List Technical Parameters of “beryllium copper suppliers”

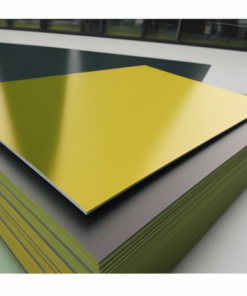

Beryllium copper is a copper-based alloy that contains beryllium as the primary alloying element. It is known for its exceptional mechanical and electrical properties, making it widely used in various industries such as aerospace, electronics, and oil and gas. Beryllium copper suppliers provide this material in various forms, including bars, rods, wires, sheets, and plates. Here are some technical parameters that characterize beryllium copper:

1. Chemical composition: Beryllium copper typically contains 0.5-3% beryllium, with copper as the main constituent. Other alloying elements may include nickel, cobalt, iron, and manganese.

2. Mechanical properties: Beryllium copper has high strength, hardness, and fatigue resistance. It also exhibits excellent thermal conductivity, which makes it suitable for heat sinks and electronic components. The material’s tensile strength can range from 600-1400 MPa, depending on the specific alloy and temper.

3. Electrical properties: Beryllium copper has high electrical conductivity, making it suitable for applications that require good electrical performance and low contact resistance. The material’s electrical conductivity can be as high as 45% IACS (International Annealed Copper Standard).

4. Corrosion resistance: Beryllium copper has good corrosion resistance in most environments, except in oxidizing acids and alkaline solutions. It also has excellent resistance to stress corrosion cracking, making it suitable for use in harsh environments.

5. Weldability: Beryllium copper is a relatively difficult material to weld due to its high thermal conductivity and susceptibility to cracking. However, it can be welded using appropriate techniques such as TIG welding and resistance welding.

6. Working and machining: Beryllium copper can be easily machined using conventional methods such as milling, drilling, and turning. However, the material’s high hardness and strength can cause tool wear and require specialized cutters.

In summary, beryllium copper is a versatile material that offers excellent mechanical and electrical properties, making it suitable for a wide range of applications. Beryllium copper suppliers provide this material in various forms, and its technical parameters include chemical composition, mechanical and electrical properties, corrosion resistance, weldability, and working and machining characteristics.

List Product features of “beryllium copper suppliers”

Beryllium copper is a type of copper alloy that contains beryllium, a rare metal that imparts several unique properties to the alloy. Due to its high strength, durability, electrical conductivity, and resistance to corrosion, beryllium copper has a wide range of applications across multiple industries, ranging from electronics and telecommunications to aerospace and oil and gas.

The following are some of the key product features offered by beryllium copper suppliers:

1. Different grades: Beryllium copper alloys come in various grades, each with its own specific composition and properties. Suppliers offer different grades based on the required application, including C17200, C17510, C1720, and others.

2. Customization: Beryllium copper suppliers offer customization to meet specific customer requirements. This may include the alloy composition, shape, dimensions, and surface finishing, among others.

3. High strength: Beryllium copper has high strength and hardness, making it ideal for applications that require resistance to wear and tear, such as connectors and switches.

4. Excellent electrical conductivity: Beryllium copper has exceptional electrical conductivity, making it useful in electrical and electronic applications, such as terminals, contacts, and springs.

5. Corrosion resistance: Beryllium copper offers excellent resistance to corrosion, making it ideal for use in environments where exposure to harsh chemicals or seawater is expected.

6. Compliance with standards: Beryllium copper suppliers comply with various national and international standards, such as ASTM, ASME, ISO, and RoHS, to ensure their products are safe and reliable.

7. Versatility: Beryllium copper alloys are versatile, making it possible to use them for different applications. Suppliers offer beryllium copper products in various forms, such as bars, sheets, wires, strips, and plates.

8. Quality assurance: Beryllium copper suppliers perform quality assurance tests to ensure their products meet the required standards. Such tests include chemical analysis, mechanical testing, ultrasonic testing, and X-ray inspection.

9. Competitive pricing: Suppliers offer competitive pricing for their beryllium copper products, providing customers with high-quality products that meet their budgetary constraints.

10. Technical support: Beryllium copper suppliers provide technical support to their customers, offering advice on alloy selection, design, fabrication, and testing, among other aspects. This ensures that customers get the best possible product for their application.

List Application of “beryllium copper suppliers”

Beryllium copper is a high-strength alloy of copper and beryllium that offers excellent corrosion resistance, thermal conductivity, and wear resistance. As such, it is widely utilized in several applications, and beryllium copper suppliers play a crucial role in ensuring that businesses have access to this high-quality material.

One of the most common applications of beryllium copper is in the production of electrical connectors and switches. The alloy’s excellent electrical conductivity, combined with its ability to withstand high temperatures and corrosive environments, makes it an ideal material choice for these applications.

Beryllium copper is also used extensively in the aerospace industry. It is employed in the manufacture of aircraft parts, such as gears, bolts, springs, and connectors. Its high strength-to-weight ratio and resistance to fatigue make it a valuable material for the aerospace sector, where safety and performance are of utmost importance.

Beryllium copper is also used in the manufacturing of various tools, including hand tools such as screwdrivers and pliers. Its high strength and wear resistance make it ideal for these applications, ensuring excellent performance and longevity.

Another critical application of beryllium copper is in the oil and gas industry. The alloy’s corrosion resistance, high strength, and excellent thermal conductivity make it an ideal material for handling and transporting oil and gas across pipelines.

Finally, beryllium copper is also used in the medical industry. It is employed in the production of medical equipment such as X-ray equipment, MRI machines, and surgical instruments. Its excellent biocompatibility and resistance to corrosion make it a valuable material for these applications where safety and reliability are paramount.

In conclusion, beryllium copper is a versatile and valuable material employed in several industries. Beryllium copper suppliers ensure that businesses have access to high-quality materials that meet their specific needs and requirements. As such, the importance of these suppliers in ensuring the smooth operation of several industries cannot be overstated.

List Various Types of “beryllium copper suppliers”

Beryllium copper (BeCu) is a metal alloy that contains copper, beryllium, and sometimes other elements. It is known for its excellent strength, electrical conductivity, thermal conductivity, and corrosion resistance. Beryllium copper is used in a variety of industries including aerospace, telecommunications, defense, and automotive.

There are various types of beryllium copper suppliers, including manufacturers, distributors, and online retailers. Manufacturers typically have large production facilities that can produce large quantities of beryllium copper products. They have the capabilities to fabricate custom parts and offer engineering and technical support to their clients. Manufacturers may also offer additional services such as heat treatment, plating, and assembly.

Distributors purchase beryllium copper products from manufacturers and resell them to their clients. They typically have a large inventory of standard parts and can provide quick delivery times. Distributors may also offer additional services such as packaging, kitting, and labeling.

Online retailers specialize in selling beryllium copper products through their website. They typically have a smaller inventory than manufacturers or distributors, but offer a wide range of products and quick delivery times. Online retailers may also offer additional services such as technical support and online chat.

Other types of beryllium copper suppliers include scrap metal recyclers, who purchase beryllium copper scrap from manufacturers and other sources and recycles it into new products. There are also brokers, who act as intermediaries between manufacturers and clients, facilitating the sale of beryllium copper products.

In conclusion, there are various types of beryllium copper suppliers, each offering unique products and services to their clients. Whether you are looking for a large quantity of custom parts or a small quantity of standard parts, there is a beryllium copper supplier that can meet your needs. It is important to research and compare different suppliers to find the one that best fits your requirements.

List The Evolution history of “beryllium copper suppliers”

Beryllium copper is a unique alloy that consists of copper with a small amount of beryllium. It is characterized by its high strength, hardness, and conductivity. Over the years, there has been a significant evolution in the production and distribution of beryllium copper, with notable advancements in technology, safety, and sustainability.

The history of beryllium copper suppliers dates back to the early 20th century when metal manufacturers began experimenting with copper alloys to improve their mechanical properties. Beryllium was discovered to be an excellent alloying element that could enhance copper’s strength and durability. However, due to its toxicity, handling beryllium presented significant health risks to workers, leading to strict safety regulations.

In the 1940s, the United States government recognized the strategic importance of beryllium copper in weapons manufacturing and began a concerted effort to develop a reliable domestic supply. This led to the establishment of several beryllium copper production facilities, including Brush Wellman (now Materion), which remains one of the leading suppliers of beryllium copper today.

As safety regulations became more stringent, beryllium copper suppliers invested heavily in creating safer working conditions for their employees. This includes implementing strict protocols for handling beryllium, investing in technology that minimizes exposure to beryllium dust and fumes, and developing alternative alloys, such as non-beryllium copper alloys.

In recent years, there has been a growing awareness of the environmental impact of beryllium copper production, leading to a renewed focus on sustainability. Many suppliers have implemented eco-friendly manufacturing practices, including recycling scrap metal and minimizing energy consumption.

Overall, the evolution of beryllium copper suppliers has been characterized by a commitment to safety, innovation, and sustainability. As demand for beryllium copper continues to grow in industries such as aerospace, automotive, and oil and gas, suppliers are poised to continue evolving to meet these demands while maintaining their focus on safety and sustainability.

List The Process of “beryllium copper suppliers”

The process of beryllium copper suppliers involves several steps that begin with the mining of beryllium ore. Once the ore is mined, it is transported to a smelting facility for processing.

In the smelting facility, the ore is heated to a high temperature to extract the beryllium metal from the ore. This process is known as the reduction process, and it involves the reaction of the ore with carbon or aluminum.

After the reduction process, the beryllium metal is usually alloyed with copper to create beryllium copper. This alloy is highly resistant to corrosion and can withstand high temperatures, making it popular in a variety of industries.

Once the beryllium copper alloy has been produced, it is typically formed into various shapes and sizes to meet the needs of different applications. This includes extruding, forging, casting, and machining the alloy to create finished products.

Beryllium copper suppliers may also offer additional services such as testing and certification of their products to ensure they meet industry standards. This can include testing for things like chemical composition, hardness, and tensile strength.

Overall, the process of beryllium copper suppliers involves a complex series of steps from mining the ore to producing finished products. This requires specialized knowledge and expertise to ensure that the products meet the high standards required by industry.

How to use “beryllium copper suppliers”

Beryllium copper is a highly valuable and useful metal alloy that is used in a wide range of industrial applications. It is a combination of copper and beryllium, which is a rare and expensive metal that adds many beneficial properties to the alloy. Beryllium copper suppliers are those that specialize in selling this metal alloy to companies and individuals who require it for their specific applications.

When looking for a reliable supplier of beryllium copper, it is important to consider a few key factors. First, it is essential to ensure that the supplier has a good reputation in the industry and is known for providing high-quality products. This can be verified by reading reviews and testimonials from other customers who have worked with the supplier in the past.

Another important factor to consider when choosing a supplier is their level of expertise and knowledge in the field of beryllium copper alloys. A good supplier will have extensive experience in this area and will be able to provide helpful advice and guidance to customers who are unsure about which type of alloy to use for their specific application.

In addition, it is also important to consider factors such as price, availability, and delivery times when choosing a beryllium copper supplier. Customers should look for a supplier that offers competitive pricing, has a reliable and consistent supply chain, and can deliver their products in a timely manner.

Overall, working with a reputable beryllium copper supplier is essential for anyone who needs this valuable alloy for their business or project. By taking the time to research and choose the right supplier, customers can ensure that they are getting high-quality products at a fair price, and can enjoy the many benefits that beryllium copper has to offer.

List Properties of “beryllium copper suppliers”

Beryllium copper is a type of alloy that is well known for its high strength, corrosion resistance, and excellent electrical conductivity. For this reason, beryllium copper is highly sought after by many different industries and applications, from aerospace and automotive manufacturing to electronics and telecommunications.

If you are interested in sourcing beryllium copper for your business, then you will likely need to work with one or more beryllium copper suppliers. Some key properties of these suppliers may include the following:

1. Expertise: Beryllium copper suppliers will typically have a deep understanding of the properties, applications, and manufacturing processes associated with this material. This expertise will allow them to provide valuable guidance on material selection, design considerations, and other related topics.

2. Quality: Given the critical nature of beryllium copper in many applications, suppliers will typically be committed to providing high quality materials that meet or exceed industry standards. This may involve rigorous testing, inspection, and certification processes.

3. Inventory: Beryllium copper suppliers will typically maintain a large inventory of materials in a variety of shapes, sizes, and configurations. This allows customers to select the specific materials that best meet their needs, without having to wait for new materials to be manufactured or sourced.

4. Customization: Beryllium copper suppliers may also offer custom fabrication and machining services, allowing customers to order materials that are tailored to their unique needs or specifications. This may involve cutting, welding, drilling, or other techniques.

5. Price: Finally, beryllium copper suppliers will typically offer competitive pricing on their materials, ensuring that customers can access the materials they need at a reasonable cost. This may involve bulk discounts, special promotions, or other pricing strategies.

Overall, working with a reputable beryllium copper supplier can be an excellent way to ensure that your business is able to access high quality materials that meet your specific needs and requirements. By carefully considering the properties and capabilities of these suppliers, you can find the best partner to help you achieve your goals and succeed in your industry.

List “beryllium copper suppliers” FAQ

1. What is beryllium copper?

Beryllium copper is a non-ferrous alloy that is used in various applications such as aerospace, electronics, automotive, and defense due to its high strength, conductivity, and corrosion resistance.

2. What are the benefits of using beryllium copper?

Beryllium copper offers several advantages including high strength, high conductivity, excellent fatigue resistance, and good corrosion resistance. It can also operate at high temperatures and can be easily fabricated into different shapes.

3. What are the applications of beryllium copper?

Beryllium copper is commonly used in electrical connectors, switches, and relays due to its high electrical conductivity and low thermal expansion. It is also used in aircraft and aerospace industries for high-stress applications such as bushings, gears, and bearings.

4. How can I find beryllium copper suppliers?

There are several ways to find beryllium copper suppliers including searching online directories, attending trade shows, and networking with industry professionals. You can also research suppliers through industry associations and publications.

5. What should I consider when selecting a beryllium copper supplier?

When selecting a beryllium copper supplier, you should consider factors such as their experience and reputation in the industry, their quality control processes, their ability to meet your specific requirements, and their pricing and delivery options.

6. Can beryllium copper be recycled?

Yes, beryllium copper can be recycled. It is a valuable material that can be reused in a variety of applications. Recycling beryllium copper also helps to conserve natural resources and reduce waste.

7. Are there any safety concerns associated with beryllium copper?

Yes, there are safety concerns associated with beryllium copper due to the potential health hazards of beryllium exposure. Beryllium copper should be handled and processed with appropriate safety measures in place to prevent exposure. This includes using protective equipment such as gloves and masks, ensuring proper ventilation, and following industry guidelines for handling and disposal.