Introduce about five axis cnc router guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

A five-axis CNC router guide is a helpful tool for understanding the capabilities and nuances of this advanced machining technology. Quality is an important factor to consider when choosing a five-axis CNC router, as precision and reliability are crucial for achieving accurate and consistent results. It is important to invest in a high-quality machine that can handle complex machining tasks with ease.

Cost is another key consideration when purchasing a five-axis CNC router, as the price can vary greatly depending on the size, speed, and features of the machine. It is important to find a balance between cost and quality to ensure the best value for your investment.

Finding a reputable supplier is essential when purchasing a five-axis CNC router, as they will provide support and guidance throughout the purchasing process. Look for suppliers who offer certification and training programs to ensure that you are investing in a reliable and well-supported machine.

Certification is an important aspect of choosing a five-axis CNC router, as it indicates that the machine meets industry standards for quality and performance. Look for machines that are certified by reputable organizations to ensure that you are getting a high-quality product.

The market for five-axis CNC routers is growing quickly, with many manufacturers offering a wide range of machines to suit various needs and budgets. It is important to research different options and compare features and prices to find the best machine for your specific requirements.

Tips for using a five-axis CNC router include properly setting up and calibrating the machine, using the correct tooling and feeds/speeds, and regularly maintaining and cleaning the machine to ensure optimal performance.

Frequently asked questions about five-axis CNC routers include inquiries about the capabilities of the machine, compatibility with different materials, and support and training options provided by the supplier. It is important to ask these questions before purchasing a machine to ensure that it meets your needs and expectations.

Types of five axis cnc router

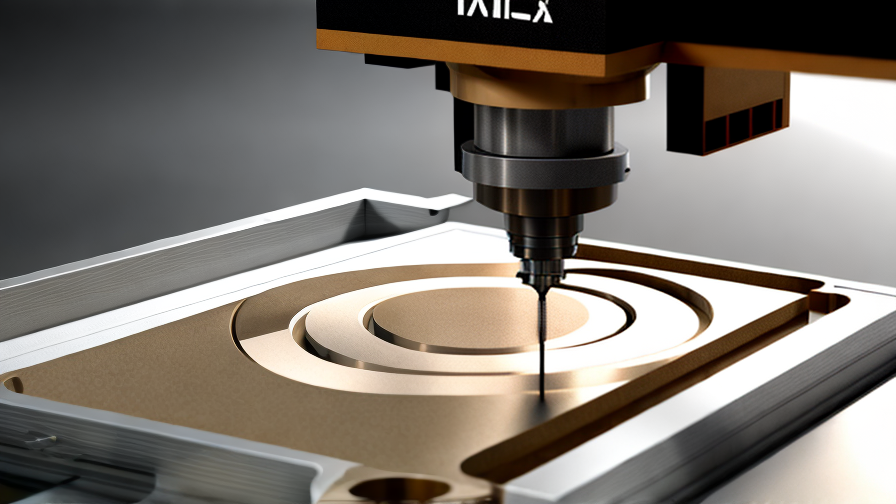

There are several types of five-axis CNC routers available in the market today, each designed to cater to specific needs and requirements. These routers are renowned for their ability to perform complex cuts and intricate milling tasks with precision and accuracy. Below are four popular types of five-axis CNC routers:

1. Gantry Style: Gantry-style five-axis CNC routers consist of a stationary table and a bridge-like structure that moves along the X, Y, and Z axes. This design offers stability and rigidity, making it suitable for heavy-duty applications, such as cutting and shaping large wooden or plastic sheets.

2. Moving Table: As the name suggests, moving table five-axis CNC routers feature a stationary bridge-like structure and a table that moves in the X, Y, and Z axes. This configuration is highly versatile and ideal for cutting smaller materials with intricate designs. The moving table design allows for increased maneuverability and ease of use.

3. Rotary Table: Five-axis CNC routers equipped with a rotary table offer additional rotational capabilities, usually on the A and B axes. This allows for the machining of cylindrical or irregularly shaped objects from different angles, making them suitable for industries such as automotive and aerospace.

4. Hybrid: Some five-axis CNC routers combine the capabilities of a CNC milling machine and a CNC lathe, creating a hybrid machine. These hybrids can perform both milling and turning operations on a single platform, which saves space and increases productivity. They are commonly used in industries that require complex components with rotational features.

Each type of five-axis CNC router mentioned above can be customized to meet specific application requirements. They can be equipped with various spindle options, automatic tool changers, and software packages tailored to the needs of the user. The choice of the right type depends on factors such as budget, space availability, material type, and desired cutting capabilities.

Pros and Cons of Using five axis cnc router

A five-axis CNC router is a versatile and powerful machine that can greatly enhance productivity and precision in various industries. However, like any technology, it has its own set of pros and cons. Below, we will discuss some of the advantages and disadvantages of using a five-axis CNC router.

Pros:

1. Increased versatility: The main advantage of a five-axis CNC router is its ability to move in multiple directions simultaneously, enabling it to create complex designs and shapes that would be difficult or impossible with a lower axis machine. This flexibility allows for more creative and innovative designs in industries such as woodworking, aerospace, and automotive.

2. Improved precision: With five-axis capability, a CNC router can achieve higher levels of precision and accuracy in cutting, drilling, and shaping materials. This is particularly important for industries that require tight tolerances and intricate details, such as the aerospace and medical industries.

3. Reduced setup time: The ability to move the workpiece from various angles and orientations eliminates the need for multiple setups, reducing the time and effort required for production. This can significantly increase productivity and efficiency, leading to faster project completion.

4. Reduced material waste: The multi-axis movement of a CNC router allows for better utilization of raw materials. By optimizing the cutting paths, the machine can minimize material waste and maximize productivity, resulting in cost savings for the business.

Cons:

1. Higher cost: Five-axis CNC routers are generally more expensive than their lower-axis counterparts due to the complex design and additional capabilities. The initial investment may be a barrier for small businesses or those with limited budgets.

2. Increased complexity: Five-axis CNC routers require more advanced programming and operation compared to simpler machines. Skilled operators and programmers are necessary to fully utilize the machine’s capabilities. Additional training and expertise may be required, adding to the operating costs.

3. Longer setup time: While the machine reduces the overall setup time for complex projects, the initial setup for a five-axis CNC router can be more time-consuming than for lower-axis machines. The setup requires precise alignment of the workpiece and extensive programming to define the toolpaths correctly.

4. Maintenance and repairs: Due to their complexity, five-axis CNC routers may require more frequent maintenance and repairs compared to simpler machines. The additional moving parts and axes increase the risk of breakdowns, which can impact productivity and result in additional costs for repairs.

In conclusion, a five-axis CNC router offers numerous advantages such as increased versatility, improved precision, reduced setup time, and minimized material waste. However, potential drawbacks include higher cost, increased complexity, longer setup time, and potential maintenance issues. Each business should carefully consider these factors before making a decision on whether to invest in a five-axis CNC router.

five axis cnc router Reference Specifications (varies for different product)

The five-axis CNC router is a versatile and high precision machine tool widely used in various industries such as woodworking, metalworking, and foam cutting. It offers the capability to perform complex multi-axis machining operations with a high degree of accuracy and efficiency.

Key specifications of a five-axis CNC router typically include a large working area ranging from 4 feet by 8 feet to 10 feet by 20 feet, allowing for the processing of large and intricate parts. The spindle speed can range from 12,000 to 24,000 RPM, providing high cutting speeds and excellent surface finish. The machine is equipped with a high precision servo motor and ball screw mechanism, ensuring smooth and accurate motion control.

The five-axis CNC router is capable of performing continuous rotary motion along the A and B axes, in addition to the traditional X, Y, and Z axes. This allows for the machining of complex shapes and contours with ease, reducing the need for multiple setups and tools. The machine is also equipped with a tool change system, enabling the use of different cutting tools for various operations.

Overall, the five-axis CNC router offers unparalleled versatility and precision in machining operations, making it an essential tool for industries requiring complex and precise part production. Its advanced features and capabilities make it a valuable asset for any manufacturing facility looking to streamline their production processes and enhance their machining capabilities.

Applications of five axis cnc router

A five-axis CNC router is a versatile machine used in many industries for various applications due to its ability to move in five different axes simultaneously. Here are some common applications of five-axis CNC routers:

1. Woodworking: Five-axis CNC routers are extensively used in the woodworking industry for creating complex and intricate designs on wooden surfaces. This includes carving, drilling, and cutting different parts or components required for furniture manufacturing, cabinetry, and other woodworking projects.

2. Plastic fabrication: Five-axis CNC routers are also popular in the plastic fabrication industry. They are used to shape and cut plastic materials such as PVC, acrylic, or polycarbonate sheets for manufacturing prototypes, signage, displays, models, and various other plastic components.

3. Aerospace industry: The aerospace industry benefits greatly from the use of five-axis CNC routers. These machines are employed to manufacture aircraft components with high precision and quality. The routers can create intricate designs and shapes on materials like aluminum, titanium, and composite materials, which are essential for aerospace manufacturing.

4. Automotive industry: Five-axis CNC routers play a vital role in the automotive industry for tasks that require precision machining and cutting. They are utilized to create complex shapes and contours on car body panels, interior components, molds, and prototypes. The routers can work on different materials such as aluminum, steel, plastic, and foam used in the automotive sector.

5. Architectural applications: Architects and designers use five-axis CNC routers to bring their creative designs to life. The routers can sculpt intricate patterns, shapes, and textures on various materials such as stone, marble, or foam, allowing the creation of visually appealing architectural elements like moldings, columns, and detailed sculptures.

6. Prototyping and modeling: Five-axis CNC routers provide great support for prototyping and modeling in various industries. These machines can precisely fabricate three-dimensional models and prototypes from different materials like foam, plastic, or wood. They help to accelerate the design and development process by quickly producing accurate prototypes for testing and evaluation.

In conclusion, the five-axis CNC router is a powerful machine that finds applications in woodworking, plastic fabrication, aerospace, automotive, architecture, and prototyping industries. Its ability to move in multiple axes simultaneously enables intricate and precise machining, ensuring high-quality end products.

The Work Process and how to use five axis cnc router

The work process of a five-axis CNC router involves several steps in order to achieve accurate and precise results. Here is a general overview of the work process and how to use a five-axis CNC router.

1. Designing: The first step is to have a 3D design of the desired object or component using computer-aided design (CAD) software. This design will serve as a blueprint for the CNC router.

2. Programming: Once the design is completed, the next step is to generate a toolpath using computer-aided manufacturing (CAM) software. This toolpath determines the specific movements and operations required for the CNC router to create the desired shape.

3. Setup: After programming, the workpiece needs to be securely mounted onto the router’s bed or table. The setup also involves attaching the necessary cutting tools to the spindle assembly.

4. Calibration: Before starting the machining process, it’s crucial to calibrate the machine’s axes to ensure accurate cutting. This involves zeroing the machine and establishing the work offsets.

5. Machining: Once everything is set up and calibrated, the machining process begins. The router’s five axes – X, Y, Z, A, and B – move simultaneously to execute the programmed toolpath. The X, Y, and Z axes control the cutter’s position, while the A and B axes control the cutter’s orientation.

6. Finishing: After the machining is complete, the workpiece may require additional finishing processes such as sanding, polishing, or painting, depending on the desired final outcome.

To effectively use a five-axis CNC router, it’s important to have a good understanding of CAD and CAM software. The CAD software helps in creating accurate designs, while the CAM software generates the required toolpaths. Being familiar with these software programs allows for seamless integration between design and manufacturing.

Furthermore, properly securing the workpiece during setup is crucial to prevent any movement or shifting that could lead to inaccurate cuts. Regular calibration ensures that the router operates within specified tolerances, resulting in precise machining.

Lastly, it’s essential to have a thorough knowledge of the machine’s controls and settings. Understanding how to program the router, adjust feed rates, and select appropriate cutting tools will contribute to efficient and successful operation.

In conclusion, the work process of a five-axis CNC router involves designing, programming, setup, calibration, machining, and finishing. Understanding CAD/CAM software, proper workpiece setup, calibration, and familiarity with the machine controls are key to effectively using a five-axis CNC router and achieving accurate and precise results.

Quality Testing Methods for five axis cnc router and how to control the quality

There are several quality testing methods that can be used for a five-axis CNC router to ensure its performance and accuracy. Some of the common methods include:

1. Accuracy testing: This involves checking the machine’s ability to consistently position the cutting tool in the correct location. This can be done using test cuts on a calibration part and measuring the dimensional accuracy of the cut features.

2. Repeatability testing: This involves verifying the machine’s ability to consistently return to a specific position after multiple tool changes or tool paths. This can be done by running multiple test cuts and measuring the deviation between each cut.

3. Surface finish testing: This involves evaluating the quality of the surface finish produced by the machine. This can be done visually or by using a surface roughness gauge to measure the average roughness value (Ra) of the machined surface.

4. Tool wear testing: This involves monitoring the wear of cutting tools over time and evaluating their performance. This can be done by inspecting the cutting edges of the tools for signs of wear and measuring their dimensions to ensure they are within tolerances.

5. Machine vibration testing: This involves monitoring the machine’s vibration levels during operation to ensure they are within acceptable limits. Excessive vibration can lead to poor surface finish, dimensional inaccuracies, and premature tool wear.

To control the quality of a five-axis CNC router, regular maintenance and calibration are essential. This includes keeping the machine clean, lubricated, and properly adjusted. Additionally, operators should follow best practices for tool selection, cutting parameters, and fixturing to optimize performance and minimize errors. Regularly monitoring and analyzing performance metrics such as accuracy, repeatability, and surface finish can help identify potential issues before they affect production quality. Lastly, implementing a robust quality control program that includes periodic testing and inspections can ensure that the machine is performing at its best.

five axis cnc router Sample Policy and Post-Purchase Considerations for five axis cnc router from China

Sample Policy:

1. Warranty: Our five axis CNC router comes with a 1-year warranty for all parts and labor. Any defective parts will be replaced free of charge within the warranty period.

2. Technical Support: We offer free technical support via phone, email, or video chat to assist with any issues or questions that may arise.

3. Return Policy: If for any reason you are not satisfied with your purchase, you may return the CNC router within 30 days for a full refund, minus a restocking fee.

4. Shipping: We offer fast and reliable shipping options, with tracking information provided for all orders.

5. Installation and Training: We can provide optional installation and training services for an additional fee to ensure you are comfortable operating your new CNC router.

Post-Purchase Considerations:

1. Maintenance: Regular maintenance and cleaning of your CNC router will help prolong its lifespan and ensure optimal performance.

2. Software Updates: Keep your software up to date to benefit from any new features or bug fixes that may be released.

3. Upgrades: Consider upgrading your CNC router with new accessories or attachments to increase its capabilities and production efficiency.

4. Training: Take advantage of any training opportunities offered by the manufacturer to fully understand how to operate and maintain your CNC router.

5. Feedback: Provide feedback to the manufacturer on your experience with the CNC router to help improve their products and services for future customers.

Sourcing five axis cnc router from China: Opportunities, Risks, and Key Players

Sourcing a five-axis CNC router from China can offer a range of opportunities for businesses looking to expand their manufacturing capabilities. The Chinese market is known for its competitive pricing, advanced technology, and extensive range of suppliers. By sourcing from China, businesses can access a wide variety of options in terms of specifications, sizes, and features, allowing them to find a CNC router that meets their specific manufacturing needs.

However, there are also risks associated with sourcing from China, including quality control issues, longer lead times, and language barriers. It is important for businesses to carefully vet potential suppliers and conduct thorough due diligence to ensure they are working with a reputable and reliable manufacturer.

Some key players in the Chinese market for five-axis CNC routers include Shandong EAAK Machinery Co., Ltd., Jinan Camel CNC Machinery Co., Ltd., and Jinan Sudiao CNC Router Co., Ltd. These companies are known for their high-quality products, advanced technology, and competitive pricing. By partnering with a trusted supplier, businesses can mitigate risks and ensure a smooth sourcing process.

Overall, sourcing a five-axis CNC router from China can be a cost-effective and beneficial option for businesses looking to enhance their manufacturing capabilities. By understanding the opportunities, risks, and key players in the Chinese market, businesses can make informed decisions to find the best CNC router for their needs.

How to find and select reliable five axis cnc router manufacturers in China,use google search manufacturers and suppliers

When looking for reliable five axis CNC router manufacturers in China, a good starting point is to use Google search to find manufacturers and suppliers.

To begin, search for “five axis CNC router manufacturers in China” to identify potential companies. Look for manufacturers with websites that feature detailed information about their products, services, and certifications. Check for customer reviews and ratings to gauge the reputation of the company.

Next, narrow down your list to a few potential manufacturers and suppliers that seem reputable and have good reviews. Contact them to request additional information such as product catalogs, pricing, manufacturing capabilities, and lead times.

When selecting a manufacturer, consider factors such as the quality of their products, manufacturing processes, customer service, and overall reliability. Look for manufacturers that have experience in producing five axis CNC routers and have a track record of delivering high-quality products.

Ask for samples or visit the manufacturing facility if possible to ensure that the company meets your requirements and standards. Also, consider factors such as warranty, after-sales support, and technical assistance when making your final decision.

By using Google search and taking the time to research and evaluate different manufacturers, you can find a reliable five axis CNC router manufacturer in China that meets your needs and specifications.

How to check five axis cnc router manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

One way to check if a five axis CNC router manufacturer’s website is reliable is to use Google Chrome with the SEOquake extension. SEOquake can provide valuable insights into the website’s overall ranking and performance.

To start, search for the manufacturer’s website on Google and see if it appears in the top 10 search results. Websites that rank highly on search engine results pages are often more reliable and trustworthy.

Next, install the SEOquake extension on your Google Chrome browser. Once installed, navigate to the manufacturer’s website and click on the SEOquake icon. This tool will provide a wealth of information about the website’s SEO metrics, including its Google PageRank, Alexa Rank, and backlink data.

By analyzing these metrics, you can get a better understanding of the website’s credibility and authority in the industry. Additionally, you can also check for any customer reviews, testimonials, or case studies on the website to gauge the manufacturer’s reputation and reliability.

In conclusion, by using Google Chrome with the SEOquake extension, you can quickly and easily assess the reliability of a five axis CNC router manufacturer’s website based on its search engine ranking and SEO metrics. Remember to also look for customer reviews and testimonials to get a more well-rounded view of the manufacturer’s reputation.

Top 10 five axis cnc router manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. **Shandong Wuen Enterprises Ltd.** – Known for their high precision five axis CNC routers, Shandong Wuen Enterprises Ltd. offers a wide range of models for various industries such as woodworking, metalworking, and stone cutting. Their machines are known for their reliability and efficiency, making them a popular choice among manufacturers.

2. **Shenzhen Hongshengda Machinery Co., Ltd.** – Specializing in custom five axis CNC routers, Shenzhen Hongshengda Machinery Co., Ltd. offers tailored solutions for specific machining needs. Their machines are equipped with advanced features such as automatic tool changers and high-speed spindles for increased productivity.

3. **Jinan Blue Elephant CNC Machinery Co., Ltd.** – Providing quality five axis CNC routers at competitive prices, Jinan Blue Elephant CNC Machinery Co., Ltd. is a trusted supplier in the industry. Their machines are designed for precision cutting and carving of materials such as wood, plastic, and aluminum.

4. **Nanjing BFW CNC Machinery Co., Ltd.** – Offering a diverse range of five axis CNC routers, Nanjing BFW CNC Machinery Co., Ltd. caters to a wide range of industries including aerospace, automotive, and mold making. Their machines are known for their high accuracy and durability.

5. **Guangzhou KDT Machinery Co., Ltd.** – Specializing in heavy-duty five axis CNC routers, Guangzhou KDT Machinery Co., Ltd. offers robust machines for large-scale manufacturing operations. Their machines are designed for continuous use in demanding production environments.

6. **Zhejiang Jingdiao Technology Co., Ltd.** – Known for their innovative five axis CNC routers, Zhejiang Jingdiao Technology Co., Ltd. offers machines with cutting-edge technology such as advanced control systems and high-speed spindles. Their machines are ideal for high-precision machining applications.

7. **Changzhou Kexin Machinery Co., Ltd.** – Providing cost-effective five axis CNC routers, Changzhou Kexin Machinery Co., Ltd. offers machines that are easy to operate and maintain. Their machines are suitable for small to medium-sized manufacturers looking for affordable machining solutions.

8. **Hangzhou Fuyang Huibo Hansway Trading Co., Ltd.** – Specializing in customized five axis CNC routers, Hangzhou Fuyang Huibo Hansway Trading Co., Ltd. offers tailored solutions for specific production needs. Their machines are designed for high-efficiency machining of a wide range of materials.

9. **Hefei Kaxing Digital Control Equipment Co., Ltd.** – Offering versatile five axis CNC routers, Hefei Kaxing Digital Control Equipment Co., Ltd. provides machines that can handle complex machining tasks with precision. Their machines are suitable for a variety of industries including furniture, signage, and prototyping.

10. **Ningbo Kaibo CNC Machinery Co., Ltd.** – Known for their reliable five axis CNC routers, Ningbo Kaibo CNC Machinery Co., Ltd. offers machines that are easy to use and maintain. Their machines are popular among small to medium-sized manufacturers for their affordability and performance.

| Manufacturer | Specialization | Features |

|—————————————-|—————————-|——————————————–|

| Shandong Wuen Enterprises Ltd. | High precision | Reliable, efficient, wide range of models |

| Shenzhen Hongshengda Machinery Co., Ltd.| Custom solutions | Automatic tool changers, high-speed spindles|

| Jinan Blue Elephant CNC Machinery Co., Ltd.| Quality at competitive prices| Precision cutting and carving |

| Nanjing BFW CNC Machinery Co., Ltd. | Diverse range | High accuracy, durability |

| Guangzhou KDT Machinery Co., Ltd. | Heavy-duty | Robust, designed for large-scale operations|

| Zhejiang Jingdiao Technology Co., Ltd. | Innovative technology | Advanced control systems, high-speed spindles|

| Changzhou Kexin Machinery Co., Ltd. | Cost-effective | Easy to operate and maintain |

| Hangzhou Fuyang Huibo Hansway Trading Co., Ltd.| Customized solutions | Tailored for specific production needs |

| Hefei Kaxing Digital Control Equipment Co., Ltd.| Versatile machines | Precision machining for a variety of industries|

| Ningbo Kaibo CNC Machinery Co., Ltd. | Reliable and easy to use | Affordable, suitable for small to medium-sized manufacturers|

In conclusion, these top 10 five axis CNC router manufacturers in China offer a diverse range of machines with various features and specializations to cater to the needs of different industries. Buyers can choose from high precision models, custom solutions, heavy-duty machines, and more based on their specific requirements and budget constraints.

Background Research for five axis cnc router manufacturers Companies in China, use qcc.com archive.org importyeti.com

There are several reputable five-axis CNC router manufacturers in China that have gained recognition in the industry. Here is a brief overview of five such manufacturers:

1. AXYZ International: A leading manufacturer of CNC routers with a global presence, AXYZ International offers a range of five-axis CNC routers that are known for their high precision and reliability. The company has a strong reputation for providing efficient solutions to industries such as sign making, woodworking, and metal fabrication.

2. Jinan Blue Elephant CNC Machinery Co., Ltd.: With over a decade of experience, Blue Elephant CNC Machinery is a well-known manufacturer of five-axis CNC routers. The company’s machines are designed to provide precision and versatility, catering to industries like woodworking, stone carving, and metalworking.

3. Shandong Baodian Electronics Technology Co., Ltd.: Baodian is a renowned manufacturer of CNC routers, including five-axis models. The company focuses on providing advanced CNC solutions to various industries, such as aerospace, automotive, and marine. Baodian’s CNC routers are praised for their high processing speed and accuracy.

4. Jinan SENKE CNC Machine Co., Ltd.: SENKE CNC Machine is a professional manufacturer of five-axis CNC routers in China. The company offers a wide range of models suitable for various applications, including woodworking, advertising, and mold making. SENKE CNC Machine is known for its commitment to innovation and customer satisfaction.

5. Weihong CNC Technology Co., Ltd.: Weihong CNC Technology specializes in producing advanced CNC systems and machines, including five-axis CNC routers. The company’s products are widely used in industries like woodworking, furniture manufacturing, and mold making. Weihong CNC Technology focuses on providing reliable, high-performance CNC solutions.

It is important to note that conducting additional research and directly contacting these manufacturers is recommended to gather more detailed and up-to-date information about their products, capabilities, and services. Websites like qcc.com and importyeti.com can be valuable resources for obtaining contact information and exploring the historical background of these companies. Additionally, the Internet Archive (archive.org) might provide insights into the historical development and changes within the companies’ websites over time.

Leveraging Trade Shows and Expos for five axis cnc router Sourcing in China

Trade shows and expos are excellent platforms for sourcing five-axis CNC routers in China. These events provide an opportunity for businesses to connect with manufacturers, suppliers, and industry experts, making the sourcing process more efficient and effective. By leveraging these trade shows and expos, companies can ensure that they find the most suitable and reliable suppliers for their specific needs.

Firstly, attending trade shows and expos allows businesses to see a wide range of five-axis CNC routers firsthand. These events feature numerous exhibitors who display their latest products and innovations. This provides an opportunity to examine the quality, functionality, and precision of different machines, helping businesses make more informed decisions. Additionally, seeing the machines in action can give a better understanding of their capabilities, ensuring that the chosen CNC router meets the required specifications.

Moreover, trade shows and expos bring together a diverse range of suppliers and manufacturers under one roof. This facilitates networking and establishing connections with potential suppliers. Engaging in face-to-face conversations with representatives allows businesses to discuss their specific requirements and negotiate terms directly. This personal interaction also helps build trust and confidence in the suppliers’ capabilities, which is crucial when sourcing high-value equipment like five-axis CNC routers.

Furthermore, these events often host seminars, demos, and workshops that impart valuable industry knowledge and insights. Attending these sessions can significantly enhance the understanding of the latest trends, technologies, and advancements in five-axis CNC routers. Being well-informed helps businesses ask the right questions, evaluate different suppliers, and ensure that they source the most up-to-date and advanced machinery.

To make the most of trade shows and expos, businesses should come well-prepared. Conducting thorough research beforehand on the participating companies and their offerings can help prioritize visits and make efficient use of time. It is also essential to have clear requirements, budget constraints, and timelines in mind to effectively communicate with potential suppliers.

In conclusion, trade shows and expos offer unparalleled opportunities for sourcing five-axis CNC routers in China. By attending these events, businesses can explore a wide variety of machines, establish personal connections with suppliers, and gain valuable industry knowledge. Leveraging these platforms enables companies to make well-informed decisions and find reliable suppliers that can meet their specific needs.

The Role of Agents and Sourcing Companies in Facilitating five axis cnc router Purchases from China

Agents and sourcing companies play a crucial role in facilitating the purchase of five-axis CNC routers from China. These professionals act as intermediaries between the buyer and the Chinese suppliers, helping streamline the procurement process and ensuring a smooth transaction.

Firstly, agents and sourcing companies possess extensive knowledge and expertise in the Chinese market. They have a deep understanding of local manufacturers, their capabilities, and the quality of their products. This knowledge allows them to identify reliable and reputable suppliers of five-axis CNC routers, ensuring that buyers can trust the products they are purchasing.

Secondly, agents and sourcing companies have established relationships with Chinese manufacturers. Their existing partnerships enable them to negotiate favorable prices and terms on behalf of the buyer, potentially saving them money and time. Additionally, these relationships often come with quality control mechanisms, as agents can request factory audits or product samples to ensure the highest standards are met.

Furthermore, language barrier and cultural differences can often complicate the procurement process. Agents and sourcing companies act as translators and intermediaries, helping bridge these gaps. They can effectively communicate buyer requirements to Chinese suppliers and convey any necessary changes or modifications. This ensures clarity and facilitates efficient communication throughout the negotiation and manufacturing process.

Moreover, agents and sourcing companies offer logistical support. They can assist with shipping arrangements, customs documentation, and import regulations, ensuring that the purchased goods arrive safely and in compliance with legal requirements. This expertise saves buyers from the hassle of navigating complex logistics independently, particularly when dealing with international trade.

In summary, agents and sourcing companies play a crucial role in facilitating the purchase of five-axis CNC routers from China. Their expertise in the Chinese market, established relationships with suppliers, language proficiency, and logistical support all contribute to a smoother and more efficient procurement process. By leveraging their services, buyers can access high-quality products at competitive prices while minimizing the challenges associated with international trade.

Price Cost Research for five axis cnc router manufacturers Companies in China, use temu.com and 1688.com

When conducting price cost research for five-axis CNC router manufacturers in China, two reliable platforms to utilize are temu.com and 1688.com. These platforms provide comprehensive information about manufacturers, their products, and pricing details. Here is a summary of the price cost research for five-axis CNC router manufacturers in China using these platforms.

1. Temu.com: This platform offers an extensive database of CNC router manufacturers in China. It provides various details such as product specifications, manufacturer profiles, and customer reviews. To find price information, follow these steps:

a. Visit temu.com and select the “CNC Router” category.

b. Filter the search to display results for “Five-Axis CNC Routers.”

c. Explore the listed manufacturers’ profiles and product pages to find pricing details.

d. Compare prices and gather information on additional costs like shipping, installation, and warranty.

2. 1688.com: This platform is a wholesale marketplace owned by Alibaba Group, offering a wide range of products, including CNC routers. Here’s a brief guide on conducting price cost research on 1688.com:

a. Visit 1688.com and enter relevant search terms like “Five-Axis CNC Router” or the specific model name.

b. Browse through the product listings and click on different products to view detailed information.

c. Note down the manufacturers’ names and their respective product prices.

d. Consider communicating with the manufacturers directly through the platform or using provided contact details to gather additional cost-related information, negotiate prices, and discuss customization options.

When conducting price cost research, it is essential to take into account factors such as quality, manufacturing capabilities, certifications, after-sales support, and delivery time, in addition to the price. Communicating with the manufacturers to gather necessary information and negotiate prices is recommended. By utilizing temu.com and 1688.com, you can efficiently gather price information for five-axis CNC router manufacturers in China.

Shipping Cost for five axis cnc router import from China

The shipping cost for importing a five axis CNC router from China will vary depending on several factors such as the weight, dimensions, shipping method, and the final destination. Generally, the most common shipping methods for importing goods from China include air freight, sea freight, and express courier services.

For a five axis CNC router, which is likely to be heavy and bulky, sea freight may be the most cost-effective option. The average cost of sea freight for a five axis CNC router from China to the United States is around $800 to $1500. This cost can vary depending on the specific port of departure and arrival, as well as any additional services required such as customs clearance or delivery to a specific location.

If you need the CNC router to arrive quickly, air freight may be a better option despite being more expensive. The average cost of air freight for a five axis CNC router from China to the United States is around $1500 to $3000. This cost can vary depending on the weight and dimensions of the CNC router, as well as the specific airport of departure and arrival.

If you prefer a faster and more convenient shipping option, express courier services such as DHL, UPS, or FedEx may be a good choice. However, these services are typically more expensive and may cost around $2000 to $4000 for a five axis CNC router from China to the United States.

In conclusion, the shipping cost for importing a five axis CNC router from China will depend on several factors and can range from $800 to $4000. It is recommended to compare different shipping options and choose the one that best fits your budget and timeline.

Compare China and Other five axis cnc router Markets: Products Quality and Price,Visible and Hidden Costs

When comparing the Chinese market with other five axis CNC router markets, there are several factors to consider such as product quality, price, visible and hidden costs.

In terms of product quality, Chinese CNC routers are often perceived as lower quality compared to other markets like Germany, Italy, Japan, and the United States. Chinese machines may have less precision and reliability, as well as lower-quality components. On the other hand, machines from countries like Germany and Japan are known for their high precision, durability, and superior performance.

When it comes to price, Chinese CNC routers are typically more affordable than those from other markets. This can be attributed to lower labor and production costs in China. However, while Chinese machines may offer a lower upfront cost, the overall cost of ownership can be higher due to maintenance and repair expenses.

In terms of visible and hidden costs, Chinese CNC routers may come with additional costs such as import duties, taxes, and shipping fees. On the other hand, machines from countries like Germany and Japan may have higher upfront costs but may come with better warranties and customer support, reducing the likelihood of unexpected expenses in the long run.

In conclusion, when comparing the Chinese market with other five axis CNC router markets, it is important to consider factors such as product quality, price, visible and hidden costs. While Chinese machines may be more affordable upfront, they may come with lower quality and higher long-term costs. Machines from countries like Germany, Italy, Japan, and the United States may have higher initial costs but offer higher quality and better overall value.

Understanding Pricing and Payment Terms for five axis cnc router: A Comparative Guide to Get the Best Deal

When it comes to purchasing a five-axis CNC router, understanding the pricing and payment terms is essential to make sure you get the best deal. This comparative guide will help you navigate through the various options available in the market.

The first step in understanding the pricing is to determine your specific requirements and budget. Five-axis CNC routers come in a range of sizes and capabilities, each with a different price point. Assessing your needs will help you avoid overspending on features you don’t require.

Next, compare prices from different manufacturers and suppliers. It is recommended to get quotes from at least three different sources to ensure accuracy and competitiveness. Consider factors such as machine quality, reputation of the supplier, and customer reviews when evaluating the quotes.

Payment terms can vary depending on the supplier. Some may offer financing options or leasing programs, which can help in managing your cash flow. Make sure to inquire about any hidden costs, such as installation, training, or maintenance fees, as these can significantly impact the total price.

Additionally, consider the warranty and after-sales service provided by the supplier. A longer warranty period and comprehensive service coverage can add value to your purchase and provide peace of mind.

To get the best deal, negotiate with the suppliers. They may be willing to offer discounts or additional perks, especially if you are purchasing in bulk or have long-term business potential. Approach negotiations with a clear understanding of your budget and requirements, and be open to compromise to reach a mutually beneficial agreement.

Lastly, don’t forget to factor in shipping and logistics costs. Five-axis CNC routers are bulky and heavy, and transportation expenses can significantly impact the overall price. Consider sourcing from suppliers closer to your location to minimize shipping costs.

In summary, understanding the pricing and payment terms for a five-axis CNC router requires thorough research, comparing multiple quotes, considering financing options, negotiating with suppliers, and factoring in additional costs. By following this comparative guide, you can ensure that you get the best deal and make an informed decision for your business.

Chinese Regulations and Industry Standards Certifications for five axis cnc router,Import Regulations and Customs for five axis cnc router from China

When importing a five-axis CNC router from China, it is important to ensure that it complies with Chinese regulations and industry standards certifications. Manufacturers in China are required to adhere to various regulations and standards to ensure the quality and safety of their products. Some of the key certifications that a five-axis CNC router should have include CE certification, ISO 9001 certification, and CCC certification.

CE certification is a mandatory conformity mark for products sold within the European Economic Area, indicating that the product meets EU safety, health, and environmental requirements. ISO 9001 certification demonstrates that the manufacturer has implemented a quality management system that meets international standards. CCC certification is required for products sold in China and signifies that the product meets safety requirements outlined by Chinese authorities.

When importing a five-axis CNC router from China, it is also crucial to understand the import regulations and customs procedures. Importers should be aware of the documentation required for customs clearance, such as the commercial invoice, packing list, and bill of lading. Additionally, importers should ensure that the product complies with any specific regulations or restrictions related to the import of machinery or electronics.

Overall, importing a five-axis CNC router from China requires careful attention to regulations, certifications, and customs procedures to ensure a smooth and compliant process. By working with reputable suppliers and staying informed about the relevant requirements, importers can successfully import a high-quality CNC router from China.

Sustainability and Environmental Considerations in five axis cnc router Manufacturing

Sustainability and environmental considerations in five-axis CNC router manufacturing are crucial for the overall well-being of our planet. By addressing these aspects, manufacturers can contribute to reducing the negative environmental impacts associated with their operations. Here are some key considerations:

1. Material Selection: Opting for sustainable and eco-friendly materials is essential. Manufacturers should prioritize utilizing renewable resources, recyclable materials, and low-impact alternatives. This reduces the reliance on finite resources and minimizes waste generation.

2. Energy Efficiency: Five-axis CNC routers consume a significant amount of energy during operation. Implementing energy-saving technologies, such as power-efficient motors or automated shutdown features, can help minimize energy consumption, resulting in reduced greenhouse gas emissions.

3. Waste Management: Proper waste management is crucial in CNC router manufacturing. Manufacturers should prioritize recycling or reusing materials wherever possible, reducing the amount of waste sent to landfill. Implementing recycling programs and encouraging employees to follow appropriate waste disposal practices are effective measures.

4. Chemical Usage: The use of chemicals in the production of CNC routers must be closely monitored. Manufacturers should focus on employing environmentally friendly alternatives and minimizing the use of hazardous substances. Regular assessments should be made to ensure compliance with relevant environmental regulations.

5. Packaging and Shipping: Reducing the carbon footprint associated with packaging and shipping is important. Manufacturers should optimize packaging dimensions to minimize material waste and use sustainable packaging materials. Implementing efficient shipping strategies, such as consolidating shipments or utilizing eco-friendly transportation methods, can further reduce environmental impacts.

In conclusion, sustainability and environmental considerations in five-axis CNC router manufacturing play a significant role in reducing the industry’s ecological footprint. By adopting practices such as sustainable material selection, energy efficiency, waste management, responsible chemical usage, and eco-conscious packaging and shipping, manufacturers can contribute to a greener future. It is essential for the industry to prioritize these considerations and work towards a more sustainable manufacturing process.

List The Evolution history of “five axis cnc router”

The evolution of the five-axis CNC router can be traced back to the early development of computer numerical control (CNC) technology in the 1940s and 1950s. The first CNC machines were primarily three-axis, meaning they could move along the X, Y, and Z axes. However, as demand for more complex and intricate designs grew, the need for additional axes of movement became evident.

In the 1970s and 1980s, the concept of a five-axis CNC machine started to emerge. This allowed for more versatility and precision in machining processes. The development of computer-aided design (CAD) and computer-aided manufacturing (CAM) software further facilitated the transition to multi-axis machining. These software programs made it easier for designers and engineers to create intricate three-dimensional models, which could then be translated into toolpaths for the five-axis CNC router.

The early versions of five-axis CNC routers involved complex mechanical setups with multiple motors and rotary tables. These machines were limited by their size and capacity and were often expensive to manufacture and maintain. As technology advanced and miniaturization became more feasible, the size and complexity of five-axis CNC routers decreased, making them more accessible to a wider range of industries.

In recent years, advancements in motor and control technology have further improved the performance and capabilities of five-axis CNC routers. High-speed spindles, advanced feedback systems, and precision servo motors have made these machines faster, more accurate, and more reliable. Additionally, the integration of advanced materials, such as carbon fiber-reinforced composite structures, has reduced the weight of the machines without compromising their stiffness and rigidity.

Five-axis CNC routers have become indispensable tools in industries like aerospace, automotive, and woodworking. They can perform complex operations such as simultaneous milling, drilling, and cutting, reducing production time and costs. The ability to rotate the workpiece at various angles allows for the creation of intricately shaped parts and components that were previously unattainable.

In conclusion, the evolution of the five-axis CNC router from its humble beginnings to its current state has been driven by advancements in computer technology, software development, and mechanical engineering. This has resulted in machines that are faster, more versatile, and more precise, revolutionizing the way complex shapes and designs are manufactured.

The Evolution and Market Trends in five axis cnc router Industry

The evolution of five axis CNC routers has been marked by significant advancements in technology and capabilities. Originally designed for the aerospace industry, these machines have become more versatile and accessible to a wider range of users. The development of more compact and affordable models has made five axis CNC routers popular in industries such as automotive, woodworking, and sign making.

Market trends in the five axis CNC router industry indicate a growing demand for increased precision and efficiency. Manufacturers are constantly innovating to develop machines that can handle complex cutting tasks with greater speed and accuracy. Customers are also looking for machines that are user-friendly and easy to operate, as well as those that can integrate seamlessly with other automation technologies.

The market for five axis CNC routers is expected to continue expanding as industries increasingly adopt advanced manufacturing techniques. With the rise of Industry 4.0 and the Internet of Things, there is a growing need for machines that can deliver high levels of automation and connectivity. This is driving the development of smarter and more efficient five axis CNC routers that can optimize production processes and improve overall productivity.

Overall, the evolution and market trends in the five axis CNC router industry are focused on meeting the demands of modern manufacturing and ensuring that customers have access to the tools they need to stay competitive in a rapidly changing market. As technology continues to advance, we can expect to see even more innovations that will further improve the capabilities and performance of these machines.

Custom Private Labeling and Branding Opportunities with Chinese five axis cnc router Manufacturers

The Chinese five axis CNC router industry offers great opportunities for custom private labeling and branding. With their advanced technology and competitive pricing, Chinese manufacturers have become popular choices for businesses looking to expand their product offerings.

Private labeling allows businesses to create their own brand identity by adding their logo, design, and packaging to products manufactured by others. In the case of five axis CNC routers, Chinese manufacturers can produce these machines with customized branding, enabling businesses to market them under their own name and establish a strong brand presence.

By opting for private labeling and branding, businesses can differentiate their products from competitors in the market. This can be particularly advantageous in industries such as woodworking, prototyping, and manufacturing, where precision and accuracy are crucial. With Chinese manufacturers offering a wide range of customization options, businesses can tailor their CNC routers to meet specific industry requirements, further enhancing their brand image.

Moreover, Chinese manufacturers also provide opportunities for branding beyond the physical product. They offer customized software solutions, user interfaces, and technical support, allowing businesses to provide a comprehensive branded experience to their customers. This can be especially beneficial for businesses targeting niche markets or seeking a competitive advantage.

While choosing a Chinese manufacturer for private labeling and branding opportunities, businesses should consider factors like the manufacturer’s expertise, production capacity, quality control measures, and customer reviews. Regular communication and quality assurance check-ups with the manufacturer are essential to ensure that the product meets the desired standards and specifications.

In conclusion, partnering with Chinese five axis CNC router manufacturers offers businesses a pathway to create their own brand identity and expand their product offerings. Through private labeling and branding, businesses can differentiate themselves in the market, meet specific industry requirements, and provide a comprehensive branded experience to their customers.

Tips for Procurement and Considerations when Purchasing five axis cnc router

When purchasing a five-axis CNC router for procurement, there are several considerations to keep in mind to ensure a successful purchase. Below are some tips to help you with the procurement process:

1. Assess your requirements: Before purchasing a CNC router, evaluate your specific needs and requirements. Consider factors such as the size and type of materials to be machined, production volume, and the complexity of the desired designs.

2. Research different models: Conduct thorough research to identify reputable manufacturers and models of five-axis CNC routers. Read reviews, compare features and specifications, and consider the track record and reputation of the manufacturer.

3. Determine your budget: Establish a budget for the purchase, including the initial cost of the machine as well as ongoing costs for maintenance, training, and tooling. Make sure your budget is realistic and aligns with your needs.

4. Quality and durability: Ensure that the CNC router you choose is made of high-quality materials and components. Check for features like robust construction, reliable components, and a solid reputation for durability.

5. Consider service and support: Look for a manufacturer or supplier that offers comprehensive customer support, including training, troubleshooting, and technical assistance. Avoid purchasing from companies with a poor after-sales service record.

6. Testimonials and references: Seek testimonials and references from customers who have purchased the same or similar CNC routers. This will provide insight into their experiences and help you make an informed decision.

7. Evaluate the software: Pay attention to the software provided with the CNC router. Ensure that it is user-friendly, compatible with your existing software, and offers the necessary features for your machining needs.

8. Training and compatibility: Check if the manufacturer provides training programs for operating and maintaining the CNC router. Also, verify if the machine is compatible with your existing software and tools.

9. Warranty and maintenance: Inquire about the warranty period and what it covers. Additionally, ask about the availability of spare parts and the ease of maintenance and repair.

10. Safety features: Make sure the CNC router has appropriate safety features, such as emergency stops, safety sensors, and enclosures, to protect operators and prevent accidents.

By considering these tips and guidelines, you can make an informed decision when purchasing a five-axis CNC router. Remember to prioritize your specific needs and take into account the long-term costs, service, and support offered by the manufacturer or supplier.

FAQs on Sourcing and Manufacturing five axis cnc router in China

1. Can I trust the quality of five axis CNC routers manufactured in China?

China has a long-standing reputation for producing high-quality machinery and equipment, including CNC routers. It is important to research and vet potential manufacturers to ensure they meet your quality standards. Working with reputable suppliers and conducting on-site inspections can help ensure the quality of the product.

2. How can I find reliable suppliers of five axis CNC routers in China?

There are several ways to find reliable suppliers in China, including attending trade shows, conducting online research, and working with sourcing agents or companies that specialize in connecting buyers with manufacturers. It is essential to do thorough due diligence and request samples or references to verify the supplier’s reliability and quality.

3. What are the advantages of sourcing five axis CNC routers from China?

China is known for its competitive pricing, efficient manufacturing processes, and technological advancements in CNC technology. Sourcing from China can often result in cost savings without compromising on quality. Additionally, China has a vast network of suppliers and manufacturers, providing buyers with a wide range of options to choose from.

4. How can I ensure the quality of the five axis CNC router during the manufacturing process?

It is essential to establish clear communication with the manufacturer, provide detailed specifications and requirements, and conduct regular quality control inspections throughout the manufacturing process. Working with a reputable third-party inspection agency can also help ensure the product meets your quality standards.

5. Are there any potential challenges or risks associated with sourcing five axis CNC routers from China?

While there are many advantages to sourcing from China, there are also potential challenges such as language barriers, cultural differences, and the risk of intellectual property theft. It is crucial to work with experienced professionals and have a solid contract in place to mitigate these risks and ensure a successful sourcing process.

Why contact sourcifychina.com get free quota from reliable five axis cnc router suppliers?

Sourcifychina.com offers a free quota from reliable five-axis CNC router suppliers due to several reasons. Firstly, Sourcifychina.com is a leading sourcing company that has established strong relationships with reputable suppliers in China. These suppliers are carefully vetted and chosen based on their credibility, product quality, and capacity to meet client specifications.

Secondly, by offering a free quota, Sourcifychina.com aims to provide an opportunity for businesses to assess the feasibility and cost-effectiveness of sourcing their CNC router needs from China. This enables potential buyers to gain insights into the quality, pricing, and capabilities of different suppliers, facilitating a more informed decision-making process.

Furthermore, Sourcifychina.com understands the importance of building trust and confidence with clients. By offering a free quota, they provide a risk-free experience to potential buyers, allowing them to evaluate the services and products of reliable suppliers without any financial commitment upfront.

Sourcifychina.com’s expertise in sourcing and supplier management ensures that the free quota provided includes relevant information and specifications requested by the buyer. This further enhances the evaluation process and increases the likelihood of finding the best supplier match for the buyer’s CNC router requirements.

In addition, Sourcifychina.com’s free quota allows businesses to explore the advantages of sourcing from China, such as lower production costs, access to advanced technology, and a wide range of suppliers. This can significantly benefit businesses looking to optimize their manufacturing processes and improve their competitiveness in the market.

Overall, Sourcifychina.com’s provision of a free quota from reliable five-axis CNC router suppliers aims to simplify and streamline the sourcing process, reduce risk for potential buyers, and help businesses make well-informed decisions when it comes to choosing the right supplier for their CNC router needs.