Knowledge about Tissue Paper Manufacturing

Tissue paper manufacturing is a process that involves the conversion of raw materials into tissue paper products. This industry has undergone significant transformation over the years, with advancements in technology and production techniques leading to improved product quality and efficiency.

The manufacturing process typically begins with the selection of raw materials, which can include virgin pulp, recycled paper, or a combination of both. Once the raw materials have been sorted, they are processed to remove any contaminants and to break them down into individual fibers.

These fibers are then mixed with water and various chemicals to create a pulp mixture. The pulp mixture is then cleaned and refined to ensure that it is of the desired quality and consistency.

Next, the pulp is fed into a paper machine, which uses a series of rollers and belts to compress and dry the pulp. As the paper moves through the machine, various treatments can be added to improve its strength, absorbency, and other properties.

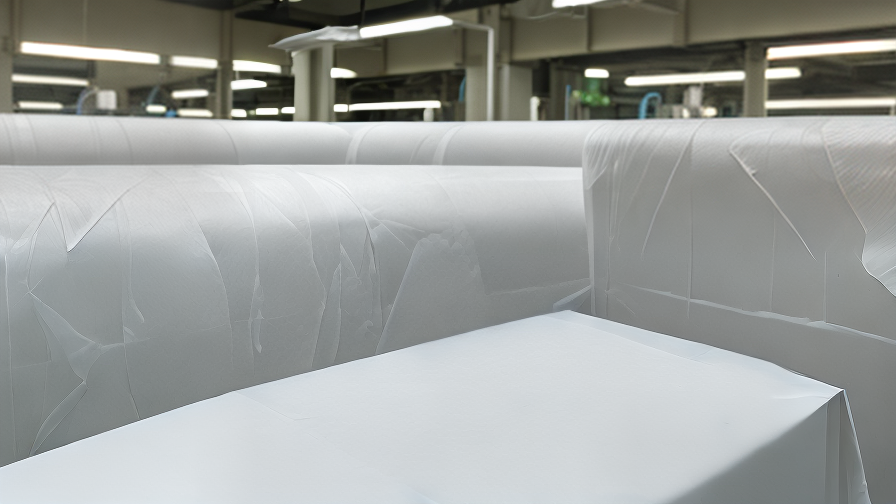

Once the paper has been produced, it is typically wound onto large rolls, which can be further processed to create final products such as toilet paper, facial tissues, and paper towels. Additional treatments, such as embossing, printing, and perforating, may also be applied to the tissue paper during this final stage of production.

Overall, tissue paper manufacturing is a complex and highly technical process that requires careful attention to detail and strict quality control measures. By understanding the basics of the manufacturing process, consumers can make more informed choices when selecting tissue paper products and can appreciate the skill and expertise that goes into their creation.

Various Types of Tissue Paper Manufacturing

Tissue paper is a lightweight and disposable material widely used for personal hygiene, cleaning, and packaging purposes. There are several types of tissue papers that you may come across in your everyday life, each with its unique properties and manufacturing process.

The most common type of tissue paper is toilet paper, which is made from a blend of virgin or recycled pulp fibers. The process of manufacturing toilet paper involves converting pulp into a thin and fluffy sheet, which is then perforated and rolled into individual rolls. The paper is softened with chemicals, such as sodium hydroxide and sodium sulfide, in the pulping process.

Facial tissue, commonly used for wiping the face or blowing the nose, is another type of tissue paper. It is usually made of softwood or hardwood fibers and is more absorbent than regular toilet paper. The paper is treated with chemicals to make it softer and more durable.

Napkins are another common type of tissue paper used for various purposes, including wiping hands, cleaning surfaces, and serving food. They are made from a blend of virgin or recycled pulp fibers and are treated with chemicals to make them soft and absorbent.

Wrapping tissue paper is a lightweight and thin paper used to wrap and protect delicate items, such as jewelry, clothing, and gifts. It is usually made from recycled pulp fibers and is treated with chemicals to prevent tearing and improve flexibility.

Furthermore, industrial tissue paper is used in various industries, including the food and beverage, healthcare, and hospitality sectors, to absorb liquids and clean surfaces. It is made from a blend of virgin or recycled pulp fibers and is treated with chemicals to make it more absorbent and durable.

In conclusion, tissue paper is an essential material in our daily lives, used for various purposes. Manufacturers use different techniques and materials to produce tissue papers that meet different requirements. Understanding the different types of tissue paper and their manufacturing process can help you choose the most suitable product for your needs.

FAQ sourcing Tissue Paper Manufacturing manufacturer from China

If you are in the market to source tissue paper manufacturing manufacturers from China, you likely have many questions. Here are some frequently asked questions with multiple answers to help guide your search.

Q: How can I find a reliable tissue paper manufacturing manufacturer from China?

A: One way to find a reliable manufacturer is to ask for referrals from other businesses in the same industry. You can also do research online, read reviews, and ask for samples before making a purchase.

Q: What types of tissue paper do manufacturers from China typically produce?

A: We can manufacture a variety of tissue paper products including toilet paper, facial tissue, napkins, kitchen wipes, and more.

Q: How long does it take to receive shipments from China?

A: Shipping times vary depending on the quantity of your order, shipping method, and location. Typically, air shipments take around 5-7 days, while sea shipments can take up to 30 days or more.

Q: What is the minimum order quantity for tissue paper manufacturing from China?

A: The minimum order quantity varies by manufacturer, but it is usually around 1,000 to 5,000 pieces.

Q: Can I customize the packaging and design of tissue paper products?

A: Yes, most manufacturers offer customization options for packaging and design.

Q: What quality standards do Chinese tissue paper manufacturers follow?

A: Chinese manufacturers must adhere to national and international quality standards, such as ISO and FDA regulations.

Q: How do Chinese manufacturers ensure the tissue paper is environmentally friendly?

A: Many Chinese manufacturers use recycled paper and implement eco-friendly production processes to reduce waste and environmental impact.

In conclusion, finding a reliable tissue paper manufacturing manufacturer from China takes research and due diligence. However, with proper research and communication, you can find a manufacturer that meets your needs and offers quality products.

Applications of Tissue Paper Manufacturing

Tissue paper may seem like a simple and inexpensive product, but it has a multitude of applications in our daily lives. Tissue paper manufacturing is a thriving industry, producing various forms of the product, from toilet paper to facial tissues to paper towels.

One of the most common uses of tissue paper is for personal hygiene, particularly in the form of toilet paper. It is an essential item in every household and public restrooms. The manufacturing of toilet paper has evolved over the years, and there are variations such as scented or recycled tissue paper that cater to the preferences of different consumers.

Another popular use of tissue paper is for facial tissue or commonly known as “tissues.” Tissues come in various sizes and softness, specifically designed to cater to delicate skin on the face. It is also used as a handkerchief substitute and has become a hygiene necessity in recent years.

Paper towels are another essential product of tissue paper manufacturing. They are typically used to clean up spills and stains and have become an important item in kitchens, restaurants, and public restrooms. There are even eco-friendly options that are more sustainable and biodegradable.

Tissue paper manufacturing also produces other products such as napkins and tablecloths, which are used in restaurants and homes. They are available in various shapes and sizes and can be customized to match the theme of an event or establishment.

In the medical field, tissue paper is used for sanitary purposes such as in surgical masks, gloves, and gowns. Facial tissues are also used in hospitals and clinics as a substitute for handkerchiefs.

Tissue paper manufacturing also contributes to the production of paper-based products such as books, newspapers, packing materials, and artwork.

In conclusion, tissue paper manufacturing has a significant impact on various aspects of our daily lives. From personal hygiene to cleaning and medical purposes, it plays an essential role in maintaining human health and cleanliness. As the demand for tissue paper continues to increase, innovative techniques and sustainable practices are

Manufactured Products made of Tissue Paper Manufacturing

Tissue paper is a lightweight and delicate paper that is commonly used for wiping and cleaning purposes, but it can also be utilized to manufacture a wide range of products. The manufacturing process involves converting the raw material into tissue paper, which is then used to create various items such as tissue paper rolls, facial tissues, paper towels, and toilet paper.

The production of tissue paper starts with a mixture of wood pulp and water, which is refined and mixed with chemicals to enhance its strength and flexibility. The pulp is then flattened and pressed through a series of rollers until it becomes a thin, uniform sheet. The sheet is then dried and cut into smaller, manageable rolls.

To create facial tissues, the tissue paper is layered into small, square sheets and folded to make a tissue box size. For toilet paper, the tissue paper is embossed with a pattern to make it more flexible and absorbent, then rolled into large spools. These spools are then cut into smaller rolls and packaged for distribution.

One of the benefits of manufacturing products from tissue paper is that it is a renewable resource. Tissue paper is made from plant fibers, which grow and can be harvested again and again. Additionally, tissue paper products are biodegradable, which means they can break down naturally in the environment and do not contribute to pollution.

Manufacturing products from tissue paper is not only practical but also profitable. These products have a high demand and are used in various settings including homes, offices, and public places. The manufacturing process is highly automated and efficient, making it an affordable option for businesses.

In conclusion, the tissue paper manufacturing process is a crucial aspect of creating a wide range of products. It is a sustainable, cost-effective, and highly demanded aspect of the manufacturing industry.

The Evolution history of Tissue Paper Manufacturing

Tissue paper manufacturing has come a long way since its birth in the early 1900s. The first tissue paper was produced in the U.S. by the Kimberly-Clark Company in 1924 using a Fourdrinier paper making process. This process involved the use of a wire screen to transfer the pulp onto a moving belt system where it was pressed, dried, and cut into rolls.

Over the next few decades, tissue paper manufacturing saw a number of significant technological advancements. In the 1930s, the use of creping technology was introduced, which allowed for the production of softer, more absorbent tissue paper. This process involved the use of a blade to gently detach the paper from the drying cylinder, creating a crimped effect that gave the tissue paper its signature softness.

In the 1950s, the advent of the continuous flow manufacturing process revolutionized tissue paper production. This process, which involved the use of a single machine to produce both the base sheet and the finished product, greatly increased the efficiency of the manufacturing process and lowered production costs.

Throughout the latter half of the 20th century, tissue paper saw a number of innovations that brought it closer to the product we know today. In the 1960s, the use of embossing technology was introduced, which added texture to the tissue paper and improved its absorbency. In the 1980s, the use of higher quality fibers, such as virgin pulp, led to the production of even softer and more durable tissue paper products.

Today, tissue paper manufacturing is a highly sophisticated and advanced industry. Modern tissue paper machines can produce up to 10,000 feet of paper per minute and can produce a wide range of products, from standard toilet paper to high-end facial tissue. With ongoing innovation and advancements in technology, it is likely that tissue paper manufacturing will continue to evolve and improve in the years to come.

The Process of Tissue Paper Manufacturing

Tissue paper is an essential household item used for a variety of purposes, such as cleaning, wiping, and other personal hygiene applications. The manufacturing process of tissue paper involves several stages that contribute to the quality and texture of the final product.

The first stage of tissue paper manufacturing is preparing pulp, which involves the mechanical or chemical breakdown of wood pulp or recycled paper to form a slurry. The slurry is then mixed with water to form a pulp, which is further cleaned to remove impurities and contaminants.

The second stage is sheet formation, where the pulp is transferred to the paper machine, and fibers are laid down in a specific pattern to form the sheet. The sheet is then dried using a series of heated rollers to remove excess moisture.

In the third stage, the tissue paper undergoes a process called creping, which involves scraping the sheet with a blade to create wrinkles, giving the sheet its characteristic softness and texture. The creped tissue paper is then rolled onto a large reel and cut into smaller rolls or sheets for packaging.

The final stage involves quality control, which ensures that the tissue paper meets the expected standards, including the absence of defects, proper size, and texture.

Various materials can be used to manufacture tissue paper, including virgin pulp or recycled paper, depending on the desired quality and texture.

Conclusion

The process of tissue paper manufacturing involves several stages, including preparing pulp, sheet formation, creping, and quality control. The quality and texture of the final product depend on the raw materials used and the manufacturing process’s efficiency. Tissue paper is an essential household item with various applications, making its production an important aspect of the paper manufacturing industry.

Benefits Advantages of Utilizing Tissue Paper Manufacturing

Tissue paper is a widely used product for various purposes, ranging from wiping hands and faces to wrapping gifts and presents. The demand for tissue paper has been increasing rapidly due to the comfort and convenience of use. Tissue paper manufacturing is a profitable industry that provides many benefits and advantages.

One of the significant benefits of tissue paper manufacturing is its low start-up cost. The machinery and raw materials needed to manufacture tissue paper are readily available, and the process is relatively simple. Additionally, tissue paper production requires low capital investment, making it an affordable option for small and medium-sized enterprises.

Furthermore, tissue paper is recyclable, making it an environmentally friendly product. As consumers become more environmentally conscious, demand for eco-friendly tissue paper is also rising. By utilizing tissue paper manufacturing, companies are contributing to the sustainable development of society.

Another advantage of tissue paper manufacturing is that it creates employment opportunities. This industry requires a skilled workforce, ranging from machine operators to engineers and technicians. As such, tissue paper manufacturing has the potential to provide many jobs, especially in developing countries experiencing high unemployment rates.

Purchasing tissue paper from an established manufacturer also provides quality assurance for consumers. Manufacturers are equipped with state-of-the-art testing facilities to ensure that their products meet global standards for safety and quality. Consumers can, therefore, trust the consistent quality of tissue paper manufactured by established companies.

In summary, tissue paper manufacturing is a lucrative industry with many benefits and advantages, including low start-up costs, eco-friendliness, employment creation, and quality assurance. The industry is well-positioned to meet the increasing demand for tissue paper, and companies that invest in tissue paper manufacturing stand to reap significant returns on investment.

Disadvantages Tissue Paper Manufacturing

Tissue paper manufacturing has a number of disadvantages, both environmental and economic. Here, we will discuss many of these drawbacks.

First and foremost, tissue paper manufacturing requires a significant amount of water. In fact, it is estimated that for every ton of tissue paper manufactured, four tons of water are consumed. This high demand for water can be a major issue in areas where water is scarce, making tissue paper manufacturing unsustainable in certain locations.

Second, tissue paper manufacturing involves the use of bleaches and other chemicals that can be harmful to the environment. These chemicals can be toxic to aquatic life and might pollute rivers, lakes, and other bodies of water. Furthermore, the manufacturing process often produces large amounts of wastewater that can contain pollutants.

The third disadvantage of tissue paper manufacturing is that it requires a significant amount of energy. The production of tissue paper requires considerable amounts of electricity, making it a highly energy-intensive process. This correlates with high levels of greenhouse gases emission which consequently cause global warming and climate change.

Next, tissue paper is often made from trees which requires deforestation. This could lead to soil erosion in the affected areas and loss of the habitat for many wild species which could negatively impact the environment’s biodiversity.

Finally, tissue paper is typically sold in plastic packaging. These plastic covers pose a serious problem to the environment due to the negative impact they have on our oceans and rivers.

In conclusion, tissue paper manufacturing has a range of disadvantages which range from environmental degradation to a higher price of production. Manufacturers must take efforts towards identifying and implementing environmentally friendly processes to mitigate these negative impacts on the environment.

Selecting the Ideal Manufacturer Tissue Paper Manufacturing

When it comes to selecting the ideal manufacturer for tissue paper manufacturing, there are several factors that need to be considered. Tissue paper manufacturing is a highly specialized field and requires the right expertise, resources, and equipment to be successful. Here are some key factors to keep in mind when selecting a tissue paper manufacturer.

Experience – Experience is one of the most important factors in selecting a tissue paper manufacturer. A manufacturer with several years of experience in tissue paper manufacturing will have the expertise and knowledge required to produce quality tissue papers.

Quality – Quality is an essential factor when choosing a tissue paper manufacturer. You need to ensure that the manufacturer produces tissue papers that meet your requirements and are of high quality. Confirm that the manufacturer uses only high-quality raw materials, and has a strict quality control process in place.

Capacity – The manufacturer’s capacity is another crucial factor to consider when selecting a tissue paper manufacturer. You need to make sure that the manufacturer has the resources and equipment necessary to handle your production needs. Choose a manufacturer whose capacity aligns with your production requirements.

Customization – Depending on your business needs, you may require customized tissue papers. Make sure that the manufacturer offers customizations services to meet your specific requirements. Check to see if the manufacturer can customize the size, thickness, design, and packaging of the tissue papers.

Location – The location of the manufacturer is another key factor. You need to ensure that the manufacturer is easily accessible and can deliver the tissue papers to your business in a timely manner. Choose a manufacturer that is located near your business or has a reliable transportation network.

In conclusion, selecting the ideal manufacturer for tissue paper manufacturing requires careful consideration of several factors. Make sure to choose a manufacturer with experience, offers quality products, has the right capacity, offers customization services, and is conveniently located. By choosing the right manufacturer, you can be confident that your tissue paper needs will be adequately met.

Things to Consider When Purchasing Tissue Paper Manufacturing

When it comes to purchasing tissue paper manufacturing equipment, there are a few things that you should consider to ensure that you get the best possible machine for your needs. In this article, we’ll cover some of the key factors that you should keep in mind when shopping for tissue paper manufacturing equipment.

First, it’s important to consider the size of the machine that you need. This will depend on factors such as the volume of tissue paper that you need to produce and the size of your facility. You should also consider the type of tissue paper that you will be producing, as this can impact the size and complexity of the machine that you need.

Another important factor to consider is the quality of the equipment that you are considering. You’ll want to look for machines that are made from high-quality materials and that are built to last. In addition, you’ll want to choose a manufacturer that has a good reputation for producing quality equipment and that provides good customer support.

Other factors to consider when purchasing tissue paper manufacturing equipment include the price of the machine, the level of automation that it offers, and any additional features or options that may be available. You should also consider the maintenance and repair costs associated with your chosen machine, as well as any training or support that may be required to operate it.

Ultimately, the key to purchasing tissue paper manufacturing equipment that meets your needs is to do your research and carefully consider all of the factors that are important to you. By taking the time to carefully evaluate your options and make an informed decision, you can ensure that you get a machine that produces high-quality tissue paper efficiently and reliably.

Properties of Tissue Paper Manufacturing

Tissue paper is a thin and soft material manufactured for household and industrial purposes. The production process of tissue paper involves several steps to create a wide range of products with different properties.

Tissue paper manufacturing starts with the raw materials, which can include virgin pulp, recycled paper, or a combination of both. The pulp is then refined and mixed with water to make a pulp slurry that is then screened to remove any impurities. The resulting mixture is then pressurized and dried to form a continuous sheet of paper.

One of the most significant properties of tissue paper is its softness. During the production process, the fibers are treated with chemicals and mechanical refining methods to enhance their flexibility and softness. Tissue paper with more plies or layers is usually softer than single-ply tissue paper.

Another critical property is absorbency. Tissue paper’s absorbency comes from its porosity, the ability to hold a significant amount of moisture in its fibers. The more porous the paper, the more absorbent it is. Tissue paper’s ability to absorb moisture makes it an essential product in personal hygiene and cleaning.

Tissue paper products also come in different colors, including white, cream, pastel shades, and bright hues. The color used in tissue paper production is usually water-soluble dyes that are safe to use on skin and on some products.

Tissue paper products can also vary in strength. Tissue paper that is used for industrial purposes or heavy-duty cleaning applications is usually made of stronger fibers and has a higher density.

In conclusion, tissue paper manufacturing involves several steps, from raw materials to the finished product. Different properties, including softness, absorbency, color, and strength, can be dependent on various production methods, making it a versatile material.

How to use Tissue Paper Manufacturing

Tissue paper is a commodity that is widely used in the world today. It has become very popular for its soft texture and absorbency. The production of tissue paper is a profitable business venture that requires a few steps to make the final product. Here’s how to use tissue paper manufacturing.

The first step is to prepare the pulp. The raw material for tissue paper is wood fibers, which are obtained from logs. The logs are soaked in water and then passed through grinders, which break them down into small pieces. The resulting pulp is washed and refined until it becomes a smooth and even consistency.

Once the pulp is ready, the next step is to feed it to the paper machine. The paper machine is a long, continuous process that consists of several sections. First, the pulp is mixed with water in a headbox and then passed through a series of rollers that press and dry the paper.

The paper is then wound onto a large reel, which is cut into smaller rolls of tissue paper. The rolls are then wrapped in plastic and transported to distribution centers or directly to retailers.

To produce high-quality tissue paper, the manufacturing process must be closely monitored. Variables such as pulp quality, moisture content, and machine settings can affect the final product’s quality. Therefore, manufacturers must invest in quality control measures and regularly inspect their equipment to ensure optimal performance.

In conclusion, tissue paper manufacturing is a lucrative business opportunity that requires careful planning and execution. The production process involves preparing the pulp, feeding it into the paper machine, and cutting the final product into rolls. With proper quality control, manufacturers can produce high-quality tissue paper that meets customer needs and expectations.

Glossary Terminology Terms for Tissue Paper Manufacturing

Tissue paper manufacturing is a complex process that involves various terminologies and technical terms. To assist in understanding this process, below is a glossary of essential terms used in the manufacture of tissue paper:

Basis weight – This is the weight in pounds of one ream (500 sheets) of tissue paper when it is cut into a specific size.

Caliper – This is the measurement in thousandths of an inch or millimeters used to determine the thickness of the tissue paper. It is used to control the product’s softness and strength.

Crepe – This is a distinctive creased texture of tissue paper achieved by drying the paper on a hot cylinder. It enhances the tissue paper’s softness and absorbent properties.

Debonders – These are chemical agents used to reduce the force needed to separate the tissue layers during the manufacturing process, making the paper softer and more absorbent.

Dryer – This is a machine used for drying the tissue paper after it has been formed and pressed.

Embossing – This is the process of producing patterns or designs on the tissue paper to improve its look and feel. An embossing roll applies pressure to the paper while it is still wet, imparting raised or recessed patterns.

Glue sprays – These are adhesive sprays used to stick the toilet tissue sheets to each other, forming a roll.

Lamination – This is a process where two or more layers of tissue paper are bonded together to form a product with specific properties.

Parent roll – This is the roll of tissue paper before it is cut into smaller rolls or sheets.

Rewinding – This is the process of converting the parent roll into smaller rolls or sheets, often using high-speed machines.

Tissue machine – This is a sophisticated device used to create tissue paper.

In conclusion, understanding these terminologies goes a long way in comprehending the technicalities of tissue paper manufacturing.

Tissue Paper Manufacturing Price

Tissue paper is an essential household item that is used for cleaning, wiping, and sanitizing. Tissue paper is essentially made from wood pulp or recycled paper. The manufacturing of the tissue paper is a multi-step process that involves different methodologies to ensure its quality.

One of the major factors that determine the price of tissue paper manufacturing is the quality of raw materials used. High-quality raw materials such as virgin wood pulp, cotton fiber, and bamboo are expensive, and their availability is limited. On the other hand, recycled paper is a cheaper alternative to making tissue paper. However, the quality of the recycled paper used can affect the quality of tissue paper produced

The machinery used in the manufacturing process also plays a critical role in determining the price of tissue paper manufacturing. Modern machinery that is efficient and fast is more expensive when compared to old and outdated machinery. Upgrading the machines can lead to an increase in production, reduction in wastage, and improvement in the quality of the tissue paper produced.

The process of tissue paper manufacturing involves the use of various chemicals and bleaching agents. The type of chemical used, and their quality may affect the environment and the quality of the tissue paper produced. Therefore, manufacturers must use environmentally friendly processes and chemicals that do not affect the quality of the product negatively.

Transportation and logistics also contribute to the final price of tissue paper manufacturing. The cost of transportation depends on the distance of the manufacturer and the location of the end user. Additionally, the availability of the tissue paper to the end user also depends on the efficiency of the distribution network.

In conclusion, the price of tissue paper manufacturing depends on various factors such as raw materials, machinery, chemicals, transportation, and logistics. Manufacturers must balance the quality and cost of tissue paper to provide a competitive and sustainable product to the end-users.