Benefits of Electric Rebar Bender

Electric rebar benders have revolutionized the construction industry by providing a fast, efficient and reliable way of bending rebar. There are several benefits that come with using an electric rebar bender, which are discussed below:

1. Time-Saving

Electric rebar benders save time by automating the bending process. This eliminates the need for manual bending, which is a time-consuming and labor-intensive process. With an electric rebar bender, operators can quickly and easily bend rebar into the desired shapes and sizes, thereby reducing construction time and increasing productivity.

2. Precision

Electric rebar benders provide accurate and precise bending, ensuring that rebar is bent to the exact specifications required. This eliminates the need for manual cutting and trimming, which can be a tedious and time-consuming process. Precise bending also ensures that construction projects are completed to a high standard and with minimal errors.

3. Consistency

Electric rebar benders ensure consistent bending throughout the project. This eliminates variations in the final product, ensuring that all rebar is bent to the same degree of accuracy. This is particularly important when working on large construction projects where consistency is key to the structural integrity of the project.

4. Safety

Electric rebar benders are designed with safety features that protect operators from injury. These features include emergency stop buttons, safety guards, and automatic shut-off functions. This ensures that operators can work with confidence, knowing that they are protected from potential hazards.

5. Cost-effective

Electric rebar benders are cost-effective because they eliminate the need for manual labor, which can be expensive and time-consuming. They also provide consistent and precise bending, reducing the risk of errors and mistakes that can lead to costly rework.

In conclusion, electric rebar benders provide numerous benefits for construction projects. They save time, provide precision, ensure consistency, improve safety, and are cost-effective. If you’re involved in the construction industry and need to bend rebar, an electric rebar bender can provide an excellent solution.

Features of Electric Rebar Bender

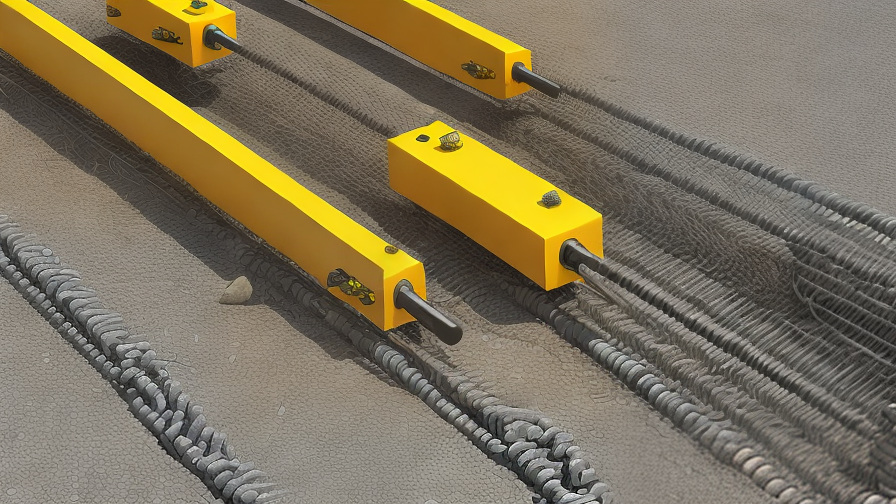

Electric rebar benders are an essential tool for any construction project involving the use of reinforced steel bars. These machines are designed to bend and manipulate rebar with ease, saving time and reducing the risk of injury.

One of the key features of electric rebar benders is their speed and efficiency. With hydraulic motors and powerful torque, these machines can bend rebar quickly and accurately. They are also able to handle a wide range of rebar sizes and types, from thin to thick and from flat to circular.

Another important feature of electric rebar benders is their ease of use. These machines come with intuitive controls that make operating them simple and straightforward. They also often have adjustable settings that allow for a high degree of customization, so users can bend rebar to their exact specifications.

Safety is another important consideration in the design of electric rebar benders. Many models are equipped with safety features such as emergency stops and guards to prevent accidental injury. The machines are also generally designed to be stable and durable, with heavy-duty frames and components that can withstand the rigors of daily use.

Finally, many electric rebar benders are also portable and easy to transport, making them ideal for use at job sites or in remote locations. They can be easily loaded onto a truck or trailer, and their compact size means they can be stored in a small space when not in use.

In summary, electric rebar benders are versatile, efficient, and easy to use machines that are an essential tool for any construction project involving reinforced steel. With a range of features designed for speed, safety, and portability, these machines are a must-have for contractors and builders.

Various Types of Electric Rebar Bender

Electric Rebar benders are tools used in the construction industry to bend steel bars or rebars accurately, easily, and efficiently. When it comes to electric rebar benders, there are several types on the market. Each of these types has unique features that make it ideal for specific applications. Here are some of the different types of electric rebar benders available:

1. Portable electric rebar bender: Portable electric rebar benders are lightweight, portable, and can be easily transported. They are ideal for small to medium-sized projects, and they can bend rebar up to 1 inch in diameter.

2. Tabletop electric rebar bender: Tabletop electric rebar benders are stationary machines that are capable of bending rebar up to 1.5 inches in diameter. They are ideal for larger construction projects, and they can bend rebar with precision and consistency.

3. Handheld electric rebar bender: Handheld rebar benders are designed for bending smaller rebars with precision and accuracy. They are lightweight and easy to use, making them ideal for small projects, such as home renovations or DIY projects.

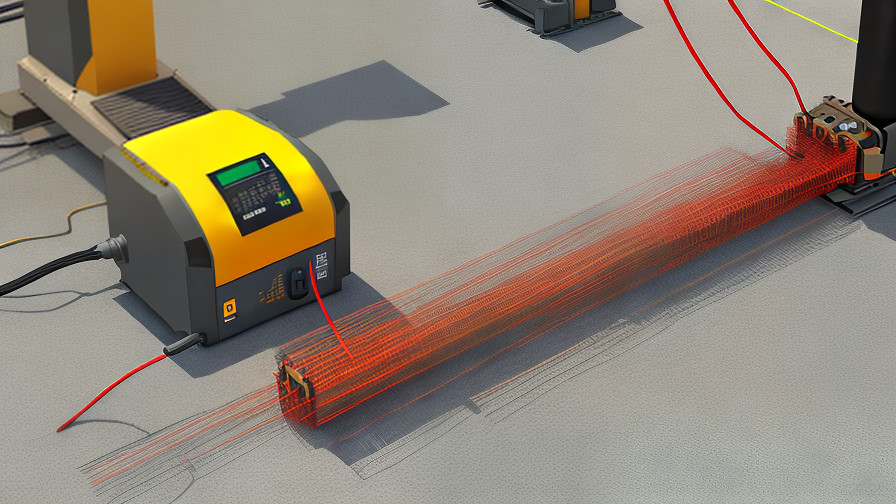

4. Automatic electric rebar bender: Automatic electric rebar benders are the most advanced type of rebar bending machines available. They are capable of bending large diameter rebars quickly and with high precision. They are ideal for use in large construction projects, such as bridges and high-rise buildings.

In conclusion, electric rebar benders are essential tools in the construction industry. With the various types available, contractors can choose the machine that best suits their specific needs. Each type of electric rebar bender has unique features that make it ideal for different projects, from small home renovations to large industrial projects. Investing in a quality electric rebar bender can save time and increase efficiency, ensuring that construction projects are completed on time and within budget.

Applications of Electric Rebar Bender

Electric rebar benders are highly beneficial for contractors, engineers and construction workers for bending steel bars. With the increasing demand for rebar benders, the electric version is highly sought after for several reasons. This article will outline some of the applications of the electric rebar bender.

The primary application of electric rebar bender is in the construction industry. The machine allows contractors to bend rebars or reinforcing bars quickly, saving time and effort. It also ensures accuracy in bending, resulting in perfectly shaped structures. In addition, the electric rebar bender is capable of bending heavy-duty rebars up to 32mm in diameter, making it a versatile tool in the construction industry.

The electric rebar bender also has applications in the manufacturing of reinforced concrete products. The machine simplifies the bending process, producing accurate bends and curves on the steel bars. This results in faster production and improved quality of reinforced concrete products like pipes, pillars, and beams.

Another application of the electric rebar bender is in the fabrication of steel structures such as bridges, high-rise buildings, and towers. The machine is used to bend steel bars according to the specified design, ensuring that the structure can withstand the required load and stress. The use of an electric rebar bender in this application minimizes the risk of error and ensures accuracy and uniformity in the bending process.

Lastly, electric rebar benders also have a significant impact on worker safety. The machine eliminates manual bending, which puts a lot of strain on the workers’ muscles, leading to musculoskeletal disorders. It also reduces the risk of accidents that may occur during the manual bending process.

In conclusion, the electric rebar bender has several applications in the construction and manufacturing industries. From simplifying the bending process to enhancing the quality of reinforced concrete products and improving worker safety, it is a vital tool that cannot be ignored in the industry.

The Process of Electric Rebar Bender

Electric rebar benders are a popular choice in the construction industry for bending reinforcing bars accurately and efficiently. The process of using an electric rebar bender involves a few simple steps that can be completed in a matter of minutes.

Firstly, the type and size of the rebar need to be identified to ensure the correct settings are used on the electric rebar bender. Once this is confirmed, the bender is switched on and the rebar is placed in the bender’s bending slot.

The operator then adjusts the angle of the bend by rotating a dial or pressing a button on the control panel, which is located on the machine. The bender will then automatically start bending the rebar to the desired angle.

It’s important to note that the electric rebar bender’s precision ensures that the rebar is bent to the exact degree required, which is critical to maintaining structural integrity in the building process.

Once the rebar has been bent, it is typically removed from the bender and measured to ensure it meets the specifications required for the project. Any adjustments can then be made with the electric rebar bender to achieve the correct angle if necessary.

Using an electric rebar bender is a safer and faster option compared to manual bending methods. It minimizes the risk of injury associated with manual bending and increases productivity by reducing the time it takes to bend each rebar, resulting in a more efficient construction process.

In conclusion, the process of using an electric rebar bender involves identifying the type and size of the rebar, placing it in the bending slot, adjusting the angle on the control panel, removing the rebar once bent, and ensuring it meets the required specifications for the project. It’s an essential equipment that every construction worker should learn to operate to increase efficiency and safety on the job site.

How to use Electric Rebar Bender

Electric rebar benders are becoming increasingly popular in the construction industry. They are powerful tools that make it easy to bend rebars quickly and with precision. Using an electric rebar bender is fairly easy, but it does require some basic knowledge and safety precautions. Here is a simple guide on how to use an electric rebar bender.

Firstly, choose the right rebar bender for the job. Electric rebar benders come in different sizes and capacities, so make sure to choose one that can handle the specific rebar size and quantity you need to bend. Also, select the appropriate bending angle and ensure the machine is plugged in and functioning properly.

Before you start, put on your safety gear, including gloves and eye protection. Make sure there are no loose clothing or jewelry that could get caught in the machine.

Next, measure and mark the rebar where you need to make the bend. This will ensure that you get the right angle and shape without wasting any rebar. Then, insert the rebar into the machine’s bending slot and make sure it is secured tightly.

Press the pedal or button to activate the machine. The electric motor will power the bending rollers, and you should start to see the rebar bending to the desired angle. Keep an eye on the process to ensure the rebar does not get twisted or kinked during bending.

Once the bending is complete, remove the rebar from the machine and check that it has the correct angle and shape. If it needs any further adjustment, repeat the process until you are satisfied with the result.

Finally, turn off the machine and unplug it from the power source. Clean the machine and return it to its storage location.

In conclusion, using an electric rebar bender is easy and efficient. However, always follow safety guidelines and instructions when using the machine. Remember to wear appropriate personal protective equipment (PPE) and choose the right machine for the job. With these tips, you can successfully bend rebar with precision using an electric rebar bender.

Selecting the Ideal Manufacturer Electric Rebar Bender

Selecting the Ideal Manufacturer Electric Rebar Bender

When it comes to construction work, having the right tools at one’s disposal is crucial. One of the tools that construction workers need is an electric rebar bender. An electric rebar bender simplifies the work of bending heavy steel bars, which are necessary for reinforcing concrete structures.

Before making a purchase, it is essential to select the right manufacturer. Some manufacturers may not offer products of high quality, which can lead to inefficiency and additional costs as the user may need to replace parts or even purchase a new unit entirely. To avoid such issues, one needs to look out for a manufacturer that has a good reputation for providing durable tools that are built to last.

One should also consider the manufacturer’s warranty, as a good manufacturer will offer a warranty for their products. This warranty provides some protection to the purchaser in case the unit develops any defects or fails to work correctly. A warranty also indicates that the manufacturer has confidence in the quality of the products they produce.

Another essential factor to consider is the power output of the electric rebar bender. Depending on the job, one may need an electric rebar bender with a lower or higher power output. A lower power output electric rebar bender may take longer to bend heavy steel bars compared to a higher power output electric rebar bender. It’s important to choose a model with the appropriate power output that can handle the size of the bars you will be bending.

Ease of use is also a critical factor when selecting an electric rebar bender. Look for a model that is simple to operate and has user-friendly controls. This ensures that users can easily manipulate the unit to get the desired bend without requiring any prior experience or skill.

In conclusion, selecting the ideal manufacturer of an electric rebar bender is crucial to achieve efficiency and quality work. By taking into account factors such as reputation, warranty, power output, and ease-of-use, one can make an informed decision and purchase the best unit for their needs.

list FAQ with answer about Electric Rebar Bender

Electric Rebar Bender is a reliable and efficient tool used for bending reinforcing steel bars. It ensures easy handling of the material, and reduces the need for manual labor. However, before buying and using this tool, it is important to understand its features, specifications and limitations.

Here is a list of frequently asked questions about electric rebar benders, along with their respective answers:

1. What is an electric rebar bender, and how does it work?

An electric rebar bender is a machine that is designed to bend steel bars into desired shapes. It works by using a motor to pull the bar through a bending plate, which creates the desired bend.

2. What are the benefits of using an electric rebar bender over a traditional manual bender?

Using an electric rebar bender increases productivity, reduces labor costs, and ensures a higher level of accuracy in bends. It also requires less physical effort and is safer to use compared to manual benders.

3. What are some safety precautions to take when using an electric rebar bender?

Always read and follow the safety guidelines in the machine manual. Wear appropriate personal protective equipment, such as safety glasses and gloves. Do not overload the machine, and never use damaged or faulty equipment.

4. What sizes of rebar can be bent with an electric rebar bender?

Electric rebar benders can handle various sizes of rebar, depending on the model. Some can handle up to #8 rebar, while others can bend up to #12 rebar.

5. Can an electric rebar bender bend multiple bars at the same time?

Some electric rebar benders can bend multiple bars at a time, but this feature varies depending on the model.

6. Can an electric rebar bender be used for other types of steel, such as rods or pipes?

Most electric rebar benders are designed specifically for bending reinforcing steel bars, but some models may be capable of bending other types of steel.

In summary, an electric rebar bender is a useful tool for anyone who needs to bend reinforcing steel bars. Proper use and understanding of the machine’s features and limitations are crucial for safe and efficient operation.

Things to Consider When Purchasing Electric Rebar Bender

When it comes to purchasing an electric rebar bender, there are a few important things to consider to make sure that you get the right tool for your needs. In this article, we’ll cover some of the key factors to keep in mind when shopping for an electric rebar bender.

One of the first things to think about when purchasing an electric rebar bender is the size of the rebar that you need to bend. Electric rebar benders come in different sizes and can handle different diameters of rebar. Make sure that you select a bender that can handle the size of rebar that you will be using on your construction or fabrication projects.

Another important consideration is the type of bend that you need to create. Some rebar benders are better suited for creating sharp bends, while others are designed for making larger bends with a greater radius. Think about the types of bends that you will need to create on your projects, and choose a bender that will be able to handle them.

Additionally, you should think about the power source for your electric rebar bender. Some models are powered by 110-volt electricity, while others require 220-volt electricity. Make sure that you choose a bender that is compatible with the power source that you have available in your workspace.

Finally, consider the quality and durability of the electric rebar bender that you are considering. Look for a model that is made with high-quality materials, and that is built to withstand heavy use in a construction or fabrication setting. You may pay a bit more for a higher-quality bender, but it will be worth it in the long run if it lasts longer and requires fewer repairs or replacements.

In summary, when shopping for an electric rebar bender, you should consider the size of the rebar, the type of bend that you need to create, the power source required, and the overall quality and durability of the tool. By keeping these factors in mind, you can select an electric rebar bender that will meet your needs and provide reliable performance on your construction or fabrication projects.

Properties of Electric Rebar Bender

An electric rebar bender is a specialized tool used in construction sites to bend and shape steel rebar. This tool uses electricity to power its motor and move the bending apparatus, making it an efficient and effective way to bend rebar to the desired lengths and angles. The properties of this tool make it an essential item for any construction site.

One of the main properties of an electric rebar bender is its ability to bend steel rebar quickly and accurately. Electric rebar benders have powerful motors that can output enough force to bend rebar up to 180 degrees. This means that it can handle a vast variety of rebar shapes and sizes efficiently, saving time and increasing the efficiency of the bending process.

Another property of the electric rebar bender is that it is easy to use. It comes with a simple interface that can be easily navigated by the user. It is also lightweight and portable, making it easy to move to different sites and locations.

The tool is also very durable and can withstand the tough conditions on construction sites. It is made of high-grade materials such as steel, which makes it tough and resistant to corrosion. These materials, coupled with the tool’s compact design, make it a reliable tool for any construction site.

Finally, the electric rebar bender comes with safety features that protect the user and the equipment. The safety features include an emergency stop button, which can be used in case of an emergency. It also has safety guards installed to prevent any accidents during the bending process.

In conclusion, an electric rebar bender has properties that make it an essential tool in construction sites. Its efficiency, ease of use, durability, and safety features make it a reliable tool for any job requiring steel rebar bending.

Technical Parameters Terms for Electric Rebar Bender

Technical Parameters Terms for Electric Rebar Bender

The electric rebar bender is an essential tool in any construction site, used in the bending and shaping of rebar for building reinforcement. To fully understand the functionality and capacity of an electric rebar bender, it is important to know the technical parameters terms used in its description.

1. Capacity – This refers to the maximum size of the rebar that the electric bender can effectively bend. It is usually stated in inches or millimeters and ranges from ⅝ inch to 1 ½ inch or more, depending on the machine’s size and power.

2. Bending Angle – The bending angle refers to the degree of the bend the machine can make. A typical angle range for an electric rebar bender is 0°-180°, meaning the machine can bend the rebar in any angle between 0 and 180. Some machines have a digital display that shows the bending angle, making it easier to get accurate bent rebar.

3. Operating Voltage – This refers to the electrical power required to operate the machine. It is usually stated in volts and ranges from 110v to 220v or higher, depending on the machine’s size and power.

4. Motor Power – The motor power determines how fast and effective the electric rebar bender can work. It is usually stated in watts or horsepower and ranges from 1.1 to 2.2 kW, depending on the machine’s capacity and size.

5. Speed – The speed of the electric rebar bender impacts the amount of work that can be done. The machine’s speed is determined by its motor power and is usually stated in rotations per minute (RPM). An electric rebar bender’s speed ranges between 5 to 15 RPM.

6. Machine Weight – The machine’s weight is an essential consideration when selecting an electric rebar bender. It determines how portable the machine is, and it is usually stated in pounds or kilograms. A lightweight machine is more portable but may have a smaller capacity, while a heavier machine can handle more significant rebar sizes but may be less portable.

By understanding these technical parameters terms, it is easier to select an electric rebar bender that is efficient, reliable, and meets specific project needs.

Electric Rebar Bender Price

Electric rebar benders are an essential machine for those who work with reinforced steel regularly. These machines are designed to help bend steel bars into various shapes and angles quickly and effectively, saving time and effort. The prices of electric rebar benders vary depending on their features and specifications, such as bending capacity and motor power.

The average price of an electric rebar bender ranges from $500 to $2000, but you can find some lower pricing models as well. The smaller ones which bend rebar up to 5/8 inch can be found for around $300. The more expensive models come equipped with a more powerful motor that enables them to bend steel bars up to 1-1/4 inches. These machines usually have a bending capacity of around 130 degrees.

However, it’s important to note that the price should not be the only consideration when buying an electric rebar bender. You should also consider their efficiency, durability, and safety features. Investing in a high-quality electric rebar bender not only saves time but also ensures safety in the workspace.

When choosing an electric rebar bender, look for a machine that is easy to operate and can be quickly adjusted to suit various tasks. The machine should be built with durable materials to ensure longevity, and safety features such as automatic shut-off and emergency stops should also be included.

In conclusion, the price of an electric rebar bender can vary depending on specifications and features. While it’s important to consider the price, efficiency, durability, and safety features are also critical factors that should be taken into account when choosing an electric rebar bender. Investing in a high-quality electric rebar bender is a wise choice that can save time, ensure safety, and improve productivity in the workspace.