Introduce about split case centrifugal pump guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

A split case centrifugal pump guide is a comprehensive resource that provides information and guidance on the usage, selection, and maintenance of split case centrifugal pumps. These pumps are widely used in various industries such as water treatment, agriculture, chemical processing, and HVAC systems.

Quality is an essential aspect when considering a split case centrifugal pump. It is crucial to ensure that the pump is manufactured using high-quality materials and meets industry standards. The guide will offer insights on what to look for in terms of durability, longevity, and performance efficiency.

Cost is another crucial factor for buyers. The guide will provide information on the price range of split case centrifugal pumps, considering their size, capacity, and specifications. It will also discuss factors that can affect costs, such as additional features, maintenance requirements, and energy efficiency. Comparing prices from different suppliers is important to find the best value for money.

When it comes to suppliers, the guide will provide a list of reputable manufacturers and suppliers who can provide high-quality split case centrifugal pumps. It will highlight their expertise, customer reviews, and after-sales service to help buyers make informed decisions.

Certification is an important consideration in purchasing a split case centrifugal pump. The guide will discuss various certifications to look for, including ISO, UL, CE, and others. These certifications ensure that the product meets specific safety, quality, and environmental standards.

Market analysis will be available in the guide, highlighting the demand and growth prospects of split case centrifugal pumps in different regions and industries. This information will help buyers understand market trends and make sound investment decisions.

Tips on installation, operation, and maintenance will be provided in the guide to assist users in maximizing the pump’s performance and lifespan. It will cover topics such as proper installation practices, regular maintenance schedules, troubleshooting, and energy-saving techniques.

Frequently Asked Questions (FAQ) section in the guide will address common queries and concerns related to split case centrifugal pumps. It will provide answers to questions about pump selection, sizing, efficiency, noise levels, and more.

In conclusion, a split case centrifugal pump guide is a valuable resource for buyers, offering information on quality, cost, suppliers, certifications, market analysis, tips, and FAQs related to split case centrifugal pumps. By utilizing this guide, buyers can make informed decisions and ensure their investment in the right equipment.

Types of split case centrifugal pump

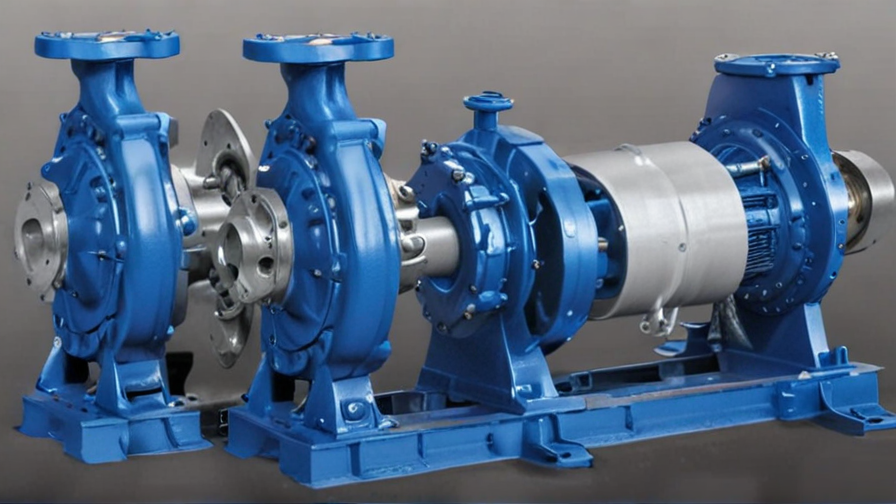

A split case centrifugal pump is a type of centrifugal pump that consists of a horizontally split casing. This design allows for easy access to the internal components, making maintenance and repairs more convenient. Split case centrifugal pumps are commonly used in applications that require high flow rates and low to medium pressures.

There are two main types of split case centrifugal pumps: single-stage and multi-stage.

1. Single-Stage Split Case Centrifugal Pump:

As the name suggests, a single-stage split case centrifugal pump has only one impeller. It is mainly used for applications that require relatively lower pressures and moderate flow rates. This type of pump is suitable for general water supply, irrigation, industrial processes, and HVAC systems.

The pump casing is horizontally split at the centerline, allowing the impeller to be easily accessed. The impeller is typically attached to a shaft that is driven by an electric motor or an engine. When the impeller rotates, it creates a low pressure at the inlet, which draws the fluid into the pump. As the fluid passes through the impeller, it gains kinetic energy and is discharged at a higher pressure through the outlet.

2. Multi-Stage Split Case Centrifugal Pump:

A multi-stage split case centrifugal pump consists of two or more impellers connected in series. Each impeller adds more energy to the fluid, resulting in higher pressures. This type of pump is used for applications that require higher pressures and flow rates, such as water transfer, high-rise building water supply, and industrial processes.

The construction of a multi-stage split case pump is similar to the single-stage pump, but with additional impellers. Each impeller is designed to handle a specific pressure, and the fluid passes through each impeller sequentially, gradually increasing the pressure.

Overall, split case centrifugal pumps are reliable, efficient, and robust, making them suitable for various applications. Their split casing design allows for easy maintenance and repairs, reducing downtime and improving the overall lifespan of the pump.

Pros and Cons of Using split case centrifugal pump

Split case centrifugal pumps have been widely used in various industries due to their efficient and reliable performance. However, like any other equipment, there are pros and cons associated with their usage. Let’s explore them:

Pros:

1. High Efficiency: Split case centrifugal pumps are known for their high efficiency, leading to lower energy consumption. This can result in significant cost savings in the long run.

2. Easy Maintenance: These pumps are relatively easier to maintain compared to other types of pumps. The split case design allows for easy access to the pump internals, making inspection and maintenance tasks quicker and more straightforward.

3. Wide Range of Flow and Head Capacities: Split case centrifugal pumps are available in a wide range of sizes and configurations, allowing them to handle various flow rates and head capacities. This versatility makes them suitable for a broad range of applications.

4. Minimal Vibration and Noise: Split case pumps are designed to operate with minimal vibration and noise, providing a quieter and more comfortable working environment.

5. Reliable Operation: Split case pumps are known for their robust construction and reliable operation. They are designed to handle demanding conditions and can operate continuously for extended periods without significant issues.

Cons:

1. Large Footprint: Split case centrifugal pumps generally require a larger footprint compared to other types of pumps. This can be a constraint in situations where space is limited.

2. Higher Initial Cost: Split case pumps often have a higher initial cost compared to other types of pumps. However, the long-term operational efficiency and reliability may offset this initial investment.

3. Limited Ability to Handle Viscous Fluids: Split case pumps are not well-suited for pumping highly viscous fluids, as the design and impeller type may limit their ability to handle such fluids efficiently.

4. Increased Maintenance and Operating Costs: While split case pumps have easier maintenance compared to some other types of pumps, they may still require periodic maintenance and occasional replacement of wearing parts, leading to increased operating costs.

In conclusion, split case centrifugal pumps offer numerous advantages in terms of efficiency, maintenance, and reliability. However, they do come with limitations such as a larger footprint, higher initial cost, limited suitability for viscous fluids, and increased maintenance and operating costs. Assessing these pros and cons will help determine if a split case centrifugal pump is the right choice for a specific application.

split case centrifugal pump Reference Specifications (varies for different product)

A split case centrifugal pump is a type of pump that is used to transport fluids, with a split casing design that allows easy access to all the internal components. This design also enables easy maintenance and repair, as the casing can be opened and closed without disturbing the pipe system.

The reference specifications for a split case centrifugal pump can vary depending on the specific product and its intended application. However, there are some common features and specifications that are often found in these pumps.

Firstly, split case centrifugal pumps typically have a horizontal, single-stage design, which means that they have only one impeller. This impeller rotates at high speed to create centrifugal force, which forces the fluid to move through the pump.

The casing of the pump is usually split along the horizontal plane, creating two halves that can be easily separated. This allows for quick access to the impeller and other internal components for inspection, maintenance, or repair.

The pump is generally designed to handle a wide range of fluids, including water, oil, and chemicals. The capacity or flow rate of the pump is an important specification and can vary depending on the specific model. The maximum capacity of a split case centrifugal pump can range from a few hundred gallons per minute to several thousand gallons per minute.

In addition, the pump is typically designed to operate at a specific pressure range, which is determined by the impeller and casing size. This pressure range can vary from a few psi (pounds per square inch) to several hundred psi.

Other important specifications include the type of materials used for the casing and impeller, as well as the power requirements, such as the motor size and voltage. These specifications can vary depending on the specific product and its intended use.

Overall, a split case centrifugal pump is a versatile pump that offers easy access for maintenance and repair. The design and specifications of these pumps can vary depending on the specific product, but they are commonly used to transport fluids in various industries, including water treatment, oil and gas, and industrial processes.

Applications of split case centrifugal pump

Split case centrifugal pumps are widely used in various industries due to their efficient and reliable performance. Here are some applications of split case centrifugal pumps:

1. Water supply and distribution: Split case centrifugal pumps are commonly used in water treatment plants, municipal water supply systems, and building services for the distribution of clean water. They provide high flow rates and can handle large volumes of water effectively.

2. Agriculture and irrigation: Farming and irrigation systems require pumps to transport water from a source, such as wells or rivers, to the fields. Split case centrifugal pumps are favored for these applications due to their ability to handle high flow rates and provide consistent water supply to large areas.

3. Power generation: Split case centrifugal pumps play a crucial role in power plants to circulate cooling water, condensate extraction, boiler feed, and other water-based processes. Their robust construction and high efficiency make them ideal for handling large volumes of water at high pressures.

4. Fire protection: Split case centrifugal pumps are commonly used in fire protection systems to provide high-pressure water supply for firefighting. These pumps are designed to deliver large amounts of water quickly to extinguish fires and protect valuable property.

5. Oil and gas industry: Split case centrifugal pumps find applications in the oil and gas industry, particularly for oil transfer, pipeline boosting, and refinery processes. Their ability to handle high viscosity fluids and operate under high pressures make them suitable for these demanding applications.

6. HVAC systems: Heating, ventilation, and air conditioning (HVAC) systems in commercial and residential buildings rely on split case centrifugal pumps for efficient circulation of chilled or hot water. These pumps ensure optimal temperature control and comfort within the building.

7. Mining industry: Split case centrifugal pumps are used in mines for dewatering operations, handling slurry, and transporting fluids underground. They are designed to handle abrasive and corrosive materials that are commonly encountered in mining processes.

8. Marine and offshore applications: In marine and offshore industries, split case centrifugal pumps are used for seawater cooling, ballast water transfer, fire-fighting systems, and other water-based processes. Their sturdy construction and ability to withstand harsh marine environments make them suitable for these applications.

In summary, split case centrifugal pumps find versatile applications in water supply, agriculture, power generation, fire protection, oil and gas, HVAC systems, mining, marine, and offshore industries. Their high flow rates, reliability, and efficient performance make them a preferred choice for handling large volumes of fluids in various industrial processes.

The Work Process and how to use split case centrifugal pump

The work process of a split case centrifugal pump involves the following steps:

1. Priming: Before starting the pump, it needs to be primed to remove any air or vapors from the casing and suction line. This is usually done by filling the casing with liquid and ensuring all air is expelled.

2. Starting the motor: The motor that drives the pump is started, either manually or automatically, and it begins to rotate. This rotation creates a centrifugal force that allows the pump to generate pressure and move the liquid.

3. Suction: The rotation of the pump impeller creates a low-pressure area at the suction side of the pump. This low-pressure zone causes the liquid to enter the pump through the suction pipe.

4. Impeller action: As the liquid enters the pump, it is driven by the centrifugal force generated by the rotating impeller. This force pushes the liquid towards the outer edges of the impeller and increases its velocity.

5. Discharge: Once the liquid reaches the outer edges of the impeller, it is thrown against the pump casing. This action converts the velocity energy into pressure energy, causing the liquid to be discharged from the pump through the discharge pipe.

6. Continuous flow: The pump continues to rotate, creating a continuous flow of liquid. The pump can handle large volumes of liquid and is used in various industrial applications, such as water supply, irrigation, HVAC systems, and firefighting.

When using a split case centrifugal pump, it is essential to ensure proper maintenance and operation to maximize its efficiency and lifespan. Some key points to consider are:

1. Regular inspection: Regularly check for any signs of leakage, vibration, or abnormal noise. Ensure that all bolts and connections are tight and secure.

2. Maintenance schedule: Follow a maintenance schedule provided by the manufacturer. This includes lubricating bearings, replacing worn-out parts, and cleaning the impeller and casing.

3. Monitoring performance: Monitor the pump’s performance regularly using pressure gauges, flow meters, and other instruments. This helps identify any performance issues or inefficiencies.

4. Safety precautions: Always follow safety protocols when working with the pump, such as electrical safety, proper grounding, and personal protective equipment (PPE).

In summary, a split case centrifugal pump works by creating a low-pressure area at the suction side, allowing the liquid to enter and then using the rotating impeller to generate pressure, resulting in the discharge of the liquid. Regular maintenance and proper operation are crucial for optimal performance and longevity of the pump.

Quality Testing Methods for split case centrifugal pump and how to control the quality

Quality testing methods for split case centrifugal pumps include performance testing, hydrostatic testing, non-destructive testing, and visual inspection. To control the quality, manufacturers should implement stringent quality control processes, such as rigorous inspection throughout the production cycle and adherence to industry standards.

Performance testing is crucial to ensure the pump operates within specified parameters. This involves testing the pump’s flow rate, head pressure, and power consumption under various operating conditions. A pump testing rig can be used for this purpose, where the pump is connected to a precision measuring system that accurately records the performance data.

Hydrostatic testing involves pressurizing the pump to a predetermined level to check for any leaks or pressure discrepancies. This ensures that the pump’s casing and internal components can withstand the designated operating pressures without failure. Commonly, water or a similar fluid is used for this type of test.

Non-destructive testing methods, such as ultrasonic or magnetic particle testing, can be employed to detect any internal flaws or defects in critical components like impellers, shafts, or seals. This helps to identify potential failures before the pump is put into service.

Visual inspection is a fundamental quality testing method where the pump is closely examined for any visible defects, irregularities, or surface damage. This can be performed at different stages of production, including after the machine work, assembly, and finishing processes.

To effectively control the quality of split case centrifugal pumps, manufacturers should establish comprehensive quality assurance programs. These programs may involve implementing stringent guidelines and procedures throughout the production cycle, including material selection, machining processes, assembly, and inspection.

Additionally, it is essential to adhere to internationally recognized standards, such as API 610 or ISO 9001, to ensure consistent quality production. Independent third-party certifications can also help validate the pump’s conformity to these standards.

Regular auditing and review of quality systems, both internally and externally, can provide feedback for continuous improvement. Furthermore, incorporating customer feedback and performing post-installation inspections can help evaluate the pump’s performance in real-world conditions, leading to further refinement of production processes.

In conclusion, quality testing methods for split case centrifugal pumps include performance testing, hydrostatic testing, non-destructive testing, and visual inspection. To control the quality, manufacturers should establish rigorous quality control processes, adhere to industry standards, and continuously improve production based on customer feedback and real-world performance evaluations.

split case centrifugal pump Sample Policy and Post-Purchase Considerations for split case centrifugal pump from China

Sample Policy:

When purchasing a split case centrifugal pump from China, it is important to establish a clear sample policy with the supplier. This ensures that the buyer receives a product that meets their requirements and expectations. The sample policy should include the following considerations:

1. Sample Availability: The supplier should be able to provide samples of the split case centrifugal pump for evaluation before making a bulk purchase. The buyer should confirm whether the samples are free or chargeable, and if charges apply, they need to be reasonable.

2. Sample Quality: The sample should accurately represent the quality, performance, and specifications of the final product. The buyer should clearly communicate their specific requirements to the supplier to ensure the sample meets their expectations.

3. Sample Testing: The buyer should request the necessary testing and inspection of the sample to verify its compliance with industry standards and regulations. This ensures that the product is safe, reliable, and suitable for its intended application.

4. Sample Approval: The buyer should have a clear process for approving or rejecting the sample. This includes establishing a timeline for evaluating the sample and providing feedback to the supplier.

Post-Purchase Considerations:

After purchasing a split case centrifugal pump from China, there are several important considerations for the buyer:

1. Quality Assurance: The buyer should implement a quality assurance process to ensure that the purchased split case centrifugal pump meets their requirements. This may involve conducting quality control inspections, performance testing, or third-party verifications.

2. Warranty and Support: The buyer should clarify the warranty terms with the supplier, including the duration and coverage. Additionally, it is important to establish a clear after-sales support system to address any issues or concerns that may arise.

3. Spare Parts Availability: The buyer should confirm the availability of spare parts for the split case centrifugal pump. This ensures that replacement parts can be easily sourced in case of any breakdown or maintenance requirements.

4. Communication and Feedback: Effective communication with the supplier is crucial for resolving any problems or addressing any needs that may arise post-purchase. Providing timely feedback and maintaining a good working relationship helps ensure a smooth and satisfactory experience.

By adhering to a well-defined sample policy and considering the post-purchase aspects, buyers can minimize risks and ensure a successful procurement process for split case centrifugal pumps from China.

Sourcing split case centrifugal pump from China: Opportunities, Risks, and Key Players

China is a major player in the global manufacturing industry and offers a plethora of opportunities for sourcing split case centrifugal pumps. These pumps are used in various applications such as water treatment, irrigation, and oil and gas industries. The following highlights the opportunities, risks, key players, and key considerations for sourcing split case centrifugal pumps from China.

Opportunities:

1. Cost Advantage: Chinese manufacturers generally offer competitive prices due to lower labor costs and economies of scale.

2. Technological Expertise: China has developed advanced manufacturing capabilities and has a strong engineering talent pool.

3. Wide Product Range: China offers a wide range of options in terms of pump specifications, sizes, and materials.

4. Efficient Supply Chain: The country has a well-established supply chain network to ensure timely delivery.

Risks:

1. Quality Control: Ensuring product quality can be a challenge due to varying standards and potential issues with counterfeit parts.

2. Intellectual Property (IP) Protection: Intellectual property theft is a concern in China, so it is crucial to protect sensitive information and designs.

3. Communication and Language Barriers: Effective communication may be hindered due to language differences, leading to misunderstandings or delays.

4. Regulations and Compliance: Compliance with international standards, certifications, and import regulations should be carefully addressed.

Key Players:

1. Shanghai East Pump Group: A leading manufacturer of split case centrifugal pumps, known for their advanced technology and high-quality products.

2. Shijiazhuang An Pump Machinery Co., Ltd.: Specializes in manufacturing industrial pumps, including split case centrifugal pumps, and has a global customer base.

3. Zhejiang Kaicheng Pump Valve Co., Ltd.: Produces various centrifugal pumps and provides customized solutions based on customer requirements.

4. Shandong Boshan Pump Science and Technology Co., Ltd.: Offers a wide range of pumps, including split case centrifugal pumps, with a focus on innovative and energy-efficient designs.

Key Considerations:

1. Thoroughly research and verify the reputation, quality, and certifications of potential suppliers.

2. Clearly communicate product specifications, quality standards, and delivery requirements.

3. Consider working with a reputable sourcing agent or engage in a direct factory inspection to ensure compliance with quality standards.

4. Protect intellectual property by implementing confidentiality agreements and trademark registrations.

Overall, sourcing split case centrifugal pumps from China presents significant opportunities due to cost advantages, technological expertise, and supply chain efficiency. However, risks related to quality control, intellectual property protection, and communication barriers should be mitigated through careful supplier selection, proper communication strategies, and legal safeguards. Key players in China’s pump industry can deliver high-quality products, provided the necessary due diligence is undertaken.

How to find and select reliable split case centrifugal pump manufacturers in China,use google search manufacturers and suppliers

When searching for reliable split case centrifugal pump manufacturers in China, Google can be a useful tool. Here are a few steps to follow in order to find and select reliable manufacturers:

1. Start by opening Google and entering relevant keywords such as “split case centrifugal pump manufacturers in China” or “reliable split case pump suppliers in China.”

2. Review the search results and visit the websites of various manufacturers and suppliers. Look for well-established companies with a professional website, clear product information, and a good reputation.

3. Explore the company’s website thoroughly to gather important details such as their manufacturing capabilities, years of experience, certifications, and any partnerships or collaborations they may have.

4. Look for customer reviews and testimonials on the manufacturer’s website or on external platforms. Positive feedback is a good indicator of reliability and customer satisfaction.

5. Consider reaching out to the manufacturer directly through their website, email, or phone to ask any specific questions you may have. Inquire about their production capacity, quality control procedures, lead times, and pricing.

6. Check if the manufacturer has the necessary certifications and compliance with international standards. Reliable manufacturers often have ISO certifications, CE marks, and other quality control certificates.

7. Seek recommendations from industry experts, colleagues, or business networks who may have prior experience working with split case centrifugal pump manufacturers in China. They can provide valuable insights and recommendations.

8. Lastly, compare and evaluate multiple manufacturers based on their product quality, reputation, customer support, price competitiveness, and delivery terms. Make an informed decision by selecting a manufacturer that best meets your requirements and offers the highest level of reliability.

Remember to verify all the information received and take necessary steps to establish trust with the manufacturer before proceeding with any agreements or purchases.

How to check split case centrifugal pump manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To ensure the reliability of a split case centrifugal pump manufacturer’s website, you can follow these steps using Google Chrome and the SEOquake extension:

1. Open Google Chrome browser and search for the manufacturer’s website by typing in the company name or relevant keywords.

2. Look for the manufacturer’s official website in the search results. Usually, the website in the top results is more reliable, but it’s important to verify the authenticity.

3. Check if the website has an SSL certificate by looking for a padlock icon in the URL bar. This indicates that the website has implemented secure encryption for your data.

4. Install the SEOquake extension on your Google Chrome browser. This extension provides valuable SEO metrics and insights about the website you are visiting.

5. Once installed, open the manufacturer’s website.

6. Click on the SEOquake extension icon in your browser’s toolbar, and a dropdown will appear with various metrics.

7. Within the dropdown, click on “Diagnostic” to access SEOquake’s advanced metrics.

8. In the “Alexa Rank” section, check if the website’s ranking falls within the top 10 million. This indicates a reasonably good level of website traffic and popularity.

9. Assess the website’s overall design and functionality. A reliable manufacturer’s website should have a professional and user-friendly layout, intuitive navigation, and up-to-date information.

10. Verify the presence of essential information such as product details, specifications, certifications, contact information, and customer support.

11. Check for customer reviews or testimonials if available on the website. Genuine customer feedback adds credibility to the manufacturer’s reputation.

12. Lastly, browse through the website’s “About Us” or “Company Profile” section to learn more about the manufacturer’s history, expertise, and industry experience.

With these steps, you can evaluate a split case centrifugal pump manufacturer’s website for reliability, using Google Chrome and the SEOquake extension. Remember to use your judgment and consider multiple factors before making a final decision.

Top 10 split case centrifugal pump manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Shanghai Liancheng Group: With over 20 years of experience, Shanghai Liancheng Group is a leading manufacturer of split case centrifugal pumps in China. Their products feature high efficiency, low noise, and reliable operation. They offer a wide range of pumps for various applications including water supply, irrigation, industrial processes, and more.

2. Pacific Pump Group Co., Ltd.: Pacific Pump Group is known for its advanced technology and innovative designs. Their split case centrifugal pumps are made of high-quality materials, ensuring excellent performance and long service life. They provide solutions for water supply, firefighting, HVAC systems, and other applications.

3. Shandong Shuanglun Co., Ltd.: Shandong Shuanglun specializes in manufacturing split case centrifugal pumps for industrial use. Their products are designed for high flow rates and low noise operation. These pumps are widely used in oil and gas industries, power plants, water treatment plants, and large-scale construction projects.

4. Hunan Neptune Pump Co., Ltd.: Neptune Pump is a reputable manufacturer of split case centrifugal pumps in China, with a strong focus on research and development. Their pumps excel in performance, energy efficiency, and reliability. They serve various sectors such as municipal, agriculture, mining, and chemical industries.

5. Zhejiang Yonjou Technology Co., Ltd.: Yonjou Technology is a leading provider of split case centrifugal pumps with a diverse range of products. Their pumps are suitable for applications in water supply and drainage, chemical processing, air conditioning systems, and more. Yonjou focuses on delivering high-quality products at competitive prices.

6. Hebei Muyuan Pump Industry Co., Ltd.: Muyuan Pump is a trusted manufacturer of split case centrifugal pumps with a wide range of offerings. Their pumps are highly efficient, corrosion-resistant, and suitable for handling large volumes of fluids. They cater to industries such as mining, metallurgy, power plants, and ore processing.

7. Jiangsu Feiyue Machine and Pumps Group Co., Ltd.: Feiyue Group specializes in manufacturing split case centrifugal pumps for industrial and agricultural use. Their pumps are designed for high efficiency, low maintenance, and reliable operation. Feiyue offers customized solutions for various applications, including water supply, irrigation, and wastewater treatment.

8. Shanghai East Pump (Group) Co., Ltd.: East Pump is a renowned manufacturer of split case centrifugal pumps with a strong research and development capability. Their pumps are widely used in industries such as chemical, oil refining, power generation, and water treatment. They focus on providing efficient and reliable pumping solutions.

9. Jiangsu Suhua Pump Co., Ltd.: Suhua Pump is a leading manufacturer of split case centrifugal pumps for various industries. Their pumps are known for their high efficiency, low vibration, and stable performance. Suhua caters to the needs of industries such as water supply, power generation, and chemical processing.

10. Hunan Zhongda Pump Industry Co., Ltd.: Zhongda Pump is dedicated to the production of split case centrifugal pumps with exceptional quality and performance. Their pumps are widely used in water supply and drainage systems, irrigation, and industrial processes. Zhongda prides itself on providing reliable and cost-effective solutions.

| Manufacturer | Key Features | Applications |

|————————–|——————————————————|—————————————|

| Shanghai Liancheng Group | High efficiency, low noise, reliable operation | Water supply, irrigation, industrial |

| Pacific Pump Group | Advanced technology, innovative design | Water supply, firefighting, HVAC |

| Shandong Shuanglun Co. | High flow rates, low noise, industrial applications | Oil and gas, power plants, water treatment |

| Hunan Neptune Pump Co. | Focus on research and development, energy efficiency | Municipal, agriculture, mining, chemical |

| Zhejiang Yonjou Tech. | Diverse range, competitive prices | Water supply, chemical processing, AC |

| Hebei Muyuan Pump Ind. | High efficiency, corrosion-resistant, industrial use | Mining, metallurgy, power plants, ore processing |

| Jiangsu Feiyue M&P Group | High efficiency, low maintenance, customized solutions | Water supply, irrigation, wastewater treatment |

| Shanghai East Pump Group | Strong R&D capability, efficient pumping solutions | Chemical, oil refining, power generation, water treatment |

| Jiangsu Suhua Pump Co. | High efficiency, low vibration, stable performance | Water supply, power generation, chemical processing |

| Hunan Zhongda Pump Ind. | Exceptional quality, reliable and cost-effective | Water supply, irrigation, industrial |

In conclusion, China offers a wide range of split case centrifugal pump manufacturers, each with their unique qualities and applications. The above-mentioned companies provide high-quality products designed for various industries such as water supply, irrigation, chemical processing, mining, and more. Whether you need pumps for industrial processes or municipal applications, these manufacturers offer efficient, reliable, and cost-effective solutions.

Background Research for split case centrifugal pump manufacturers Companies in China, use qcc.com archive.org importyeti.com

There are several split case centrifugal pump manufacturers in China, and qcc.com, archive.org, and importyeti.com provide relevant information about these companies.

Qcc.com is a popular Chinese website that offers comprehensive business information on companies in China. It provides data on company registrations, industry classifications, financial information, and more. By searching for split case centrifugal pump manufacturers on qcc.com, one can find a list of companies along with their contact details, company profiles, and business scope.

Archive.org is a website that archives and stores web pages from around the world. It allows users to access and retrieve information from websites that may no longer be available. By using archive.org, one can explore historical data and information about split case centrifugal pump manufacturers in China. This can include old company websites, product catalogs, and other relevant information that may not be present on current websites.

Importyeti.com is a platform that provides data on international trade and import/export activities. This website can be utilized to search for Chinese split case centrifugal pump manufacturers and gather information about their export activities, shipment history, and trading partners. This data can be useful in understanding the global market presence and competitiveness of these companies.

Through these platforms, researchers can gather valuable background information about split case centrifugal pump manufacturers in China. This includes details about the companies, their history, production capabilities, certifications, and export/import activities. It is important to note that these platforms can provide a general overview of the industry and the specific companies but may not include the most up-to-date information. Therefore, it is advisable to contact the manufacturers directly for the most current and accurate information.

Leveraging Trade Shows and Expos for split case centrifugal pump Sourcing in China

Trade shows and expos are excellent platforms for sourcing split case centrifugal pumps in China. These events provide a unique opportunity to connect with numerous suppliers, evaluate product offerings, and establish reliable business relationships. By effectively leveraging trade shows and expos, companies can streamline the sourcing process, minimize risks, and ensure high-quality products.

Firstly, trade shows and expos bring together a wide range of suppliers from different regions of China. This allows buyers to access a large pool of potential manufacturers, making it easier to compare product offerings, prices, and production capabilities. Visiting these events enables companies to physically examine products, discuss specifications, and negotiate favorable terms directly with suppliers.

Furthermore, trade shows and expos provide an opportunity to attend seminars and presentations delivered by industry experts. This valuable knowledge sharing enables buyers to better understand the market trends, technological advancements, and regulatory requirements related to split case centrifugal pumps. This information equips companies with the necessary insights to make informed sourcing decisions, ensuring the selection of reliable and compliant suppliers.

Additionally, trade shows and expos foster networking opportunities. Attendees can engage in face-to-face discussions with suppliers, build trust, and establish long-lasting partnerships. Direct communication allows for seamless collaboration, including discussing customizations, quality control measures, and delivery schedules. Building strong relationships with suppliers at these events increases the likelihood of successful sourcing and reduces potential risks.

To make the most of trade shows and expos, it is essential to plan ahead. Before attending, research the exhibitor list and select the most relevant suppliers to visit. Prepare a list of questions and requirements to discuss with potential manufacturers. Consider attending seminars and workshops to stay updated on industry trends and best practices.

In conclusion, trade shows and expos present unparalleled opportunities for sourcing split case centrifugal pumps in China. By capitalizing on these events, companies can efficiently evaluate suppliers, stay informed about market developments, and establish strong business relationships. Leveraging trade shows and expos can ultimately lead to successful sourcing endeavors and ensure access to high-quality products.

The Role of Agents and Sourcing Companies in Facilitating split case centrifugal pump Purchases from China

Agents and sourcing companies play a crucial role in facilitating split case centrifugal pump purchases from China. With their expertise and network, these intermediaries streamline the process, ensuring a smooth and successful transaction.

Firstly, agents and sourcing companies act as a link between the buyer and the Chinese supplier. They provide a bridge of communication, assisting in negotiating terms, discussing product specifications, and addressing any concerns or questions the buyer may have. This intermediary role helps eliminate language and cultural barriers, ensuring that both parties understand each other’s requirements clearly.

Secondly, these agents and sourcing companies perform thorough market research and due diligence to identify reliable and reputable Chinese manufacturers or suppliers. By leveraging their extensive network and knowledge of the industry, they connect the buyer with trustworthy companies that offer high-quality split case centrifugal pumps at competitive prices. This minimizes the risk of dealing with fraudulent or substandard suppliers, which is especially crucial when importing from a foreign country.

Furthermore, agents and sourcing companies assist in the supplier selection process. They review the supplier’s track record, assess their production capacity, and inspect their manufacturing facilities to ensure they meet the buyer’s standards. This step is vital in guaranteeing the quality and reliability of the purchased products.

Agents and sourcing companies also facilitate the logistics and shipping process. They provide assistance in arranging transportation, customs clearance, and documentation, ensuring a hassle-free delivery of the purchased split case centrifugal pumps from China to the buyer’s location. This expertise helps streamline the import process and reduces the buyer’s administrative burden.

Overall, agents and sourcing companies play a vital role in facilitating split case centrifugal pump purchases from China. With their industry knowledge, network, and ability to bridge the gap between buyers and suppliers, they ensure a smooth and successful transaction, minimizing risks and enhancing the buyer’s experience.

Price Cost Research for split case centrifugal pump manufacturers Companies in China, use temu.com and 1688.com

When it comes to split case centrifugal pump manufacturers in China, two well-known platforms that can be utilized for price cost research are temu.com and 1688.com.

temu.com is a reputable online marketplace that connects buyers and sellers in various industries. It offers a wide range of products, including centrifugal pumps, to cater to different needs. Users can easily search for split case centrifugal pump manufacturers on the platform and compare prices offered by various suppliers. The platform also provides detailed product descriptions, specifications, and customer reviews to help buyers make informed decisions.

1688.com, on the other hand, is a popular B2B platform owned by Alibaba Group, specifically designed for the Chinese market. It serves as a comprehensive wholesale marketplace for a vast array of products, including split case centrifugal pumps. Buyers can easily navigate through the platform and find reliable manufacturers and suppliers who offer competitive prices. 1688.com also offers features such as product comparison and supplier ratings, aiding in price cost research.

Conducting price cost research using these platforms is straightforward. Interested buyers can visit either temu.com or 1688.com, search for split case centrifugal pump manufacturers, and compare the prices offered by different suppliers. It is advisable to closely examine the product descriptions and specifications to ensure that they meet the required quality standards. Additionally, checking customer reviews and ratings can help gauge the reputation and reliability of the manufacturers.

By utilizing temu.com and 1688.com, buyers can efficiently research and compare prices offered by split case centrifugal pump manufacturers in China, enabling them to make informed decisions and secure competitive deals.

Shipping Cost for split case centrifugal pump import from China

The shipping cost for importing a split case centrifugal pump from China can vary depending on various factors such as the weight, dimensions, shipping method, and destination. Typically, there are two main shipping methods to consider – air freight and sea freight.

If you opt for air freight, the shipping cost will generally be higher but the transit time will be shorter. On the other hand, sea freight is more cost-effective, but the transit time is longer.

To provide a rough estimate, for a split case centrifugal pump weighing around 500 kg and with dimensions of 1.5m x 1.2m x 0.8m, the air freight cost from China to a major destination in Europe or the United States could range from $1,500 to $3,000. This estimate includes air freight charges, customs clearance fees, and local delivery charges.

Alternatively, if you choose sea freight, the cost for a shipment of this size could range from $500 to $1,500. This estimate includes sea freight charges, documentation fees, customs clearance fees, and local delivery charges. However, it is important to note that the transit time for sea freight could take around 20 to 40 days depending on the destination.

It is crucial to obtain accurate quotes from shipping companies or freight forwarders as costs can vary based on specific requirements and additional services needed, such as insurance or expedited shipping. Additionally, consider customs duties, taxes, and any other regulations or charges imposed by the importing country.

In conclusion, the shipping cost for importing a split case centrifugal pump from China will depend on factors such as weight, dimensions, shipping method, and destination. To get an accurate cost estimate, it is recommended to consult with shipping companies or freight forwarders who can provide tailored quotes based on your specific requirements.

Compare China and Other split case centrifugal pump Markets: Products Quality and Price,Visible and Hidden Costs

China is one of the leading manufacturers and exporters of split case centrifugal pumps in the global market. When comparing China to other split case centrifugal pump markets in terms of product quality and price, there are several factors to consider.

In terms of product quality, China has emerged as a major player, consistently improving the quality and reliability of its split case centrifugal pumps. Chinese manufacturers have invested heavily in advanced technologies, stringent quality control measures, and strict adherence to international standards. This has resulted in a significant improvement in the overall product quality, with many Chinese pumps meeting or even exceeding the quality of pumps manufactured in other countries.

However, it is important to note that not all Chinese split case centrifugal pumps are of the same quality. China has a vast range of manufacturers, and the quality standards may vary among different suppliers. Therefore, buyers should carefully research and select a reliable and reputable supplier to ensure the desired level of product quality.

In terms of pricing, China offers competitive prices for split case centrifugal pumps. The country’s manufacturing capabilities, economies of scale, and low labor costs contribute to relatively lower prices compared to manufacturers in other countries. This makes Chinese pumps an attractive option for many buyers who are price-sensitive.

When comparing visible and hidden costs, buyers should consider factors such as shipping costs, import duties, taxes, and any additional fees associated with importing split case centrifugal pumps from China or other markets. These costs can vary depending on the distance, transportation method, and government regulations.

It is crucial for buyers to thoroughly evaluate not only the upfront price but also the total cost of ownership, which includes maintenance, spare parts availability, and the pump’s expected lifespan. Opting for a lower-priced pump without considering these factors may result in higher long-term costs if the pump requires frequent repairs or has a short lifespan.

In conclusion, China has made significant strides in improving the quality of split case centrifugal pumps and offers competitive prices due to its manufacturing capabilities and economies of scale. However, buyers should conduct thorough research to identify reliable suppliers and carefully consider the total cost of ownership to make informed purchasing decisions.

Understanding Pricing and Payment Terms for split case centrifugal pump: A Comparative Guide to Get the Best Deal

When purchasing a split case centrifugal pump, understanding the pricing and payment terms is crucial to ensure that you get the best deal. Here is a comparative guide to help you navigate through these aspects.

Pricing for a split case centrifugal pump can vary significantly depending on various factors such as the pump size, material construction, brand reputation, and additional features. To get the best deal, it is recommended to obtain quotes from multiple suppliers or manufacturers. This will allow you to compare prices and negotiate for a competitive offer.

When evaluating the pricing, it is essential to consider the quality and reliability of the pump. Cheaper options might compromise on the pump’s durability, performance, and after-sales services. Therefore, it is advisable to strike a balance between cost and quality to ensure a long-term, cost-effective solution.

Payment terms for centrifugal pump purchases also differ across suppliers. Common options include full prepayment, partially upfront payment, or installment-based payments. It is recommended to negotiate for a payment plan that suits your business’s cash flow and financial capabilities.

Additionally, understanding the warranty terms is vital. Ensure that the warranty period offered by the supplier aligns with your requirements. It is important to consider both the warranty duration and the level of technical support available during the warranty period. A strong warranty can provide peace of mind and protect your investment in case of any unforeseen issues.

Other factors to consider include the supplier’s reputation, delivery terms (including lead time), and any ancillary services they offer such as installation support or training programs.

To summarize, when looking for the best deal on a split case centrifugal pump, collect and compare quotes from various suppliers while considering factors like pump quality, warranty terms, payment options, and additional services. Striking the right balance between cost and quality is essential to ensure the best long-term value for your investment.

Chinese Regulations and Industry Standards Certifications for split case centrifugal pump,Import Regulations and Customs for split case centrifugal pump from China

Chinese Regulations and Industry Standards Certifications for split case centrifugal pump:

In China, split case centrifugal pumps are regulated by various government departments and must adhere to certain industry standards. The main regulatory authority in China for industrial product certifications is the China Quality Certification Center (CQC). The CQC provides certifications for split case centrifugal pumps based on national standards and regulations.

One of the most important standards that split case centrifugal pump manufacturers must comply with is the GB/T 5657-2014 standard. This standard specifies the technical requirements, test methods, inspection rules, and marking, packaging, transportation, and storage requirements for split case centrifugal pumps.

Additionally, the split case centrifugal pump industry in China also follows the ISO 2858-1:1993 standard, which specifies the general requirements for the performance, construction, and testing of centrifugal pumps.

To obtain certifications for their products, manufacturers must undergo a rigorous testing and evaluation process. The tests include performance tests, mechanical tests, electrical tests, and safety tests. Once a split case centrifugal pump meets all the requirements, it is awarded the necessary certifications, such as the CCC mark, which indicates compliance with Chinese regulations.

Import Regulations and Customs for split case centrifugal pump from China:

Importing split case centrifugal pumps from China involves complying with certain import regulations and customs procedures. The import of these pumps is governed by the customs authority and the relevant regulatory agencies in the importing country.

Firstly, importers need to ensure that the split case centrifugal pumps comply with the technical requirements and standards of their respective countries. This includes verifying the certifications obtained from the Chinese regulatory authorities, such as the CQC.

Secondly, importers must prepare the necessary import documentation, including invoices, packing lists, and transport documents, such as bills of lading or airway bills. These documents should accurately describe the imported goods, their quantity, and value.

Thirdly, importers need to pay attention to customs duties and taxes. These fees vary depending on the importing country and are calculated based on the value of the imported goods. Importers should consult with local customs authorities or seek professional advice to determine the applicable fees.

Lastly, importers may also need to comply with specific customs procedures, such as obtaining import permits or licenses. These requirements are specific to each country and should be thoroughly researched to ensure compliance.

Overall, importing split case centrifugal pumps from China requires adherence to technical standards, proper documentation, and compliance with customs regulations in the importing country. It is advisable to consult with import experts or customs brokers to navigate the import process efficiently.

Sustainability and Environmental Considerations in split case centrifugal pump Manufacturing

Sustainability and environmental considerations in split case centrifugal pump manufacturing are crucial for the industry to reduce its ecological footprint and contribute to a greener future. Here, we discuss some key factors and practices that can be adopted to achieve sustainability in the manufacturing process.

Firstly, energy efficiency plays a vital role in reducing environmental impact. Designing and manufacturing split case centrifugal pumps with high energy efficiency can significantly reduce power consumption and consequently lower greenhouse gas emissions. This can be achieved through the use of advanced motor technology, improved hydraulic designs, and optimized impeller and volute configurations.

Additionally, material selection is crucial to ensure environmental sustainability. Manufacturers should prioritize using materials that are recyclable, non-toxic, and have a low carbon footprint. There should also be a focus on reducing the use of hazardous substances, such as lead or mercury, during the manufacturing process. Implementing a closed-loop material management system can help minimize waste and promote recycling practices.

Furthermore, water conservation measures should be integrated into the manufacturing process. This can include recycling and reusing water used for testing and cleaning purposes, as well as implementing water-efficient practices in production. Wastewater treatment facilities can also be installed to ensure that any discharged water meets environmental standards.

Reducing the overall environmental impact of transportation is another important consideration. Manufacturers should aim to minimize the distance between raw material suppliers, production facilities, and customers. This can be achieved by establishing local supply chains and optimizing logistics to reduce carbon emissions associated with transportation.

Finally, manufacturers should strive for continuous improvement through regular audits and assessments of their environmental performance. Setting targets and monitoring progress towards sustainability goals will lead to innovation and the implementation of new technologies and practices.

In conclusion, sustainability and environmental considerations in split case centrifugal pump manufacturing are essential for reducing the industry’s ecological footprint. By prioritizing energy efficiency, material selection, water conservation, transportation optimization, and continuous improvement, manufacturers can contribute to a greener future while meeting market demands for sustainable products.

List The Evolution history of “split case centrifugal pump”

The split case centrifugal pump has undergone several significant advancements throughout its evolution history. Originally developed in the early 1900s, this type of pump has continuously evolved to enhance its efficiency, performance, and reliability.

The first split case centrifugal pump designs featured a horizontally split casing, which allowed for easy access to the rotating elements for maintenance and repairs. These early models were driven by steam or gasoline engines, providing moderate flow rates and pressures.

In the 1920s, advancements in manufacturing techniques led to the introduction of double suction impellers. This innovation allowed the pump to draw fluid from both sides of the impeller, resulting in higher flow rates and improved hydraulic efficiency. This design modification significantly enhanced the pump’s performance and made it more versatile for various applications, such as water supply, irrigation, and industrial processes.

During the mid-20th century, the split case centrifugal pump saw several improvements in terms of material selection, seal technology, and motor integration. Engineered plastics, such as polypropylene and PVC, were introduced to handle corrosive fluids, while mechanical seals replaced traditional gland packing for better sealing performance and reduced leakage. Additionally, electric motors became the standard drive mechanism, improving energy efficiency and ease of operation.

In recent years, further advancements have emerged to optimize the split case centrifugal pump’s performance and reliability. Computational Fluid Dynamics (CFD) analysis and computer-aided design (CAD) tools have enabled pump manufacturers to fine-tune the impeller geometry and hydraulic profiles. This has resulted in higher efficiencies, reduced energy consumption, and improved operational stability.

Additionally, the integration of advanced monitoring and control systems has allowed for real-time performance tracking, predictive maintenance, and remote operation capabilities. These technologies have increased the longevity of the pump, minimized downtime, and enhanced overall system reliability.

As the world becomes increasingly focused on sustainability and energy efficiency, the split case centrifugal pump continues to evolve. Manufacturers are exploring innovative materials, optimizing hydraulic designs, and integrating smart technologies to ensure these pumps remain at the forefront of fluid transfer solutions while minimizing environmental impact.

In conclusion, the evolution history of the split case centrifugal pump spans over a century. From early horizontal split casings to modern smart pump technologies, continuous advancements have shaped this pump type into a versatile, efficient, and reliable solution for various applications.

The Evolution and Market Trends in split case centrifugal pump Industry

The split case centrifugal pump industry has witnessed significant evolution and market trends in recent years. This type of pump is widely used in various industries, including water treatment plants, power generation, oil and gas, and HVAC systems, among others.

One of the key evolutions in the split case centrifugal pump industry is the incorporation of advanced technology. Manufacturers are now focusing on the development of high-performance pumps with features like variable speed drives, smart monitoring systems, and energy-efficient designs. These advancements have led to improved pump reliability, reduced maintenance costs, and increased energy savings for end-users.

Another notable trend in the market is the growing demand for customized solutions. End-users are seeking pumps that are tailored to their specific requirements and operational needs. This has led manufacturers to offer a wide range of options, including various materials of construction, different impeller designs, and pump sizes. Customization ensures that the pumps are optimized for efficiency and durability, resulting in improved performance and longer operational life.

Furthermore, sustainability and environmental concerns have become key factors influencing market trends. End-users are increasingly investing in eco-friendly and energy-efficient solutions to reduce their carbon footprint and comply with stringent regulations. As a result, manufacturers are focusing on the development of pumps with low energy consumption and minimal environmental impact. These pumps not only provide cost savings but also contribute to sustainability initiatives.

The split case centrifugal pump industry is also witnessing a shift towards digitalization and the Industrial Internet of Things (IIoT). Manufacturers are integrating smart technologies, such as sensors and connectivity features, into their pumps. This allows for real-time monitoring, remote control, and predictive maintenance, enhancing the overall reliability and efficiency of the pumps. The ability to collect and analyze data enables proactive decision-making, reducing downtime and optimizing pump performance.

In conclusion, the split case centrifugal pump industry has experienced significant evolution driven by advancements in technology, customization demands, sustainability, and digitalization. The market is expected to continue growing as more industries recognize the importance of high-performance, energy-efficient pumps that can be tailored to their specific needs.

Custom Private Labeling and Branding Opportunities with Chinese split case centrifugal pump Manufacturers

Chinese split case centrifugal pump manufacturers offer custom private labeling and branding opportunities to meet the specific needs of businesses. These manufacturers understand the importance of brand recognition and the competitive advantage it provides in the market.

By collaborating with Chinese manufacturers, businesses have the flexibility to create their own unique brand identity through private labeling. They can design customized logos, labels, and packaging materials that align with their brand image. This allows businesses to establish a distinct visual identity that sets them apart from competitors and enhances brand recognition.

Moreover, Chinese split case centrifugal pump manufacturers offer branding opportunities by providing customization options for product specifications. Businesses can tailor the pumps according to their specific requirements, including performance attributes, materials, and sizes. This customization helps businesses to position their products as high-quality, reliable, and tailored to meet the exact needs of their target customers.

In addition to private labeling and customization, Chinese manufacturers also assist businesses in developing brand awareness strategies. They provide guidance on market trends, product positioning, and marketing strategies to help businesses effectively leverage their brand identity.

Collaborating with Chinese split case centrifugal pump manufacturers for private labeling and branding opportunities offers businesses numerous benefits. It allows them to differentiate their products in the market, create brand recognition, and tailor products to meet customer demands. By leveraging the expertise and manufacturing capabilities of Chinese manufacturers, businesses can strengthen their brand and gain a competitive edge in the industry.

Tips for Procurement and Considerations when Purchasing split case centrifugal pump

When purchasing a split case centrifugal pump for procurement, there are several tips and considerations to keep in mind. This type of pump is commonly used in applications requiring high flow rates and moderate to high head requirements. Here are some key points to consider:

1. Flow rate and head requirements: Determine the required flow rate and head pressure of your system to ensure the selected pump can meet these specifications. The flow rate is measured in gallons per minute (GPM) or cubic meters per hour (m³/h), while the head pressure is represented in feet or meters.

2. Efficiency: Look for pumps with high-efficiency ratings to minimize energy consumption and reduce operating costs. Check the pump curve to understand how the efficiency varies across the range of flow rates and heads.

3. Construction materials: Consider the nature of the fluid being pumped and select materials that can withstand its properties. Common options include cast iron, stainless steel, bronze, and various alloys. Additionally, ensure that the materials used are resistant to corrosion and abrasion if the fluid being pumped is aggressive.

4. Maintenance and serviceability: Choose a pump that is easy to maintain and service. Look for designs that provide access to critical components without dismantling the entire pump. This will help reduce downtime and maintenance costs in the long run.

5. Reliability and lifespan: Select a pump from reputable manufacturers with a proven track record of reliability. Look for features like heavy-duty shafts, precision bearings, and robust seals that increase the pump’s lifespan and reduce the risk of breakdowns.

6. Cost: Consider the initial purchase price of the pump alongside its long-term operational costs. A higher-priced pump with better efficiency and reliability can often result in lower overall costs over its lifespan.

7. Noise and vibration: Centrifugal pumps can generate noise and vibration, which may be problematic depending on the application. Look for pumps with built-in features or accessories that minimize noise levels and provide stable operation.

8. Warranty and after-sales support: Ensure the manufacturer offers a comprehensive warranty and has a reliable after-sales service network. This ensures prompt assistance in case of any issues or required repairs.

By considering these tips and factors, you can select a split case centrifugal pump that best suits your requirements, providing efficient and reliable operation for your application.

FAQs on Sourcing and Manufacturing split case centrifugal pump in China

1. What is a split case centrifugal pump?

A split case centrifugal pump is a type of pump commonly used for fluid transportation. It consists of a casing that is split into two separate parts, allowing for easy access to the internal components such as impellers and bearings. This design makes maintenance and repairs more convenient.

2. Why consider sourcing and manufacturing split case centrifugal pumps in China?

China has emerged as a major player in the global manufacturing industry, offering competitive prices and a wide range of products. The country has a well-established infrastructure and a skilled workforce, making it an attractive destination for sourcing and manufacturing. Additionally, Chinese manufacturers often have experience in producing high-quality pumps that meet international standards.

3. Are there any advantages to sourcing split case centrifugal pumps from China?

Yes, sourcing split case centrifugal pumps from China can offer several advantages. Firstly, Chinese manufacturers often offer lower production costs due to economies of scale and lower labor costs. This can result in more competitive pricing compared to sourcing from other countries. Secondly, China has a vast network of suppliers, making it easier to source various components needed for the pumps. Finally, Chinese manufacturers can provide flexible production quantities, allowing businesses to meet specific demand requirements.

4. What should I consider when sourcing and manufacturing split case centrifugal pumps in China?

When sourcing and manufacturing pumps in China, it is important to consider several factors. Firstly, ensure that the chosen manufacturer has experience in producing centrifugal pumps and can meet relevant industry standards. Conduct thorough research to assess their reputation and quality control measures. Additionally, communication is crucial, so choose a manufacturer that can effectively communicate in English or your preferred language. Lastly, consider logistics and shipping costs, as well as potential import/export regulations that may affect the overall cost and timeline of the process.

5. How can I ensure the quality of split case centrifugal pumps manufactured in China?

To ensure the quality of split case centrifugal pumps manufactured in China, it is recommended to conduct on-site inspections and quality control checks throughout the manufacturing process. This allows for early detection of any issues and ensures that the final product meets your specified requirements. It is also advisable to request product samples and certifications from the manufacturer to verify their quality standards. Working with a reputable sourcing agent or engaging a third-party quality inspection service can further enhance the quality assurance process.

In conclusion, sourcing and manufacturing split case centrifugal pumps in China offers advantages such as cost-effectiveness, access to a wide range of suppliers, and flexible production quantities. However, careful consideration of factors such as manufacturer experience, quality control measures, communication, logistics, and quality assurance processes is crucial to ensure a successful sourcing and manufacturing outcome.

Why contact sourcifychina.com get free quota from reliable split case centrifugal pump suppliers?

Sourcifychina.com offers a free quota from reliable split case centrifugal pump suppliers for several reasons. Firstly, they aim to provide their clients with a seamless sourcing experience by connecting them with trusted and verified suppliers. By offering a free quota, sourcifychina.com allows clients to access the services of reliable split case centrifugal pump suppliers without any financial commitment upfront.

Secondly, the provision of a free quota allows sourcifychina.com to showcase their expertise in supplier selection and evaluation. By carefully vetting suppliers and ensuring they meet high-quality standards, sourcifychina.com builds trust with their clients. The free quota serves as evidence of the platform’s ability to connect clients with reputable suppliers who specialize in split case centrifugal pumps.

Moreover, providing a free quota helps sourcifychina.com to attract potential clients who may be hesitant to engage in the sourcing process due to uncertainty or budget constraints. By eliminating the cost barrier, sourcifychina.com encourages more clients to utilize their services and benefit from the expertise of reliable split case centrifugal pump suppliers.

Additionally, offering a free quota aligns with sourcifychina.com’s commitment to transparency and customer satisfaction. By providing upfront information on pricing, services, and the capabilities of suppliers, clients can make informed decisions. This transparency helps foster long-term relationships between clients and suppliers, creating a win-win situation for all parties involved.

In conclusion, sourcifychina.com offers a free quota from reliable split case centrifugal pump suppliers to provide a seamless sourcing experience, showcase their expertise, attract potential clients, and promote transparency. This approach ensures that clients can access reliable suppliers without any financial commitment and make informed decisions for their sourcing needs.