Types of Pulverizer machine

A pulverizer machine is a mechanical device used to grind various types of materials into fine powder or granules. There are different types of pulverizer machines based on their uses and functionality. In this article, we will discuss some of the commonly used types of pulverizers.

1. Hammer Mill Pulverizer: A hammer mill pulverizer is commonly used for crushing and grinding a variety of materials, such as grains, minerals, wood, chemicals, etc. They are efficient and relatively easy to operate. Hammer mills consist of a series of hammers mounted on a rotating shaft. The material is fed into the chamber and struck by the hammers, crushing it into small particles.

2. Ball Mill Pulverizer: A ball mill pulverizer is a cylindrical device used to grind or mix materials like ores, chemicals, ceramic raw materials, and paints. Ball mills rotate around a horizontal axis, grinding the material to a fine powder. The pulverizer is used in the mining, chemical, metallurgical, and pharmaceutical industries.

3. Impact Pulverizer: An impact pulverizer is a versatile machine used to pulverize various materials, including clay, metal, glass, rock, minerals, etc. It utilizes the principle of impact crushing, where the material is reduced in size by impulsive force.

4. Jet Pulverizer: A jet pulverizer, also known as a fluid energy mill, is used for fine grinding and pulverizing of materials. It uses high-speed compressed air to generate a jet stream that impacts the material, reducing its size. This type of pulverizer is commonly used in pharmaceutical, food processing, and chemical industries.

5. Disk Pulverizer: A disk pulverizer, also known as a disk mill, is a type of grinder that consists of a rotating disk with grooves or teeth to grind various materials. It is commonly used in laboratories for sample preparation and analysis.

6. Cage Mill Pulverizer: A cage mill pulverizer is a specialized pulverizing machine designed for breaking down or pulverizing materials into fine powder. It consists of a series of cages or bars to impact the material and reduce its size. This type of pulverizer is commonly used in the fertilizer and agricultural industries.

In conclusion, there are various types of pulverizer machines designed for different applications. Each type has its own unique features and benefits, depending on the materials being processed. From hammer mills to impact pulverizers and ball mills, these machines play a crucial role in various industries, helping to grind materials into fine powders or granules.

Pros and Cons of Using Pulverizer machine

A pulverizer machine is a mechanical device used to grind various types of materials into fine particles. It offers a cost-effective way to reduce hard metals, minerals, and raw materials for various applications. However, like any other equipment, a pulverizer machine has its own set of pros and cons.

One of the main advantages of using a pulverizer machine is its ability to process a wide range of materials. Whether it be rocks, minerals, plastics, or chemicals, the machine can effectively reduce them to the desired particle size. This versatility makes it suitable for various industries, including mining, pharmaceuticals, and agriculture.

Another benefit of using a pulverizer machine is its high efficiency. The machine operates at a high speed and uses air pressure to deliver a powerful impact force, which results in the quick and efficient grinding of materials. This can lead to increased productivity and reduced processing time, thus saving both time and money.

Furthermore, a pulverizer machine offers a consistent and uniform grinding result. It is designed with precision, ensuring that the particles are ground evenly, which is crucial for many applications. This uniformity allows for better quality control and ensures that the final product meets the required specifications.

On the other hand, there are also some disadvantages to using a pulverizer machine. One of the main concerns is the high energy consumption associated with the equipment. Due to its powerful grinding mechanism, the machine requires a significant amount of energy to operate. This can result in higher operational costs and increased electricity consumption.

Another disadvantage is the potential for wear and tear on the machine. The constant grinding action and impact force can lead to the deterioration of certain parts, requiring regular maintenance and repair. This can add to the overall operating costs and may cause downtime in the production process.

Lastly, the noise and vibration produced by a pulverizer machine can be a drawback in certain environments. The high-speed operation of the machine can generate a considerable amount of noise, which may cause disturbance or discomfort to the operators or nearby personnel. Additionally, the vibration can affect the stability of the machine and its surrounding structures.

In conclusion, a pulverizer machine offers several advantages, including its versatility, high efficiency, and consistent grinding results. However, it also has its drawbacks, such as high energy consumption, maintenance requirements, and noise/vibration issues. Therefore, when considering the use of a pulverizer machine, it is essential to weigh the pros and cons based on specific requirements and operating conditions.

Pulverizer machine Reference Specifications (varies for different product)

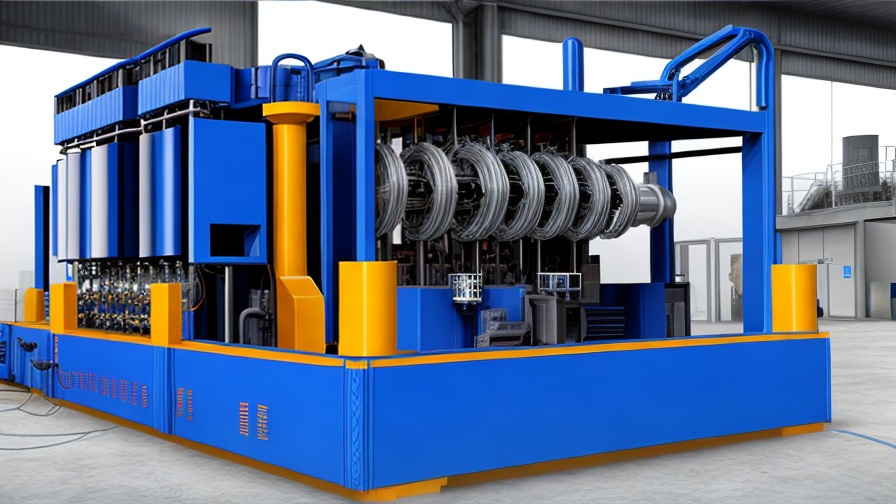

A pulverizer machine is a mechanical device that is used to grind various types of materials into fine powders. These machines can crush, grind, or pulverize materials such as coal, minerals, limestone, metal oxides, pigments, and more. The resulting powders can be used in various industries, such as mining, construction, pharmaceuticals, agriculture, and chemicals.

The specifications of a pulverizer machine may vary depending on the specific product being processed. However, some common reference specifications can be highlighted. These machines typically consist of a sturdy frame, a grinding chamber, a motor, grinding discs or hammers, and a discharge outlet.

The frame of a pulverizer machine is often made of durable materials like steel or cast iron to ensure stability and longevity. The grinding chamber houses the grinding components, which can be discs, hammers, or blades depending on the nature of the material being pulverized. These components rotate at high speeds to crush or grind the materials.

The motor of a pulverizer machine is an essential component, providing the necessary power to drive the grinding mechanism. The power of the motor can vary based on the size and capacity of the machine, ranging from a few horsepower to several hundred horsepower.

Another important factor is the discharge outlet, through which the pulverized material exits the machine. The size and design of the outlet can be customized to meet specific requirements and ensure efficient material flow.

In addition to these general specifications, different types of pulverizer machines may have specific features or abilities. For example, some machines may have adjustable settings to control the fineness of the output powder. Others may have built-in air classifying systems to separate the fine particles from the coarse ones.

It is crucial to consider the specific requirements and characteristics of the materials to be processed when selecting a pulverizer machine. Manufacturers often provide detailed specifications and options tailored to various applications, ensuring optimal performance and efficiency for specific industries and materials.

In conclusion, a pulverizer machine is a versatile equipment used for grinding various materials into fine powders. Its reference specifications can vary depending on the product being processed. Factors such as the frame, grinding components, motor power, and discharge outlet play critical roles in determining the machine’s performance and suitability for specific applications.

Applications of Pulverizer machine

Pulverizer machines are highly versatile tools that are used to reduce the size of different materials through grinding, crushing, or cutting. They find extensive applications in various industries and are known for their efficiency and reliability. Here are some common applications of pulverizer machines:

1. Food and Beverage Industry: Pulverizer machines are widely used in the food and beverage industry for grinding, pulverizing, and homogenizing various food products such as spices, cereals, pulses, sugar, and nuts. These machines are designed to produce a uniform and fine texture, essential for producing high-quality food products.

2. Pharmaceutical Industry: Pulverizer machines play a crucial role in the pharmaceutical industry by providing efficient and consistent size reduction of pharmaceutical compounds and ingredients. They are used for pulverizing drugs, excipients, powdered herbs, vitamins, and other pharmaceutical raw materials, facilitating uniform mixing and improved drug performance.

3. Chemical Industry: Pulverizers find extensive use in the chemical industry for processing various chemical compounds and substances. They can pulverize chemicals to a fine powder, resulting in increased surface area and enhanced chemical reactions. This is particularly useful in applications such as grinding pigments, dyes, resins, polymers, and other chemical compounds.

4. Mining and Construction Industry: Pulverizers are vital equipment in the mining and construction industry for breaking down and reducing the size of rocks, stones, and minerals. They are used for primary and secondary crushing, grinding, and pulverizing of materials like limestone, coal, gypsum, shale, and other minerals, facilitating their transport and subsequent processing.

5. Recycling Industry: Pulverizer machines are widely employed in the recycling industry for processing and reducing the size of various waste materials such as plastics, rubber, paper, textiles, and electronic waste. These machines enable the efficient reduction of waste volume, making it easier for further recycling processes.

6. Agriculture Industry: Pulverizers have applications in the agriculture industry for grinding and pulverizing agricultural products like grains, seeds, spices, and animal feed. They help enhance the digestibility and nutritional value of these products, ensuring better livestock health and improved crop yield.

Overall, pulverizer machines are essential tools in various industries for reducing the size of different materials. They provide consistent and efficient size reduction, leading to improved product quality, increased productivity, and cost savings. With their versatility and adaptability, these machines continue to find new applications and contribute to the advancement of several industries.

The Work Process and how to use Pulverizer machine

The Work Process and How to Use a Pulverizer Machine

A pulverizer machine is a mechanical device that is used to grind various types of materials into fine powder. It operates by using a high-speed rotating blade to crush the material fed into it. This machine is commonly used in industries such as mining and construction to pulverize materials like coal, rock, and concrete.

The work process of a pulverizer machine begins with the raw material being fed into a hopper. From there, it is transported into the grinding chamber where the high-speed rotating blade is located. As the blade spins, it rapidly breaks down the material into smaller particles.

To effectively use a pulverizer machine, there are a few important steps to follow. Firstly, ensure that the machine is clean and free from any debris or foreign objects. Next, inspect the blades and make sure they are sharp and in good condition. Dull or damaged blades can affect the overall performance and efficiency of the machine.

Once the machine is ready, carefully pour the material you wish to pulverize into the hopper. It is essential to feed the material in small, controlled amounts to prevent overloading the machine. Overloading can cause the pulverizer to jam or overheat, damaging the machine and hampering its performance.

After feeding the material, turn on the machine and allow it to operate for the desired amount of time. The duration of the grinding process will depend on the type and hardness of the material being pulverized. It is recommended to start with short grinding cycles and gradually increase the duration until the desired fineness is achieved.

Once the material has been sufficiently pulverized, turn off the machine and allow it to cool down. Carefully remove the pulverized material from the grinding chamber, taking care to avoid any contact with the rotating blade. Dispose of the pulverized material as per the respective waste management guidelines.

Regular maintenance and cleaning are essential to keep a pulverizer machine in optimal condition. After each use, carefully clean the machine to remove any residual material and prevent contamination. Inspect the blades and other components regularly and replace or repair any damaged parts to ensure efficient operation.

In conclusion, a pulverizer machine is a powerful tool used to grind various materials into fine powder. By following the proper work process, which includes cleaning, blade inspection, controlled feeding, and regular maintenance, users can maximize the efficiency and longevity of the machine.

Quality Testing Methods for Pulverizer machine and how to control the quality

Quality testing methods for a pulverizer machine involve several key steps to ensure efficient operation and reliable performance. These methods include:

1. Visual inspection: The first step is to visually inspect the pulverizer machine for any visible defects or damages. This includes checking for corrosion, wear and tear, loose or broken parts, and proper alignment of components.

2. Functional testing: The machine should undergo functional testing to evaluate its performance. This can involve running the machine at different speeds and loads to ensure proper functioning of all components and systems. The output quality of the pulverized material is also assessed during this testing.

3. Material analysis: The quality of the pulverized material also plays a crucial role in assessing the machine’s performance. Material analysis techniques, such as particle size analysis, can be used to determine if the pulverizer machine is producing the desired particle size range. This can be done using sieve analysis or laser diffraction methods.

4. Efficiency testing: To control the quality of a pulverizer machine, efficiency testing is essential. This involves measuring the energy consumption of the machine and calculating its efficiency. This can be done by monitoring the power input and the pulverizer’s throughput. Lower energy consumption and higher output indicate better efficiency.

To control the quality of a pulverizer machine, some measures should be implemented:

1. Regular maintenance: Timely maintenance and inspection are crucial to detect any potential issues and ensure smooth operation. This includes lubrication of moving parts, checking for loose connections, and replacing worn-out components.

2. Calibration: Regular calibration of the machine’s controls and measuring instruments, such as speed controllers and pressure gauges, is essential to maintain accuracy and reliability.

3. Operator training: Providing adequate training to the machine operators is important to ensure they understand the proper operation and maintenance procedures. This reduces the likelihood of human errors and promotes safe and efficient use of the machine.

4. Quality control checks: Implementing systematic quality control checks at various stages of the production process is essential. This can include regular inspections, performance monitoring, and adherence to quality control standards.

By following these quality testing methods and implementing control measures, pulverizer machine manufacturers and users can ensure the optimal performance and longevity of the equipment, as well as maintain the desired quality of the pulverized material.

Pulverizer machine Sample Policy and Post-Purchase Considerations for Pulverizer machine from China

Sample Policy:

1. Payment Terms: Prior to placing the order, it is essential to discuss and agree upon the payment terms with the supplier. Generally, a 30% deposit is required before production, followed by the balance payment before delivery.

2. Packaging and Delivery: Confirm with the supplier about the packaging method and delivery terms. Ensure that the pulverizer machine is securely packed to prevent any damage during transit. Additionally, negotiate the delivery terms, such as the shipping method, transportation time, and associated costs.

3. Quality Assurance: Request the supplier to provide necessary certifications for the machine, such as ISO or CE certificates. It is also recommended to clarify if the supplier offers a warranty period for their product. This information ensures that the purchased machine meets quality standards and any potential issues can be addressed promptly.

Post-Purchase Considerations:

1. Installation and Training: After receiving the pulverizer machine, it is crucial to consult with the supplier about the installation process. Discuss whether professional assistance or installation guidance is provided. Moreover, inquire about training sessions that can help operators understand the machine’s functionalities, maintenance procedures, and safety precautions.

2. After-Sales Support: Ensure that the supplier offers reliable after-sales support, including technical assistance, spare parts availability, and troubleshooting guidance. This will determine the ease of dealing with any potential issues that may arise during the machine’s operational lifespan.

3. Regular Maintenance Schedule: Establish a regular maintenance schedule to keep the pulverizer machine in optimal working condition. Consult the supplier for recommended maintenance procedures, including cleaning, lubrication, and replacement of specific parts. Adhering to a preventative maintenance plan can prolong the machine’s lifespan and ensure consistent performance.

4. Feedback and Reviews: Provide feedback to the supplier regarding the performance and overall satisfaction with the pulverizer machine. Positive feedback helps build a good reputation for the supplier, while addressing any issues promptly ensures the buyer’s expectations are met.

In conclusion, conducting thorough research, negotiating favorable terms, and ensuring proper support and maintenance are crucial post-purchase considerations when buying a pulverizer machine from China.

Sourcing Pulverizer machine from China: Opportunities, Risks, and Key Players

China is a leading exporter and manufacturer of pulverizer machines, which are widely used in industries such as mining, construction, and agriculture. Sourcing pulverizer machines from China provides various opportunities, but also involves certain risks. Understanding the key players in the market is crucial for making an informed decision.

Opportunities:

1. Cost-effectiveness: China is known for its competitive pricing in the global market, making it an attractive sourcing destination for pulverizer machines. Manufacturers in China offer cost-effective options without compromising quality.

2. Wide variety: China’s market offers a wide variety of pulverizer machines, catering to diverse industry needs. Whether it is for grinding, crushing, or pulverizing materials, Chinese manufacturers provide a range of options to choose from.

3. Technological advancements: Chinese manufacturers have been investing significantly in research and development, leading to advancements in pulverizer machine technology. Sourcing from China allows buyers to access innovative and efficient machines.

Risks:

1. Quality control: One of the key risks in sourcing from China is maintaining quality control. It is essential to thoroughly vet suppliers, ensuring that they adhere to international quality standards and have a proven track record of delivering high-quality products.

2. Intellectual property rights infringement: China has faced criticism for intellectual property rights (IPR) infringement issues in the past. It is crucial to work with reputable suppliers who respect IPR and have mechanisms in place to protect buyer’s designs or patented technologies.

3. Communication and language barriers: Sourcing from China may involve language barriers and cultural differences, making effective communication challenging. This can lead to misunderstandings and delays in product development or delivery.

Key players:

1. Jiangyin Baoli Machinery Manufacturing Co., Ltd.: This company specializes in the research, development, and production of pulverizer machines catering to various industries. They have a strong reputation for producing high-quality equipment.

2. Jiangsu Hongda Powder Equipment Co., Ltd.: With years of experience in the industry, this company provides a wide range of pulverizing machines and services. They are known for their advanced technology and reliable customer support.

3. Jiangyin BrightSail Machinery Co., Ltd.: Known for its modern manufacturing facilities and innovative designs, this company offers a diverse range of pulverizer machines suitable for various applications.

In conclusion, sourcing pulverizer machines from China can provide opportunities in terms of cost-effectiveness, variety, and technological advancements. However, the risks of quality control, intellectual property rights infringement, and communication barriers should be carefully managed. Engaging with reputable key players, such as Jiangyin Baoli Machinery Manufacturing Co., Ltd., Jiangsu Hongda Powder Equipment Co., Ltd., and Jiangyin BrightSail Machinery Co., Ltd., can mitigate these risks and ensure a successful sourcing experience.

How to find and select reliable Pulverizer machine manufacturers in China,use google search manufacturers and suppliers

Finding reliable pulverizer machine manufacturers in China can be a daunting task, but with the help of Google search and some careful filtering, you can narrow down your options. Here are some steps to follow:

1. Begin your search on Google by typing in relevant keywords such as “pulverizer machine manufacturers in China.” This will give you a list of manufacturers and suppliers available.

2. Explore the websites of the companies that appear in the search results. Look for information about their experience, expertise, certifications, and the range of products they offer.

3. Check if the manufacturer has a physical address mentioned on their website. This can help verify their legitimacy and where they are based.

4. Look for customer reviews and testimonials. Search for the manufacturer’s name along with “reviews” or “feedback” to see if there are any positive or negative comments from previous customers. This can give you an idea of their reputation and the quality of their machines.

5. Check if the manufacturer has any certifications or quality management system (ISO) certifications. This indicates that they follow certain quality standards and processes.

6. Contact the manufacturer directly and ask for more information about their pulverizer machines. Inquire about their production capabilities, warranty policies, technical consultation, and after-sales service.

7. Request samples or visit their factory if possible. Inspecting the quality of the products in person can give you a better understanding of their manufacturing process and the overall quality of their machines.

8. Compare prices, specifications, and other relevant factors among different manufacturers to make an informed decision.

Remember, it is always recommended to conduct due diligence and perform thorough research before finalizing any business with a manufacturer. It is useful to read up on trade regulations, customs requirements, and other legalities involved in importing machinery from China to avoid any potential issues.

How to check Pulverizer machine manufacturers website reliable,use semrush.com google chrome plugin check website ranking in 10M

When it comes to checking the reliability of a Pulverizer machine manufacturer’s website, there are a few steps you can follow. One reliable tool you can use is the SEMrush.com Google Chrome plugin to check the website’s ranking within the top 10 million sites. Here’s a brief guide on how to do this, using not more than 300 words:

1. Install the SEMrush.com Google Chrome plugin: First, open your Google Chrome browser and search for the SEMrush.com Google Chrome plugin. Follow the instructions to install it onto your browser.

2. Access the Pulverizer machine manufacturer’s website: Visit the website of the manufacturer you want to check. Take note of the website’s URL.

3. Use the SEMrush plugin: Once the plugin is installed, you should see the SEMrush icon in your browser toolbar. Click on the icon to open the plugin.

4. Check the website’s ranking: In the SEMrush plugin, you will find a search bar. Enter the website’s URL in the search bar and click on the search button. The plugin will provide you with information about the website, including its current ranking among the top 10 million websites.

5. Evaluate the website’s ranking: Websites with lower rankings, such as those above 1 million, might indicate lower traffic and potentially less reliability. On the other hand, websites with higher rankings, such as those below 100,000, generally receive more traffic and may be more reliable.

6. Consider other factors: While the website’s ranking can give you an idea of its reliability, it is important to consider other factors as well. Look for customer reviews or testimonials, check if the website provides detailed product information and contact details, and see if they have certifications or affiliations with industry associations.

In conclusion, by using the SEMrush.com Google Chrome plugin and checking a Pulverizer machine manufacturer’s website ranking within the top 10 million sites, you can get an indication of its reliability. However, it’s important to consider other factors as well before making a final judgment.

Top 10 Pulverizer machine manufacturers in China

1. Jiangyin Baoli Machinery Manufacturing Co., Ltd.

Jiangyin Baoli Machinery Manufacturing Co., Ltd. specializes in manufacturing various types of pulverizers, including universal pulverizers, herbal pulverizers, and high-efficiency pulverizers. The company’s advanced manufacturing facilities and strict quality control processes ensure the durability and efficiency of their products.

2. Jiangyin Hongda Powder Equipment Co., Ltd.

Established in 1992, Jiangyin Hongda Powder Equipment Co., Ltd. is a leading manufacturer of pulverizers, mixers, conveyors, and other powder processing equipment. The company’s pulverizer machines are widely used in industries such as pharmaceuticals, chemicals, and food processing.

3. Jiangyin Kaiyue Machinery Manufacturing Co., Ltd.

Jiangyin Kaiyue Machinery Manufacturing Co., Ltd. focuses on the production of various pulverizer machines, including cryogenic pulverizers, impact pulverizers, and air-cooled pulverizers. The company’s precision engineering and quality control measures ensure the performance and reliability of their products.

4. Jiangyin thought jet mill

Jiangyin thought jet mill is a professional manufacturer of powder equipment, with over 30 years of experience in the field. The company offers a wide range of pulverizer machines, including jet mills, impact mills, and classifiers. Their products are known for their high precision and efficiency.

5. Shanghai Xichuang Powder Equipment Co., Ltd.

Shanghai Xichuang Powder Equipment Co., Ltd. specializes in the research, development, and production of pulverizer machines. Their products include jet mills, impact mills, and granulators. The company’s advanced technologies and innovative designs have gained them a strong reputation in the market.

6. Shanghai Clirik Machinery Co., Ltd.

Shanghai Clirik Machinery Co., Ltd. is a leading manufacturer of pulverizer machines in China. They offer a wide range of pulverizer machines, including hammer mills, ball mills, Raymond mills, and more. The company’s products are known for their high performance and reliability.

7. China Henan Fengde Machinery Manufacturing Co., Ltd.

China Henan Fengde Machinery Manufacturing Co., Ltd. specializes in the production of pulverizers, crushers, and other mining equipment. Their pulverizer machines are widely used in industries such as mining, metallurgy, and construction. The company’s products are known for their durability and efficiency.

8. Nanjing T-Bota Scietech Instruments & Equipment Co., Ltd.

Nanjing T-Bota Scietech Instruments & Equipment Co., Ltd. is a leading manufacturer of pulverizer machines in China. They offer a wide range of pulverizers, including laboratory pulverizers, industrial pulverizers, and more. The company’s products are known for their high precision and ease of use.

9. Zhangjiagang Huibang Machinery Co., Ltd.

Zhangjiagang Huibang Machinery Co., Ltd. specializes in the production of pulverizer machines for the plastics industry. Their products include plastic pulverizers, PVC pulverizers, and HDPE pulverizers. The company’s advanced manufacturing processes and quality control measures ensure the efficiency and reliability of their products.

10. Zhejiang LEAP Pulverization Equipment Co., Ltd.

Zhejiang LEAP Pulverization

Background Research for Pulverizer machine manufacturers Companies in China, use qcc.com archive.org importyeti.com

China is known for its extensive manufacturing industry, which includes the production of various types of machinery and equipment. One specific machinery category is pulverizer machines, which are widely used in industries such as mining, construction, pharmaceuticals, and others. In order to gather background information on pulverizer machine manufacturers in China, three useful sources can be utilized: qcc.com, archive.org, and importyeti.com.

QCC.com is a Chinese business data platform that provides comprehensive information about companies in China. By searching for pulverizer machine manufacturers on qcc.com, one can find a list of relevant companies along with their contact details, registered capital, and other important information. This resource is particularly valuable for identifying reputable and established manufacturers.

Archive.org is an online archival platform that stores snapshots of websites over time. By searching for specific manufacturers or their websites on archive.org, one can access historical records and see how the companies have evolved over time. This helps in understanding their growth trajectory and market presence.

Importyeti.com is a platform that provides trade data and import/export records. By searching for pulverizer machines or manufacturers on importyeti.com, one can gain insights into the export activities of these manufacturers. This data helps in identifying manufacturers with a strong international presence and can provide an understanding of the scale and capacity of their operations.

In conclusion, qcc.com, archive.org, and importyeti.com are valuable resources for gathering background research on pulverizer machine manufacturers in China. These platforms provide information about the companies, their history, and their market presence, which enables potential buyers or researchers to make informed decisions when engaging with these manufacturers. With the help of these sources, one can acquire a comprehensive understanding of the pulverizer machine manufacturing industry in China.

Leveraging Trade Shows and Expos for Pulverizer machine Sourcing in China

Trade shows and expos can be highly effective platforms for sourcing pulverizer machines in China. These events bring together numerous suppliers and manufacturers, allowing businesses to explore a wide range of options and make informed decisions. Here’s how you can leverage trade shows and expos for pulverizer machine sourcing in China:

1. Pre-event research: Before attending a trade show or expo, conduct thorough research on the exhibitors and identify the ones offering pulverizer machines. Make a list of potential suppliers and prioritize the ones that align with your requirements.

2. Attend relevant events: Look for trade shows and expos that specifically focus on machinery, automation, or manufacturing. These events attract a high number of industry professionals, creating a conducive environment for sourcing pulverizer machines.

3. Engage with suppliers: Take time to visit different booths and engage with the suppliers. Discuss your specific requirements, seek product demonstrations, and ask for technical specifications. This direct interaction allows you to assess the quality of their products and gauge their expertise.

4. Compare offerings: Visit multiple suppliers offering pulverizer machines and compare their products, prices, and after-sales support. This will help you identify the most suitable option for your business.

5. Establish relationships: Trade shows and expos provide an opportunity to establish meaningful connections with suppliers. Build relationships with potential manufacturers by exchanging contact information, discussing future collaborations, and negotiating partnerships.

6. Attend seminars and workshops: Many trade shows and expos include industry-specific seminars and workshops. Attend these sessions to expand your knowledge about pulverizer machines, learn about the latest advancements, and understand the market trends.

7. Follow up after the event: After the trade show or expo, make sure to follow up with the suppliers you are interested in. Request additional information, samples, or quotes to facilitate decision-making.

By leveraging trade shows and expos in China, businesses can efficiently source pulverizer machines. These events provide a centralized and interactive platform to explore different suppliers, compare offerings, establish relationships, gain industry insights, and ultimately make informed decisions.

The Role of Agents and Sourcing Companies in Facilitating Pulverizer machine Purchases from China

Agents and sourcing companies play a crucial role in facilitating the purchase of pulverizer machines from China. These entities act as intermediaries between the buyers and manufacturers, helping to streamline the process and ensure a successful transaction. They provide a range of services, including identifying reliable manufacturers, conducting quality checks, negotiating prices, managing logistics, and handling customs documentation.

One of the main advantages of using an agent or sourcing company is their deep knowledge and understanding of the Chinese market. They have extensive networks and connections with manufacturers, allowing them to easily identify reputable suppliers who can meet the specific requirements and quality standards of the buyer. Through their expertise, they can provide recommendations and advice on the best suppliers and assist in verifying the authenticity and credibility of the manufacturers.

Agents and sourcing companies also play a crucial role in negotiating prices on behalf of the buyer. They are well-versed in the negotiation process and have an understanding of the local market conditions. Their negotiation skills can help secure competitive prices and favorable terms for the buyer.

Moreover, these entities manage the logistics of the purchase, ensuring that the pulverizer machines are shipped safely and efficiently. They handle the necessary paperwork, including customs documentation, export licenses, and other legal requirements. This helps to simplify the import process and ensures compliance with local regulations.

Furthermore, agents and sourcing companies can also provide quality control services. They conduct thorough inspections and tests to ensure that the purchased pulverizer machines meet the required standards and specifications. This minimizes the risk of receiving substandard or defective products, providing the buyer with peace of mind.

In summary, agents and sourcing companies play a vital role in facilitating the purchase of pulverizer machines from China. Their knowledge, expertise, and network enable them to identify reliable manufacturers, negotiate prices, manage logistics, and ensure product quality. By utilizing their services, buyers can streamline the purchasing process and mitigate potential risks associated with international trade.

Price Cost Research for Pulverizer machine manufacturers Companies in China, use temu.com and 1688.com

Pulverizer machines are widely used in various industries for grinding and crushing purposes. If you are looking to conduct price cost research for pulverizer machine manufacturers in China, two popular websites that can be utilized are temu.com and 1688.com.

Temu.com is a B2B marketplace that connects global buyers with verified Chinese suppliers. To conduct price cost research for pulverizer machine manufacturers on this platform, you can start by creating an account and searching for relevant suppliers. Use keywords like “pulverizer machine” or “grinding machine” to narrow down your search.

Once you have found potential suppliers, you can compare prices and product specifications provided by different manufacturers. It is important to also consider factors such as certifications, quality standards, delivery terms, and after-sales services offered by the suppliers. Temu.com allows direct communication with suppliers, giving you the opportunity to inquire about pricing and negotiate discounts if required.

1688.com, operated by Alibaba Group, is another popular e-commerce platform in China that connects buyers with Chinese manufacturers and suppliers. Using this platform, you can conduct similar price cost research by searching for pulverizer machine manufacturers. 1688.com provides detailed product information, allowing you to compare prices, specifications, and other relevant details provided by different suppliers.

To get in touch with suppliers on 1688.com, you might need assistance from translation tools as the platform is primarily in the Chinese language. However, many suppliers on 1688.com also have profiles on Alibaba.com, which is available in multiple languages and can be another valuable resource for researching manufacturers and comparing prices.

In conclusion, with the help of platforms like temu.com and 1688.com, conducting price cost research for pulverizer machine manufacturers in China becomes more accessible. Consider factors beyond price, such as quality, certifications, and after-sales services, to make an informed decision when selecting a supplier.

Shipping Cost for Pulverizer machine import from China

The shipping cost for importing a pulverizer machine from China can vary depending on several factors such as the size and weight of the machine, the shipping method, and the destination country. Generally, there are two common shipping methods, namely sea freight and air freight.

Sea freight is typically the more cost-effective option for heavy and bulky machinery like a pulverizer machine. The cost is calculated based on the volume or weight of the machine along with the distance it needs to travel. Additionally, other charges such as customs fees, port handling fees, and destination charges may be applicable. On average, sea freight costs for a pulverizer machine can range from $700 to $3000, depending on the factors mentioned above.

On the other hand, air freight is significantly faster but more expensive compared to sea freight. It is a suitable choice for urgent shipments and smaller-sized pulverizer machines. The cost is calculated based on the weight of the machine, and additional charges such as customs fees and destination fees may apply. Generally, air freight costs for a pulverizer machine can range from $1500 to $5000, depending on the factors discussed.

It is essential to consider other potential costs when importing a pulverizer machine from China. These include customs duties, taxes, insurance, and any necessary documentation fees. Additionally, it is advisable to work with a reputable freight forwarder or shipping agent who can provide accurate cost estimates and assistance with the import process.

To minimize shipping costs, it is recommended to optimize the packaging of the pulverizer machine to reduce its size and weight. Consolidating multiple orders in one shipment or exploring different shipping options can also help achieve cost savings.

In conclusion, the shipping cost for importing a pulverizer machine from China can range from $700 to $5000, depending on various factors such as size, weight, shipping method, and destination. Careful consideration of these factors and working with experienced professionals can help ensure a smooth and cost-effective shipping process.

Compare China and Other Pulverizer machine Markets: Products Quality and Price,Visible and Hidden Costs

China has emerged as a key player in the global pulverizer machine market. When comparing China with other pulverizer machine markets, several factors come into play, including products quality and price, visible and hidden costs.

In terms of product quality, China has made significant progress over the years. With advancements in technology and manufacturing capabilities, Chinese manufacturers now offer a wide range of pulverizer machines with high-quality components and efficient performance. These machines are built to meet international standards and are often at par with the offerings from other markets.

The price factor is where China has a competitive edge. Chinese manufacturers are able to offer pulverizer machines at relatively lower prices compared to other markets. This price advantage can be attributed to several factors, including lower labor costs, economies of scale, and government policies to promote the manufacturing sector. As a result, buyers can often find cost-effective solutions from Chinese suppliers.

When considering visible costs, China again stands out due to its extensive supply chain and logistics network. The country has a well-established infrastructure for transporting machines domestically and internationally, ensuring prompt delivery to customers. This streamlined supply chain helps in reducing transportation costs, ultimately benefiting the buyers.

However, it is crucial to consider hidden costs as well. One such cost is related to intellectual property rights (IPR) protection. China has faced criticism in the past for intellectual property infringement, which can result in the theft or unauthorized replication of product designs and technologies. This can lead to costs associated with legal proceedings and loss of market share for original equipment manufacturers.

Another hidden cost is related to compliance with international standards and certifications. Buyers need to ensure that the machines they purchase adhere to safety and quality standards to avoid potential risks. Ensuring compliance can involve additional costs for inspections, certifications, and documentation.

In summary, China’s pulverizer machine market offers products with comparable quality to other markets, but at more competitive prices due to various factors. The visible costs, such as transportation and logistics, are well-managed, providing efficient supply chain solutions. However, it is important for buyers to account for the hidden costs, such as intellectual property rights protection and compliance with international standards, when making purchasing decisions.

Understanding Pricing and Payment Terms for Pulverizer machine: A Comparative Guide to Get the Best Deal

Pricing and payment terms for purchasing a pulverizer machine can vary significantly depending on various factors such as the brand, model, specifications, and the supplier or manufacturer. To get the best deal on a pulverizer machine, it is crucial to have a clear understanding of the pricing structure and payment terms involved. Here is a comparative guide to help you navigate through this process.

1. Research and Compare Prices: Start by researching different brands and models of pulverizer machines available in the market. Compare their features, specifications, and prices from multiple suppliers or manufacturers. Consider factors such as the machine’s quality, durability, and reputation of the supplier.

2. Request for Quotations: Reach out to the shortlisted suppliers or manufacturers and request quotations for the desired pulverizer machine. Ensure that the quotations include detailed information about the machine, such as its model number, specifications, and any additional accessories or services provided.

3. Determine Pricing Structure: Understand the pricing structure offered by each supplier. Some may provide a fixed price for the machine, while others may offer discounts based on factors like bulk orders or long-term contracts. Additionally, inquire about any additional charges or taxes that may apply to the machine’s purchase.

4. Negotiate: Once you have received quotations, negotiate the pricing with the potential suppliers. Use the information gathered from your research to leverage better deals, such as requesting price matching or additional benefits like extended warranties or maintenance services.

5. Evaluate Payment Terms: Apart from the price, it is essential to understand the payment terms offered by different suppliers. Common payment options include upfront payments, installments, or financing options. Consider the feasibility and cost-effectiveness of each payment term and choose the one that aligns with your budget and preferences.

6. Analyze After-sales Support: Assess the after-sales support provided by the suppliers. A comprehensive warranty, spare part availability, and servicing assistance are crucial factors to consider when making your decision. Suppliers that offer excellent after-sales support may provide more value in the long run, even if their initial pricing is slightly higher.

7. Consider Total Cost of Ownership: When comparing pricing, it is crucial to consider the total cost of ownership. This includes factors such as machine maintenance and repair costs, energy consumption, and operational efficiency. A cheaper machine may result in higher overall costs in the long term if it requires frequent repairs or consumes excessive power.

By following this comparative guide, you can ensure that you get the best deal when purchasing a pulverizer machine. Carefully analyze the pricing structure, negotiate effectively, and consider the payment terms and after-sales support provided by different suppliers. Remember to evaluate the total cost of ownership to make an informed decision that aligns with your requirements and budget.

Chinese Regulations and Industry Standards Certifications for Pulverizer machine,Import Regulations and Customs for Pulverizer machine from China

China has established various regulations and industry standards certifications for pulverizer machines to ensure product quality, safety, and environmental protection. These certifications are crucial for importers to comply with regulatory requirements and gain market access in China. Some of the key certifications and regulations for pulverizer machines in China are:

1. Quality Management System Certification: Pulverizer machine manufacturers need to obtain the ISO 9001 certification, which demonstrates their compliance with quality management system standards.

2. Environmental Management System Certification: To meet environmental standards, manufacturers must obtain ISO 14001 certification, highlighting their adherence to environmental management practices during production.

3. Occupational Health and Safety Certification: Pulverizer machine manufacturers are also required to obtain OHSAS 18001 certification, which signifies their adherence to occupational health and safety standards in the workplace.

4. China Compulsory Certification (CCC): The CCC certification is mandatory for various product categories, including electrical and mechanical equipment. Pulverizer machines falling under these categories must undergo CCC certification to ensure compliance with safety and quality standards.

5. National Standards Compliance: Pulverizer machines must meet the national standards set by the Standardization Administration of China (SAC). Compliance with these standards ensures product quality and safety.

When importing pulverizer machines from China, importers need to be aware of the following regulations and customs procedures:

1. Customs Declarations: Importers must provide accurate and comprehensive information regarding the imported pulverizer machines, including product specifications, quantities, and values.

2. Customs Duties and Taxes: Importers are required to pay applicable customs duties and taxes based on the classification and value of the pulverizer machines.

3. Import License: Some specific categories of pulverizer machines might require an import license issued by the relevant authorities before importation is allowed.

4. Inspection and Quarantine: Pulverizer machines need to undergo inspection and quarantine procedures to ensure compliance with quality, safety, and environmental regulations.

5. Documentation Requirements: Importers must provide necessary documentation, such as the bill of lading, commercial invoice, packing list, and certificates of conformity or compliance.

Importers are advised to work closely with their freight forwarders, customs agents, or professional import consultants to ensure smooth customs clearance and compliance with regulations when importing pulverizer machines from China.

Sustainability and Environmental Considerations in Pulverizer machine Manufacturing

In recent years, there has been a growing concern for sustainability and environmental considerations in various industries. The manufacturing of pulverizer machines is not an exception. Pulverizer machines are widely used in industries such as food processing, pharmaceuticals, and mining. These machines grind and crush materials into fine powders, making them an essential tool in many manufacturing processes.

When considering sustainability and environmental factors in the manufacturing of pulverizer machines, several aspects need to be taken into account. Firstly, the choice of materials used in the construction of these machines plays a significant role. Opting for sustainable materials, such as recycled or renewable resources, can reduce the environmental impact associated with their production.

Manufacturers can also focus on energy efficiency during the manufacturing process. Implementing energy-saving technologies and utilizing renewable energy sources can help reduce carbon emissions and decrease reliance on fossil fuels. Additionally, improving the overall energy efficiency of the machines themselves can ensure that they consume less energy during operation, further minimizing their environmental footprint.

Reducing waste generation is another crucial consideration. Manufacturers can implement waste management practices such as recycling and reusing materials wherever possible. By optimizing manufacturing processes and reducing material waste, the overall environmental impact can be minimized.

Furthermore, incorporating sustainable design principles in pulverizer machine manufacturing can lead to longer product lifecycles and improved durability. This can result in reduced energy and resource consumption associated with frequent replacements or repairs. Manufacturers can also consider designing machines that are more easily disassembled and recycled at the end of their life, promoting a circular economy.

Lastly, manufacturers should promote responsible disposal and end-of-life management for pulverizer machines. Ensuring proper recycling or safe disposal of these machines at the end of their usefulness can prevent environmental contamination and promote a more sustainable waste management system.

In summary, the manufacturing of pulverizer machines can be made more sustainable by considering aspects such as the choice of materials, energy efficiency, waste management, sustainable design principles, and responsible disposal. By incorporating these considerations, manufacturers can minimize the environmental impact of these machines and contribute to a more sustainable future.

List The Evolution history of “Pulverizer machine”

The evolution of the pulverizer machine dates back to ancient times when various cultures used different tools and techniques to crush and grind materials for various purposes. The concept of pulverizing, which involves reducing solid particles into smaller sizes, has evolved significantly over the centuries. Here is a brief history of the evolution of the pulverizer machine:

1. Ancient Times: The earliest form of pulverization can be traced back to the use of mortars and pestles in ancient civilizations. These simple tools were used to crush grains, herbs, and other materials manually.

2. Medieval Era: With the advent of water wheels and windmills, more sophisticated mechanical pulverizers were developed. These machines utilized the power generated by natural forces to pulverize grains, spices, and other agricultural products.

3. Industrial Revolution: During the 18th and 19th centuries, the industrial revolution brought significant advancements in manufacturing processes. Steam-powered mills and crushers were introduced, designed to pulverize various materials such as coal, ore, and limestone to support the growing industries.

4. Mechanical Innovations: In the 20th century, mechanical innovations led to the development of more efficient and specialized pulverizer machines. The introduction of high-speed rotating impactors and hammer mills allowed for faster and finer pulverization of materials.

5. Electric Power: With the widespread availability of electricity in the early 20th century, the pulverizer machines were adapted to run on electric motors. This enhanced their efficiency and made them more convenient to use in various industries.

6. Modern Technology: In recent decades, technological advancements have revolutionized the field of pulverization. Computer-controlled pulverizer machines with advanced sensors and monitoring systems have emerged. These machines can precisely control the size and quality of the pulverized material, making them highly efficient and reliable.

Today, pulverizer machines are used in various industries such as agriculture, mining, pharmaceuticals, and food processing. They play a crucial role in reducing the size of different materials, improving efficiency, and enabling the production of finer end products.

The Evolution and Market Trends in Pulverizer machine Industry

The pulverizer machine industry has come a long way in terms of evolution and market trends. Over the years, there have been significant advancements in technology and innovation, leading to improved pulverizer machines that offer enhanced performance and efficiency.

One of the key evolutions in the industry is the development of more powerful and versatile pulverizer machines. These machines are capable of handling a wide range of materials, from soft and delicate substances to hard and abrasive materials. This versatility has expanded the applications of pulverizer machines across various industries, including pharmaceuticals, chemicals, mining, and construction.

Another major evolution in the industry is the incorporation of advanced control systems and automation. Modern pulverizer machines are equipped with intelligent control systems that allow operators to easily monitor and adjust various parameters such as speed, feed rate, and fineness of the output product. This not only improves operational efficiency but also ensures consistent product quality.

In terms of market trends, there is a growing demand for pulverizer machines that are energy-efficient and environmentally friendly. Manufacturers are investing in research and development to develop machines that consume less energy while maintaining high performance. This trend is driven by increasing energy costs and stricter environmental regulations.

Market consolidation is another emerging trend in the pulverizer machine industry. Small and medium-sized players are looking to merge or form strategic partnerships with larger companies to gain a competitive edge. This is primarily driven by the need to access better distribution networks, increase product offerings, and enhance market presence.

Lastly, there is a rising demand for customization in pulverizer machines. Customers are looking for machines that are tailor-made to suit their specific requirements and applications. Manufacturers are responding to this trend by offering a wide range of customization options, such as different size options, material options, and additional features.

In conclusion, the evolution of pulverizer machines has led to improved performance, increased efficiency, and enhanced control capabilities. The market trends in the industry include the demand for energy-efficient machines, market consolidation, and customization options. These trends indicate a positive outlook for the pulverizer machine industry, with continued growth and development in the coming years.

Custom Private Labeling and Branding Opportunities with Chinese Pulverizer machine Manufacturers

Chinese pulverizer machine manufacturers offer custom private labeling and branding opportunities to cater to the specific needs of businesses. With their expertise in manufacturing high-quality pulverizer machines, they can help businesses establish their own unique brand identity.

Private labeling allows businesses to have their own brand name and logo on the pulverizer machines, giving them a distinct advantage in the market. This branding opportunity not only helps in building brand recognition but also enhances customer trust and loyalty.

Chinese pulverizer machine manufacturers understand the importance of customization and offer businesses the flexibility to choose from a variety of designs, colors, and features. This allows businesses to tailor the pulverizer machines according to their specific requirements and target audience.

Additionally, Chinese manufacturers provide OEM (Original Equipment Manufacturer) services, enabling businesses to develop their own unique range of pulverizer machines. From design and development to production and packaging, manufacturers work closely with businesses to ensure that the products meet their desired specifications.

Chinese manufacturers also ensure high-quality standards and certifications, such as ISO and CE, guaranteeing the reliability and safety of the pulverizer machines. This not only benefits businesses but also reassures customers of the quality of the products they are purchasing.

Moreover, Chinese manufacturers offer competitive pricing, efficient production capabilities, and timely delivery, making them a reliable partner for businesses looking to establish their own brand in the market.

In conclusion, Chinese pulverizer machine manufacturers provide custom private labeling and branding opportunities, allowing businesses to differentiate themselves in the market. With their expertise in customization and commitment to quality, they are an ideal choice for businesses looking to establish their own brand identity within the pulverizer machine industry.

Tips for Procurement and Considerations when Purchasing Pulverizer machine

When purchasing a pulverizer machine for your business, there are several important considerations and tips to keep in mind. Here are some key factors to consider before making your procurement decision:

1. Understanding your needs: Determine the specific requirements of your business and the type of material you need to pulverize. This will help you choose the right machine that can handle your workload efficiently.

2. Quality and durability: Look for a pulverizer machine that is made from high-quality materials and built to last. Choose a reputable manufacturer with a good track record to ensure you are buying a reliable and durable machine.

3. Capacity and output: Consider the required capacity and output of the pulverizer machine to meet your production needs. Make sure the machine you choose can handle the desired volume and deliver the required pulverization quality.

4. Maintenance and support: Assess the ease of maintenance and availability of spare parts for the machine. Look for a manufacturer that offers good after-sales support and maintenance services to minimize downtime.

5. Safety features: Ensure that the pulverizer machine has proper safety features in place to protect operators from potential accidents or injuries. This includes features like emergency stop buttons, safety locks, and protective covers.

6. Energy efficiency: Opt for a pulverizer machine that is energy-efficient to reduce operational costs. Look for features like low power consumption and intelligent controls that optimize energy usage.

7. Cost-effectiveness: Consider the initial investment cost of the machine as well as the long-term operating costs. Compare prices and features from different suppliers to find the most cost-effective option without compromising quality.

8. Reviews and references: Read reviews and testimonials from other customers who have purchased the same machine to gather insights about its performance and reliability. Ask the manufacturer for references and contact previous buyers for feedback.

9. Future scalability: Consider the potential expansion of your business and the machine’s scalability to accommodate increased production needs. Ensure that the pulverizer machine can be upgraded or expanded if required in the future.

10. Warranty and service agreement: Review the warranty terms and ensure that the manufacturer provides a comprehensive service agreement. This will help you address any potential issues that may arise after the purchase.

By considering these tips and factors, you can make an informed decision when purchasing a pulverizer machine that suits your business requirements and maximizes your operational efficiency.

FAQs on Sourcing and Manufacturing Pulverizer machine in China

Q1: What is a pulverizer machine?

A pulverizer machine is a mechanical device used to grind, crush, and pulverize various materials into fine powders. It is commonly used in industries such as mining, agriculture, chemical, and food processing.

Q2: Why should I consider sourcing and manufacturing a pulverizer machine in China?

China is known for its vast manufacturing capabilities and cost-effective pricing. Sourcing and manufacturing a pulverizer machine in China can offer significant cost savings compared to other countries. Additionally, China has a well-developed supply chain, experienced suppliers, and advanced technology, making it an ideal choice for this type of machinery.

Q3: How can I find reliable suppliers for pulverizer machines in China?

To find reliable suppliers in China, you can use various approaches. Firstly, you can attend trade shows and exhibitions in China related to your industry, where you can directly connect with manufacturers and evaluate their products. Secondly, you can utilize online B2B platforms like Alibaba, Global Sources, or Made-in-China, which allow you to search for and communicate with numerous suppliers. Lastly, you can seek recommendations from industry professionals, trade associations, or contacts who have previously sourced from China.

Q4: What factors should I consider when choosing a supplier for a pulverizer machine in China?

When choosing a supplier for a pulverizer machine in China, it is essential to consider several factors. These include the supplier’s experience, reputation, production capabilities, quality control measures, certifications (such as ISO 9001), technical expertise, and after-sales service. It is advisable to request product samples, visit the supplier’s facilities if possible, and conduct thorough due diligence before making a final decision.

Q5: Can I customize the design and specifications of a pulverizer machine from Chinese manufacturers?

Yes, most Chinese manufacturers offer customization services. You can work with the supplier to tailor the design, specifications, and even the packaging of the pulverizer machine to meet your specific requirements. However, it is recommended to clearly communicate your customization needs upfront and ensure that the supplier has the capabilities to fulfill them.

Q6: What are the typical lead times for manufacturing a pulverizer machine in China?

Lead times can vary depending on factors such as the complexity of the machine, customization requirements, and the supplier’s production capacity. Typically, lead times can range from 4-12 weeks, including manufacturing, quality control, and shipping. It is crucial to discuss lead times with potential suppliers and ensure that they can meet your desired delivery schedule.

Q7: Are there any specific certifications or quality standards I should look for when sourcing a pulverizer machine from China?

Some common certifications and quality standards to consider when sourcing a pulverizer machine in China include ISO 9001 (Quality Management System), CE (Conformité Européene), and RoHS (Restriction of Hazardous Substances). Additionally, it is advisable to request the supplier’s quality control plan and inquire about their adherence to international standards, such as ASTM or GB/T.

In conclusion, sourcing and manufacturing a pulverizer machine in China can be a cost-effective and efficient option. However, thorough research, due diligence, and clear communication with potential suppliers are essential to ensure a successful sourcing experience.

Why contact sourcifychina.com get free quota from reliable Pulverizer machine suppliers?

SourcifyChina.com is able to obtain a free quota from reliable Pulverizer machine suppliers due to several reasons. Firstly, SourcifyChina.com has established and maintained strong relationships with various pulverizer machine suppliers in China. These suppliers see the value in partnering with SourcifyChina.com as it provides them with increased exposure and access to a larger customer base.

Secondly, SourcifyChina.com has a reputation for being a trusted and reliable sourcing platform. Suppliers are more inclined to offer free quotas to SourcifyChina.com as they are confident that the platform will bring them genuine and serious buyers. SourcifyChina.com ensures that all suppliers go through a rigorous verification process, ensuring their credibility and reliability.

Furthermore, the platform has a large customer base, attracting a significant number of potential buyers. Suppliers recognize the potential for increased sales by offering a free quota to SourcifyChina.com. The platform’s reach and influence in the market make it an attractive platform for suppliers to showcase their products.

Lastly, SourcifyChina.com has a track record of driving successful business partnerships between suppliers and buyers. By offering a free quota, suppliers are more likely to secure potential deals and build long-term relationships with customers. This not only increases their sales revenue but also enhances their reputation in the industry.

In conclusion, SourcifyChina.com is able to obtain a free quota from reliable pulverizer machine suppliers due to its strong relationships, trusted reputation, large customer base, and successful track record. These factors give suppliers confidence in the platform’s ability to connect them with potential buyers and drive successful business partnerships.