Benefits of Flute Laminating Machines

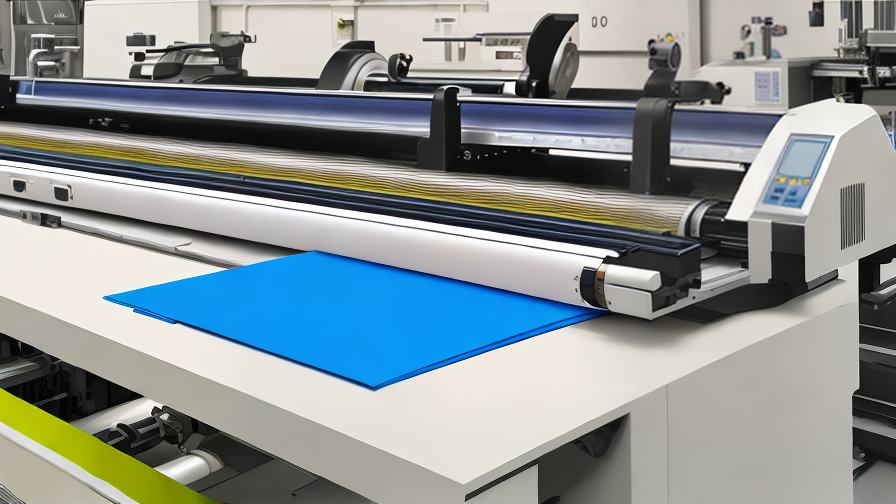

Flute laminating machines are an essential tool in the packaging industry. The machine performs the function of gluing a sheet of paperboard to a fluted sheet, creating a rigid and durable material suitable for packaging products. The benefits of owning a flute laminating machine are numerous.

Firstly, it is cost-effective. The machine is designed to operate at high speeds, making it possible to manufacture a large volume of packaging materials within a short period. The production speed reduces the production cost per unit, making packaging affordable for both producers and end-users.

Secondly, the machine increases productivity. Packaging companies require fast and efficient production processes to meet tight deadlines while ensuring the quality of the packaging materials. A flute laminating machine can efficiently produce packaging materials that meet the required standards, which ensures that the company has a higher output rate compared to the traditional method.

Thirdly, the quality of the packaging material produced by the laminating machine is high. The machine has a precise glue application mechanism, which ensures that the glue is applied evenly throughout the surface. This ensures that the adhesive does not dry out before the paperboard is laminated, eliminating the risk of lamination errors.

Furthermore, the machine is user-friendly. The machine only requires a minimal workforce to operate, making it easy for producers to train new operators. The machine also has an automatic shutdown feature, which puts the machine into a standby mode when not in use, conserving energy.

Lastly, the machine is adaptable to various paperboard and fluted sheet sizes. The machine is designed to handle a variety of paperboard and fluted sheet sizes, making it possible for packaging companies to customize their packaging to their preferred specifications.

In conclusion, owning a flute laminating machine is a valuable investment for packaging companies. The machine provides cost-effective, high-quality, and efficient packaging solutions that meet the needs of producers and end-users. With numerous benefits, the flute laminating machine is an essential tool in the packaging industry.

Features of Flute Laminating Machines

Flute laminating machines are an essential part of the packaging industry. They are used for bonding two sheets of corrugated cardboard together, with a sheet of paper in between, providing sturdy and robust packaging materials. These machines come with several amazing features that ensure they can work efficiently and provide the best results. In this article, we will discuss some of the significant features of flute laminating machines.

Automatic Stacking and Feeding:

One of the notable features of flute laminating machines is that they come with automatic stacking and feeding capabilities. This means that the machine can continuously stack and feed cardboard sheets through the machine, reducing the need for manual labour and increasing the production efficiency.

Quick Set-Up:

Flute laminating machines are designed to be user-friendly and easy to set up. They come with a quick-changeover system, which enables the operator to switch to a different size of the corrugated sheet with ease. This feature saves time and helps to boost productivity in the manufacturing process.

High-Quality Bonding:

Flute laminating machines are built to deliver high-quality bonding. The machines come with adhesive systems that ensure that the corrugated sheets bond together flawlessly. This feature ensures that the end packaging products are robust and durable, providing adequate protection for the products being packaged.

Low Maintenance:

Flute laminating machines require minimal maintenance, even when used daily. The parts and components are made from high-quality materials, which can withstand the wear and tear of daily use. This feature makes the machines more durable, reducing the cost of replacements and repairs.

In conclusion, the features of flute laminating machines are essential to the manufacturing process of corrugated packaging materials. They deliver quick set-up, high-quality bonding, automation, and low maintenance, all of which contribute to ensuring that the manufacturing process is more efficient and productive. Companies that invest in high-quality flute laminating machines are guaranteed to improve their production processes and deliver high-quality products to their clients.

Various Types of Flute Laminating Machines

Flute laminating machines are often used in the industry to manufacture corrugated cardboard boxes. These machines are designed to bond multiple layers of paper and corrugated board together by applying adhesive. There are various types of flute laminating machines available, each with its unique set of features and capabilities.

The first type is the automatic flute laminator, which is equipped with advanced sensors and controls that allow for a highly accurate and precise lamination process. These machines can bond sheets of different sizes and thicknesses with ease, making them highly versatile.

The second type is the semi-automatic flute laminator, which requires some manual intervention during the lamination process. These machines are often used for lower volume production runs or when dealing with more complex cardboard box designs.

The third type is the manual flute laminator, which has limited automation, and the lamination process is carried out entirely by the operator. These machines are the most economical but require highly skilled operators to achieve accurate results.

Another type of flute laminating machine is the rotary die cutter laminator. This machine can simultaneously cut and laminate corrugated board, resulting in highly efficient and streamlined production.

Finally, there are inline and offline flute laminating machines. Inline machines are built into the corrugated board production line, allowing for continuous high-speed production. Offline machines, on the other hand, are standalone machines that can be used for smaller production runs, and they do not require the same level of integration with the rest of the production line.

In conclusion, selecting the right type of flute laminating machine is critical to the production process, and it is essential to consider factors such as the required production volume, the complexity of the designs, and the available budget when making a decision. By choosing the right machine, manufacturers can achieve faster production speeds, higher quality, and greater cost efficiency.

Applications of Flute Laminating Machines

Flute laminating machines are among the most widely used machines in the packaging industry. They are designed to join corrugated sheets of different thicknesses and materials using adhesives or heat. With the demand for packaging solutions on the rise, flute laminating machines have become essential for companies across various industries.

One of the primary applications of flute laminating machines is in the production of cardboard boxes. Flute laminating machines produce boxes that are sturdy, durable, and resistant to wear and tear, making them ideal for shipping and storage. Furthermore, these machines can produce boxes in various shapes and sizes, thus offering customization options to meet specific needs.

Flute laminating machines are also ideal for producing point-of-purchase (POP) displays. POP displays, usually seen at retail stores, help to promote products by catching the attention of potential customers. The machines can produce high-quality POP displays that are strong enough to hold products, making them essential for the packaging industry.

Flute laminating machines are also vital in the production of mailers and envelopes. These machines can produce envelopes of different shapes and sizes and can also print customized messages or branding on them. Moreover, they can produce mailers with padded interiors, thus offering cushioning and protection for delicate items.

In conclusion, flute laminating machines have numerous applications in the packaging industry. They are ideal for producing sturdy, durable, and customized cardboard boxes, POP displays, mailers, and envelopes. With the ever-growing demand for packaging solutions in various industries, these machines have become an integral part of the production process.

The Process of Flute Laminating Machines

Flute laminating machines are crucial equipment in corrugated packaging production. These machines are designed to bond multiple sheets of paper or cardboard to form a stronger material suitable for packaging and shipping purposes. The process of flute laminating machines involves several stages, including feeding, printing, gluing, laminating, and cutting.

First, the feeding stage involves inserting sheets of paper or cardboard into the machine. The material is then guided to the printing stage, where it can be customized with any design or logo that the packaging requires. Printing can be done using a flexographic or digital print machine.

After printing, the sheets are fed through the gluing station, where they are coated with an adhesive. The adhesive used is usually a water-based polymer or a hot melt adhesive. Water-based adhesives are more environmentally friendly, while hot melt adhesives are faster to dry and produce a stronger bond.

Next, the sheets are placed in a laminating station, which consists of several rollers that apply pressure and heat to ensure a precise bond. The laminating stage is critical, and the machine operator must ensure that the necessary heat and pressure are applied uniformly to avoid any irregularities in the final product.

Finally, the laminated sheets are fed through a cutting station, where they are trimmed and cut into their final shape. The cutting process is done using a die cutting machine that cuts the sheets based on a predetermined design.

In conclusion, the process of flute laminating machines is a critical component of the packaging industry. These machines allow for the production of high-quality packaging materials that are essential for protecting and shipping goods. It is essential to ensure that the machine operator is well trained and equipped to handle the various stages involved in the process of flute laminating machines.

How to use Flute Laminating Machines

Flute laminating machines are essential equipment for businesses that handle huge volumes of products like cardboard boxes for packaging, display stands, and posters. The machine is used to bond corrugated materials to create high-quality, rigid display boards or cases. Typically, it will have a series of rollers that feed the materials into the machine and apply adhesive as necessary. In layman’s terms, it’s a fancier and automated version of glueing your cardboard box to make it durable and attractive.

To successfully use a flute laminating machine, here are some useful tips to keep in mind:

1. Choose the Right Machine

The first step when using a flute laminating machine is to choose the right one for the job. These machines come in different sizes and designs, so it’s essential to select the one that fits your needs. It’s worth noting that the machines can handle different thicknesses, and some are more efficient than others. Therefore, you need to determine your project’s needs, and then choose the right machine accordingly.

2. Prepare the Materials

Before you start the lamination process, you need to ensure that the materials you wish to laminate are ready. Cut the cardboard boxes to required sizes and organize them in a stack. This step will ensure that the feed into the machine will run smoothly, thereby reducing unnecessary downtime.

3. Apply Adhesive

Most flute laminating machines use hot or cold glue for bonding the materials. For hot glue, apply the adhesive to the flute side of the corrugated board before placing the paperboard sheet. On the other hand, the cold glue requires you to apply the adhesive to both the paperboard sheet and the corrugated board before feeding them into the machine.

4. Adjust the Settings

Different projects may require a specific setting to ensure that the bonding is perfect. Therefore, before starting the machine, ensure that the rollers are set according to your project’s requirements. This adjustment will guarantee that the pressure and speed are appropriately set in the machine for optimal results.

5. Feed the Materials

Once everything is set, it’s time to start feeding your materials into the machine. Ensure that the stack is tidy and that the sheets feed into the machine correctly. It’s advisable to have another person help load the materials into the machine.

In conclusion, lamination enhances the lifespan and quality of different products. However, the process requires keen attention to detail, especially when using machines. Therefore, following the above tips should help you maximize the potential of your flute laminating machine.

Selecting the Ideal Manufacturer Flute Laminating Machines

Flute laminating machines are becoming increasingly popular in the manufacturing industry for their ability to create strong and durable packaging materials. However, with so many machines available in the market, it can be overwhelming to select the ideal one for your needs. Here are some factors to consider when selecting the ideal manufacturer flute laminating machines.

Firstly, consider the speed of the machine. The speed of the machine will depend on the volume of output you want to achieve. High-speed machines are ideal for bulk production, while slower machines are better for smaller volumes.

Secondly, consider the size of the machine. Depending on the size of your production facility, you should select a machine that will fit comfortably in the space available. You should also consider the size of the materials you intend to laminate.

Thirdly, consider the type of material the machine is designed to laminate. Some machines are designed to laminate thin materials such as paper and card, while others can laminate thicker materials such as corrugated cardboard.

Fourthly, consider the level of automation. If you have a larger production facility, you may want to consider a fully automated machine that will require less manual input. However, if you have a smaller facility, a semi-automated machine may be more suitable for your needs.

Finally, consider the cost of the machine. Flute laminating machines can vary in price depending on their features and capabilities. You should consider your budget and select a machine that will provide the most value for your money.

In summary, selecting the ideal manufacturer flute laminating machine requires careful consideration of factors such as speed, size, material, automation level and cost. By taking these factors into consideration, you can select a machine that will meet your production needs and provide a good return on investment.

list FAQ with answer about Flute Laminating Machines

Flute laminating machines are essential equipment for manufacturers who want to produce high-quality corrugated cardboard boxes. With these machines, it is possible to create reinforced boxes that are capable of withstanding the rigors of transportation and handling. However, not everyone may be familiar with the operation and maintenance of these machines. Here are some frequently asked questions about flute laminating machines and their answers.

Q: What is a flute laminating machine?

A: A flute laminating machine is a device used to attach a thin sheet of paperboard to the surface of a corrugated cardboard box. This process reinforces the box and adds a glossy finish to it.

Q: What are the types of flute laminating machines?

A: There are different types of flute laminating machines that a manufacturer can choose from. Some of the common ones include manual laminators, semi-automatic laminators, and fully automatic laminators.

Q: What is the process for laminating a box?

A: First, the box is fed into the machine. Then, the glue is sprayed onto the surface of the corrugated cardboard. Next, the sheet of paperboard is added to the surface of the corrugated cardboard. The two materials are pressed together to create a strong bond.

Q: What is the maintenance procedure for a flute laminating machine?

A: The maintenance of a flute laminating machine involves regular cleaning and lubrication of the components. The machine must also be inspected regularly for wear and tear.

Q: What are the advantages of using a flute laminating machine?

A: Flute laminating machines increase the strength and durability of the boxes. They also create a glossy finish, which enhances the appearance of the product. In addition, flute laminating machines speed up the production process, thereby increasing the manufacturer’s productivity.

Conclusion:

Flute laminating machines are essential equipment for manufacturers who want to produce high-quality corrugated cardboard boxes. Knowing the basics of how they work and how to maintain them can help ensure the machines function at their fullest potential. By following the maintenance procedures and operating instructions, manufacturers can create strong and aesthetically-pleasing boxes that are suitable for a wide range of applications.

Things to Consider When Purchasing Flute Laminating Machines

Flutes laminating machines are crucial equipment that helps to laminate two or more materials together. Purchasing a machine could be a challenging task, especially if you’re new to the industry. Before investing your resources, there are certain factors you should consider to ensure that you’re making the right decision.

Firstly, you should consider the machine’s speed capacity. The velocity of the laminating machine determines the productivity of your business. If you’re dealing with a large scale production, you’ll want to go for a machine with a higher speed capacity to meet your business’s demand.

Secondly, the size of the machine is another crucial factor. If you have a limited workspace, it’s advisable to purchase a smaller machine to avoid clutters. However, if you have a large space, you can consider purchasing a larger machine.

Thirdly, check the machine’s warranty before making a purchase. Some machines come with a warranty of over five years, while others have none. It’s advisable to go for a machine that has a longer warranty period to ensure your investment is safe.

The fourth factor is the machine’s durability. A durable machine is vital, especially for businesses that deal with high production capacities. A durable machine guarantees longevity and reduces maintenance costs.

Lastly, consider the integration of the laminating machines. Some machines can easily integrate into your company’s existing production line, while others require modifications. It’s advisable to check the machine’s compatibility with your production line before making a purchase.

In conclusion, purchasing a flutes laminating machine can be an overwhelming task. However, by considering the factors mentioned above, you can make an informed decision that’ll be profitable for your business.

Properties of Flute Laminating Machines

Flute laminating machines are an essential component in the production of corrugated cardboard. These machines are responsible for bonding the outer liner, the inner liner, and the fluted medium of the cardboard to produce a sturdy and durable end product. In this article, we will discuss the properties of flute laminating machines.

Firstly, flute laminating machines are designed to be efficient and reliable. They automate the entire process of bonding the different layers of corrugated cardboard, resulting in a high output rate. This feature is particularly important for manufacturers who have a large volume of production.

Secondly, flute laminating machines are designed to be versatile. They can handle various types of corrugated cardboard, including single face corrugated, double face corrugated, and triple wall corrugated. This versatility makes them an essential investment for manufacturers who deal with different types of corrugated cardboard.

Thirdly, flute laminating machines are designed to be user-friendly. They have user-friendly interfaces that allow operators to monitor and control the production process easily. They also come with detailed manuals and customer support to ensure that operators can troubleshoot any issues that may arise quickly.

Fourthly, flute laminating machines are designed to be safe. They come with safety features such as emergency stop buttons and safety guards to prevent accidents at the workplace. This feature is particularly important given the machinery’s high output rate and the need to ensure the safety of workers.

Lastly, flute laminating machines are designed to be durable. They are made from high-quality materials that are resistant to wear and tear, ensuring that they have a long lifespan. This feature is particularly important for manufacturers who want to maximize their return on investment.

In conclusion, the properties of flute laminating machines make them an essential investment for manufacturers in the corrugated cardboard industry. They are efficient, versatile, user-friendly, safe, and durable. Investing in a high-quality flute laminating machine is a sure way of ensuring the production of high-quality corrugated cardboard.

Technical Parameters Terms for Flute Laminating Machines

Flute laminating machines are used for laminating a corrugated sheet and a liner sheet to produce a combined board that is used for product packaging, displays, and other purposes. Technical parameters are important factors that determine the performance and efficiency of these machines.

One of the important technical parameters is the maximum machine speed. This parameter indicates the speed at which the machine can run continuously without causing any problems such as jams or wrinkling of the material. The maximum machine speed is usually expressed in meters per minute (m/min).

Another important technical parameter is the maximum board size. This parameter refers to the size of the corrugated and liner sheets that can be processed by the machine. The maximum board size is usually expressed in millimeters or inches.

The flute type is also an important technical parameter. The flute type refers to the type of corrugated sheet used in the laminating process. There are three main types of flutes: A, B, and C flutes. A flute is the largest and thickest, while C flute is the thinnest.

The glue system is another important technical parameter. The glue system refers to the type of adhesive used in the laminating process. Common types of adhesives include water-based and hot-melt adhesives. The type of adhesive used affects the quality and durability of the final product.

The machine dimensions and weight are also important technical parameters. These parameters determine the space requirements and installation requirements for the machine. It is important to ensure that the machine can be easily installed and operated in the available space.

In conclusion, technical parameters are important factors that determine the performance and efficiency of flute laminating machines. These parameters include the maximum machine speed, maximum board size, flute type, glue system, machine dimensions, and weight. It is important to consider these parameters when selecting a flute laminating machine to ensure optimal performance and efficiency.

Flute Laminating Machines Price

Flute laminating machines are a vital piece of equipment for any business that is involved in printing, packaging or paper manufacturing. These machines are used to bond layers of different materials together, such as paper and cardboard, to form a durable final product. The bond formed by the laminating process provides the final product with increased strength, durability and customization options.

The price of flute laminating machines can vary widely depending on the type, size, and features of the machine. The most common types of flute laminating machines are semi-automatic and fully automatic machines. Semi-automatic machines are more affordable and suitable for smaller businesses. They require a human operator to load the materials onto the machine and to start the laminating process. Fully automatic machines, on the other hand, are more expensive and can handle larger volumes of materials. They do not require a human operator and have a higher level of efficiency.

The size of a flute laminating machine also plays a role in determining its price. Larger machines are more expensive due to their increased capacity and the complexity of the mechanism. In addition to size, the features also influence the price of the machine. Some features include auto feeder, auto stacker, pneumatic shafts, and digital control systems. These extra features increase the ease of use and the efficiency of the machine but come with a higher cost.

The price of flute laminating machines can also be influenced by the brand name. Machines from established brands generally cost more than those from lesser-known brands. However, these machines come with the assurance of quality, reliability, and technical support.

In summary, the price of flute laminating machines can range from a few thousand dollars to tens of thousands of dollars depending on the type, size, and features of the machine. It is important to choose a machine that suits the specific needs and budget of the business. A proper investment in a quality flute laminating machine can lead to significant improvements in production efficiency, product quality, and business profitability.