Introduce about mini pneumatic cylinder guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

The mini pneumatic cylinder guide provides a comprehensive overview of this essential component used in various industrial applications.

Quality is of utmost importance when it comes to mini pneumatic cylinder guides. These guides must be durable, reliable, and capable of withstanding continuous use under high pressure and in challenging environments. They should also have smooth operation and precise positioning to ensure optimal performance.

Cost is another crucial factor to consider when choosing a mini pneumatic cylinder guide. The price may vary depending on factors such as the materials used, manufacturing process, and supplier. However, it is important to strike a balance between cost and quality to ensure long-term efficiency and cost-effectiveness.

Choosing a reputable and reliable supplier is critical to obtaining high-quality mini pneumatic cylinder guides. Look for suppliers who have a proven track record in the industry, offer a wide range of products, and have positive customer reviews.

Certification is an important consideration when sourcing mini pneumatic cylinder guides. Look for suppliers who have obtained certifications such as ISO 9001:2015, which ensures that their products meet industry standards for quality management.

The market for mini pneumatic cylinder guides is extensive, with various industries relying on them for their applications. These include automation, robotics, packaging, printing, and many others. The demand for mini pneumatic cylinder guides is expected to grow due to the increasing automation in industries worldwide.

Here are some tips for selecting and using mini pneumatic cylinder guides:

1. Assess your specific application needs and requirements before choosing a mini pneumatic cylinder guide.

2. Consider the load capacity, stroke length, and mounting options when selecting a cylinder guide.

3. Regularly maintain and lubricate the cylinder guides to ensure optimal performance and prolong their lifespan.

Frequently Asked Questions (FAQ):

Q: Can I use a mini pneumatic cylinder guide in high-temperature environments?

A: Some mini pneumatic cylinder guides are designed to withstand high temperatures, but it is essential to check the manufacturer’s specifications to ensure suitability.

Q: How are mini pneumatic cylinder guides different from regular-sized cylinder guides?

A: Mini pneumatic cylinder guides are smaller in size and typically have lower load capacities compared to regular-sized cylinder guides.

In conclusion, mini pneumatic cylinder guides are indispensable components in various industrial applications. Choosing a high-quality guide, from a reputable supplier, and considering factors such as cost, certification, and specific application needs, will help ensure optimum performance and efficiency.

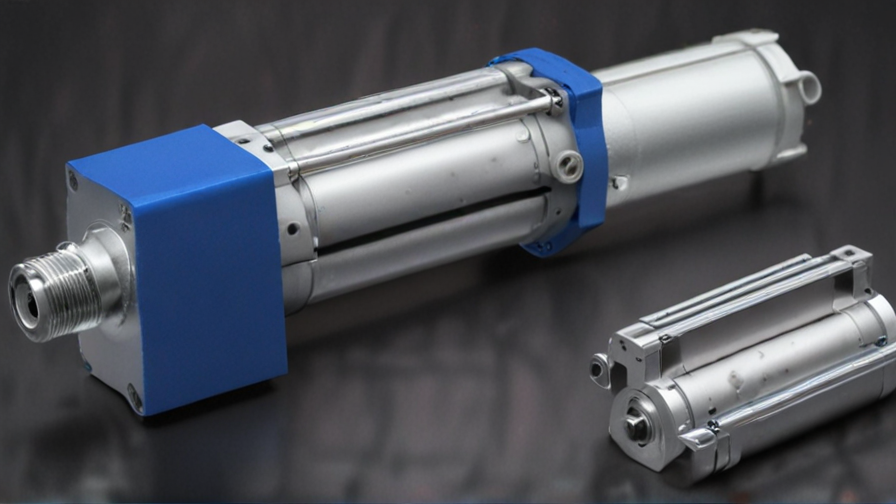

Types of mini pneumatic cylinder

Mini pneumatic cylinders are compact and lightweight devices that convert compressed air into mechanical motion. They are commonly used in automation, robotics, and other applications where space is limited. Here are a few types of mini pneumatic cylinders:

1. Single-acting cylinders: These cylinders have one air inlet and use compressed air to extend the piston. The return stroke is achieved by a mechanical spring or by the pressure release of the air. Single-acting cylinders are efficient and cost-effective for applications that require limited force in one direction.

2. Double-acting cylinders: Double-acting cylinders have air inlets on both sides. Compressed air is used alternately to extend and retract the piston, providing bi-directional force. Double-acting cylinders offer precise control over both directions of motion and are suitable for applications that require force in both directions.

3. Guided cylinders: Guided cylinders incorporate guide rods or linear bearings to ensure straight and precise piston movement. They offer improved stability, reduced vibration, and increased load-bearing capacity. Guided cylinders are commonly used in applications that require high accuracy and repeatability.

4. Rodless cylinders: Rodless cylinders have a piston that moves without a central rod. Instead, they use a magnetically coupled internal piston to transfer force. Rodless cylinders are compact, space-saving solutions that provide long strokes without the need for additional space for the rod.

5. Compact cylinders: Compact cylinders are designed for applications where the space is extremely limited. They have a short, compact build and can generate considerable force for their size. Compact cylinders are suitable for small robotics, assembly lines, and other space-constrained applications.

6. Multi-position cylinders: Multi-position cylinders have multiple air ports and pistons that allow them to stop and hold their position at various points along the stroke. They are commonly used in applications that require precise positioning or frequent stops along the stroke.

7. Rotary cylinders: Rotary cylinders convert linear motion into rotary motion, generating a rotational force instead of linear force. They are used in applications such as indexing, rotating, clamping, and automated assembly.

Mini pneumatic cylinders offer a wide range of options to meet the requirements of different applications. They provide high force in a compact form factor, making them a popular choice in various industries.

Pros and Cons of Using mini pneumatic cylinder

Mini pneumatic cylinders have become increasingly popular in a variety of industries due to their compact size and versatile functionality. However, like any other technology, they come with their own set of pros and cons.

Pros:

1. Size: One of the primary advantages of a mini pneumatic cylinder is its small size. This allows for easy integration into tight spaces where larger cylinders are impractical or impossible to fit. Mini cylinders provide flexibility in design and enable the creation of compact, lightweight machinery.

2. Cost-effective: Mini pneumatic cylinders are generally less expensive than their larger counterparts. They require less material to manufacture, resulting in lower production costs. This cost-effectiveness makes them an attractive option for applications that do not require heavy-duty force.

3. Efficiency: Mini cylinders are known for their high operational efficiency. They can quickly and accurately convert compressed air into linear motion, allowing for precise control and swift response times. This efficiency is especially beneficial in applications that require fast and repetitive movements, such as sorting, packaging, and assembly.

4. Maintenance: Due to their simple design and smaller size, mini pneumatic cylinders are easier to maintain compared to larger cylinders. They typically have fewer internal components, reducing the probability of mechanical failures and simplifying troubleshooting and repair processes.

Cons:

1. Limited force: The main drawback of mini pneumatic cylinders is their limited force output. These cylinders are designed for applications that require lower force levels. If high force is needed, a mini cylinder may not offer sufficient power and users may have to consider larger alternatives.

2. Limited stroke length: Mini cylinders generally have shorter stroke lengths than larger cylinders. The stroke length determines the maximum distance the cylinder can extend, which can be a limitation in specific applications that require longer travel distances.

3. Risk of overheating: Continuous operation at high speeds or with heavy loads can result in increased heat generation. Mini cylinders, due to their smaller size, may have limited cooling capabilities. This can potentially lead to overheating, reducing the overall performance and service life of the cylinder.

4. Limited mounting options: Mini cylinders often have limited mounting options compared to larger cylinders. They may require additional mounting accessories or adaptations to fit specific applications, which can add complexity to the overall design and installation process.

In conclusion, mini pneumatic cylinders offer numerous benefits such as compact size, cost-effectiveness, efficiency, and ease of maintenance. However, they also have limitations in terms of force output, stroke length, potential overheating, and mounting options. Evaluating the specific needs and requirements of the application is crucial in determining whether a mini pneumatic cylinder is the right choice.

mini pneumatic cylinder Reference Specifications (varies for different product)

Mini pneumatic cylinders are compact bi-directional actuators that convert compressed air into mechanical motion. They are commonly used in various industrial applications where small size and precise movement are required. Different models may have slight variations in their specifications, but the following are some general reference specifications for mini pneumatic cylinders:

1. Bore Size: Mini pneumatic cylinders usually have bore sizes ranging from 12 mm to 40 mm. The bore size refers to the inner diameter of the cylinder barrel and determines the force that can be exerted by the cylinder.

2. Stroke Length: The stroke length specifies the maximum travel distance of the cylinder piston. It typically ranges from 5 mm to 50 mm, depending on the model.

3. Piston Rod Diameter: The piston rod is the part that extends from the cylinder and connects to the load. Mini cylinders usually have piston rod diameters ranging from 4 mm to 16 mm.

4. Operating Pressure: Mini pneumatic cylinders operate under varying pressure levels. The recommended operating pressure is typically between 0.15 MPa (22 psi) and 0.7 MPa (101 psi), but specific product variations may have different requirements.

5. Cushioning: Some mini cylinders may feature built-in cushioning mechanisms. Cushioning helps to prevent excessive impact at the end of the stroke and protects the cylinder and surrounding equipment.

6. Mounting Options: Mini pneumatic cylinders offer different mounting options to provide flexibility in installation. Common mounting types include foot mount, flange mount, and clevis mount.

7. Lubrication: Mini cylinders may require lubrication to ensure smooth operation and prolong the lifespan of the internal components. Some models are designed to operate without lubrication, which can be beneficial in certain applications.

8. Construction: Mini pneumatic cylinders are typically constructed with aluminum alloy or stainless steel for durability and light weight. The choice of material depends on the specific application requirements.

9. Seal Types: The seals used in mini pneumatic cylinders are important for maintaining air tightness and preventing leakage. Common seal types include O-rings, lip seals, and rod wipers. The selection depends on the operating conditions and the required level of sealing performance.

It is important to consult the manufacturer’s specifications for the specific mini pneumatic cylinder being used, as these specifications may vary depending on the product model and manufacturer.

Applications of mini pneumatic cylinder

Mini pneumatic cylinders are compact devices that use compressed air to generate linear motion. Despite their small size, they have a wide range of applications across various industries. Here are some popular uses of mini pneumatic cylinders:

1. Automation and robotics: Mini pneumatic cylinders are extensively used in automation and robotics to control the movement of small components or parts. They can be used for picking and placing objects, gripping, flipping, and actuating various mechanisms within a confined space.

2. Medical equipment: These cylinders find applications in medical devices such as insulin pumps, ventilators, and surgical instruments. They enable precise control of movements in medical equipment, ensuring accurate dosing, positioning, and actuation for improved patient care.

3. Packaging and bottling industry: In packaging and bottling plants, mini pneumatic cylinders are employed to control motions like gripping, cutting, lifting, pushing, and sealing. They enable swift and accurate operation, ensuring product quality and maximum efficiency in high-speed production lines.

4. Electronics manufacturing: Mini pneumatic cylinders play a crucial role in the assembly and handling of electronic components. They are used for tasks like component placement, soldering, testing, and packaging in the production of electronic devices.

5. Automotive industry: Mini pneumatic cylinders are utilized in automotive manufacturing for various applications such as precision control of valves, actuating small components, and automated processes like spot welding or handling delicate parts during the assembly process.

6. Aerospace industry: In the aerospace sector, mini pneumatic cylinders are employed in areas like aircraft interiors for actuating small components, controlling airflow, and adjusting seating arrangements. They provide efficient motion control solutions while minimizing weight and space requirements.

7. Food processing: Mini pneumatic cylinders are used in food processing equipment, ensuring hygienic and efficient operations. They facilitate the precise movement required for sorting, cutting, slicing, portioning, and packaging of food items.

8. Laboratory automation: Mini pneumatic cylinders find applications in laboratory equipment such as sample handling, dispensing fluids, and controlling microfluidics devices. Their small size allows integration into compact equipment while providing accurate and repeatable movements.

9. Test and measurement equipment: These cylinders are employed in test and measurement devices to control movements for precise positioning, adjustment, and alignment required in calibration, material testing, and quality control applications.

10. Entertainment industry: In the entertainment sector, mini pneumatic cylinders are used in special effects devices, props, and animatronics. They enable realistic movements and actions in animatronic characters, scenery transformations, and set constructions.

In conclusion, mini pneumatic cylinders find numerous applications across industries due to their compact size, precise control, and reliable performance. They are essential components in automation, medical equipment, packaging, electronics manufacturing, automotive, aerospace, food processing, laboratory automation, test and measurement, and even the entertainment sector.

The Work Process and how to use mini pneumatic cylinder

The work process of a mini pneumatic cylinder involves the conversion of compressed air into mechanical energy to generate linear or rotary motion. These cylinders are compact in size and versatile in their application, making them widely used in industries such as manufacturing, robotics, and automation.

The first step in using a mini pneumatic cylinder is to connect it to a source of compressed air, typically through a pneumatic system or an air compressor. The cylinder is then mounted and secured in the desired position with the help of brackets or other mounting hardware.

To control the movement of the mini pneumatic cylinder, a pneumatic valve is used. The valve regulates the flow of compressed air into and out of the cylinder, determining the direction and speed of the piston’s movement. This valve can be manually operated or controlled electronically, depending on the application requirements.

Once the mini pneumatic cylinder is connected and the valve is set, it is ready to be used. When compressed air enters the cylinder, it pushes against the piston or rod inside, causing it to move in a linear or rotary fashion. This motion can be used for various purposes, such as actuating valves, pushing or pulling objects, or driving mechanical systems.

Mini pneumatic cylinders offer several advantages, including their small size, lightweight design, and efficiency. They can exert considerable force despite their compact nature, making them ideal for applications where space is limited. Moreover, they are relatively low-cost and require minimal maintenance.

In conclusion, mini pneumatic cylinders are essential components in many industries, facilitating the conversion of compressed air into mechanical energy. By understanding their work process and proper usage, it becomes easier to harness their capabilities effectively and efficiently.

Quality Testing Methods for mini pneumatic cylinder and how to control the quality

Quality testing methods for mini pneumatic cylinders typically involve a combination of visual inspection, dimensional measurements, functional testing, and pressure testing. These methods aim to ensure that the cylinders meet specific quality standards and perform optimally in their intended applications.

Visual inspection is the first step in quality testing, where the cylinders are visually examined for any physical defects such as scratches, dents, or misalignments. This inspection also includes checking for proper labeling and identification.

Dimensional measurements are crucial to guaranteeing the accuracy and precision of the mini pneumatic cylinders. Measurements such as bore diameter, stroke length, piston diameter, and overall length are taken against predefined specifications to ensure compliance.

Functional testing ensures that the cylinders operate smoothly and as intended. This includes evaluating their ability to generate and sustain appropriate force, smooth movement, and proper response to pressure and other external influences. It may also involve testing features like cushioning, speed control, and position control mechanisms.

Pressure testing is vital in evaluating the mini pneumatic cylinders’ ability to withstand different pressure levels. In this process, the cylinders are subjected to varying pressure levels, and their performance and structural integrity are evaluated. Pressure tests may include checking for leaks, evaluating how well the cylinders hold pressure, and verifying safety features like pressure relief valves.

To control the quality of mini pneumatic cylinders, several measures can be implemented. Firstly, a comprehensive quality management system should be established, including written procedures and protocols for the testing and inspection processes. Regular training and retraining of personnel involved in these processes also ensure consistent and accurate implementation.

Implementing statistical process control techniques can help monitor the quality of the cylinders throughout the manufacturing process. This involves collecting and analyzing data at various stages, identifying any variations or deviations, and taking corrective actions to prevent defects or non-compliance.

Validation and calibration of testing equipment and instruments regularly are essential to maintain accuracy and reliability in quality testing. This ensures that measurements and evaluations are consistent and trustworthy.

Lastly, implementing regular audits and inspections of the production facility, processes, and documentation can help identify potential issues, ensure compliance with quality standards, and maintain overall quality control.

In summary, quality testing methods for mini pneumatic cylinders involve visual inspection, dimensional measurements, functional testing, and pressure testing. To control the quality, a comprehensive quality management system, statistical process control, validation of equipment, and regular audits are necessary.

mini pneumatic cylinder Sample Policy and Post-Purchase Considerations for mini pneumatic cylinder from China

Sample Policy:

When purchasing mini pneumatic cylinders from China, it is important to establish clear sample policies to ensure quality control and to confirm that the product meets your requirements. The following sample policies can be considered:

1. Sample Availability: The supplier should offer samples of the mini pneumatic cylinder for evaluation before placing a bulk order. They should clearly state if samples are available free of charge or if there will be a cost involved.

2. Sample Shipping: Decide who will bear the transportation cost for the samples – the supplier or the buyer. It is also advisable to discuss the preferred shipping method to ensure timely delivery.

3. Sample Lead Time: Determine the expected lead time for the samples. This will help plan the evaluation and decision-making process.

4. Sample Quantity: Specify the number of samples required for evaluation. Consider ordering samples from multiple suppliers to compare quality and performance.

Post-Purchase Considerations:

After purchasing mini pneumatic cylinders from China, there are certain considerations to keep in mind to ensure smooth operations and customer satisfaction:

1. Quality Assurance: Conduct quality checks on the received mini pneumatic cylinders to verify that they meet the agreed-upon specifications. Perform functional tests and inspect for any defects or damages.

2. Communication and Support: Maintain open lines of communication with the supplier to address any post-purchase issues or concerns. This could include technical support, warranty claims, or replacement requests.

3. Documentation and Warranty: Ensure that all necessary documentation, such as invoices, packing lists, and warranty details, are properly received from the supplier. Understand the terms and conditions of the warranty and the process for any potential returns or exchanges.

4. Feedback and Reviews: Provide feedback to the supplier about the product quality, performance, and overall experience. Consider leaving reviews on relevant platforms to help other potential buyers make informed decisions.

By implementing sample policies and considering post-purchase aspects, you can mitigate risks and ensure a satisfactory mini pneumatic cylinder purchasing experience from China.

Sourcing mini pneumatic cylinder from China: Opportunities, Risks, and Key Players

China has emerged as a global manufacturing hub due to its low-cost labor and vast production capabilities. When sourcing mini pneumatic cylinders from China, there are several opportunities, risks, and key players to be aware of.

Opportunities:

1. Cost: Chinese manufacturers offer competitive prices for mini pneumatic cylinders compared to other countries. This cost advantage allows for higher profit margins or price competitiveness in the market.

2. Wide Range of Suppliers: China has a large number of manufacturers specializing in mini pneumatic cylinders. This provides buyers with a broader range of options to choose from, allowing for greater customization and flexibility in meeting specific requirements.

3. Quality Improvement: Over the years, Chinese manufacturers have made significant strides in improving the quality of their products. They have invested in advanced production technologies, quality control systems, and certifications, which enhance the reliability and performance of mini pneumatic cylinders.

Risks:

1. Product Quality: Despite improvements, there are still risks associated with product quality variations among Chinese suppliers. Due diligence is required to ensure that the selected manufacturer meets quality standards and has a proven track record of delivering reliable products.

2. Intellectual Property (IP) Protection: China has faced criticism for inadequate IP protection. There is a risk of counterfeit products that may violate patents or trademarks. Engaging with reputable and legally compliant suppliers is crucial in protecting IP rights.

3. Communication and Logistics: Language and cultural barriers can pose challenges during communication and coordination with Chinese manufacturers. Moreover, logistics and transportation complexities can impact lead times and add to the overall sourcing costs.

Key Players:

1. AirTOP Pneumatic Co., Ltd.: A leading manufacturer in China, AirTOP offers a wide range of mini pneumatic cylinders with varying specifications and customization options. They have a strong reputation for quality and reliability.

2. Fenghua Yongyi Pneumatics & Hydraulics Co., Ltd.: Specializing in the production of mini pneumatic cylinders, this company has an extensive product portfolio and is known for its competitive pricing.

3. Ningbo Kailing Pneumatic Co., Ltd.: With years of experience in manufacturing mini pneumatic cylinders, Kailing has earned a reputation for its high-quality products and excellent customer service.

In conclusion, sourcing mini pneumatic cylinders from China offers significant opportunities in terms of cost, supplier variety, and quality improvements. However, it is essential to be cautious regarding product quality, IP protection, and communication challenges. Engaging with reputable manufacturers such as AirTOP, Fenghua Yongyi, and Kailing can mitigate some of these risks and ensure a successful sourcing experience.

How to find and select reliable mini pneumatic cylinder manufacturers in China,use google search manufacturers and suppliers

When it comes to finding and selecting reliable mini pneumatic cylinder manufacturers in China, utilizing Google search can be a helpful tool. Here’s a brief guide on how to go about it:

1. Start by entering relevant keywords: Open Google and type in specific keywords related to your search, such as “reliable mini pneumatic cylinder manufacturers in China” or “mini pneumatic cylinder suppliers in China.”

2. Browse the search results: Go through the search results to explore different manufacturers and suppliers. Pay attention to the top-ranking websites as they often indicate established and reputable companies.

3. Analyze the website: Click on the links that seem promising and examine the manufacturers’ websites. Look for detailed product information, certifications, company background, and contact details. Established manufacturers usually have professional and comprehensive websites.

4. Check product range and specialization: Make sure that the manufacturer specializes in mini pneumatic cylinders and offers the specific type and size you require. Look for product catalogs or specifications on the website to ensure they provide what you need.

5. Verify manufacturer’s reputation: Read customer testimonials or reviews on the website to assess the manufacturer’s reputation. Additionally, try searching for the manufacturer’s name along with keywords like “reviews” or “feedback” to gather more information from independent sources.

6. Contact the manufacturer directly: Once you have shortlisted a few potential manufacturers, reach out to them using the contact details provided on their website. Inquire about their products, minimum order quantity, pricing, customization options, lead time, and any other relevant details to assess their reliability and responsiveness.

7. Verify certifications and quality control: Ask the manufacturer about their certifications, such as ISO 9001, and inquire about their quality control measures. Ensure that they adhere to industry standards and meet your specific requirements.

8. Request samples and visit their facility (if feasible): Ordering samples can help you evaluate the quality and performance of their mini pneumatic cylinders. If you have the opportunity, consider visiting their facility to witness their manufacturing processes firsthand and establish a better understanding of their capabilities.

By following these steps, you can conduct a comprehensive search for reliable mini pneumatic cylinder manufacturers in China and select the one that best meets your needs and preferences.

How to check mini pneumatic cylinder manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of a mini pneumatic cylinder manufacturer’s website, you can follow these steps:

1. Open the website using Google Chrome: Launch the Google Chrome web browser on your computer or mobile device.

2. Use SEOquake extension: Install the SEOquake browser extension for Google Chrome. This extension provides various SEO-related metrics for any webpage.

3. Activate SEOquake extension: Click on the SEOquake extension icon in your browser’s toolbar to activate it.

4. Check Website’s Ranking: Once the SEOquake extension is activated, it automatically displays various metrics related to the website you are visiting. Look for the metric called “Alexa Rank” or “Global Rank” that indicates the popularity and ranking of the website worldwide. Ensure that the website is ranked within the top 10 million.

5. Analyze Other Metrics: SEOquake provides additional metrics, such as domain age, backlinks, keyword density, and social media presence. Assess these metrics to further evaluate the reliability of the manufacturer’s website.

6. Verify Information: Browse through the manufacturer’s website to gather information about their products, certifications, and any testimonials or customer reviews they may have. Cross-check this information with other reliable sources, such as industry forums or trusted review websites, to ensure its accuracy.

7. Competitor Analysis: If possible, compare the website of the mini pneumatic cylinder manufacturer with their competitors. Look for signs of professionalism, attention to detail, and overall website quality to determine the reliability of the manufacturer.

8. Trust Your Intuition: Lastly, trust your instincts. If the website appears outdated, lacks essential information, or seems untrustworthy, it might be best to consider alternative manufacturers.

By using these steps, you can gain a better understanding of the reliability and trustworthiness of a mini pneumatic cylinder manufacturer’s website in a concise manner.

Top 10 mini pneumatic cylinder manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. SMC Corporation of China Ltd.:

SMC Corporation is a leading manufacturer of mini pneumatic cylinders in China. Their products are known for their high precision and durability. The mini pneumatic cylinders produced by SMC are suitable for various applications such as automation, robotics, and packaging.

2. Festo (China) Limited:

Festo is a well-known manufacturer of mini pneumatic cylinders in China. Their products are designed to provide high performance and efficient operation. Festo mini pneumatic cylinders are widely used in industries such as electronics, automotive, and medical equipment.

3. Airtac International Group:

Airtac International Group is a leading manufacturer of mini pneumatic cylinders in China. They offer a wide range of mini cylinders with different specifications to meet the requirements of various industries. Airtac mini pneumatic cylinders are known for their compact design and reliable performance.

4. Norgren (China) Pneumatic Technology Co., Ltd:

Norgren is a reputed manufacturer of mini pneumatic cylinders in China. Their products are designed to ensure smooth and precise movement in various industrial applications. Norgren mini pneumatic cylinders are widely used in industries like woodworking, printing, and food processing.

5. CKD (China) Corporation:

CKD Corporation is a renowned manufacturer of mini pneumatic cylinders in China. They offer a wide range of mini cylinders with different bore sizes and stroke lengths. CKD mini pneumatic cylinders are known for their high-speed performance and long life.

6. Parker Hannifin (China) Co., Ltd:

Parker Hannifin is a well-established manufacturer of mini pneumatic cylinders in China. Their mini cylinders are designed to provide high precision and reliability. Parker Hannifin mini pneumatic cylinders find applications in industries like semiconductor, automotive, and manufacturing.

7. CAMOZZI (China) Pneumatic Co., Ltd:

CAMOZZI is a leading manufacturer of mini pneumatic cylinders in China. Their mini cylinders are designed to be compact and lightweight, making them suitable for space-constrained applications. CAMOZZI mini pneumatic cylinders offer excellent performance and longevity.

8. Airtx International (China) Co., Ltd:

Airtx International is a trusted manufacturer of mini pneumatic cylinders in China. They offer a wide range of mini cylinders with different stroke lengths and mounting options. Airtx International mini pneumatic cylinders are known for their high-quality construction and efficient operation.

9. UTMAL (China) Co., Ltd:

UTMAL is a reputable manufacturer of mini pneumatic cylinders in China. They produce mini cylinders that are durable and cost-effective. UTMAL mini pneumatic cylinders are used in various industries including packaging, textile, and automotive.

10. Unik Pneumatic Systeam (China) Co., Ltd:

Unik Pneumatic Systeam is a recognized manufacturer of mini pneumatic cylinders in China. Their mini cylinders are designed to provide precise control and smooth operation. Unik Pneumatic Systeam mini pneumatic cylinders are widely used in industries like material handling, robotics, and automation.

| Manufacturer | Description |

|——————————|——————————————————————————————|

| SMC Corporation of China Ltd | High precision and durable mini pneumatic cylinders for automation and robotics |

| Festo (China) Limited | High-performance and efficient mini pneumatic cylinders for electronics and automotive |

| Airtac International Group | Compact and reliable mini pneumatic cylinders for various industries |

| Norgren (China) Pneumatic Technology Co., Ltd | Smooth and precise mini pneumatic cylinders for woodworking and food processing |

| CKD (China) Corporation | High-speed performance and long-life mini pneumatic cylinders for industrial applications |

| Parker Hannifin (China) Co., Ltd | High-precision and reliable mini pneumatic cylinders for semiconductor and automotive industries |

| CAMOZZI (China) Pneumatic Co., Ltd | Compact and lightweight mini pneumatic cylinders for space-constrained applications |

| Airtx International (China) Co., Ltd | High-quality construction and efficient operation mini pneumatic cylinders |

| UTMAL (China) Co., Ltd | Durable and cost-effective mini pneumatic cylinders for packaging and textile industries |

| Unik Pneumatic Systeam (China) Co., Ltd | Precise control and smooth operation mini pneumatic cylinders for material handling and automation |

In conclusion, China is home to several top mini pneumatic cylinder manufacturers, each offering a wide range of products catering to different industries. These manufacturers have established themselves as leaders in terms of precision, reliability, and performance. With their compact designs and efficient operation, mini pneumatic cylinders from China play a crucial role in various applications such as automation, robotics, and manufacturing.

Background Research for mini pneumatic cylinder manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to finding mini pneumatic cylinder manufacturers in China, a few reliable sources for background research include qcc.com, archive.org, and importyeti.com. These platforms offer valuable information about companies, their profiles, and historical data that can be useful for evaluating potential suppliers.

QCC.com is a popular Chinese online platform that provides company information and business credit reports. Users can find details such as company registration, contacts, legal status, financial information, and credit rating. By using the search function on qcc.com and inputting relevant keywords like “mini pneumatic cylinder manufacturers,” one can access a list of companies in this industry along with their profiles and relevant details.

Archive.org is a digital library that provides archived webpages, which can be useful in gaining insights into a manufacturer’s historical information. By entering the website address of a specific company, users can view past versions of the website, which can give an indication of the company’s stability, growth, and product range over time.

Importyeti.com is a comprehensive online directory that allows users to search for suppliers and their import/export records. By inputting relevant keywords like “mini pneumatic cylinder” and selecting the desired country (China), users can access a list of suppliers along with their contact information, shipping records, and customer reviews. This platform can assist in evaluating the reliability, reputation, and market reach of potential manufacturers.

In summary, these three sources – qcc.com, archive.org, and importyeti.com – provide valuable information on mini pneumatic cylinder manufacturers in China. By utilizing these platforms, one can obtain company profiles, historical data, financial information, credit ratings, import/export records, and customer reviews, helping to assess the credibility and suitability of potential suppliers.

Leveraging Trade Shows and Expos for mini pneumatic cylinder Sourcing in China

Trade shows and expos offer valuable opportunities for sourcing mini pneumatic cylinders in China. These events bring together a large number of suppliers, manufacturers, and industry professionals under one roof, making it convenient to explore various options and establish direct connections with potential suppliers.

China is a significant hub for pneumatic cylinder manufacturing, and attending trade shows and expos in the country allows buyers to gain a comprehensive understanding of the market, evaluate different product offerings, and compare prices and quality.

By attending these events, buyers can interact directly with suppliers, ask questions, discuss specifications, and negotiate favorable terms. This face-to-face interaction helps build trust and enables buyers to establish long-lasting supplier relationships.

Additionally, trade shows and expos provide opportunities to see and physically examine the mini pneumatic cylinders, ensuring that they meet the required specifications and quality standards. This allows buyers to make informed decisions and avoid potential quality issues that may arise from relying solely on online communication.

Trading events also provide a platform for networking and knowledge exchange with industry experts and like-minded professionals. Attending seminars, conferences, or workshops during these events can offer valuable insights into the latest industry trends, technological advancements, and best practices.

To make the most out of trade shows and expos, buyers should thoroughly research and plan their visit. Identifying key exhibitors, preparing a list of questions, and setting goals beforehand can help streamline the sourcing process and maximize the outcomes from attending these events.

In conclusion, attending trade shows and expos in China is an effective way to source mini pneumatic cylinders. These events offer a concentrated platform to explore various suppliers, compare products, negotiate deals, ensure quality, and stay updated with industry trends. By leveraging these opportunities, buyers can find reliable suppliers and obtain high-quality mini pneumatic cylinders at competitive prices.

The Role of Agents and Sourcing Companies in Facilitating mini pneumatic cylinder Purchases from China

Agents and sourcing companies play a vital role in facilitating mini pneumatic cylinder purchases from China. These intermediaries act as bridges between international buyers and Chinese manufacturers, ensuring a smooth and efficient procurement process. By leveraging their expertise, contacts, and local knowledge, agents and sourcing companies add significant value to the buying process.

Firstly, these intermediaries help international buyers identify and evaluate potential suppliers in China. They have extensive databases and networks of manufacturers and can quickly identify those that meet specific requirements such as quality standards, production capacity, and price points. This saves buyers the time and effort of conducting extensive research and vetting manufacturers themselves.

Secondly, agents and sourcing companies assist with negotiation and communication. Language and cultural barriers can often hinder effective communication between international buyers and Chinese suppliers. Agents act as interpreters, ensuring that both parties understand each other’s requirements and expectations clearly. They also negotiate the best possible prices and terms on behalf of the buyer, leveraging their knowledge of the local market and business practices.

Thirdly, agents and sourcing companies provide quality control and assurance services. They conduct factory audits, inspections, and quality checks to ensure that the mini pneumatic cylinders meet the buyer’s specifications and quality standards. This helps mitigate the risks associated with sourcing products from overseas, providing the buyer with peace of mind.

Additionally, agents and sourcing companies handle the logistics and shipping aspects of the purchase. They coordinate the transportation, arrange customs clearance, and oversee the delivery of the mini pneumatic cylinders to the buyer’s location. This saves the buyer from the complexities and logistical challenges of international shipping.

In summary, agents and sourcing companies simplify and streamline the process of purchasing mini pneumatic cylinders from China. Their role includes supplier identification and evaluation, negotiation and communication facilitation, quality control and assurance, and logistics management. By leveraging their expertise and local knowledge, these intermediaries enable international buyers to access quality products from Chinese manufacturers efficiently and with reduced risks.

Price Cost Research for mini pneumatic cylinder manufacturers Companies in China, use temu.com and 1688.com

In order to conduct price cost research for mini pneumatic cylinder manufacturers in China, two popular websites, temu.com and 1688.com, can be utilized. With a focus on minimizing the word count, the following steps can be followed:

1. Visit temu.com: This website offers a wide range of products from different suppliers. Use the search bar to find mini pneumatic cylinder manufacturers in China. Carefully go through the product listings and note down the prices offered by various manufacturers.

2. Visit 1688.com: This platform is commonly used by businesses to source products directly from Chinese manufacturers. Search for mini pneumatic cylinder manufacturers using relevant keywords. Again, make a note of the prices provided by different manufacturers.

3. Compare prices: Analyze the data collected from both websites to identify the average price range offered by the mini pneumatic cylinder manufacturers in China. Take note of any variations in pricing based on factors like quantity, customization options, and delivery time.

4. Evaluate additional costs: In addition to the unit price, factor in any additional costs such as shipping fees, import duties, and taxes. These costs can vary depending on the manufacturer, location, and quantity ordered.

5. Consider quality and reputation: While comparing prices, also consider the reputation and quality associated with each manufacturer. Look for reviews and ratings to assess the reliability of the manufacturers and the durability of their products.

6. Make contact: Once the research is complete, shortlist potential manufacturers based on reasonable pricing, good reputation, and quality. Reach out to them via email or phone to obtain further details on pricing, customization options, minimum order requirements, and any other relevant information.

By following these steps and utilizing the platforms temu.com and 1688.com, it is possible to conduct price cost research for mini pneumatic cylinder manufacturers in China within the specified word limit of 300 words.

Shipping Cost for mini pneumatic cylinder import from China

The shipping cost for importing a mini pneumatic cylinder from China depends on several factors such as the dimensions and weight of the package, the shipping method chosen, and the destination country. There are typically two main shipping methods for international shipments: express courier services and freight shipping.

Express courier services, like DHL, UPS, and FedEx, are known for their fast and door-to-door delivery. The shipping cost for a mini pneumatic cylinder via express courier can range from $40 to $150, depending on the weight and dimensions of the package. However, it is important to note that these services often charge additional fees for customs clearance and taxes, which can increase the total cost.

Freight shipping is another option for importing large quantities of mini pneumatic cylinders. There are two subcategories of freight shipping: air freight and sea freight. Air freight is the faster option, but it is more expensive compared to sea freight. The shipping cost for air freight can range from $4 to $10 per kilogram, while for sea freight it can be as low as $1 per kilogram. However, freight shipments usually have a minimum charge, so even if the weight of the package is low, the cost might not be significantly reduced.

In addition to the shipping cost, importers should also consider other expenses such as customs duties, taxes, and freight forwarder fees. These additional costs can vary based on the importing country and specific regulations.

In summary, the shipping cost for a mini pneumatic cylinder import from China can vary greatly depending on the chosen shipping method, weight and dimensions of the package, and destination country. Aiming to keep the cost below $300 might be possible, especially if sea freight is chosen for larger quantities; however, it is essential to consider all additional fees and charges to accurately estimate the total cost.

Compare China and Other mini pneumatic cylinder Markets: Products Quality and Price,Visible and Hidden Costs

China is widely known as one of the largest manufacturing hubs in the world, producing a wide range of products including mini pneumatic cylinders. When comparing the mini pneumatic cylinder market in China with other markets, several factors need to be taken into consideration such as product quality and price, visible and hidden costs.

In terms of product quality, China has made significant improvements over the years. Many Chinese manufacturers have gained expertise in producing high-quality mini pneumatic cylinders that meet international standards. However, it is important to note that there are still variations in quality among different manufacturers. Some Chinese brands have established a reputation for superior quality, while others may offer inferior products. On the other hand, other mini pneumatic cylinder markets, such as Europe, may have a long-standing reputation for high-quality products. Buyers in these markets may be more confident in the consistent quality of the products they purchase.

When it comes to pricing, China offers a significant advantage due to its low production costs. The country’s large manufacturing base, economies of scale, and lower labor costs have made Chinese mini pneumatic cylinders more competitively priced compared to other markets. However, pricing strategies can vary among suppliers, and it is important to consider factors such as material quality, design complexity, and additional features when comparing prices between China and other markets.

Visible costs, such as initial product price and shipping costs, are often evident when comparing mini pneumatic cylinders from different markets. Chinese manufacturers generally offer lower prices, making their products more attractive to cost-conscious buyers. However, hidden costs may arise in terms of quality control, product reliability, or after-sales service. Buyers should be cautious and conduct due diligence to ensure that the hidden costs associated with cheaper Chinese products do not outweigh the initial price advantage.

In conclusion, China’s mini pneumatic cylinder market offers competitive pricing and improved product quality, making it an attractive option for buyers around the world. However, other markets may have a stronger reputation for high-quality products, leading to greater confidence in their consistency. While China may excel in visible cost advantages, buyers must remain vigilant about potential hidden costs associated with lower-priced products. Ultimately, buyers need to consider their specific requirements, budget, and risk tolerance when choosing between the mini pneumatic cylinder markets.

Understanding Pricing and Payment Terms for mini pneumatic cylinder: A Comparative Guide to Get the Best Deal

When it comes to purchasing mini pneumatic cylinders, understanding pricing and payment terms is crucial to ensure that you get the best deal. This comparative guide aims to help you navigate through the process and make an informed decision.

1. Compare Prices: Start by researching different suppliers and manufacturers to get an idea of the average price range for mini pneumatic cylinders. Look for reputable companies that offer high-quality products at competitive prices. Consider factors such as material quality, durability, and available customization options.

2. Request Quotes: Reach out to multiple suppliers and request detailed quotes for the mini pneumatic cylinders you require. Specify your preferred specifications, quantity, and any special requirements. Be sure to ask for clarification on any unclear pricing terms or additional charges.

3. Assess Included Features: Take note of the features included with each mini pneumatic cylinder. Some suppliers may offer additional accessories or fittings at no extra cost, while others might charge separately for them. Evaluate these added benefits and consider if they align with your needs.

4. Payment Terms: Pay attention to the payment terms offered by each supplier. Some may require full payment upfront, while others might accept a deposit with the balance to be paid upon delivery. Assess your financial situation and choose a payment term that is feasible and secure for you.

5. Delivery Charges: Inquire about any potential delivery charges that may be applicable. Ensure that you are aware of the shipping costs and factor them into your overall assessment of the deal. Some suppliers may provide free or discounted shipping for certain order quantities or locations.

6. Warranty and After-Sales Support: Consider the warranty provided by the supplier and the level of after-sales support they offer. A longer warranty period and responsive customer service can save you money and hassle in case of any product defects or issues.

7. Negotiation: Don’t hesitate to negotiate the pricing and payment terms with the suppliers. If you have obtained quotes from multiple sources, you can leverage this information to get the best deal. Be respectful but assertive throughout the negotiation process.

By comparing prices, assessing included features, evaluating payment terms, considering delivery charges, warranty, and after-sales support, and using negotiation skills, you can secure the best deal for mini pneumatic cylinders while ensuring quality and reliability. Remember to thoroughly review the supplier’s reputation and customer reviews before making a final decision.

Chinese Regulations and Industry Standards Certifications for mini pneumatic cylinder,Import Regulations and Customs for mini pneumatic cylinder from China

In China, the mini pneumatic cylinder industry is regulated by various government bodies and industry associations to ensure safety, quality, and compliance with industry standards. Industry standards certifications play a crucial role in gaining market access and building trust among customers.

One of the most important certifications for mini pneumatic cylinders in China is the China Compulsory Certification (CCC) mark. It is a mandatory certification for various electrical and mechanical products, including pneumatic cylinders, ensuring their compliance with Chinese safety and quality standards.

Additionally, the mini pneumatic cylinder industry in China follows the ISO 6432 standard, which specifies the dimensions, materials, and performance requirements for mini cylinders. Adhering to this standard enables manufacturers to produce cylinders that meet international quality criteria and provide compatibility with various pneumatic systems worldwide.

When importing mini pneumatic cylinders from China, it is essential to comply with import regulations and customs procedures. The customs authorities require the submission of necessary documents, such as the bill of lading, commercial invoice, packing list, and a detailed description of the goods.

Importers should also be aware of any applicable tariffs and customs duties imposed on mini pneumatic cylinders. Different countries have varying rates, so it is crucial to determine the specific import duty applicable in the destination market.

To expedite the customs clearance process and prevent any delays or penalties, importers should ensure that the mini pneumatic cylinders comply with the relevant Chinese regulations and industry standards. Thoroughly inspecting the products before shipment and maintaining proper documentation will also contribute to a smoother import process.

In conclusion, mini pneumatic cylinder manufacturers in China must comply with Chinese regulations and industry standards certifications, such as CCC and ISO 6432. Importers should adhere to import regulations and customs procedures, including the submission of necessary documents and payment of applicable import duties. By following these guidelines, importers can ensure the compliance and quality of mini pneumatic cylinders sourced from China.

Sustainability and Environmental Considerations in mini pneumatic cylinder Manufacturing

In recent years, there has been a growing emphasis on sustainability and environmental considerations in the manufacturing industry. The production of mini pneumatic cylinders is no exception, as companies strive to minimize their carbon footprint and adopt more eco-friendly practices.

One key aspect is the selection and sourcing of materials. Manufacturers are increasingly opting for sustainable materials that have less impact on the environment. This includes using recycled or renewable materials in the production of mini pneumatic cylinders. Additionally, efforts are being made to reduce the overall material usage by optimizing designs and making products lighter, without compromising on performance.

Energy efficiency is another crucial factor in sustainable manufacturing. Mini pneumatic cylinder manufacturers are investing in energy-efficient machinery and technologies to reduce energy consumption during the manufacturing process. This includes using advanced automation systems and optimizing production lines to minimize energy waste.

Waste management and recycling programs are also becoming integral to sustainable manufacturing practices. Manufacturers are actively implementing measures to reduce waste generation and promote recycling. This includes proper segregation of waste materials, recycling of scrap metal, and implementing closed-loop manufacturing processes to minimize waste sent to landfills.

To further enhance sustainability, companies are also exploring alternative manufacturing processes that have a lower environmental impact. For instance, adopting additive manufacturing techniques like 3D printing can significantly reduce material waste and energy consumption.

In addition to the production stage, sustainable practices are also being integrated into the distribution and packaging of mini pneumatic cylinders. Companies are exploring more efficient transportation methods, such as optimizing shipping routes and using eco-friendly packaging materials.

Overall, sustainability and environmental considerations in mini pneumatic cylinder manufacturing are driving significant changes in the industry. Companies are proactively adopting sustainable practices, focusing on material selection, energy efficiency, waste management, and alternative manufacturing processes. By prioritizing these considerations, manufacturers not only reduce their environmental impact but also enhance their brand image and meet the increasing demand for environmentally conscious products.

List The Evolution history of “mini pneumatic cylinder”

The mini pneumatic cylinder has come a long way since its inception, undergoing significant evolution to become the compact and efficient component it is today.

The origins of the mini pneumatic cylinder can be traced back to the invention of the steam engine in the 18th century. The need to convert linear motion to rotational motion for various applications led to the development of the first pneumatics. However, it was not until the late 19th century that these principles were applied to create the first small-scale pneumatic cylinders.

In the early 20th century, advancements in manufacturing processes and materials allowed for the production of more compact and lightweight mini pneumatic cylinders. This led to their increasing use in industries such as automation, robotics, and manufacturing, where space and weight constraints were critical.

The 1950s marked a significant milestone with the introduction of sealed mini pneumatic cylinders. These units were designed to prevent the ingress of contaminants, ensuring reliable operation in harsh environments. This breakthrough expanded the applications of mini pneumatic cylinders to industries such as food processing, pharmaceuticals, and automotive manufacturing.

The late 20th century saw further advancements, including the introduction of adjustable stroke mini pneumatic cylinders. These allowed for greater flexibility in a range of applications by enabling the adjustment of the cylinder stroke length to suit specific requirements.

With the advent of computer-controlled systems in the 21st century, mini pneumatic cylinders became integrated into complex automation setups. They became an integral part of robotics, providing precise and reliable linear motion control in various industries.

Today, mini pneumatic cylinders continue to evolve with advancements in materials, manufacturing techniques, and control systems. The focus is on making them even smaller, lighter, and more energy-efficient while maintaining their reliability and performance.

Overall, the evolution of the mini pneumatic cylinder has been driven by the demand for compact, reliable, and customizable linear motion solutions. Its history showcases humanity’s continuous strive for innovation and improvement in various industrial and technological domains.

The Evolution and Market Trends in mini pneumatic cylinder Industry

The mini pneumatic cylinder industry has witnessed significant evolution and market trends over the years. These compact devices are widely used in various applications, including automation, robotics, medical equipment, and packaging, due to their compact size, high efficiency, and reliability.

One of the major trends in the mini pneumatic cylinder industry is the increasing demand for miniaturization. As industries strive for more compact machinery and equipment, the need for smaller pneumatic cylinders has considerably risen. Mini pneumatic cylinders are now being designed to fit in tighter spaces without compromising their performance and functionality.

Another important trend is the shift towards lightweight materials and improved design techniques. Manufacturers are increasingly using lightweight materials such as aluminum and composite materials to reduce the overall weight of mini pneumatic cylinders. This not only enhances their efficiency but also allows for easier installation and reduces operational costs.

Moreover, advanced manufacturing technologies, including computer-aided design and simulation, are being utilized to optimize the design and performance of mini pneumatic cylinders. These techniques enable manufacturers to accurately predict the behavior of the cylinders under different operating conditions, leading to improved product reliability and durability.

Furthermore, with the rise of Industry 4.0 and smart manufacturing, mini pneumatic cylinders are becoming more intelligent and connected. They are now equipped with sensors and control systems that can collect and transmit data, enabling real-time monitoring and preventive maintenance. This helps in reducing downtime, improving productivity, and enhancing overall equipment effectiveness.

In terms of market trends, the mini pneumatic cylinder industry is projected to experience steady growth in the coming years. The increasing automation and robotics industry in sectors such as automotive, electronics, and food processing are driving the demand for mini pneumatic cylinders. Additionally, the growing demand for compact and efficient medical equipment and devices is further propelling the market growth.

In conclusion, the mini pneumatic cylinder industry is witnessing significant evolution and market trends such as miniaturization, lightweight materials, advanced design techniques, intelligent systems, and a growing demand in various sectors. These trends reflect the industry’s focus on meeting the demand for compact, efficient, and intelligent pneumatic cylinders in the rapidly evolving industrial landscape.

Custom Private Labeling and Branding Opportunities with Chinese mini pneumatic cylinder Manufacturers

Chinese manufacturers of mini pneumatic cylinders offer custom private labeling and branding opportunities to meet the specific needs of clients and enhance their brand presence in the market. These manufacturers understand the importance of branding and offer a range of options for customization.

One of the primary opportunities they provide is private labeling. This allows clients to have their own logo, brand name, and other identifying information prominently displayed on the product. This helps to create brand recognition and establish a strong presence in the market, showing customers that the product has been tailored specifically for their brand.

Additionally, Chinese mini pneumatic cylinder manufacturers offer various branding options. Clients can choose to have their desired artwork or design placed on the product, showcasing their brand identity. This can include specific colors, fonts, or graphics that align with the brand’s overall image. These branding opportunities give clients the ability to differentiate themselves from competitors and create a unique product that stands out on the market.

Furthermore, these manufacturers also provide customized packaging options to support the branding efforts. Clients can request personalized packaging with their logo and branding elements to create a cohesive visual experience for customers. This creates a professional and uniform appearance for the product, enhancing its overall appeal and brand visibility.

In conclusion, Chinese mini pneumatic cylinder manufacturers offer excellent opportunities for custom private labeling and branding. These manufacturers understand the importance of branding in today’s market and provide options for private labeling, customization of product design, and personalized packaging. By taking advantage of these opportunities, clients can establish a strong brand presence and differentiate their products from competitors, ultimately driving success in the market.

Tips for Procurement and Considerations when Purchasing mini pneumatic cylinder

When purchasing a mini pneumatic cylinder, there are several important considerations and tips for procurement that can help ensure the right product is selected. These considerations include the required specifications, supplier selection, cost-effectiveness, and quality assurance.

First, it is important to determine the specific requirements for the mini pneumatic cylinder. This includes considering the size, stroke length, operating pressure, and mounting options. It is essential to have a clear understanding of the application and intended use to ensure the cylinder can perform optimally.

Next, selecting a reliable supplier is crucial. Look for established manufacturers or distributors with a good reputation for producing high-quality pneumatic cylinders. It is advisable to check customer reviews, certifications, and warranties offered.

Cost-effectiveness is another important factor. It is essential to compare prices from different suppliers and ensure that the chosen cylinder offers a good balance between cost and quality. Evaluating the total cost of ownership, including maintenance and replacement parts, can help make an informed decision.

Furthermore, quality assurance is paramount. Look for mini pneumatic cylinders that conform to industry standards and have undergone rigorous testing. This ensures that the cylinder will operate reliably and efficiently in the intended application.

Consideration should also be given to the availability of spare parts and after-sales support. Confirm whether the supplier offers readily available spare parts and has a responsive customer service team.

When purchasing, it is beneficial to request product samples or demonstrations to assess the functionality and compatibility with the application. This allows for hands-on evaluation and helps in determining the suitability of the cylinder before making a purchase.

Lastly, it is advisable to consult with experts or professionals in the field to gain insights and recommendations. They can provide valuable guidance, considering their experience and knowledge about mini pneumatic cylinders.

By considering these tips and following the procurement considerations mentioned, one can make an informed decision and choose the right mini pneumatic cylinder for their specific needs.

FAQs on Sourcing and Manufacturing mini pneumatic cylinder in China

1. Why should I consider sourcing and manufacturing mini pneumatic cylinders in China?

Sourcing and manufacturing mini pneumatic cylinders in China offers several advantages. China has a well-established manufacturing infrastructure, lower labor costs, and a vast network of suppliers. Additionally, Chinese manufacturers have experience in producing a wide range of products, ensuring high-quality production at competitive prices.

2. How do I find reliable manufacturers for mini pneumatic cylinders in China?

To find reliable manufacturers, start by conducting thorough research. Utilize online platforms, trade directories, and industry-specific websites to identify potential suppliers. It is crucial to verify their credentials, including certifications, production capabilities, and quality control processes. Furthermore, requesting samples and conducting factory audits can help assess their reliability.

3. What factors should I consider when selecting a manufacturer in China?

Consider several factors when selecting a manufacturer, such as their experience in producing mini pneumatic cylinders, production capacity, quality control measures, pricing, lead times, and their ability to comply with international standards and regulations. Communication and language proficiency are also essential for effective collaboration.

4. How can I manage quality control during the manufacturing process?

To manage quality control, establish clear specifications and requirements with the manufacturer. Regular communication, including video conferences or factory visits, can help ensure that the mini pneumatic cylinders meet your standards. Implementing a comprehensive quality control plan, conducting inspections, and testing the products at various stages of production are effective quality assurance measures.

5. What are the payment terms and options with manufacturers in China?

Payment terms typically vary, but commonly used options include Telegraphic Transfer (T/T), Letter of Credit (L/C), and PayPal. Negotiate the payment terms that best suit your business and ensure transparency and security throughout the transaction process.

6. How long does the manufacturing process typically take?

The manufacturing process duration depends on factors such as production volume, complexity, and the manufacturer’s capacity. On average, it can take several weeks to several months, including the time for prototyping, tooling, production, quality control, and shipping. Clear communication and planning with the manufacturer can help establish realistic delivery dates.

7. What are the shipping options for importing mini pneumatic cylinders from China?

Shipping options include air freight, sea freight, and express courier services. The choice depends on factors such as delivery time requirements, cost, and the volume of products ordered. Chinese manufacturers often have experience coordinating international shipping and can assist in choosing the most suitable option.

Remember, sourcing and manufacturing mini pneumatic cylinders in China can be a fruitful endeavor if proper due diligence and effective communication are employed throughout the process.

Why contact sourcifychina.com get free quota from reliable mini pneumatic cylinder suppliers?

Sourcifychina.com offers a free quota from reliable mini pneumatic cylinder suppliers for several reasons. Firstly, Sourcifychina.com aims to provide a trusted platform for sourcing products from China. By offering a free quota from reliable suppliers, they assure their customers that they are partnering with genuine and trustworthy manufacturers.

Secondly, establishing a relationship with reliable suppliers is crucial for ensuring the quality and credibility of the products. Sourcifychina.com understands this and thus provides a free quota to allow customers to evaluate suppliers’ capabilities without any financial commitment. It enables customers to assess factors like product quality, production capacity, delivery time, and pricing before proceeding with any large-scale orders.

Moreover, this free quota service helps customers save time and effort in searching for suitable suppliers independently. Sourcifychina.com has already pre-screened and verified these suppliers, ensuring that they meet the required standards. By offering a free quota, customers can directly connect with these reliable suppliers, eliminating the need for extensive research and reducing the risk of dealing with untrustworthy or low-quality manufacturers.

Additionally, the free quota gives customers the opportunity to negotiate and compare pricing with multiple suppliers. This allows them to make informed decisions based on competitive offers and find the best possible deal for their requirements.

In summary, Sourcifychina.com provides a free quota from reliable mini pneumatic cylinder suppliers to build trust, ensure product quality, save time, facilitate direct connections, and enable price comparisons. This service ultimately benefits customers by streamlining the sourcing process and enhancing their chances of finding reputable suppliers for their mini pneumatic cylinder needs.