.

4. Consider the machine’s capabilities: Assess the CNC mill’s capabilities, such as its spindle speed, axis movement, and worktable dimensions. Ensure it can handle the size and complexity of your projects. Additionally, check if the machine can accommodate future upgrades or enhancements as your needs evolve.

5. Check software compatibility: Verify that the CNC mill’s operating software is compatible with the computer system you plan to use. Ensure the software is user-friendly and has the necessary features for your specific requirements. Compatibility issues can significantly impact productivity.

6. Assess after-sales support: Look for a supplier that offers good after-sales support. This includes access to technical assistance, documentation, and readily available replacement parts. Responsive customer support can help address any issues that may arise during machine operation.

7. Understand the warranty terms: Thoroughly read and understand the warranty terms offered by the supplier. Check for warranty coverage on key components and be aware of any limitations or exclusions. A reliable warranty can provide added peace of mind.

8. Consider ownership costs: Besides the upfront price, consider the long-term ownership costs. Evaluate factors such as maintenance requirements, energy consumption, and ongoing software updates. A cheaper machine may result in higher running costs over time.

By considering these tips and taking the time to research and evaluate your options, you can make an informed decision when purchasing a cheap CNC mill. Remember that compromising on quality or functionality may have long-term implications.

FAQs on Sourcing and Manufacturing cheap cnc mill in China

Q: Can I source a cheap CNC mill from China?

A: Yes, China is a popular destination for sourcing affordable CNC mills due to its large manufacturing industry and competitive pricing.

Q: What factors should I consider when sourcing a CNC mill from China?

A: It is crucial to research and evaluate various factors, such as the supplier’s reputation, quality of their products, price, delivery time, after-sales service, and compliance with safety standards. Additionally, it is essential to communicate your requirements clearly to the supplier to ensure they can meet your expectations.

Q: How can I find reliable suppliers in China?

A: To find trustworthy suppliers, you can leverage online B2B platforms like Alibaba, Global Sources, or Made-in-China. It’s recommended to shortlist several suppliers based on their reputation, customer reviews, and product catalog. Contact them directly to discuss your requirements and gauge their responsiveness and professionalism.

Q: Are there any risks associated with sourcing CNC mills from China?

A: While there are risks involved in any international sourcing, proper due diligence can help mitigate them. Some common risks include potential quality issues, delivery delays, communication barriers, intellectual property infringement, and cultural differences. It is advisable to thoroughly research and verify a supplier’s credentials before finalizing any deal.

Q: How do I ensure the quality of CNC mills manufactured in China?

A: To ensure product quality, request samples or visit the supplier’s manufacturing facility for an inspection. You can also ask for certifications like ISO 9001 to verify their quality management system. Third-party quality control agencies can also be hired to conduct inspections and testing on your behalf.

Q: What is the typical price range for a cheap CNC mill in China?

A: The price of a cheap CNC mill in China can vary depending on factors like machine specifications, brand reputation, and quantity ordered. However, the range typically spans from a few hundred to a few thousand dollars.

Q: How can I handle shipping and import duties when sourcing from China?

A: Most suppliers offer shipping services or can recommend reliable freight forwarders. To handle import duties, get acquainted with your own country’s import regulations and consult with a customs broker to ensure compliance. You should also factor in shipping costs and any potential taxes into your budget.

In conclusion, when sourcing a cheap CNC mill from China, diligent research, effective communication, and thorough supplier evaluation are key to finding a reliable and cost-effective solution.

Why contact sourcifychina.com get free quota from reliable cheap cnc mill suppliers?

Sourcifychina.com is able to get a free quota from reliable and cheap CNC mill suppliers because it acts as a sourcing agent and negotiates with these suppliers on behalf of its clients. The website has established a strong network and partnerships with numerous suppliers in China, enabling it to leverage its connections and secure favorable deals.

One reason why Sourcifychina.com can obtain a free quota is because it provides a large volume of business to these suppliers. By collectively sourcing orders from multiple clients, the website is able to consolidate the demand and negotiate lower prices or additional benefits, such as free quotas, from the suppliers.

Additionally, Sourcifychina.com has a team of experienced professionals who understand the CNC mill industry and can effectively negotiate with the suppliers. These professionals have extensive knowledge of the market, prices, and quality standards, allowing them to secure the best possible deals for their clients. They are also skilled at building long-term relationships with suppliers, which further strengthens their negotiating power.

Moreover, the website may have established a reputation for providing reliable and consistent business to the suppliers, thereby earning their trust and goodwill. This trust factor plays a crucial role in the suppliers’ willingness to offer certain benefits, such as free quotas, to Sourcifychina.com.

In conclusion, Sourcifychina.com is able to get a free quota from reliable and cheap CNC mill suppliers due to its ability to generate significant business volumes, its knowledgeable and skilled negotiation team, and its reputation for reliability in the industry.