A Beginner’s Guide to electric motors manufacturer

An electric motor is a device that converts electrical energy into mechanical energy, which can be used to power various machines and appliances. Electric motors are widely used in industries, automobiles, and home appliances due to their efficiency, reliability, and low maintenance requirements. As a beginner, it is essential to understand the basics of electric motors and their manufacturers.

There are two main types of electric motors: AC (Alternating Current) motors and DC (Direct Current) motors. AC motors are commonly used in household appliances and industrial equipment, while DC motors are typically found in battery-powered devices and electric vehicles.

When looking for an electric motor manufacturer, consider the following factors:

1. Reputation: Choose a manufacturer with a good reputation in the industry for producing high-quality and reliable motors. Research online reviews, ask for recommendations, and check for any certifications or awards the company may have received.

2. Experience: Look for a manufacturer with a long history and experience in producing electric motors. This ensures that they have the necessary expertise and knowledge to produce high-quality products.

3. Product Range: A good manufacturer should offer a wide range of electric motors, catering to different applications and requirements. This includes various types of AC and DC motors, as well as motors with different power ratings, sizes, and features.

4. Customization: Some manufacturers offer customization options, allowing you to tailor the motor to your specific needs. This can be particularly useful if you have unique requirements or need a motor for a specialized application.

5. After-sales Support: A reliable manufacturer should provide excellent after-sales support, including technical assistance, spare parts availability, and warranty coverage. This ensures that you receive the necessary support and assistance throughout the motor’s lifespan.

Some well-known electric motor manufacturers include ABB, Siemens, GE, and Nidec. These companies have a strong presence in the market and are known for their high-quality products and excellent customer support.

In conclusion, understanding the basics of electric motors and their manufacturers is crucial for making informed decisions when purchasing a motor for your application. Consider factors such as reputation, experience, product range, customization options, and after-sales support when choosing a manufacturer to ensure you receive a high-quality and reliable product.

How to Select a Reliable electric motors manufacturer

Selecting a reliable electric motors manufacturer is crucial for ensuring the quality, efficiency, and longevity of your motors. Here are some key factors to consider when choosing a manufacturer:

1. Experience and Reputation: Look for a manufacturer with a proven track record in the industry. A company with several years of experience is more likely to have a strong understanding of the market and the latest technologies. Check online reviews, testimonials, and case studies to gauge their reputation and the satisfaction level of their clients.

2. Quality Certifications: A reliable manufacturer should have relevant quality certifications, such as ISO 9001, which demonstrate their commitment to maintaining high-quality standards in their products and processes. These certifications can provide assurance that the manufacturer follows industry best practices and adheres to strict quality control measures.

3. Technical Expertise: Choose a manufacturer with a strong technical team that can provide expert advice and support throughout the motor selection process. They should be able to understand your specific requirements and recommend the most suitable motor for your application. Additionally, they should be able to provide technical documentation, such as datasheets and performance curves, to help you make an informed decision.

4. Customization Capabilities: A reliable manufacturer should be able to offer customization options to meet your specific needs. This may include custom winding configurations, shaft modifications, or mounting options. Make sure the manufacturer has the flexibility and resources to accommodate your unique requirements.

5. After-sales Support: A good manufacturer should provide comprehensive after-sales support, including warranty coverage, spare parts availability, and technical assistance. This ensures that you have a reliable partner to turn to in case of any issues or maintenance requirements.

6. Competitive Pricing: While price should not be the sole determining factor, it is essential to choose a manufacturer that offers competitive pricing without compromising on quality. Request quotes from multiple manufacturers and compare their offerings to find the best value for your investment.

7. Lead Times and Delivery: Consider the manufacturer’s lead times and their ability to meet your delivery deadlines. A reliable manufacturer should have efficient production processes and a robust supply chain to ensure timely delivery of your motors.

By considering these factors, you can select a reliable electric motors manufacturer that meets your specific needs and ensures the quality and performance of your motors.

Comparing electric motors manufacturer and Suppliers: Which is Better?

When comparing electric motor manufacturers and suppliers, it is essential to consider various factors to determine which one is better suited for your needs. Here are some key aspects to consider:

1. Product Range: A good manufacturer or supplier should offer a wide range of electric motors to cater to different applications and industries. This includes various types, sizes, and power ratings. A broader product range indicates that the company is well-established and can cater to diverse customer requirements.

2. Quality and Reliability: The quality and reliability of electric motors are crucial for their performance and longevity. Look for manufacturers and suppliers with a reputation for producing high-quality, durable products. Check for certifications like ISO, CE, or UL, which indicate adherence to international quality standards.

3. Customization Capabilities: Depending on your specific requirements, you may need customized electric motors. A better manufacturer or supplier should have the capability to customize their products to meet your unique specifications.

4. Technical Support and Customer Service: A good manufacturer or supplier should provide excellent technical support and customer service. This includes assistance in selecting the right motor for your application, troubleshooting, and after-sales support. Look for companies with a dedicated team of engineers and technicians who can provide prompt and efficient support.

5. Pricing: Competitive pricing is essential when comparing manufacturers and suppliers. However, it is crucial not to compromise on quality for the sake of lower prices. A better company should offer a good balance between quality and cost.

6. Lead Time and Delivery: A reliable manufacturer or supplier should be able to deliver products within a reasonable time frame. Check their lead times and ensure they can meet your deadlines. Also, consider their shipping options and costs.

7. Reputation and Experience: A company with a long-standing reputation and experience in the industry is more likely to provide better products and services. Look for customer reviews, testimonials, and case studies to gauge their credibility and expertise.

In conclusion, the better electric motor manufacturer or supplier is the one that offers a comprehensive product range, high-quality and reliable products, customization capabilities, excellent technical support and customer service, competitive pricing, reasonable lead times, and has a strong reputation and experience in the industry. It is essential to evaluate these factors to make an informed decision that best suits your needs.

The Manufacturing Process of electric motors manufacturer

The manufacturing process of electric motors involves several key steps, including design, component production, assembly, and testing.

1. Design: The process begins with the design of the motor, which includes determining the specifications, such as power output, torque, speed, and efficiency. Engineers use computer-aided design (CAD) software to create detailed drawings and models of the motor components.

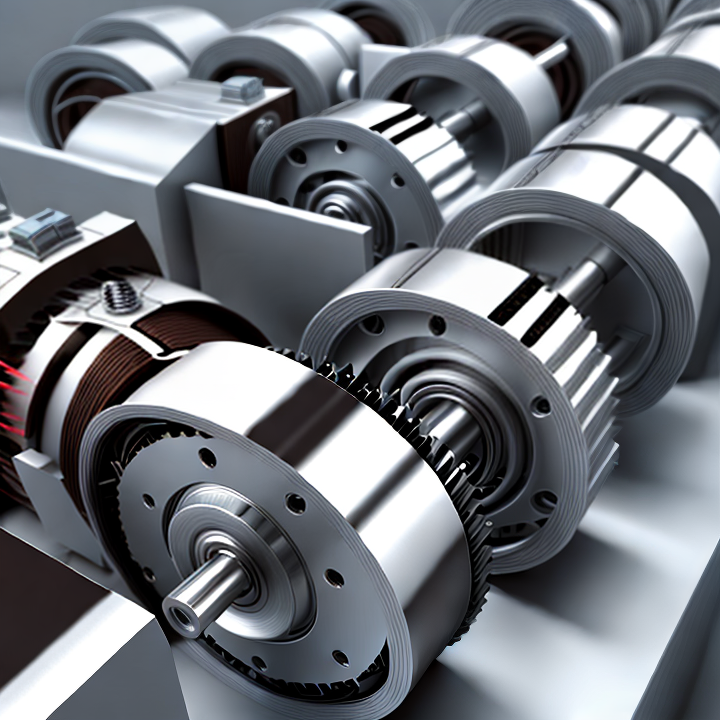

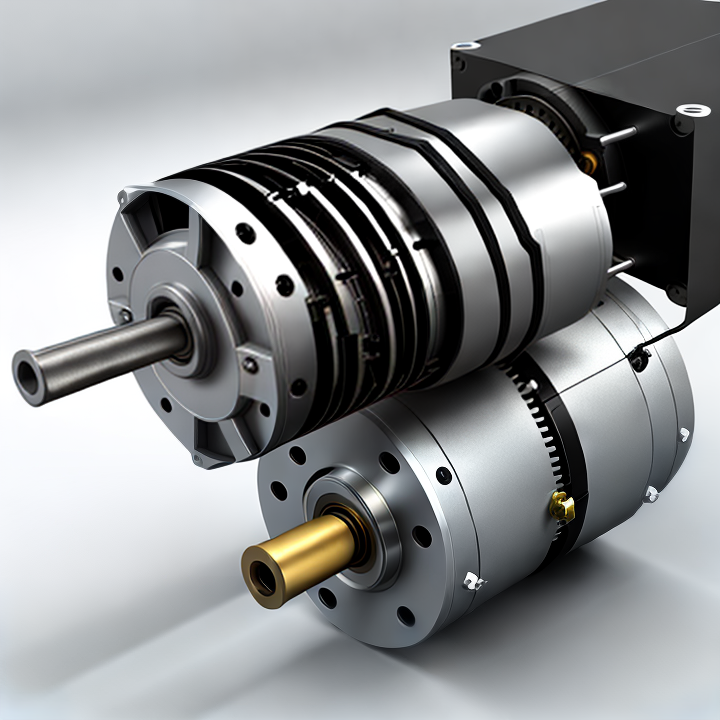

2. Component production: Once the design is finalized, the production of individual components begins. This includes the stator (stationary part), rotor (rotating part), bearings, shaft, and other parts. The stator is made by winding copper wire around a laminated iron core, while the rotor is made by casting aluminum or copper bars into a laminated iron core. These components are then machined to achieve the required dimensions and tolerances.

3. Assembly: The next step is the assembly of the motor components. The stator and rotor are placed together, with the rotor positioned inside the stator. Bearings are installed on the shaft, which is then inserted into the motor housing. The end shields, which hold the bearings in place, are attached to the housing. The assembly process may also include the installation of additional components, such as brushes, commutators, or electronic control units, depending on the motor type.

4. Testing: After assembly, the motors undergo rigorous testing to ensure they meet the required performance and quality standards. This may include tests for efficiency, power output, torque, speed, temperature, vibration, and noise levels. Any motors that fail to meet the required standards are either repaired or discarded.

5. Packaging and shipping: Once the motors have passed all tests, they are packaged and shipped to customers or distributors. The packaging process involves placing the motors in protective boxes or crates, along with any necessary accessories or documentation.

In summary, the manufacturing process of electric motors involves designing the motor, producing the components, assembling the motor, testing its performance, and finally packaging and shipping it to customers. This process requires a combination of skilled engineering, precision machining, and strict quality control to ensure the production of high-quality, reliable motors.

Custom Manufacturing Options for electric motors manufacturer

Electric motor manufacturers have several custom manufacturing options to cater to the diverse needs of their clients. These options allow manufacturers to produce motors that meet specific requirements, ensuring optimal performance and efficiency in various applications.

1. Custom Motor Design: Manufacturers can create custom motor designs based on client specifications, such as size, power output, speed, and torque. This may involve modifying existing designs or developing entirely new motor models to meet unique requirements.

2. Material Selection: Manufacturers can choose from a variety of materials for motor components, such as laminations, windings, bearings, and housings. Material selection can impact motor performance, durability, and cost. Clients may have specific material preferences based on their application or industry requirements.

3. Winding Configurations: Custom winding configurations can be developed to optimize motor performance for specific applications. This may involve altering the number of wire turns, wire gauge, or coil arrangement to achieve desired torque, speed, and efficiency characteristics.

4. Cooling Systems: Manufacturers can design custom cooling systems to manage heat dissipation in electric motors. This may include air or liquid cooling options, depending on the application’s thermal requirements and available space.

5. Enclosures and Mounting Options: Custom enclosures and mounting options can be designed to fit specific application requirements. This may involve creating unique motor housings, mounting brackets, or flange designs to ensure proper motor integration and alignment.

6. Custom Shaft and Bearing Options: Manufacturers can offer various shaft and bearing options to meet specific application needs. This may include custom shaft lengths, diameters, keyways, or splines, as well as specialized bearing types or materials for improved durability or performance.

7. Integrated Sensors and Controls: Electric motor manufacturers can integrate sensors and control systems into their custom motor designs. This may involve adding temperature, position, or speed sensors, as well as custom control algorithms for improved motor performance and efficiency.

8. Specialized Coatings and Finishes: Manufacturers can apply specialized coatings and finishes to motor components for enhanced durability, corrosion resistance, or aesthetic appeal. This may include powder coating, anodizing, or plating processes.

9. Certifications and Compliance: Manufacturers can ensure that custom electric motors meet specific industry standards or certifications, such as UL, CE, or NEMA. This may involve additional testing and documentation to verify compliance with these standards.

By offering these custom manufacturing options, electric motor manufacturers can provide clients with tailored solutions that meet their unique application requirements, ensuring optimal performance, reliability, and efficiency.

Quality Control in electric motors manufacturer

Quality control is a crucial aspect in the manufacturing of electric motors, as it ensures that the final products meet the required performance, safety, and reliability standards. In an electric motor manufacturing company, quality control involves a series of processes and procedures that are designed to identify and rectify any defects or deviations from the specified requirements at various stages of production.

The quality control process in electric motor manufacturing begins with the inspection and verification of raw materials and components. This involves checking the quality of materials such as copper, steel, and insulation materials, as well as the components like bearings, brushes, and capacitors. Suppliers must provide certificates of conformity to ensure that the materials and components meet the required specifications.

During the production process, quality control measures are implemented at various stages to ensure that the manufacturing process is carried out according to the predefined standards. This includes monitoring and controlling the winding process, assembly, and testing of the motors. In-process inspections are conducted to identify any deviations from the set standards and take corrective actions immediately.

Testing is a critical part of the quality control process in electric motor manufacturing. Motors are subjected to various tests, such as performance tests, insulation resistance tests, temperature rise tests, and vibration tests, to ensure that they meet the required specifications. These tests help in identifying any defects or issues that may affect the performance, safety, and reliability of the motors.

In addition to these tests, electric motor manufacturers also implement quality management systems, such as ISO 9001, to ensure that the entire organization is committed to maintaining high-quality standards. This involves continuous improvement of processes, employee training, and regular audits to ensure compliance with the quality management system.

In conclusion, quality control in electric motor manufacturing is essential to ensure that the final products meet the required performance, safety, and reliability standards. This is achieved through a combination of inspections, testing, and adherence to quality management systems. By implementing effective quality control measures, electric motor manufacturers can minimize the risk of product failures, reduce warranty claims, and maintain a strong reputation in the market.

Import and Export Regulations for electric motors manufacturer

Electric motors manufacturers must adhere to various import and export regulations to ensure compliance with international trade laws and standards. These regulations are in place to maintain safety, quality, and environmental standards, as well as to prevent illegal activities such as smuggling and counterfeiting. The following are some key import and export regulations that electric motors manufacturers should be aware of:

1. Product Classification: Electric motors are classified under the Harmonized System (HS) code, which is a standardized system for classifying traded products. Manufacturers must correctly classify their products under the appropriate HS code to ensure compliance with customs requirements and to determine applicable tariffs and taxes.

2. Safety and Quality Standards: Electric motors must meet specific safety and quality standards in the importing country. For example, in the European Union, electric motors must comply with the Low Voltage Directive (LVD) and the Machinery Directive. In the United States, electric motors must meet the standards set by the National Electrical Manufacturers Association (NEMA) and Underwriters Laboratories (UL).

3. Environmental Regulations: Electric motors manufacturers must comply with environmental regulations in both the exporting and importing countries. This may include regulations related to energy efficiency, hazardous substances, and waste management. For example, electric motors sold in the European Union must comply with the Ecodesign Directive and the Restriction of Hazardous Substances (RoHS) Directive.

4. Export Controls: Some countries may impose export controls on electric motors, particularly if they are considered to have potential military applications or if they are subject to trade sanctions. Manufacturers should consult their country’s export control regulations to ensure compliance.

5. Customs Documentation: When exporting electric motors, manufacturers must provide accurate and complete customs documentation, including commercial invoices, packing lists, and certificates of origin. These documents are necessary for customs clearance and to determine applicable duties and taxes.

6. Intellectual Property Rights: Electric motors manufacturers should be aware of intellectual property rights (IPR) regulations in the importing country. This includes ensuring that their products do not infringe on any patents, trademarks, or copyrights, and obtaining any necessary licenses or permissions.

7. Anti-Dumping and Countervailing Duties: In some cases, importing countries may impose anti-dumping or countervailing duties on electric motors if they believe that the products are being sold at unfairly low prices or are subsidized by the exporting country’s government. Manufacturers should be aware of these potential duties and factor them into their pricing strategies.

In conclusion, electric motors manufacturers must navigate a complex web of import and export regulations to ensure compliance with international trade laws and standards. By understanding and adhering to these regulations, manufacturers can minimize the risk of legal issues, protect their intellectual property, and maintain a competitive edge in the global market.

The Role of Agents and Sourcing Companies in Facilitating Purchases from electric motors manufacturer

Agents and sourcing companies play a crucial role in facilitating purchases from electric motors manufacturers. These intermediaries bridge the gap between buyers and manufacturers, ensuring a smooth and efficient procurement process. Their expertise in the industry, market knowledge, and established relationships with manufacturers make them invaluable partners for businesses looking to purchase electric motors.

One of the primary roles of agents and sourcing companies is to identify and evaluate potential manufacturers. They conduct thorough research and assess the capabilities, production capacity, quality standards, and pricing of various electric motor manufacturers. This helps buyers make informed decisions and choose the most suitable manufacturer for their needs.

Another key function of agents and sourcing companies is to negotiate the best possible terms and conditions for their clients. They leverage their industry knowledge and relationships with manufacturers to secure competitive pricing, favorable payment terms, and timely delivery schedules. This not only saves time and resources for the buyer but also ensures that they get the best value for their investment.

Quality control is another critical aspect of the procurement process that agents and sourcing companies manage. They work closely with manufacturers to ensure that the electric motors produced meet the required specifications and quality standards. They may also arrange for third-party inspections and certifications to guarantee product compliance and performance.

Furthermore, agents and sourcing companies assist in managing the logistics and documentation involved in international trade. They coordinate with manufacturers, freight forwarders, and customs authorities to ensure that the electric motors are shipped and delivered efficiently and in compliance with all applicable regulations.

In conclusion, agents and sourcing companies play a vital role in facilitating purchases from electric motor manufacturers. They help buyers navigate the complex procurement process, ensuring that they select the right manufacturer, negotiate favorable terms, maintain quality standards, and manage logistics. By partnering with these intermediaries, businesses can save time, resources, and mitigate risks associated with international trade, ultimately leading to a successful and cost-effective procurement experience.

Supply Chain Management for electric motors manufacturer

Supply Chain Management (SCM) is a crucial aspect for any electric motor manufacturer, as it involves the efficient management of raw materials, components, and finished products, ensuring timely delivery and cost optimization. In the electric motor industry, the supply chain encompasses various stages, including procurement, production, transportation, and distribution.

The first step in SCM for an electric motor manufacturer is procurement, which involves sourcing raw materials and components such as copper, steel, magnets, and bearings from reliable suppliers. This process requires establishing long-term relationships with suppliers, negotiating contracts, and monitoring supplier performance to ensure quality and timely delivery of materials.

Next, the production stage involves transforming raw materials into finished electric motors through various processes such as machining, assembly, and testing. Efficient production planning and scheduling are essential to minimize lead times, reduce inventory costs, and ensure the availability of finished products to meet customer demand. This stage also involves managing the workforce, equipment, and facilities to optimize productivity and minimize production costs.

Transportation and logistics play a vital role in SCM, as they ensure the timely delivery of raw materials to the production facilities and finished products to the customers. This involves selecting the most cost-effective and reliable transportation modes, optimizing routes, and managing freight costs. Additionally, warehousing and inventory management are crucial to store raw materials, work-in-progress, and finished products, ensuring their availability when needed.

The final stage of SCM is distribution, which involves delivering the finished electric motors to the customers. This requires efficient order management, customer service, and after-sales support to ensure customer satisfaction and maintain long-term relationships. Moreover, effective demand forecasting and sales planning are essential to balance supply and demand, preventing stockouts or excess inventory.

In conclusion, effective supply chain management is crucial for electric motor manufacturers to ensure the timely delivery of high-quality products at competitive prices. By optimizing procurement, production, transportation, and distribution processes, manufacturers can enhance their competitiveness, improve customer satisfaction, and achieve sustainable growth in the dynamic electric motor industry.

Negotiating with electric motors manufacturer

Subject: Partnership Proposal for Electric Motors Manufacturing

Dear [Manufacturer’s Name],

I hope this email finds you well. I am reaching out to explore the possibility of a mutually beneficial partnership between [Your Company’s Name] and [Manufacturer’s Name] in the electric motors manufacturing sector. Our company has been closely following the impressive growth and innovative products of [Manufacturer’s Name], and we believe that a collaboration between our organizations could lead to significant advancements in the industry.

As a leading player in the [Your Industry], we have a strong network of clients and partners who are increasingly seeking energy-efficient and environmentally friendly solutions. We believe that integrating your cutting-edge electric motors into our product offerings would not only meet the growing demand but also position both our companies as pioneers in sustainable technology.

To ensure a successful partnership, we propose the following key points for discussion:

1. Product Customization: Collaborating on the design and development of electric motors tailored to the specific needs of our clients, ensuring optimal performance and seamless integration with our existing product line.

2. Pricing and Discounts: Establishing a competitive pricing structure and volume-based discounts to incentivize the adoption of electric motors among our clients and partners.

3. Technical Support and Training: Providing our team with comprehensive training and ongoing technical support to ensure the successful implementation and maintenance of electric motor solutions.

4. Marketing and Promotion: Jointly promoting our partnership and the benefits of electric motors through various marketing channels, including trade shows, industry events, and online platforms.

5. Exclusivity: Exploring the possibility of an exclusive partnership in our target markets to strengthen our competitive edge and foster long-term growth.

We are excited about the potential of this partnership and are confident that our combined expertise and resources will lead to significant achievements in the electric motors manufacturing space. We would be grateful for the opportunity to discuss this proposal further and address any questions or concerns you may have.

Please let us know your availability for a call or meeting at your earliest convenience. We look forward to the possibility of working together and making a lasting impact on the industry.

Best regards,

[Your Name] [Your Company’s Name] [Your Contact Information]Protecting Intellectual Property When Working with electric motors manufacturer

Protecting intellectual property (IP) is crucial when working with an electric motors manufacturer, as it ensures that your innovations, designs, and ideas are not misused or copied without your permission. Here are some steps to take to safeguard your IP:

1. Identify your IP assets: The first step is to identify the intellectual property assets that need protection. These may include patents, trademarks, copyrights, and trade secrets related to your electric motor designs, technology, and manufacturing processes.

2. Non-disclosure agreements (NDAs): Before sharing any sensitive information with the manufacturer, have them sign a non-disclosure agreement (NDA). This legally binding document ensures that the manufacturer cannot disclose or use your confidential information for any purpose other than the agreed-upon project.

3. Conduct due diligence: Research the manufacturer’s reputation and track record in the industry. Check for any history of IP infringement or legal disputes related to intellectual property. This will help you determine if the manufacturer is trustworthy and reliable.

4. Register your IP: Register your patents, trademarks, and copyrights in the countries where you plan to manufacture and sell your electric motors. This will provide you with legal protection and the ability to enforce your rights in case of infringement.

5. Monitor and enforce your IP rights: Regularly monitor the market for any potential infringement of your IP. If you find any unauthorized use of your intellectual property, take swift legal action to enforce your rights and prevent further infringement.

6. Maintain control over critical IP: Limit the access to your most valuable IP assets to a select few individuals within your organization and the manufacturer. This will minimize the risk of unauthorized disclosure or misuse of your IP.

7. Include IP clauses in contracts: When drafting contracts with the manufacturer, include clauses that clearly outline the ownership and usage rights of your IP. This will help prevent any misunderstandings and potential disputes in the future.

8. Work with IP experts: Consult with intellectual property attorneys and experts to ensure that your IP protection strategy is comprehensive and effective. They can help you navigate the complexities of IP law and provide guidance on the best practices for safeguarding your assets.

By taking these steps, you can protect your intellectual property when working with an electric motors manufacturer, ensuring that your innovations and ideas remain secure and under your control.

Avoiding Scams When Working with electric motors manufacturer

When working with electric motors manufacturers, it is essential to be cautious and take necessary steps to avoid scams and fraudulent activities. Here are some tips to help you ensure a safe and secure business relationship with electric motor manufacturers:

1. Research the manufacturer: Before engaging with any electric motor manufacturer, conduct thorough research on their background, reputation, and credibility. Check for online reviews, testimonials, and any potential red flags. Look for a proven track record of successful projects and satisfied customers.

2. Verify their credentials: Ensure that the manufacturer has the necessary certifications, licenses, and permits to operate in their respective industry. This may include ISO certifications, CE marking, or other relevant industry-specific certifications. Request for copies of these documents and verify their authenticity.

3. Check for a physical address: A legitimate electric motor manufacturer should have a verifiable physical address. Be cautious of companies that only provide a PO Box or virtual office address. If possible, visit the manufacturer’s facility to get a firsthand look at their operations and assess their capabilities.

4. Request for references: Ask the manufacturer for a list of clients they have worked with in the past. Contact these clients to inquire about their experiences with the manufacturer and the quality of the products they received.

5. Obtain detailed quotations: Request for detailed quotations from multiple manufacturers to compare prices, lead times, and terms of payment. Be cautious of manufacturers offering prices that are significantly lower than the industry average, as this may be an indication of substandard products or a potential scam.

6. Use secure payment methods: Avoid making payments through unsecured channels or using methods that offer little to no protection, such as wire transfers. Instead, opt for secure payment methods such as credit cards or escrow services that provide a level of protection in case of disputes.

7. Establish clear communication: Maintain open and transparent communication with the manufacturer throughout the entire process. Ensure that all agreements, specifications, and expectations are clearly documented in writing to avoid misunderstandings and potential disputes.

8. Monitor the production process: If possible, conduct regular inspections during the production process to ensure that the electric motors are being manufactured according to your specifications and quality standards.

By following these guidelines, you can minimize the risk of scams and ensure a successful partnership with a reputable electric motor manufacturer.

How to use import and export data website importyeti.com to search the company and electric motors manufacturer

ImportYeti is a powerful search engine that allows you to access and analyze US import data, including information on companies and manufacturers. To search for a specific company and electric motors manufacturer using ImportYeti, follow these simple steps:

1. Visit the ImportYeti website: Go to https://www.importyeti.com/ to access the search engine.

2. Enter the search query: In the search bar, type in the name of the company or electric motors manufacturer you are looking for. For example, if you are searching for a company called “ABC Motors,” type “ABC Motors” in the search bar.

3. Refine your search: If you want to narrow down your search results, you can use filters available on the ImportYeti website. For example, you can filter by country of origin, HS code (Harmonized System code), or date range. To do this, click on the “Filters” button located below the search bar and select the appropriate filters.

4. Analyze the search results: After entering your search query and applying any desired filters, click the “Search” button. ImportYeti will display a list of search results related to your query. Each result will show the company name, address, and a summary of their import data.

5. Review the import data: Click on the company name in the search results to access more detailed information about their import activities. This will include data such as the total number of shipments, shipment details, product descriptions, and more.

6. Export the data: If you want to save the import data for further analysis or reporting, ImportYeti allows you to export the data in various formats, such as CSV, Excel, or PDF. To export the data, click on the “Export” button located at the top right corner of the page and select your preferred format.

By following these steps, you can efficiently use ImportYeti to search for companies and electric motors manufacturers, gaining valuable insights into their import activities and making informed business decisions.

How to use Chinese Business Search Platform: qcc.com to check electric motors manufacturer company credit

Qcc.com is a Chinese business search platform that provides information on companies, including their credit status, financial data, and other relevant details. To check the credit of an electric motors manufacturer company on qcc.com, follow these steps:

1. Visit the website: Go to qcc.com in your web browser. The website is in Chinese, so you may need to use a translation tool like Google Translate to navigate the site.

2. Create an account: To access the full range of information on qcc.com, you will need to create an account. Click on the “注册” (Register) button at the top right corner of the homepage and follow the instructions to sign up.

3. Search for the company: Once you have logged in, enter the name of the electric motors manufacturer company in the search bar at the top of the page. Click the magnifying glass icon or press “Enter” to start the search.

4. Select the correct company: The search results will display a list of companies with similar names. Identify the correct company by checking the company’s address, legal representative, or other identifying information. Click on the company name to access its detailed information page.

5. Check the company credit: On the company information page, you will find various sections with details about the company’s registration, financial data, and credit status. Look for the “信用评级” (Credit Rating) section, which will display the company’s credit score and rating. A higher score indicates a better credit status.

6. Review additional information: Besides the credit rating, you can also check other relevant information about the company, such as its business scope, registration status, shareholders, and financial data. This information can help you assess the overall credibility and stability of the electric motors manufacturer company.

7. Save or export the information: If you want to keep a record of the company’s credit information, you can save the page as a PDF or export the data to a spreadsheet. This will allow you to easily compare the credit status of different electric motors manufacturers.

By following these steps, you can use qcc.com to check the credit of electric motors manufacturer companies in China, helping you make informed decisions when selecting a supplier or business partner.

How to use archive.org to check electric motors manufacturer business website history

Archive.org, also known as the Wayback Machine, is a digital archive that allows users to access historical versions of websites. To check the history of an electric motors manufacturer’s business website, follow these steps:

1. Visit archive.org: Open your web browser and go to the Archive.org website (https://archive.org/).

2. Locate the Wayback Machine search bar: On the homepage, you will find a search bar labeled “Wayback Machine” at the top of the page.

3. Enter the website URL: Type or paste the URL of the electric motors manufacturer’s business website into the search bar. Make sure to include the “http://” or “https://” prefix and press Enter.

4. View the website’s history: After pressing Enter, you will be taken to a calendar view that displays the history of the website. Each blue circle on the calendar represents a snapshot of the website on that specific date. The more circles you see, the more frequently the website was archived.

5. Browse the snapshots: Click on a blue circle to view the website’s snapshot for that date. You can navigate through the website as you would on the live version, but keep in mind that some links or images may not work properly in the archived version.

6. Compare different snapshots: To compare different versions of the website, open multiple snapshots in separate tabs or windows. This will allow you to see how the website has evolved over time, including changes in design, content, and product offerings.

7. Analyze the website’s history: As you browse through the snapshots, take note of any significant changes or trends in the electric motors manufacturer’s business. This can provide valuable insights into the company’s growth, strategy, and market positioning.

By using Archive.org, you can gain a comprehensive understanding of an electric motors manufacturer’s business website history, helping you make informed decisions about potential partnerships, investments, or purchases.

Why contact sourcifyChina.com get free quota from reliable electric motors manufacturer?

Contacting SourcifyChina.com to get a free quote from reliable electric motor manufacturers is a smart move for businesses looking to source high-quality, cost-effective electric motors from China. Here are the top reasons why you should consider reaching out to SourcifyChina.com:

1. Expertise in the Chinese market: SourcifyChina.com has extensive knowledge and experience in the Chinese manufacturing industry. They have built strong relationships with reliable suppliers and manufacturers, ensuring that you get the best possible deal for your electric motors.

2. Quality assurance: SourcifyChina.com only works with reputable manufacturers that have a proven track record of producing high-quality products. They perform thorough quality checks and inspections to ensure that the electric motors you receive meet your expectations.

3. Competitive pricing: By working directly with manufacturers, SourcifyChina.com can negotiate the best possible prices for your electric motors. This means you can save money without compromising on quality.

4. Customization options: SourcifyChina.com can help you find manufacturers that offer customization options for your electric motors, allowing you to tailor the product to your specific needs and requirements.

5. Time-saving: Sourcing products from China can be a time-consuming process, especially if you’re unfamiliar with the market. SourcifyChina.com takes care of the entire sourcing process for you, from finding the right manufacturer to handling logistics and shipping, allowing you to focus on other aspects of your business.

6. Risk reduction: SourcifyChina.com’s expertise and experience in the Chinese market help mitigate the risks associated with international trade, such as language barriers, cultural differences, and potential scams.

7. Free quote: By offering a free quote, SourcifyChina.com allows you to explore your options without any financial commitment. This enables you to make an informed decision about whether sourcing electric motors from China is the right choice for your business.

In conclusion, contacting SourcifyChina.com to get a free quote from reliable electric motor manufacturers is a wise decision for businesses looking to source high-quality, affordable electric motors from China. Their expertise, quality assurance, competitive pricing, customization options, time-saving services, risk reduction, and free quote make them an invaluable partner in your sourcing journey.