Knowledge about Concrete brick making machine

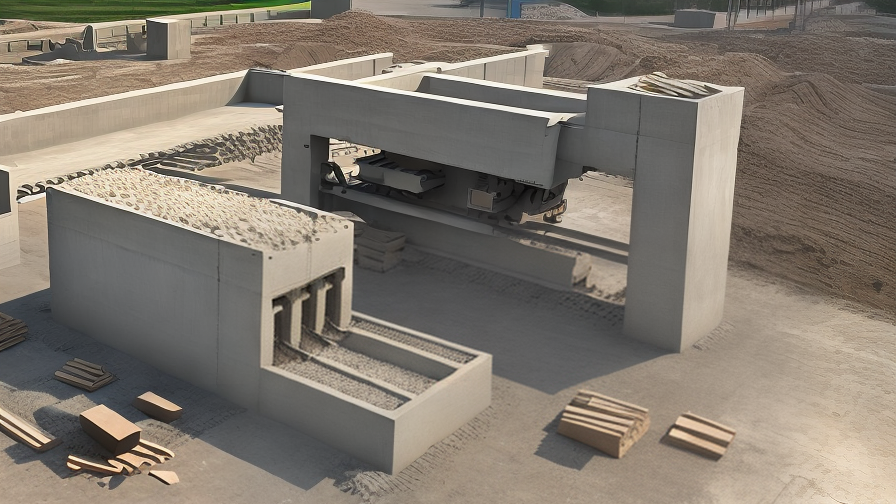

A concrete brick making machine is a tool used for manufacturing bricks made of cement, sand and water. These machines use a hydraulic pressure mechanism to compress the materials into a brick shape and then release them to be stacked and cured. A wide variety of shapes and sizes can be produced by these machines, depending on the molds used.The key components of a concrete brick making machine are the mainframe, hydraulic system, and electrical control system. The mainframe houses the mold, while the hydraulic system provides pressure to compress the materials and release the bricks. The electrical control system controls the machine’s movements and monitors the parameters of the brick-making process.

There are various types of concrete brick making machines available in the market, such as static machines, mobile machines, and fully automatic machines. Static machines are the simplest, most affordable option and require a manual operation. Mobile machines are more versatile and can be transported to different locations for on-site brick making. Fully automatic machines are the most advanced type and require minimal human intervention, with all processes being monitored and controlled by the machine’s computer.

Concrete brick making machines offer numerous advantages, including high production rates, consistency in brick size and shape, and low labor costs. The bricks produced by these machines are also durable and long-lasting, making them suitable for use both indoors and outdoors.

In conclusion, a concrete brick making machine is an essential tool for anyone interested in producing large quantities of bricks efficiently and effectively. There are various types of machines available, each with its own advantages and capabilities. With the right machine, one can produce high-quality bricks that are both strong and durable, making them ideal for use in construction projects of all sizes.

Various Types of Concrete brick making machine

In the construction industry, concrete brick making machines are essential equipment used to manufacture concrete blocks used for building and construction purposes. These machines can produce a wide range of concrete blocks, including solid, hollow, interlocking, paver, and curbstone blocks. Here are some of the most common types of concrete brick making machines:1. Hydraulic Concrete Brick Making Machine: This type of machine uses hydraulic pressure to compress the molded mixture of concrete and other materials into the desired shape.

2. Automatic Concrete Brick Making Machine: An automated system controls this type of machine, which performs all operations automatically, from feeding raw materials to the production of the final product.

3. Semi-automatic Concrete Brick Making Machine: This machine operates on semi-automatic controls, meaning that certain operations are done manually while others are automatic.

4. Egg-laying Concrete Brick Making Machine: This type of machine is designed to produce blocks that are laid on the ground rather than being produced vertically. It is capable of producing a wide range of different shapes and sizes of blocks.

5. Mobile Concrete Brick Making Machine: This type of machine is portable and can be easily moved from one location to another. It is ideal for construction sites that require on-site production of blocks.

In conclusion, the type of concrete brick making machine used will depend on the needs and objectives of the construction project. It is essential to choose the right type of machine to ensure that the blocks produced meet the required specifications, and the overall construction project is completed efficiently and cost-effectively.

FAQ sourcing Concrete brick making machine manufacturer from China with multiple answers

1. How do I find a reliable concrete brick making machine manufacturer in China?A: One way to find a reliable manufacturer is by attending international trade fairs or exhibitions where Chinese manufacturers showcase their products. You can also search online through B2B platforms such as Alibaba, Made-in-China, or Global Sources.

2. What should I look for in a reliable concrete brick making machine manufacturer?

A: Look for manufacturers with good reputation and years of experience in the industry. They should have a wide range of product offerings, transparent communication, reasonable pricing, and excellent after-sales service.

3. How do I select the appropriate model of brick making machine for my business?

A: Consider factors such as the size of your production area, the quantity of bricks you plan to produce, your budget, and the types of bricks you want to make. It is also important to choose a machine that is easy to operate and maintain.

4. Is it possible to customize a brick making machine according to my specific needs?

A: Yes, many manufacturers offer customization services to meet their clients’ unique needs. You can discuss your requirements with the manufacturer and they can provide solutions that fit your specifications.

5. What are the payment terms offered by concrete brick making machine manufacturers?

A: Payment terms vary depending on the manufacturer, but most accept payment through wire transfer or letter of credit. Some may also offer payment through online platforms such as Alibaba Trade Assurance or PayPal. It is important to clarify the payment terms and process before placing orders.

6. How long does it take for the manufacturer to deliver the machine?

A: Delivery times vary depending on the manufacturer’s production capacity, shipping method, and the destination. The manufacturer should provide a clear delivery timeline before the order is confirmed.

7. What kind of after-sales service can I expect from the manufacturer?

A: A reliable manufacturer should offer technical support, training for machine operation and maintenance, and provide spare parts when needed. They should also offer warranties for their products. Clarify the after-sales service terms before making a purchase.

Applications of Concrete brick making machine

Concrete brick making machines are versatile machines used in a wide range of construction applications. They are designed to produce durable and high-quality concrete blocks that can be used for various types of building construction projects. Here are some of the applications of concrete brick making machines:1. Residential Construction – Concrete brick making machines are widely used in residential construction projects for building walls, foundations, and other construction elements. The durable and strong concrete blocks produced by these machines can withstand extreme weather conditions and keep homes safe and sturdy.

2. Commercial Construction – Concrete blocks produced by brick making machines are also widely used in commercial construction projects such as large buildings, malls, and offices. The blocks have high compressive strength and can support the weight of heavy equipment and machinery.

3. Paving Roads and Pathways – Using concrete bricks in road construction offers a durable and long-lasting solution to building a smooth and solid surface. Concrete brick making machines produce high-quality concrete blocks that are perfect for paving roads, pathways, and driveways.

4. Landscaping – Concrete brick making machines can also be used in landscaping applications. The blocks produced by the machines can be used for building retaining walls, garden beds, and other garden features that require durability and strength.

5. Building Public Infrastructure – Public infrastructure projects such as bridges, dams, and airports require strong and durable building materials. Concrete brick making machines produce concrete blocks with high compressive strength that can be used for building these kinds of structures.

In conclusion, concrete brick making machines have numerous applications in construction, landscaping, and infrastructure building. The machines are versatile and produce high-quality concrete blocks that have the durability and strength required for various types of construction projects.

Manufactured Products made of Concrete brick making machine

Concrete brick-making machines are designed to manufacture high-quality concrete bricks using a process that combines water, cement, and aggregates. The manufacturing process involves a series of steps that start with mixing these raw materials to produce a homogenous mixture that is then molded into brick shapes using a brick-making machine. These machines use different methods to produce bricks such as semi-automatic, fully automatic, hydraulic, or mechanical. Concrete brick-making machines are commonly used for the construction of offices, schools, hospitals, warehouses, and other structures that require strength and durability.One of the advantages of using concrete brick-making machines is that they produce bricks with a high level of strength and durability. Concrete is a durable material that can withstand harsh weather conditions and last for many years without significant wear and tear. This makes it ideal for construction projects that require long-lasting structures. Additionally, concrete brick making machines are cost-effective since they can be used to produce a large number of bricks quickly and efficiently, thus reducing labor costs.

Another advantage of using concrete brick-making machines is that they are environmentally friendly. Concrete is an eco-friendly building material that is made from natural materials like sand, gravel, and cement. Additionally, concrete bricks can be recycled, helping to reduce the amount of waste generated by construction projects.

In conclusion, concrete brick-making machines are an excellent investment for any construction project that requires durable and cost-effective building materials. They provide a simple and efficient way to produce high-quality concrete bricks, making them an essential tool for any construction site. By using these machines, builders can deliver reliable construction projects that meet the highest standards of strength, durability, and safety.

The Evolution history of Concrete brick making machine

Concrete brick making machines have a long history of evolution. The first concrete brick making machine was invented by German inventor Friedrich Hoffmann in 1858. However, it was not until the early 1900s that mass production of concrete bricks became possible due to improvements in the brick making machines.In the early 1900s, the first rotary press machines were developed, allowing for faster and more efficient production of concrete bricks. These machines used molds that could produce multiple bricks at once, reducing the time and labor needed for brick production.

In the 1920s and 1930s, hydraulic brick making machines were invented. These machines used hydraulic pressure to compress the concrete mix into molds, resulting in denser, stronger bricks.

In the 1950s and 1960s, automatic brick making machines were introduced. These machines were equipped with automated systems that could mix, mold, and stack bricks without the need for human intervention. This led to a further increase in production efficiency and capacity.

Today, modern concrete brick making machines use computerized systems to control the entire production process. These machines are able to produce bricks of different sizes, shapes, and colors with high precision and quality. They are also equipped with features for recycling materials and reducing waste, making them environmentally friendly.

Overall, the evolution of concrete brick making machines has been driven by the need for faster, more efficient, and more sustainable brick production. As technology continues to advance, it is expected that concrete brick making machines will become even more advanced and innovative in the future.

The Process of Concrete brick making machine

Concrete brick making machines are used in the process of creating concrete bricks, which are a popular and versatile building material. The process of making concrete bricks involves a number of steps and the use of specialized equipment, including the concrete brick making machine itself, which is responsible for shaping the bricks into their final form.The first step in the process of making concrete bricks is mixing the concrete. This involves combining cement, water, and aggregates like sand and gravel in the proper proportions. The resulting mixture is then poured into the hopper of the concrete brick making machine.

The machine then vibrates the mixture, which helps to ensure that the concrete is evenly distributed throughout the mold. The mold itself is made of metal and is designed to shape the concrete into the familiar brick shape.

After the mold has been filled, the excess concrete is scraped away using a knife or trowel. The bricks are then left to dry for a period of several days, during which time they harden and become ready for use.

Once the bricks have dried, they are typically stacked and stored until they are needed for use. At this point, they can be transported to a construction site or used in any number of building projects.

Overall, the process of making concrete bricks is a relatively straightforward one, but it requires careful attention to detail and the use of specialized equipment. With the right equipment and the proper techniques, however, it is possible to produce high-quality concrete bricks that are durable and long-lasting, making them an excellent choice for a wide range of building applications.

Benefits Advantages of Utilizing Concrete brick making machine

Concrete brick making machines are an innovative equipment designed to produce bricks of various shapes and sizes using concrete as the raw material. The use of these machines comes with numerous benefits and advantages, some of which include:1. Speed and Efficiency: One of the primary benefits of using a concrete brick making machine is speed and efficiency. These machines are designed to operate at high speeds and can produce a significant number of bricks in a short period. This makes them ideal for use in large construction projects.

2. Cost-Effective: Concrete brick making machines are a cost-effective way of producing bricks, as they only require concrete as the raw material. Compared to other brick-making methods, such as using clay or brick, using concrete is less expensive.

3. High-Quality Bricks: Since these machines are designed to operate at high speeds, they produce high-quality bricks with consistent shapes, sizes, and textures. This ensures that the bricks are durable, strong, and have a longer lifespan.

4. Easy to Operate: Concrete brick making machines are easy to operate, and you do not need to have any special skills or experience to operate them. They come with easy-to-follow instructions that anyone can understand and follow, making them ideal for use by both professionals and DIY enthusiasts.

5. Adaptability and Versatility: Concrete brick making machines can produce bricks of various shapes and sizes, making them adaptable and versatile. This means they can be used to produce different types of bricks, such as interlocking, hollow, solid, and paving bricks.

6. Customization: With a concrete brick making machine, you can easily customize your bricks to match your specific needs and preferences. This includes the color, texture, shape, and size of the bricks.

In conclusion, the use of concrete brick making machines is a sure way to achieve time, cost, and quality efficiency in your construction projects. They provide you with speed, cost-effectiveness, and high-quality bricks, making them an essential investment in any construction project.

Disadvantages Concrete brick making machine

There are several disadvantages to using a concrete brick making machine, which can limit its effectiveness in certain situations. Firstly, these machines can be quite expensive to purchase, particularly for small-scale or individual users. The initial investment required to buy the machine may be beyond the budget of many people, and this can be a barrier to entry for those who want to produce bricks for their own use.Secondly, concrete brick making machines can be quite complex and require a significant amount of skill and experience to operate effectively. This means that individuals who are new to the industry may struggle to produce high-quality bricks, which can limit their profitability and ability to compete with more established manufacturers.

Thirdly, concrete block making machines can be quite noisy and produce a lot of dust and debris. This can be a health and safety concern for workers who operate the machines without proper protective equipment. Additionally, the noise and mess created by the machines may be a nuisance to others in the surrounding area, which can cause conflicts and complaints.

Finally, concrete brick making machines may have limited production capacities, depending on the model and size. This means that they may not be suitable for producing bricks in large quantities or for major commercial projects. In such cases, it may be more cost-effective to use other methods of brick production, such as manual labour or larger-scale machines.

In summary, while concrete brick making machines can be a useful tool for producing bricks, they have several disadvantages that need to be taken into account when deciding whether to use them. These include their high cost, complexity, noise and dust production, and limited production capacity, which may make them unsuitable for certain applications.

Selecting the Ideal Manufacturer Concrete brick making machine

When selecting the ideal manufacturer for a concrete brick making machine, there are various factors that you need to consider to ensure that you get a machine that is reliable, efficient, and durable.Quality and durability of the machine

The first thing that you should consider when selecting a manufacturer is the quality and durability of the machine. You should look for a manufacturer that uses high-quality materials and components to ensure that the machine is durable and can withstand the tough working conditions.

Capacity and output of the machine

The capacity and output of the machine should also be considered when selecting a manufacturer. You should choose a manufacturer that offers machines with different capacities to meet your specific production needs.

Ease of operation and maintenance

Another factor to consider is the ease of operation and maintenance of the machine. You should choose a manufacturer that provides machines that are easy to operate, maintain and repair, and whose spare parts are readily available.

Customer support and after-sales service

The manufacturer’s customer support and after-sales service are also crucial factors to consider. You should choose a manufacturer that offers excellent customer support and after-sales service to ensure that you get the necessary help and support whenever you need it.

Price and affordability

Lastly, you should consider the price and affordability of the machine. You should choose a manufacturer that offers machines at affordable prices without compromising on quality, durability, and efficiency.

In conclusion, selecting the ideal manufacturer for a concrete brick making machine requires careful consideration of various factors, as outlined above. By choosing a reputable, reliable, and well-established manufacturer, you can invest in a high-quality machine that meets your specific production needs and provides an excellent return on investment.

Things to Consider When Purchasing Concrete brick making machine

When considering purchasing a concrete brick making machine, there are several important factors to take into account to ensure that you are selecting the appropriate machine for your needs and budget.Firstly, you should consider the production capacity of the machine, as this will determine how many bricks you can produce per hour. This figure is important to know as it will dictate how much time you will need to allocate to making bricks, and how much product you can produce to meet the needs of your customers.

Another important factor to consider is the type of bricks you intend to make. Different machines are designed to produce different types of bricks, and it is important to select a machine that has the capabilities to create the specific type of bricks you need.

The size of the machine is also an important consideration, as you will need to ensure that you have adequate space to store and operate the machine. It is also important to consider the weight of the machine, as this will impact its portability and transportability.

Furthermore, it is pertinent to carefully evaluate the brand of machine you intend to purchase, ensuring the company is reputable and has a proven track record in producing high-quality machines. Additionally, ensure the machine you purchase has a warranty and the availability of replacement parts.

Finally, you must consider your budget. While purchasing a brick making machine is a worthwhile investment, it is important to ensure that you can afford the machine you intend to purchase without compromising on quality. Therefore, it is vital to do your research, identify your needs and choose a machine that will give value for money.

In conclusion, choosing the right concrete brick making machine is vital for your business needs, and you should consider the production capacity, brick type, size, brand, warranty, parts replacement, and budget before making your decision.

Properties of Concrete brick making machine

A concrete brick making machine is an advanced machine that is designed to make high-quality bricks using cement, water, sand, and aggregates. It consists of various components that work together to produce bricks of different shapes and sizes.One of the main properties of a concrete brick making machine is its efficiency. A good machine can produce a large number of bricks in a relatively short time, which makes it ideal for commercial brick-making businesses. Additionally, it has a low energy consumption rate, meaning that it requires less power to produce more bricks.

Another important property of a concrete brick making machine is its versatility. It can be used to make different types of bricks, including solid, hollow, interlocking, and paving bricks. This versatility allows brick-making businesses to produce different types of bricks to meet the demands of their customers.

Durability is also a key property of a concrete brick making machine. The machine is made from high-quality materials that are resistant to wear and tear, ensuring that it can withstand the harsh conditions of the brick-making process. This guarantees the longevity of the machine, making it a valuable investment for brick-making businesses.

Ease of use is another crucial property of a concrete brick making machine. It is designed to be user-friendly, with simple controls and an easy-to-understand interface. This feature makes it easy for operators to operate the machine and produce high-quality bricks consistently.

Finally, a good concrete brick making machine should be low maintenance. It should be designed in such a way that it is easy to clean, service and maintain. This ensures that the machine remains in optimal condition for many years, reducing operational costs and maximizing productivity.

How to use Concrete brick making machine

Concrete brick making machine is a versatile piece of equipment that is essential for anyone interested in making high-quality concrete bricks. Here are the steps to follow when using the machine:1. First, make sure that the machine is installed and set up correctly. Follow the manufacturer’s guidelines for installation and setup.

2. Next, prepare the raw materials for making the bricks. This may include cement, sand, water, and any additives that are required for the specific type of brick you want to produce.

3. Load the mixer with the raw materials, and mix them thoroughly to create a consistent and well-blended mixture.

4. Once the mixture is ready, load it into the brick-making machine’s hopper. Use the machine’s control panel to set the desired size and shape of the bricks you want to produce.

5. Activate the machine and let it run until the desired number of bricks has been produced. Depending on the size of the machine, this process may take anywhere from a few minutes to several hours.

6. Once the bricks are done, remove them from the machine and allow them to cure for several days. This will ensure that they are properly hardened and can be used for construction.

7. Finally, clean the machine thoroughly after use. This will prevent any build-up of concrete that could affect the machine’s performance and longevity.

In conclusion, using a concrete brick making machine is a relatively straightforward process, as long as you follow the manufacturer’s instructions carefully. By doing so, you can ensure that you produce high-quality bricks that are suitable for a range of construction purposes.

Terms for Concrete brick making machine

Concrete brick making machine is a modern industrial machine that is used to manufacture bricks and blocks out of concrete. It is a cost-effective solution for the construction sector to produce high-quality bricks that are strong and durable.The machine is designed to have a compact structure that is easy to operate. It is engineered to have a robust frame, which is made of cast-iron or steel. The machine comes with a variety of mold designs that can be customized according to the needs of the user. The molds are made of high-quality steel to ensure that they can withstand the high pressure generated by the machine.

The machine can be operated manually or automatically. Manual operation requires the user to operate the machine by hand to mold the bricks. Automatic operation, on the other hand, involves the use of a fully automated system that controls all the operations, including material supply, mixing, molding, and curing.

The machine can produce a variety of brick sizes and shapes, including standard and non-standard sizes. The bricks produced by the machine are of high quality and consistency. The machine is capable of producing large quantities of bricks in a short time, making it the ideal choice for mass production.

Other features of the machine include a vibration system, which compacts the concrete mixture to remove air pockets and ensure that the bricks are solid and durable. It is also equipped with a water cooling system, which prevents the machine from overheating during operation.

In conclusion, the concrete brick making machine is an essential machine for the construction sector. It is an efficient and cost-effective way to produce high-quality bricks that are durable and long-lasting. The machine is designed to have a compact structure, making it easy to operate and maintain. With its numerous features and capabilities, the machine is an excellent investment for any construction company seeking to improve its brick and block production process.

Concrete brick making machine Price

When it comes to making concrete bricks, the process requires a solid brick making machine that is reliable, efficient, and affordable. The price of a concrete brick making machine depends on several factors, including the quality, capacity, and features of the machine.As a general rule, the larger the machine and the higher the production capacity, the more expensive it will be. A basic concrete brick making machine can cost anywhere from $1,000 to $5,000, while a top-of-the-line model can run upwards of $50,000 or more.

One of the most important factors to consider when purchasing a concrete brick making machine is its production capacity. The machine’s capacity will determine how many bricks it can produce per hour, which in turn will affect the overall cost of your project.

Another important consideration is the type of bricks you plan to produce. Different types of bricks come with different size and shape requirements, which will influence the kind of machine you need to buy. For example, if you need to produce large sized bricks, then you need a machine with a bigger mold size.

The size of the machine is also a factor in determining price. A smaller, portable machine like the QMY4-30A Mobile Concrete Brick Making Machine will cost less than a larger machine like the HFB5230A Brick Making Machine.

When purchasing a concrete brick making machine, it’s important to look for a reliable and reputable manufacturer. Some of the top brands in the market include Teka, FAW Group, Sany, and XCMG.

In conclusion, the price of a concrete brick making machine can vary depending on various factors. It is essential to consider the production capacity, type of bricks, machine size, and manufacturer before making a purchase decision. We recommend setting a budget and doing your research before making a final decision.