List Technical Parameters of “water bottle manufacturer”

The technical parameters that are important for a water bottle manufacturer include the material of the bottle, capacity, design, weight, durability, and safety features.

Material: Manufacturers use different materials to make water bottles, including glass, plastic, stainless steel, aluminum, and ceramic. The choice of material depends on the desired qualities of the bottle, such as durability, weight, insulation, and resistance to breakage.

Capacity: Water bottles come in different sizes, ranging from small bottles that can hold 250ml of water to large ones that can hold up to 2 liters. The capacity of the bottle is determined by the intended use, such as outdoor activities, sports, or everyday use.

Design: The design of the water bottle can have a significant impact on its usability and functionality. Water bottle manufacturers design bottles with different features, such as handles, spouts, straws, and caps, to make them easier to use, clean, and carry.

Weight: Water bottle weight is an important factor for those who carry their bottles for extended periods. Lighter bottles are easier to carry and reduce the overall weight load. Different materials are used to achieve lightweight bottles, such as plastic and aluminum.

Durability: The durability of water bottles is important for outdoor activities and sports. Durable bottles are resistant to damage and can withstand harsh conditions such as high temperatures and rough handling.

Safety features: Manufacturers ensure the safety of their water bottles through the use of non-toxic materials, BPA-free plastic, and leak-proof caps. These features help prevent contamination and ensure the water remains safe for consumption.

In conclusion, a water bottle manufacturer must consider multiple technical parameters such as material, capacity, design, weight, durability, and safety features. This ensures that their product meets the consumer’s needs and preferences for a functional and safe water bottle.

List Product features of “water bottle manufacturer”

A water bottle manufacturer is a company that specializes in producing various types of water bottles. There are several product features that a water bottle manufacturer can offer to their customers, including:

1. Material: Most water bottle manufacturers use plastic, stainless steel, glass, or aluminum to create water bottles. Each material has its unique benefits and drawbacks in terms of durability, weight, and portability.

2. Size: Water bottle manufacturers can produce water bottles ranging from 12oz to 64oz in capacity. This means that you can find a water bottle that fits your hydration needs and lifestyle.

3. Shape: Water bottles come in various shapes, including cylindrical, square, or flat, and with different mouth openings such as narrow or wide. The shape of a water bottle can affect its ease of use and capacity.

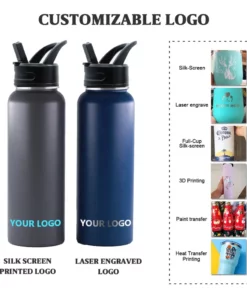

4. Customization: Water bottle manufacturers can customize water bottles with logos, colors, and labels for various events, promotions, or branding purposes.

5. Insulation: Insulated water bottles keep drinks hot or cold for an extended period and are perfect for outdoor activities or long commutes.

6. Cap or closure: Most water bottles have an easy-to-use cap or closure, such as a screw-on lid, flip-top, or push-pull spout. The type of cap can affect the ease of drinking and the bottle’s leak-proofing.

7. Accessories: Some water bottle manufacturers offer accessories such as carrying straps, bottle brushes, or replacement caps to enhance the user’s experience.

8. Safety: Water bottle manufacturers must ensure that their products meet safety standards to prevent chemical leaching and contamination.

In conclusion, a water bottle manufacturer can offer various product features to meet different customers’ preferences and needs in terms of material, size, shape, customization, insulation, cap or closure, accessories, and safety.

List Application of “water bottle manufacturer”

Water bottle manufacturing is a rapidly growing industry as more people realize the importance of carrying water with them wherever they go. The application of water bottle manufacturers is broad and reaches many industries including sports, outdoor activities, travel, and healthcare. Below are some specific applications of water bottle manufacturers:

1. Sports industry: Water bottles are essential for athletes during training or competitions. Manufacturers can produce water bottles designed specifically for different types of sports, such as cycling, running, or hiking. These bottles can be designed to be lightweight, easy to grip, and leak-proof.

2. Outdoor activities: Water bottles for outdoor activities such as camping or fishing should be durable, leak-proof, and insulated. Manufacturers can produce water bottles that are able to keep water cold for several hours without adding any extra weight to the user’s backpack.

3. Travel: Travelers also require water bottles that are easy to carry, spill-proof, and leak-proof. Water bottle manufacturers can produce travel-friendly bottles that can easily fit into backpacks, bags, or carry-on luggage.

4. Healthcare industry: The healthcare industry also makes use of water bottles, particularly those designed to be used by patients in hospitals or care facilities. Manufacturers can produce bottles that are safe for use with medications and easy to clean to reduce the risk of infections.

5. Corporate branding: Many companies use water bottle manufacturers to produce branded water bottles that they can give away as promotional items or to their employees. These bottles can be customized with the company logo and used as a marketing tool.

In conclusion, the application of water bottle manufacturers is broad and reaches several industries. Water bottles designed for different activities and purposes have different specifications, and manufacturers can produce customizable bottles to suit the specific needs of each industry.

List Various Types of “water bottle manufacturer”

1. Single-use plastic water bottle manufacturer – These manufacturers produce disposable water bottles made of plastic that are intended to be used only once. These bottles are not recyclable and contribute to plastic pollution.

2. Reusable water bottle manufacturer – These manufacturers produce durable water bottles that can be used multiple times. These bottles are often made of materials such as stainless steel, glass, or BPA-free plastic.

3. Collapsible water bottle manufacturer – These manufacturers produce water bottles that can be compressed when they are empty, making them ideal for hiking, camping, and other outdoor activities where space is limited.

4. Filtering water bottle manufacturer – These manufacturers produce water bottles that have built-in filters, which purify tap water or other water sources as it is poured into the bottle.

5. Insulated water bottle manufacturer – These manufacturers produce water bottles that can keep liquids cold or hot for hours, making them ideal for outdoor activities or long commutes.

6. Custom water bottle manufacturer – These manufacturers allow custom designs, logos, or text to be printed on water bottles. They are often used as marketing tools or for special events.

7. Sports water bottle manufacturer – These manufacturers produce water bottles that are specifically designed for athletes and sports enthusiasts. These bottles typically have a non-slip grip, are easy to carry, and provide easy access to water during physical activity.

8. Kids water bottle manufacturer – These manufacturers produce water bottles that are designed for children, with features such as spill-proof lids, fun designs, and smaller sizes.

Overall, the water bottle manufacturing industry has evolved to cater to the various needs and preferences of consumers, whether it be convenience, sustainability, or functionality.

List The Evolution history of “water bottle manufacturer”

The evolution history of water bottle manufacturing has been marked by significant advancements in design, materials, and technology. Initially, water bottles were mostly made of glass and were primarily used for storing and transporting liquids such as milk, juice, and soda. However, with advances in plastic molding techniques, plastic bottles emerged in the 1970s, and they soon became popular for consumer use.

The 1990s saw the introduction of environmentally-friendly bottles, made from recycled plastics, and the introduction of the first collapsible and reusable water bottles. In the early 2000s, with concerns about environmental pollution and the harmful effects of plastic, innovative water bottle manufacturing companies began exploring non-plastic options for water bottles, including glass and stainless steel.

Nowadays, water bottle manufacturers focus on producing sustainable, reusable, and durable products. Also, they are striving to reduce the carbon footprint from the manufacturing process, aiming for eco-friendly packaging and using recycled materials in their manufacturing.

The hydration market is highly competitive, and companies are constantly innovating to produce high-quality bottles with unique features, advanced insulation, hygiene mechanisms, and design appeal. Consumers are becoming environmentally-conscious and perceive reusable bottles as an eco-friendly option than single-use alternatives.

In conclusion, as the awareness of environmental impact on climate change grows, water bottle manufacturers have evolved to offer products that meet consumer’s preferences and eco-friendly goals. Thus, the water bottle industry continues to change and evolve, and the focus on innovative, eco-friendly, and sustainable products will drive the future of water bottle manufacturing.

List The Process of “water bottle manufacturer”

The process of water bottle manufacturing starts with designing the bottle. This may involve computer-aided design (CAD) or manual sketching. Once the design is finalized, it is sent to the mold-making department. Here, a mold is created based on the design specifications. The mold is made of steel and is designed in a way that allows molten plastic to take its shape.

The next step is the plastic injection molding process. Plastic pellets are loaded into the injection molding machine, where they are heated until they become liquid. The liquid plastic is injected into the mold cavity and left to cool and solidify. Once the plastic is solid, the mold is opened and the finished bottle is removed.

After the bottle is formed, it is sent to be decorated. This may involve applying labels or screen printing the company’s logo or artwork. The bottles are then sent for quality control checks to ensure they meet the required standards for strength, durability, and safety.

Once the bottles are approved, they are packaged and prepared for shipping. The packaging may vary – some companies prefer to pack the bottles in shrink-wrap or cardboard boxes, while others use plastic bags or individual packaging.

In summary, the process of water bottle manufacturing involves designing, mold-making, plastic injection molding, decoration, quality control checks, and packaging. This process ensures that the final product meets the required standards and is ready for sale to the public.

How to use “water bottle manufacturer”

A water bottle manufacturer is a company that produces different types of water bottles. These bottles can range from plastic, metal, or glass and can come in various sizes and shapes. Water bottle manufacturers cater to a vast range of clients, from individuals to large corporations.

To use a water bottle manufacturer, you need to follow some steps. First, you should determine the kind of bottles you need. For instance, if you want to make custom water bottles for your business, you should specify the design, color, size, and material.

Once you have your specifications, you can start looking for the right water bottle manufacturer. You can search for manufacturers online or ask for referrals from other businesses or individuals who have used their services before. It would be best if you also read reviews and check the manufacturer’s reputation.

After selecting a manufacturer, you should contact them and provide them with your specifications. The manufacturer will then provide you with a quote and the estimated turnaround time. If you agree with the quote, you can then proceed to make an order.

It is important to note that the cost of manufacturing water bottles will depend on various factors, such as the materials used, design complexity, and the quantity ordered. The more bottles you order, the lower the unit cost will be.

Finally, you should ensure that you have a good working relationship with the manufacturer. This will help you to get quality products and ensure that the manufacturing process is smooth. Additionally, you should ensure that you communicate effectively and regularly with the manufacturer to avoid any delays or problems during the manufacturing process.

In conclusion, using a water bottle manufacturer is a useful way of getting custom water bottles for your business or personal use. To get the best results, you should follow the outlined steps and work with a reliable and reputable manufacturer.

List Properties of “water bottle manufacturer”

Water bottle manufacturers are companies that produce and distribute various types of water bottles to meet the demand of consumers all over the world. These manufacturers create water bottles that cater to different needs, including travel, outdoor activities, sports, personal use, and even medical purposes.

One major property of water bottle manufacturers is their ability to create environmentally sustainable water bottles. They use materials that are eco-friendly, such as bioplastics, recycled plastic, and glass. These bottles can be reused many times and are designed to minimize waste. This property is essential because it helps to reduce the impact of plastic waste on the environment.

Another critical property of water bottle manufacturers is their ability to create durable and functional water bottles. They use high-quality materials to manufacture bottles that are leak-proof, shatterproof, and easy to refill. These bottles are designed to withstand various activities and harsh conditions, making them suitable for people with an active lifestyle.

Water bottle manufacturers also focus on creating innovative designs that appeal to different consumers. They offer a wide range of sizes, shapes, colors, and patterns to meet diverse preferences. Some water bottle manufacturers also provide customization options that allow customers to add their personal touch to the bottles.

Moreover, water bottle manufacturers prioritize health and safety. They ensure that the materials used in manufacturing water bottles are food-grade and safe for consumers. Some manufacturers also incorporate features like UV protection, insulation, and filtration systems to enhance the quality of the water stored in the bottles.

Finally, water bottle manufacturers are known for producing products that are affordable and accessible. They cater to consumers from all walks of life, offering water bottles at different price points to meet various budgets. Many manufacturers also distribute their products globally, making it easy for consumers to access high-quality water bottles no matter where they are in the world.

In summary, some properties of water bottle manufacturers include eco-friendliness, durability, functionality, innovation, health and safety, and affordability. These properties help manufacturers to meet the needs of consumers and promote a healthier and more sustainable lifestyle.

List “water bottle manufacturer” FAQ

1. What materials do you use to make your water bottles?

We use a variety of materials, such as stainless steel, aluminum, and BPA-free plastics to make our water bottles.

2. Are your water bottles dishwasher safe?

Most of our water bottles are dishwasher safe, but please refer to the care instructions on the packaging to ensure proper cleaning.

3. Do you offer custom designs for water bottles?

Yes, we offer custom designs for water bottles. Please contact our customer service team to discuss your needs.

4. Can I use hot beverages in your water bottles?

Some of our water bottles are designed to hold hot beverages, but please refer to the packaging or product description to make sure the bottle is suitable for hot liquids.

5. Are your water bottles eco-friendly?

Yes, we are committed to using environmentally friendly materials and production methods to reduce our carbon footprint.

6. Can I order in bulk for my business or organization?

Yes, we offer bulk ordering for businesses and organizations. Please contact our sales department to discuss your needs.

7. What is your return policy for water bottles?

We have a 30-day return policy for our water bottles. If you are not satisfied with your purchase, please contact our customer service team for assistance.

8. Do you offer a warranty for your water bottles?

Yes, we offer a warranty for our water bottles. Please refer to the packaging or product description for specific details.

9. What sizes do your water bottles come in?

We offer a range of sizes for our water bottles, from small 12oz bottles to large 32oz bottles. Please refer to the packaging or product description for specific details.

10. Can I order replacement parts for my water bottle?

Yes, we offer replacement parts for our water bottles. Please contact our customer service team to order replacement parts.