Introduce about epdm rubber seal guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

EPDM rubber seal guide:

EPDM (ethylene propylene diene monomer) rubber seals are widely used in various industries for their excellent physical properties and durability. This guide aims to provide an introduction to EPDM rubber seals, including information on quality, cost, suppliers, certifications, market demand, tips, frequently asked questions (FAQs), and more.

Quality:

EPDM rubber seals are known for their high-quality performance. They exhibit excellent resistance to extreme temperatures, weathering, UV radiation, ozone, and many chemicals. EPDM rubber seals also provide good flexibility, low compression set, and long-term thermal stability, ensuring their suitability for various applications.

Cost:

The cost of EPDM rubber seals can vary depending on factors such as size, shape, quantity, and complexity. Generally, EPDM rubber seals are cost-effective due to their longevity and resistance to wear and tear. However, specific cost details can be obtained from suppliers based on individual requirements.

Supplier:

There are numerous suppliers of EPDM rubber seals globally. It is essential to choose a reputable supplier with a proven track record of providing high-quality products. Reliable suppliers can offer customizations, complete product range, technical support, and timely delivery.

Certification:

EPDM rubber seals are often manufactured following industry standards and certifications. Some common certifications related to EPDM rubber seals include ISO 9001 (quality management system), ISO 14001 (environmental management system), and ASTM (American Society for Testing and Materials) standards.

Market:

The demand for EPDM rubber seals is significant across various sectors, including automotive, construction, electrical, and marine industries, among others. EPDM rubber seals are used for gasketing, weatherstripping, vibration isolation, sound dampening, and sealing applications. The market for EPDM rubber seals is expected to grow steadily due to their excellent performance and versatility.

Tips:

– Specify the required dimensions, tolerance, and other specifications clearly when ordering EPDM rubber seals.

– Consider suppliers who offer technical support and guidance for selecting the right EPDM rubber seals for your application.

– Regularly inspect and maintain EPDM rubber seals to ensure their optimal performance and longevity.

FAQs:

Commonly asked questions about EPDM rubber seals include their temperature range, compatibility with different chemicals, installation methods, specific application suitability, and customization options. Suppliers and technical resources can provide detailed answers to these questions.

In conclusion, EPDM rubber seals are high-quality, cost-effective sealing solutions for various industries. Choosing a reliable supplier, understanding certifications, and considering specific application requirements can ensure the successful use of EPDM rubber seals.

Types of epdm rubber seal

EPDM (Ethylene Propylene Diene Monomer) rubber seals are widely used in various industries due to their excellent resistance to heat, ozone, weathering, and various chemicals. There are several types of EPDM rubber seals available, each designed to meet specific requirements and applications. These include:

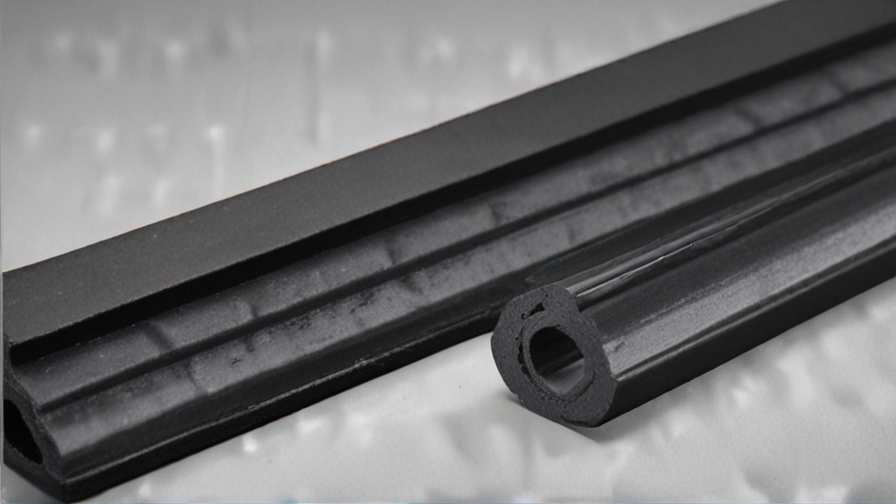

1. Solid EPDM rubber seals:

Solid EPDM rubber seals are one of the most common types used in industrial applications. They are manufactured as extrusions, gaskets, or O-rings and are versatile in sealing applications where resistance to weathering and water is crucial. Solid EPDM rubber seals can be custom-made to fit specific equipment or machinery parts.

2. Sponge EPDM rubber seals:

Sponge EPDM rubber seals are soft, compressible, and lightweight. They are primarily used for applications requiring low compression force and excellent flexibility. Sponge EPDM rubber seals provide excellent sealing properties, making them ideal for weather-stripping, sealing doors and windows, and other similar applications.

3. Self-Adhesive EPDM rubber seals:

Self-adhesive EPDM rubber seals have an adhesive backing for easy installation. They are commonly used for sealing gaps and joints in windows, doors, and other structures. Self-adhesive EPDM rubber seals offer excellent resistance to moisture, UV radiation, and extreme temperatures.

4. EPDM rubber tubing:

EPDM rubber tubing is widely used in automotive and industrial applications for fluid transfer. It has excellent resistance to heat, ozone, and chemicals, making it suitable for conveying various liquids and gases. EPDM rubber tubing comes in various sizes and can be reinforced with fabric or wire for increased durability.

5. EPDM rubber profiles:

EPDM rubber profiles are used in diverse sealing applications such as windows, doors, automotive weather-stripping, construction, and industrial machinery. They are custom-made to fit specific requirements and ensure effective sealing against air, water, dust, and noise.

In summary, EPDM rubber seals come in various forms, including solid seals, sponge seals, self-adhesive seals, tubing, and profiles. These seals are chosen based on their specific capabilities and compatibility with the required application. EPDM rubber seals provide reliable sealing properties, long-term durability, and resistance to various environmental factors, making them a popular choice in many industries.

Pros and Cons of Using epdm rubber seal

EPDM (Ethylene Propylene Diene Monomer) rubber is a versatile material commonly used for sealing applications due to its excellent resistance to weathering, ozone, UV radiation, and temperature extremes. Here are the pros and cons of using EPDM rubber seals:

Pros:

1. Reliable sealing: EPDM rubber seals provide excellent compression and durability, ensuring a reliable and long-lasting seal. They are capable of maintaining an airtight, watertight, and dustproof seal, making them suitable for various applications.

2. Weather resistance: EPDM rubber exhibits remarkable resistance to extreme weather conditions, including sunlight, rain, snow, and temperature fluctuations. It can withstand exposure to ozone and UV radiation without deterioration, making it an ideal choice for outdoor applications.

3. Chemical resistance: EPDM rubber seals offer good chemical resistance against a wide range of acids, alkalis, and other harsh chemicals. This characteristic makes them suitable for use in industries where exposure to chemicals is common, such as automotive, agriculture, and chemical manufacturing.

4. High-temperature resistance: EPDM rubber seals can withstand high temperatures ranging from -50°C to +150°C (-58°F to +302°F), depending on the specific grade. This property makes them suitable for applications requiring resistance to elevated temperatures, such as automotive engine compartments and industrial machinery.

5. Cost-effective: Compared to other sealing materials, EPDM rubber seals are generally more cost-effective. They offer a good balance between performance and price, making them a popular choice for both small-scale and large-scale sealing applications.

Cons:

1. Not suitable for certain oils and solvents: Although EPDM rubber provides good chemical resistance, it may not perform well with certain oils, solvents, and fuels. It is important to consider the compatibility of EPDM with specific chemicals before using it in applications where exposure to these substances is expected.

2. Limited compression set resistance: EPDM rubber may experience compression set over time when subjected to constant pressure or deformation, resulting in decreased sealing performance. This limitation can affect long-term durability in applications that require consistent compression and recovery.

3. Relatively harder and less flexible: Compared to other rubber materials, EPDM rubber is relatively harder and has lower flexibility. This can make it more challenging to install in applications that require a high degree of flexibility or conformability to irregular surfaces.

4. Limited resistance to certain solvents: While EPDM rubber generally exhibits good chemical resistance, it may not be suitable for applications involving exposure to certain organic solvents, ketones, and aromatic hydrocarbons. Careful consideration must be given to the specific chemicals present in the application environment.

Overall, EPDM rubber seals offer numerous advantages, including reliable sealing, weather resistance, and cost-effectiveness. However, they may not be suitable for all applications, particularly in situations where certain chemicals or extreme flexibility is required. It is important to evaluate the specific needs and conditions of the application before deciding to use EPDM rubber seals.

epdm rubber seal Reference Specifications (varies for different product)

EPDM rubber seals are a commonly used material in various industries due to their excellent resistance to weathering, UV radiation, ozone, and temperature extremes. The Reference Specifications for EPDM rubber seals may vary depending on the specific product, application, and industry requirements. However, a typical set of specifications and properties for EPDM rubber seals can be outlined:

1. Material Composition: EPDM (Ethylene Propylene Diene Monomer) rubber seals are made from a synthetic rubber compound consisting of primarily ethylene, propylene, and a small amount of diene monomer. The ratio of these components affects the EPDM’s physical properties, such as hardness, flexibility, and resistance to chemicals.

2. Hardness: EPDM rubber seals possess an excellent balance of flexibility and hardness. Generally, they have a durometer hardness ranging from 40 to 90 on the Shore A scale, depending on the application’s requirements.

3. Temperature Resistance: EPDM rubber seals can withstand a wide range of temperature extremes, typically varying from -40°C to +120°C (-40°F to +248°F). This high-temperature resistance makes EPDM suitable for outdoor applications, automotive industries, and environments subject to extreme weather conditions.

4. Weatherability: EPDM rubber seals exhibit exceptional resistance to weathering, UV radiation, and ozone. These properties prevent premature degradation, cracking, and color fading when exposed to sunlight, atmospheric conditions, and environmental pollutants.

5. Chemical Resistance: EPDM rubber seals offer excellent resistance to various chemicals, including acids, alkalis, ketones, alcohols, and some solvents. However, their compatibility with certain chemicals may depend on concentration, temperature, and exposure duration.

6. Water Resistance: EPDM rubber seals demonstrate excellent water resistance, making them widely used in sealing systems to prevent water ingress. They are suitable for applications where exposure to moisture, rain, or water splash is expected.

7. Compression Set Resistance: Compression set refers to the ability of a rubber seal to recover its original shape after being compressed. EPDM rubber seals typically exhibit low compression set, ensuring long-term sealing performance and durability.

8. Flame Retardancy: EPDM rubber seals can be formulated to achieve flame-retardant properties in compliance with industry standards and regulations.

It is important to note that these specifications may vary for different EPDM rubber seal products, as they are tailored to meet specific industry requirements, such as automotive, construction, electrical, or general sealing applications. Therefore, it is recommended to refer to the manufacturer’s product data sheets or consult with a technical expert for precise specifications suitable for a particular application.

Applications of epdm rubber seal

EPDM rubber seals, also known as ethylene propylene diene monomer seals, are widely used across various industries due to their excellent resistance to weathering, ozone, UV radiation, and a broad range of chemicals. With their superior durability and flexibility, EPDM rubber seals offer outstanding sealing properties and find applications in diverse fields. Here are some common uses of EPDM rubber seals:

1. Automotive Industry: EPDM rubber seals are extensively used in the automotive sector, particularly for sealing doors, windows, trunks, sunroofs, hoods, and various other components. These seals prevent water, air, dust, and noise from entering the vehicle, enhancing its comfort and reducing energy consumption for climate control.

2. Construction Industry: EPDM rubber seals are widely preferred for construction applications. They provide a dependable waterproofing solution, ensuring effective sealing in windows, curtain walls, roofs, expansion joints, and other structures. EPDM seals also offer resistance to extreme temperatures, making them suitable for both hot and cold climatic conditions.

3. Electrical Industry: EPDM rubber seals are employed in electrical equipment and cable connectors to provide insulation and protect against moisture, dust, and debris. These seals also possess excellent electrical insulation properties, making them ideal for applications in electric motors, transformers, electrical enclosures, and power distribution systems.

4. HVAC Systems: EPDM rubber seals are widely used in heating, ventilation, and air conditioning (HVAC) systems. They provide airtight seals in HVAC ducts, pipes, dampers, and air handling units, ensuring efficient energy transfer and preventing leaks or contamination.

5. Marine Industry: Due to their exceptional resistance to water, EPDM rubber seals are used in maritime applications. They provide watertight seals for boat hatches, portholes, windows, bulkheads, and through-hull fittings, preventing water ingress and ensuring the vessel’s structural integrity.

6. Appliance Manufacturing: EPDM rubber seals are employed in the manufacturing of domestic appliances, such as refrigerators, freezers, washing machines, dishwashers, and ovens. These seals ensure proper insulation, seal integrity, and protection against moisture and dust.

7. Aerospace Industry: EPDM rubber seals are utilized in various aerospace applications, including aircraft windows, doors, hatches, gaskets, fuel tanks, and weatherstripping. They provide reliable sealing in extreme temperature and pressure conditions.

8. Medical Equipment: EPDM rubber seals are used in medical devices and equipment due to their biocompatibility, resistance to sterilization methods, and sealing capabilities. They find application in dialysis machines, surgical instruments, fluid handling systems, and other medical devices.

Overall, the exceptional properties of EPDM rubber seals make them indispensable in numerous industries, offering reliable sealing solutions for enhanced performance, durability, and safety.

The Work Process and how to use epdm rubber seal

The work process of using EPDM rubber seal involves several steps.

First, it is important to ensure that the surface where the seal will be applied is clean and free from any dirt, dust, or debris. This will help ensure proper adhesion of the seal.

Next, measure the length of the area where the seal is needed and cut the EPDM rubber seal to the appropriate size using a sharp utility knife or scissors. It is recommended to leave a little extra length to ensure a tight fit.

Before applying the seal, it is recommended to use a primer or adhesive promoter on the surface for better adhesion. This will help the rubber seal adhere more securely to the surface and prevent it from peeling or coming off in the future.

Carefully position the EPDM rubber seal along the intended area, making sure it is aligned properly and fits snugly. Press down firmly on the seal to ensure good contact with the surface and eliminate any air bubbles or gaps.

If needed, use a roller or a flat object to further secure the seal and ensure proper adhesion. Be sure to apply even pressure during this step.

Finally, allow sufficient time for the seal to cure and bond with the surface. This typically takes around 24-48 hours, but it is always best to check the manufacturer’s instructions for specific curing times.

Overall, using EPDM rubber seal requires attention to detail and proper surface preparation to ensure a long-lasting and effective seal. By following these steps, you can successfully utilize EPDM rubber seal in various applications such as weatherstripping, plumbing, or automotive sealing.

Quality Testing Methods for epdm rubber seal and how to control the quality

Quality testing methods for EPDM rubber seals involve various tests and inspections to ensure that the product meets the desired specifications and performance requirements. Here are some commonly used methods along with quality control measures.

1. Visual inspection: This involves checking the physical appearance of the rubber seals for any visible defects, such as cracks, deformations, or discolorations.

2. Dimensional measurements: The dimensions of EPDM rubber seals should be precisely controlled to fit the intended application. Measurements using tools like calipers or micrometers help ensure conformity.

3. Hardness testing: The hardness of EPDM rubber seals can be measured using a Shore durometer. Different applications may require different hardness levels, and the test helps verify if the rubber meets the specified hardness.

4. Tensile strength and elongation tests: These tests determine the mechanical properties of the rubber seal. Tensile strength measures the rubber’s resistance to being pulled apart, while elongation measures its stretchability before breaking.

5. Compression set testing: This test evaluates the ability of the rubber to return to its original shape after being compressed for a specified period. It ensures that the seal maintains its effectiveness during repeated compression-decompression cycles.

6. Heat and aging resistance testing: EPDM rubber seals must withstand heat, UV exposure, and chemical degradation. Accelerated aging tests simulate these conditions to assess the material’s long-term durability and resistance.

To control the quality of EPDM rubber seals, manufacturers should implement the following measures:

1. Establishing quality standards: Clear standards and specifications should be defined for the rubber seals, including material composition, hardness, dimensions, and performance requirements.

2. Regular quality inspections: Conduct routine inspections during the production process to identify any defects or deviations from the set standards. This includes visual inspections and sample testing.

3. Sample testing: Randomly select samples for thorough testing to ensure that the rubber seals meet the required specifications and performance expectations.

4. Supplier evaluation: Evaluate the quality and reliability of the EPDM rubber material suppliers to ensure consistent and reliable raw material inputs.

5. Process control: Implement process control measures to minimize variations and maintain consistency during manufacturing. This includes monitoring and controlling factors such as temperature, pressure, and curing time.

6. Continuous improvement: Regularly review and analyze quality data to identify areas of improvement and implement corrective actions to enhance product quality.

By following these testing methods and quality control measures, manufacturers can ensure that EPDM rubber seals meet the desired specifications, perform reliably, and provide long-lasting sealing solutions.

epdm rubber seal Sample Policy and Post-Purchase Considerations for epdm rubber seal from China

Sample Policy:

When purchasing EPDM rubber seals from China, it is important to consider the sample policy of the supplier. Many reputable manufacturers offer free samples to potential buyers to ensure the product meets their specific requirements. This allows customers to test the quality, durability, and compatibility of the EPDM rubber seal before making a bulk purchase. It is recommended to inquire about the sample policy with the supplier and request samples of various sizes or specifications that are needed.

Post-Purchase Considerations:

After the purchase of EPDM rubber seals from China, there are several post-purchase considerations to keep in mind. Firstly, it is essential to inspect the received products upon delivery. Thoroughly examine the seals to ensure they meet the specifications and quality standards agreed upon during the ordering process.

If any discrepancies or defects are identified, promptly notify the supplier to seek resolution. It is crucial to maintain clear communication with the supplier throughout the process. International shipments may face customs regulations and transportation challenges, so it is important to address any issues promptly to avoid further complications.

Testing the EPDM rubber seal in the intended application is another vital consideration. Verify that the seal fits properly and functions as expected, providing the required level of sealing, weather resistance, and durability. If any issues arise, contact the supplier to seek advice or a potential replacement.

Monitoring the long-term performance of the EPDM rubber seal is also recommended. Assess its resistance to environmental factors such as UV rays, temperature fluctuations, moisture, and chemical exposure. Regular inspections can help identify any signs of deterioration or wear over time, allowing for timely maintenance or replacement if necessary.

In conclusion, to ensure a successful purchase of EPDM rubber seals from China, it is important to understand the sample policy of the supplier as well as consider post-purchase factors such as inspection, testing, and long-term performance monitoring. Effective communication with the supplier and timely resolution of any issues are key to a satisfactory product experience.

Sourcing epdm rubber seal from China: Opportunities, Risks, and Key Players

China is a major global player in the manufacturing industry, including the production of EPDM rubber seals. Sourcing EPDM rubber seals from China presents several opportunities for businesses.

Firstly, China offers cost advantages, as labor and production costs are generally lower compared to other countries. This allows businesses to procure EPDM rubber seals at a more competitive price, resulting in a cost advantage over competitors. Additionally, the extensive supply chain in China ensures a wide range of options for sourcing EPDM rubber seals, providing businesses with greater flexibility in meeting their specific requirements.

However, sourcing from China also entails certain risks. Quality control can be a concern, as some manufacturers may compromise on quality to cut costs. Thorough due diligence is necessary to identify reputable suppliers who adhere to international quality standards. This can be achieved through conducting factory audits, requesting product samples, and obtaining certifications. Intellectual property risks are another concern, as unauthorized use and infringement of intellectual property rights can occur in China. Businesses should ensure the protection of their intellectual property through agreements and legal measures.

Key players in the EPDM rubber seal industry in China include manufacturers such as Hutchinson, Cooper Standard, Toyoda Gosei, and Nishikawa Rubber. These companies have extensive experience and expertise in producing EPDM rubber seals for various applications. However, the market is highly competitive, and there are numerous other manufacturers in China who can provide EPDM rubber seals.

In conclusion, sourcing EPDM rubber seals from China offers opportunities in terms of cost advantages and a diverse supply chain. However, businesses should carefully manage risks associated with quality control and intellectual property. Identifying reputable suppliers and conducting due diligence is crucial. Key players in the industry include Hutchinson, Cooper Standard, Toyoda Gosei, and Nishikawa Rubber, among others.

How to find and select reliable epdm rubber seal manufacturers in China,use google search manufacturers and suppliers

Finding and selecting reliable EPDM rubber seal manufacturers in China can be a daunting task, but using Google search to identify manufacturers and suppliers can be a good starting point. Here are a few steps to help you in your search:

1. Begin by typing relevant keywords into the Google search bar, such as “EPDM rubber seal manufacturers in China” or “EPDM rubber seal suppliers.”

2. Review the first few pages of search results. Look for reliable and established companies that appear in multiple search results. These companies are more likely to have a strong online presence and be trusted by other customers.

3. Visit the websites of shortlisted manufacturers to gather more information. Focus on websites that provide detailed product descriptions, company profiles, certifications, and contact information. A professional and informative website indicates a company’s commitment to quality and customer service.

4. Assess the manufacturer’s experience and reputation. Look for companies that have been in the industry for several years. Check if they have any certifications or memberships in industry associations. Additionally, read customer reviews or testimonials to gain insights into their product quality and customer satisfaction.

5. Contact the shortlisted manufacturers directly. Use the contact information available on their websites to obtain further details about their EPDM rubber seals. Inquire about their manufacturing capabilities, product customization options, lead times, and pricing. A prompt and helpful response is indicative of a reliable manufacturer.

6. Request samples or catalogs from multiple manufacturers. Compare the quality, specifications, and pricing of their products. Assess if their products meet your specific requirements.

7. Consider other factors such as customer service, communication proficiency, and after-sales support when making a decision. Choosing a manufacturer that offers excellent customer support can facilitate a smooth and reliable business relationship.

By following these steps and conducting thorough research, you should be able to find and select reliable EPDM rubber seal manufacturers in China who can meet your specific needs and requirements.

How to check epdm rubber seal manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To determine the reliability of an EPDM rubber seal manufacturer’s website, you can follow these steps, including utilizing Google Chrome with the SEOquake tool:

1. Open Google Chrome: Use Google Chrome as your web browser for this task.

2. Install SEOquake: Install the SEOquake extension in your Google Chrome browser. You can find this extension in the Chrome Web Store and add it to your browser.

3. Search for the manufacturer: Go to the Google search engine and type in the name of the EPDM rubber seal manufacturer you want to evaluate.

4. Check the search results: Look for the manufacturer’s website in the search results. Typically, reliable and established companies will have their website listed within the top search results.

5. Use SEOquake to analyze the website’s ranking: Click on the SEOquake extension in your browser’s toolbar, and it will provide you with a variety of data and metrics about the website. Look for the website’s ranking in the top 10 million (which usually means it’s a well-established and recognized site).

6. Analyze the website’s design and content: Once you have accessed the manufacturer’s website, examine its design, layout, and overall appearance. A reliable website usually has a professional and polished look. Verify if the website provides comprehensive information about the EPDM rubber seals, the company’s history, certifications, manufacturing process, product specifications, and contact information.

7. Look for customer reviews and testimonials: Check if the website includes customer reviews or testimonials, which can serve as a validation of the company’s products and services.

8. Verify contact information: Ensure that the website provides accurate contact information, including a physical address, phone number, and email address. This allows you to contact the manufacturer for any queries or inquiries.

Remember that while these steps can help you assess the reliability of an EPDM rubber seal manufacturer’s website, it’s always recommended to further conduct thorough research, check online reviews, and compare different manufacturers before making a final decision.

Top 10 epdm rubber seal manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Xingtai Zhuomei Rubber & Plastic Products Co., Ltd: Xingtai Zhuomei offers a wide range of EPDM rubber seals, including EPDM rubber gaskets, EPDM rubber strips, and EPDM rubber seals for windows and doors. Their products are known for their high tensile strength and excellent resistance to weathering, ozone, and UV radiation.

2. Hangzhou Rubber & Plastic Industry Co., Ltd: Hangzhou Rubber & Plastic Industry specializes in manufacturing EPDM rubber profiles and seals for various applications. Their EPDM rubber seals feature good electrical insulation, high elasticity, and excellent resistance to aging, water, and low-temperature environments.

3. Qingdao Hushan Industrial Co., Ltd: Qingdao Hushan Industrial produces EPDM rubber seals for automotive, construction, and industrial sectors. Their EPDM rubber seals are highly durable, resistant to extreme weather conditions, and provide an effective sealing solution.

4. JINGDONG RUBBER: JINGDONG RUBBER is a leading manufacturer of EPDM rubber seals in China. Their EPDM rubber seals are widely used in the automotive industry, construction, and infrastructure projects. Their seals exhibit excellent resistance to heat, water, and corrosion.

5. Tianjin Zeguang Rubber and Plastic Products Co., Ltd: Tianjin Zeguang specializes in manufacturing EPDM rubber seals, gaskets, and profiles. Their EPDM rubber seals are resistant to high and low temperatures, ozone, and chemical substances, making them suitable for various sealing applications.

6. Dalian Yida Precision Rubber Products Co., Ltd: Dalian Yida offers a comprehensive range of EPDM rubber seals and gaskets. Their EPDM rubber seals provide excellent weather resistance, ensuring a reliable and long-lasting seal.

7. Nanjing Skypro Rubber & Plastic Co., Ltd: Nanjing Skypro manufactures EPDM rubber seals and gaskets for various industries. Their EPDM rubber seals possess excellent compression set resistance, elasticity, and resistance to environmental factors.

8. Xiamen Maihua Rubber Products Co., Ltd: Xiamen Maihua specializes in producing EPDM rubber seals, gaskets, and profiles. Their EPDM rubber seals are widely used in automotive, construction, and marine applications due to their excellent resistance to aging, ozone, and weather.

9. Wuxi Aoweite Silicon Co., Ltd: Wuxi Aoweite Silicon offers top-quality EPDM rubber seals and gaskets. Their EPDM rubber seals are highly heat-resistant, UV-resistant, and provide effective sealing against moisture, dust, and noise.

10. Suzhou Dezhor Polymer Material Co., Ltd: Suzhou Dezhor Polymer specializes in EPDM rubber extrusions and seals. Their EPDM rubber seals are highly flexible, UV-resistant, and capable of enduring extreme temperatures, making them suitable for a wide range of sealing applications.

| Manufacturer | Key Features |

|—————————–|——————————————————|

| Xingtai Zhuomei | High tensile strength, excellent weather resistance |

| Hangzhou Rubber | Good electrical insulation, high elasticity |

| Qingdao Hushan | Durable, weather-resistant, effective sealing |

| JINGDONG RUBBER | Heat, water, and corrosion-resistant |

| Tianjin Zeguang | Resistant to temperature, ozone, chemical substances |

| Dalian Yida | Excellent weather resistance, reliable seal |

| Nanjing Skypro | Compression set resistance, environmental resistance |

| Xiamen Maihua | Resistance to aging, ozone, and weather |

| Wuxi Aoweite | Heat and UV resistance, effective sealing |

| Suzhou Dezhor Polymer | Flexible, UV-resistant, withstands extreme temperatures |

This table provides a comparison of the key features offered by the top 10 EPDM rubber seal manufacturers in China. Depending on your specific requirements, you can choose a manufacturer that aligns with your needs regarding tensile strength, weather resistance, electrical insulation, temperature resilience, or other essential attributes.

Background Research for epdm rubber seal manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to finding EPDM rubber seal manufacturers in China, several online platforms can help in conducting background research efficiently. This research can be conducted by utilizing three prominent websites: qcc.com, archive.org, and importyeti.com.

Qcc.com is a comprehensive Chinese business data platform providing information on companies registered in China. This website offers details about a company’s registration status, legal representative, company size, scope of business, and more. It can be utilized to verify the legitimacy and reputation of EPDM rubber seal manufacturers.

Archive.org, also known as the Wayback Machine, is a digital archive of the World Wide Web. It allows users to access websites’ historical versions captured over time. By utilizing Archive.org, researchers can track the development and changes made to the websites of EPDM rubber seal manufacturers, helping to assess their stability and growth.

Importyeti.com is a platform that provides data related to import and export activities. It offers shipment records, providing insights into the trading history of EPDM rubber seal manufacturers in China. This information can include details such as the destination country, quantity, value, and buyer information. Importyeti.com can help researchers review the export capabilities and international business engagements of these manufacturers.

Conducting research using these platforms by analyzing the registration status, historical records, and export activities of EPDM rubber seal manufacturers in China can provide valuable insights for business decisions. Remember to use the information obtained from these sources judiciously and cross-check with other reliable industry resources to ensure accuracy and comprehensiveness.

Leveraging Trade Shows and Expos for epdm rubber seal Sourcing in China

Trade shows and expos are excellent platforms for sourcing EPDM rubber seals in China. These events bring together a wide range of suppliers, manufacturers, and industry professionals, making it easier for businesses to find reliable partners and products.

Attending trade shows and expos dedicated to rubber products and manufacturing allows buyers to directly connect with potential suppliers. These events offer the opportunity to meet face-to-face, establish relationships, and evaluate the quality of products on display. It also allows buyers to negotiate pricing and discuss specific requirements or customizations.

One prominent event for rubber products sourcing in China is the China International Rubber Industry Exhibition (RubberTech China). This exhibition features a comprehensive range of products, including EPDM rubber seals, and attracts both domestic and international exhibitors. Buyers can easily compare offerings from various suppliers and find the best fit for their needs.

Another beneficial trade show for EPDM rubber seal sourcing is the Asia Rubber & Plastics Expo. This expo brings together manufacturers, suppliers, and professionals from the rubber and plastics industries. It provides an opportunity to explore a variety of products and connect with potential partners from China and other Asian countries.

To make the most of trade shows and expos for EPDM rubber seal sourcing, it is crucial to plan ahead. Researching the event’s exhibitor list and floor plan, as well as contacting potential suppliers beforehand, can help maximize time at the event. Buyers should prepare clear specifications, target pricing, and necessary testing or compliance requirements to communicate effectively with potential suppliers.

Overall, trade shows and expos in China are invaluable resources for sourcing EPDM rubber seals. These events offer ample opportunities to find reliable suppliers, evaluate product quality, and negotiate favorable terms. By leveraging these platforms, businesses can efficiently and effectively source EPDM rubber seals from reputable Chinese manufacturers.

The Role of Agents and Sourcing Companies in Facilitating epdm rubber seal Purchases from China

Agents and sourcing companies play a crucial role in facilitating the purchase of EPDM rubber seals from China. These entities act as intermediaries between buyers and suppliers, streamlining the procurement process and ensuring a smooth transaction. Here are some key ways they contribute:

1. Supplier identification: Agents and sourcing companies have an extensive network of suppliers in China. They help buyers find reliable and reputable manufacturers or distributors of EPDM rubber seals. With their knowledge of the local market and industry, they can quickly identify suitable suppliers that meet the buyer’s requirements.

2. Negotiations and contracts: Agents and sourcing companies have expertise in negotiation tactics and can negotiate favorable terms on behalf of the buyer. They help ensure that the buyer gets competitive pricing, quality assurances, and appropriate terms and conditions. They also handle the contract drafting and review process, ensuring both parties are protected.

3. Quality control: EPDM rubber seals’ quality is essential for their effectiveness in various applications. Agents and sourcing companies conduct comprehensive quality checks throughout the production process. They inspect the factory, review quality control procedures, and monitor production to maintain a high standard. This guarantees that the buyer receives EPDM rubber seals that meet their specifications.

4. Logistics and shipping: Managing logistics and shipping can be complex, especially when dealing with international trade. Agents and sourcing companies have experience in handling logistics and arranging shipping from China. They help coordinate the transportation, including choosing the most suitable shipping method, completing all necessary documentation, and managing customs clearance.

5. Language and cultural bridge: Agents and sourcing companies act as a bridge between buyers and Chinese suppliers, handling communication and cultural differences. They are proficient in the local language, eliminating miscommunications and ensuring smoother interactions between parties. This reduces the risk of misunderstandings, delays, or other issues arising from cultural and language barriers.

Overall, agents and sourcing companies streamline the procurement process for EPDM rubber seals from China. They provide valuable support in supplier identification, negotiation, quality control, logistics, and communication. Their expertise helps buyers navigate the complexities of international trade and ensures a successful purchase experience.

Price Cost Research for epdm rubber seal manufacturers Companies in China, use temu.com and 1688.com

EPDM rubber seals are widely used in various industries for their excellent properties such as weather resistance, heat resistance, and durability. China is one of the major manufacturers and exporters of EPDM rubber seals worldwide. To investigate the price and cost of EPDM rubber seals in China, two popular online platforms, Temu.com and 1688.com, can be utilized.

Temu.com is a global B2B platform that provides a wide range of products from different suppliers. It allows users to search for EPDM rubber seal manufacturers in China and compare their prices and product specifications. By exploring this platform, one can gather information on various factors that influence the price, such as quantity, size, quality, and customization options.

1688.com, on the other hand, is a popular Chinese wholesale platform that connects buyers with domestic manufacturers. It offers a vast selection of EPDM rubber seal manufacturers in China. Users can browse through different suppliers, view their product catalogs, and assess their pricing strategies. This platform enables buyers to directly communicate with manufacturers, negotiate prices, and perhaps even establish long-term partnerships.

When conducting price and cost research for EPDM rubber seals, it is important to consider several factors. Firstly, the cost of raw materials, including EPDM rubber compounds, additives, and processing aids, will significantly affect the final price. Secondly, manufacturing technologies and production efficiency will play a role in determining costs. Labor and energy costs, as well as machinery investment, will also impact the prices offered by manufacturers.

Furthermore, factors such as shipping and logistics should be considered when comparing prices. It is crucial to evaluate the delivery time, packaging options, and transportation costs offered by different suppliers.

In conclusion, Temu.com and 1688.com are valuable resources for researching the price and cost of EPDM rubber seals in China. By utilizing these platforms and considering factors like raw material costs, manufacturing technologies, and logistics, one can analyze and compare the offerings of various manufacturers to make informed purchasing decisions.

Shipping Cost for epdm rubber seal import from China

The shipping cost for importing EPDM rubber seals from China can vary depending on various factors such as the weight, volume, destination, shipping method, and the shipping company chosen. Generally, there are two main shipping methods: air freight and sea freight.

Air freight is a faster but more expensive option. The average cost for air freight of EPDM rubber seals from China to destinations such as the United States, Europe, or Australia is around $4-7 per kilogram. This cost includes packaging, handling, customs clearance, and delivery to the nearest airport. However, it does not include any additional local fees, customs duties, or taxes.

Sea freight is a slower but cheaper alternative. The cost is calculated based on the volume or weight of the goods, whichever is higher. For a 20-foot container, the shipping cost can range from $1000 to $5000, depending on the destination port. Keep in mind that additional charges may apply, such as container handling fees, customs duties, and local delivery charges.

It is essential to consider other aspects when calculating the overall cost of importing EPDM rubber seals. These include sourcing costs, quality control inspections, import taxes and duties, customs clearance fees, as well as any potential additional charges related to documentation, packaging, and insurance.

To get the most accurate shipping cost, it is advisable to consult with freight forwarders or shipping companies directly. They can provide you with detailed quotes based on your specific requirements. Additionally, it is vital to consider the reputation and experience of the chosen shipping company to ensure a smooth and reliable shipping process.

Compare China and Other epdm rubber seal Markets: Products Quality and Price,Visible and Hidden Costs

China is the largest producer and exporter of EPDM rubber seals in the world, and its market is highly competitive. The quality of EPDM rubber seals produced in China varies significantly. While some Chinese manufacturers produce high-quality seals that meet international standards, others may produce lower quality products that may not perform as well or have a shorter lifespan.

In terms of price, China offers competitive prices for EPDM rubber seals due to its low manufacturing costs and large production capacity. This makes it an attractive market for buyers looking for cost-effective solutions. However, it is important to consider the trade-offs between price and quality when sourcing from China.

When comparing China to other EPDM rubber seal markets, it is also important to consider visible and hidden costs. Visible costs refer to the upfront expenses such as the cost of the product itself, shipping, and customs duties. China’s lower manufacturing costs may contribute to lower visible costs compared to other markets.

On the other hand, hidden costs include factors such as product defects, delays in delivery, and communication barriers. These hidden costs can have a significant impact on the overall cost and efficiency of sourcing from China. For example, if the product quality is not up to standard, it may result in the need for replacements or repairs, increasing costs in the long run. Communication barriers can also lead to misunderstandings and delays, which can impact project timelines and increase costs.

Overall, while China offers competitive pricing for EPDM rubber seals, the quality and hidden costs should not be overlooked. Buyers should carefully evaluate suppliers, consider independent product testing, and establish effective communication channels to ensure the best balance between quality and price. It is essential to carefully assess the specific requirements and risks associated with sourcing from China versus other markets in order to make an informed decision.

Understanding Pricing and Payment Terms for epdm rubber seal: A Comparative Guide to Get the Best Deal

When it comes to purchasing EPDM rubber seals, understanding pricing and payment terms is crucial to getting the best deal possible. EPDM rubber seals are commonly used for sealing applications due to their excellent resistance to extreme temperatures, weather conditions, and chemicals. This guide aims to provide a comparative overview of factors to consider when assessing pricing and payment options for EPDM rubber seals.

Pricing for EPDM rubber seals can vary depending on several factors. Firstly, the quantity required plays a significant role in determining the price. Suppliers often offer bulk discounts, so it is essential to communicate the estimated order quantity accurately. Secondly, the dimensions and specifications of the EPDM rubber seals can impact the price. Customized or non-standard sizes may cost more due to additional production requirements. Lastly, the quality and brand reputation of the supplier can influence the price. It is advisable to research and compare different suppliers to ensure a competitive price without compromising on quality.

Payment terms for EPDM rubber seals vary among suppliers. It is common for suppliers to require a certain percentage of the total invoice as an upfront deposit to initiate the production process. The remaining balance is typically due upon completion of the order. However, some suppliers may offer alternative payment arrangements, such as installments or credit options. It is important to clarify the payment terms upfront to ensure a smooth transaction process.

When aiming to get the best deal on EPDM rubber seals, it is beneficial to consider a few strategies. Firstly, obtaining quotes from multiple suppliers allows for effective comparison based on price and terms. Additionally, negotiating the price and payment terms with the chosen supplier can often lead to favorable outcomes. Establishing a long-term partnership with a reliable supplier can also enable better pricing and flexible payment options in the future.

To conclude, understanding pricing and payment terms is essential when purchasing EPDM rubber seals. Considering factors like quantity, specifications, and supplier reputation helps in negotiating the best price. Clarity on payment terms and exploring various options ensure a convenient and cost-effective purchasing process. By applying these strategies, one can secure a good deal while obtaining high-quality EPDM rubber seals.

Chinese Regulations and Industry Standards Certifications for epdm rubber seal,Import Regulations and Customs for epdm rubber seal from China

China has strict regulations and industry standards for the production and export of EPDM rubber seal. The key regulatory body in China is the General Administration of Quality Supervision, Inspection, and Quarantine (AQSIQ). They establish and enforce standards to ensure the quality and safety of products.

EPDM rubber seal manufacturers in China are required to comply with the national standard GB/T 24944-2010, which specifies requirements for various properties of EPDM rubber seals, such as hardness, tensile strength, elongation at break, and aging resistance. This standard ensures that the EPDM rubber seals meet the necessary quality standards.

In addition to the national standard, manufacturers can also obtain industry certifications to enhance their credibility and competitiveness. One such certification is the ISO 9001:2015, which demonstrates that the manufacturer has implemented a quality management system to consistently provide high-quality products.

Importing EPDM rubber seals from China requires compliance with import regulations and customs procedures. Importers need to follow the regulations and requirements set by their respective countries. They must ensure that the EPDM rubber seals meet the necessary safety and quality standards.

Customs procedures involve documentation and declaration processes. Importers need to provide relevant documents, such as commercial invoices, packing lists, and the bill of lading or airway bill. They also need to declare the value, quantity, and other details of the imported EPDM rubber seals to the customs authorities.

Furthermore, it is important for importers to be aware of any specific requirements or restrictions imposed by their countries regarding EPDM rubber seals. This may include compliance with specific safety or environmental standards.

In summary, China has regulations and industry standards for EPDM rubber seals, such as the national standard GB/T 24944-2010. Manufacturers can enhance their credibility by obtaining certifications like ISO 9001:2015. Importers need to comply with import regulations and customs procedures while ensuring that the EPDM rubber seals meet safety and quality standards specified by their countries.

Sustainability and Environmental Considerations in epdm rubber seal Manufacturing

When considering sustainability and environmental aspects in the manufacturing of EPDM rubber seals, several key factors come into play. These factors include raw material sourcing, production processes, waste management, and product lifespan.

EPDM rubber is derived from petroleum, a non-renewable resource. However, efforts can be made to use recycled or biobased materials in the manufacturing process, reducing dependence on virgin petroleum. Additionally, the proximity of the raw material source to the manufacturing facility should be considered to minimize transportation-related emissions.

Production processes must also be optimized to minimize energy consumption and reduce greenhouse gas emissions. Implementing energy-efficient technologies, such as using renewable energy sources and improving machinery efficiency, can significantly reduce the environmental impact. Moreover, implementing closed-loop water systems and employing water-conservation techniques can minimize water usage and wastewater generation.

Another crucial consideration is waste management. Minimizing waste generation through improved manufacturing processes and material utilization is essential. Additionally, implementing recycling and reusing techniques for any generated waste can minimize the environmental impact. Proper disposal of hazardous materials or chemicals should also be ensured to prevent pollution.

Furthermore, the durability and lifespan of EPDM rubber seals should be maximized to reduce their overall environmental footprint. This can be achieved through quality control measures during manufacturing and regular maintenance practices. Extending the product lifespan reduces the need for frequent replacements, saving resources and reducing waste generation.

Finally, implementing environmentally conscious certifications, such as ISO 14001, can demonstrate a commitment to sustainability in EPDM rubber seal manufacturing. These certifications require adherence to stringent environmental management systems and can help track and improve sustainability performance.

In conclusion, sustainability and environmental considerations in EPDM rubber seal manufacturing involve sourcing renewable or recycled materials, optimizing production processes to reduce energy consumption and emissions, efficient waste management, maximizing product lifespan, and obtaining relevant certifications. Adhering to these practices will contribute to a more sustainable and environmentally conscious manufacturing process.

List The Evolution history of “epdm rubber seal”

Ethylene Propylene Diene Monomer (EPDM) rubber seals have a rich and diverse evolution history, starting from their discovery and development to their widespread application in various industries.

In the mid-1960s, EPDM rubber was developed as a synthetic material by the tire industry. The original goal was to create a rubber that could resist weathering, ozone, and exposure to ultraviolet (UV) radiation better than natural rubber or other synthetic rubber compounds available at the time. This new material was named EPDM due to its main components: ethylene, propylene, diene, and monomer.

EPDM rubber seals gained popularity due to their exceptional resistance to a wide range of environmental conditions such as extreme temperatures, sunlight, ozone, and chemicals. This made them ideal for various outdoor applications, including automotive, construction, and marine industries.

Over time, EPDM rubber seals advanced in terms of manufacturing techniques and formulations. Techniques such as extrusion and molding became widely used to produce seals in different shapes and sizes, catering to the specific needs of various industries. Additionally, advancements in compounding methods and additives allowed EPDM rubber to be customized to enhance specific properties like durability, longevity, and resistance to heat, cold, or chemicals.

The increasing demand for EPDM rubber seals in automotive manufacturing, particularly for weatherstripping, led to further refinements in the material. Auto manufacturers required seals that could efficiently keep out water, air, and noise, resulting in the development of dense extruded EPDM rubber profiles for precise and reliable sealing applications.

With environmental concerns becoming more prominent, EPDM rubber seals played a crucial role in sustainable construction practices. Their excellent weather and UV resistance, coupled with their ability to withstand extreme temperature changes, made them an ideal choice for window and door gaskets, roofing systems, and expansion joints.

In recent years, EPDM rubber seals have witnessed further advancements, such as the addition of self-adhesive backing for easy installation, improved tear resistance, and enhanced chemical resistance to accommodate specific industry needs. Today, they are also widely used in electrical insulation, industrial machinery, and consumer products.

The evolution of EPDM rubber seals reflects the ever-increasing demand for durable, weather-resistant, and versatile sealing solutions across industries. As technology and manufacturing techniques continue to advance, EPDM rubber seals are likely to evolve further, offering even better performance and expanding their applications in the future.

The Evolution and Market Trends in epdm rubber seal Industry

The EPDM rubber seal industry has witnessed a significant evolution over the years, driven by advancements in technology and changing market trends. EPDM (Ethylene Propylene Diene Monomer) rubber seals are widely used for sealing applications in various industries, including automotive, construction, and manufacturing.

One of the key factors driving the evolution of the EPDM rubber seal industry is the increasing demand for reliable and durable sealing solutions. EPDM rubber seals offer excellent resistance to chemicals, weathering, and extreme temperatures, making them suitable for a wide range of applications. This has led to a growing adoption of EPDM rubber seals in industries where sealing is critical for product performance and safety.

In addition to their excellent sealing properties, EPDM rubber seals are also known for their low cost and ease of manufacturing. EPDM rubber can be easily extruded into various shapes and sizes, making it ideal for different sealing requirements. Manufacturers are constantly striving to improve the production processes and enhance the performance characteristics of EPDM rubber seals to meet the evolving industry demands.

Another significant trend in the EPDM rubber seal industry is the growing focus on sustainability and environmental consciousness. EPDM rubber is a recyclable material, and there is an increasing emphasis on developing eco-friendly sealing solutions. Manufacturers are investing in research and development to produce EPDM rubber seals that have a reduced carbon footprint and are derived from sustainable sources.

Moreover, the market trends in the EPDM rubber seal industry indicate a rising demand for customized sealing solutions. As industries become more specialized and diverse, there is a growing need for tailored EPDM rubber seals that can meet specific application requirements. Manufacturers are offering a wide range of options in terms of size, shape, and performance characteristics to cater to this demand.

In conclusion, the evolution of the EPDM rubber seal industry has been driven by advancements in technology, changing market trends, and the need for reliable and sustainable sealing solutions. The industry has witnessed a growing demand for EPDM rubber seals due to their excellent sealing properties, cost-effectiveness, and ease of manufacturing. The market trends also indicate a shift towards customized and eco-friendly sealing solutions to meet the evolving industry requirements.

Custom Private Labeling and Branding Opportunities with Chinese epdm rubber seal Manufacturers

Chinese manufacturers offer excellent opportunities for custom private labeling and branding of EPDM rubber seals. EPDM (Ethylene Propylene Diene Monomer) rubber seals are widely used in various industries, including automotive, construction, and manufacturing. With Chinese manufacturers’ expertise and cost-effective production capabilities, businesses can leverage these advantages to enhance their branding and expand their market presence.

Private labeling allows businesses to customize rubber seals with their own brand name, logo, and packaging. Chinese manufacturers collaborate closely with businesses to understand their branding requirements and deliver tailored products that reflect their unique identity. This customization extends to the design, color, shape, and size of the rubber seals, meeting specific market demands and enhancing product differentiation.

Furthermore, Chinese manufacturers provide branding opportunities through the incorporation of advanced printing technologies. These technologies enable the application of intricate designs, vibrant colors, and high-definition printing on EPDM rubber seals, ensuring superior product aesthetics. Such branding efforts help businesses establish a strong brand image, enhance brand recognition, and make a lasting impression on customers.

The cost-effective nature of Chinese manufacturing benefits businesses by providing competitive pricing for private labeling and branding services. Chinese manufacturers leverage their extensive supply chains, efficient production processes, and economies of scale to offer cost advantages without compromising on quality. This enables businesses to increase their profit margins, deliver value to customers, and remain competitive in the market.

In conclusion, collaborating with Chinese EPDM rubber seal manufacturers presents exceptional opportunities for custom private labeling and branding. Businesses can leverage Chinese manufacturers’ expertise, advanced printing technologies, and cost advantages to create customized products that enhance their brand image and market presence. With these opportunities, businesses can differentiate themselves, attract customers, and achieve long-term success.

Tips for Procurement and Considerations when Purchasing epdm rubber seal

When purchasing EPDM rubber seals for procurement purposes, there are several important considerations that you should keep in mind. Here are some tips to help you make an informed decision:

1. Quality: Ensure that the EPDM rubber seals you are buying meet the required quality standards. Look for reputable manufacturers who have a track record of producing high-quality products. Check for certifications and ratings that indicate compliance with industry standards.

2. Durability: EPDM rubber seals should be durable to withstand varying environmental conditions and resist degradation due to exposure to UV rays, ozone, and extreme temperatures. Look for seals that have excellent weather resistance and can maintain their elasticity and structural integrity over time.

3. Compatibility: Consider the specific application requirements and make sure that the EPDM rubber seals you choose are compatible with the materials they will be in contact with. EPDM rubber is known for its compatibility with a wide range of chemicals, including acids, alkalis, and hydrocarbons, but it is always advisable to check for compatibility charts provided by manufacturers.

4. Size and Shape: Determine the correct size and shape of the EPDM rubber seal required for your application. Take accurate measurements and ensure that the seal will fit securely and provide an effective barrier against leaks and moisture ingress.

5. Price: While price should not be the sole determining factor, it is important to compare prices from different suppliers to ensure that you are getting the best value for your money. Consider factors such as quality, durability, and warranty while evaluating different pricing options.

6. Manufacturer Support: Look for manufacturers who provide excellent customer support and after-sales service. This can be particularly important if you encounter any issues or have questions regarding the performance or installation of the EPDM rubber seals.

7. Environmental Factors: Consider any specific environmental factors that may affect the performance of the EPDM rubber seal. For instance, if the application involves exposure to chemicals or extreme temperatures, you may need to choose a specialized EPDM formulation that can withstand these conditions.

By considering these factors and following these tips, you can make an informed decision while procuring EPDM rubber seals and ensure that you choose the right product for your specific requirements.

FAQs on Sourcing and Manufacturing epdm rubber seal in China

Q: What is EPDM rubber seal?

A: EPDM (ethylene propylene diene monomer) rubber seal is a synthetic rubber material commonly used in industrial applications, automotive components, and building construction. It is known for its excellent weather resistance, durability, flexibility, and heat resistance.

Q: Why source and manufacture EPDM rubber seals in China?

A: China has established itself as a leading global manufacturing hub, offering competitive pricing, advanced manufacturing capabilities, and a wide range of suppliers specializing in rubber products. Chinese manufacturers often have extensive experience in producing EPDM rubber seals, ensuring high-quality products at competitive prices.

Q: What are the advantages of sourcing EPDM rubber seals in China?

A: Sourcing EPDM rubber seals in China offers several advantages, including:

1. Cost-Effectiveness: Chinese manufacturers often provide competitive pricing due to low production costs, labor advantages, and economies of scale.

2. Manufacturing Expertise: China boasts a vast manufacturing ecosystem with experienced engineers and technicians who are familiar with EPDM rubber seal production processes. They can meet various design and manufacturing requirements.

3. Diverse Supplier Base: China houses numerous EPDM rubber seal suppliers, allowing businesses to choose from a wide range of options to find the best fit for their specific requirements.

4. Quality Assurance: Many Chinese manufacturers have adopted ISO certifications and adhere to international quality standards. Regular quality inspections and audits can be conducted to ensure the desired quality.

5. Efficient Supply Chain: China has well-established logistics networks and shipping infrastructure, enabling the efficient sourcing and delivery of EPDM rubber seals to global destinations.

Q: How to find reliable EPDM rubber seal manufacturers in China?

A: To find reliable manufacturers, it is recommended to follow these steps:

1. Thorough Research: Utilize online directories, trade platforms, and industry-specific websites to identify potential EPDM rubber seal manufacturers in China.

2. Verify Credentials: Scrutinize the manufacturer’s website, check their certifications, years of operation, and customer reviews or testimonials to gauge their credibility.

3. Samples and Prototypes: Request samples or prototypes to evaluate the quality, design, and functionality of the EPDM rubber seals.

4. On-Site Visits: Arrange on-site visits to the manufacturing facilities, if feasible, to assess their production capabilities, quality control measures, and overall operations.

5. Communication and Contracts: Establish clear communication channels, ensure language compatibility, and negotiate pricing and terms before finalizing a contract.

6. Regular Inspections: Conduct regular quality inspections during manufacturing and before shipment to maintain product integrity.

Q: Are there any challenges or risks in sourcing EPDM rubber seals from China?

A: While China offers numerous advantages, there are potential challenges and risks associated with sourcing EPDM rubber seals:

1. Language and Cultural Differences: Communication challenges and cultural gaps can sometimes hinder effective collaboration between buyers and manufacturers.

2. Intellectual Property Protection: Ensuring the protection of intellectual property, such as design or proprietary information, can be a concern in China. Non-disclosure agreements and legal safeguards may be necessary.

3. Product Quality Control: While many Chinese manufacturers maintain high-quality standards, occasional quality discrepancies may arise. Implementing rigorous inspection processes can mitigate this risk.

4. Supply Chain Management: Managing the logistics and supply chain, especially for international buyers, requires effective planning and coordination to ensure timely delivery, customs compliance, and potential language barriers.

5. Certifications and Compliance: Verify that the chosen manufacturer adheres to the necessary certifications, regulations, and compliance standards applicable to EPDM rubber seals.

Endcount: 348 words

Why contact sourcifychina.com get free quota from reliable epdm rubber seal suppliers?

Sourcifychina.com may offer a free quota to contact reliable EPDM rubber seal suppliers for several reasons.

Firstly, providing a free quota encourages potential buyers to engage with sourcifychina.com’s services. By removing the financial barrier, it attracts more customers to explore the platform and discover its benefits. This not only increases exposure for sourcifychina.com but also broadens the supplier pool available to buyers.

Secondly, by focusing on “reliable” EPDM rubber seal suppliers, sourcifychina.com aims to establish itself as a trusted sourcing platform. Offering a free quota allows buyers to reach out and evaluate different suppliers without any commitment upfront. This builds trust and credibility in the services provided by sourcifychina.com, ensuring that buyers feel confident in their sourcing decisions.

Additionally, the use of EPDM rubber seal suppliers specifically suggests a targeted market segment. By securing free quotas for this type of supplier, sourcifychina.com demonstrates its specialization and expertise in sourcing materials for industries using EPDM rubber seals. It may have established strong relationships with these suppliers, ensuring a reliable and high-quality supply chain for interested buyers.

Overall, by providing free quotas to contact reliable EPDM rubber seal suppliers, sourcifychina.com aims to attract potential buyers, establish itself as a trustworthy platform, and demonstrate its expertise in sourcing specific materials.