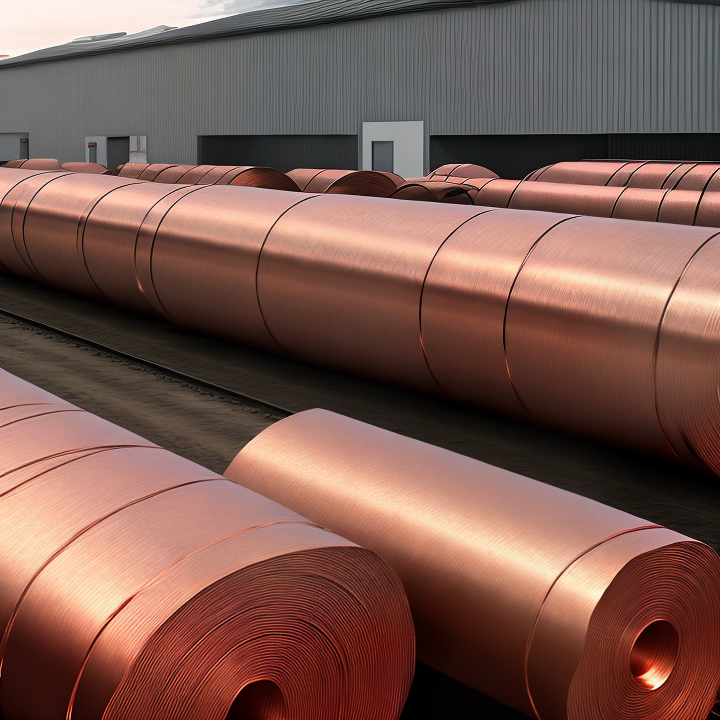

Copper Sheet Suppliers

Benefits:

– High thermal conductivity

– Corrosion resistant

– Malleable and ductile

– Highly conductive

Features:

– Available in various dimensions and thicknesses

– Can be easily worked with hand tools

– Environmental friendly

– Long-lasting and durable

Specifications:

– Material: Copper

– Thickness: Varies from 0.05mm to 3.2mm

– Width: Varies from 100mm to 1200mm

– Length: Varies from 500mm to 3000mm

Applications:

Copper sheets find their applications in various industries and sectors such as:

– Architecture and construction

– Electrical and electronics

– Chemical and petrochemical

– Automotive and transportation

– Marine and offshore

– Arts and crafts

FAQ:

Q) Which is the best way to cut copper sheets?

A) Copper sheets can be easily cut with a pair of metal scissors or tin snips.

Q) Can copper sheets be soldered?

A) Yes, copper sheets can be soldered using a standard soldering iron and flux.

Q) What is the thickness range of copper sheets?

A) Copper sheets are available in a thickness range of 0.05mm to 3.2mm.

Q) How can I prevent copper sheets from tarnishing?

A) Copper sheets can be polished with a brass or copper polish to prevent tarnishing.

Q) What is the maximum temperature range that copper sheets can withstand?

A) Copper sheets can withstand a temperature range of -200°C to 200°C.

In conclusion, copper sheets are highly versatile and durable materials that find application in various industries. They are easily customizable and can be easily cut and worked with hand tools. Copper sheet suppliers offer a range of dimensions and thicknesses that can meet the requirements of various industries.

List Technical Parameters of “copper sheet suppliers”

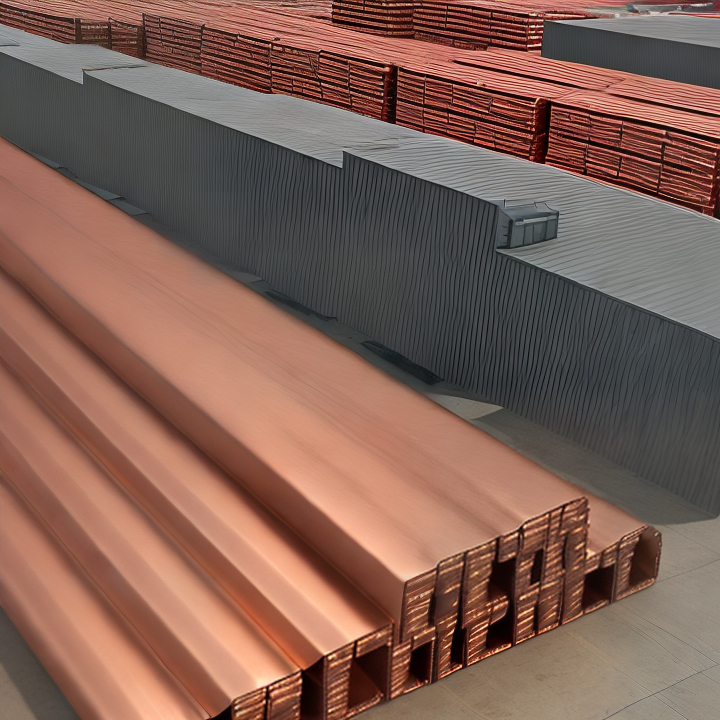

Copper is an essential raw material for various industries such as construction, electronics, and transportation. Copper sheet suppliers play a vital role in providing copper sheet products of different sizes, thicknesses, and grades. Some of the technical parameters that copper sheet suppliers offer include:

1. Thickness: Copper sheets come in different thicknesses, from thin sheets measuring less than 0.05mm to thicker sheets measuring more than 8mm.

2. Width and Length: Copper sheet suppliers offer copper sheets in various dimensions, including different width and length specifications.

3. Grade: Copper sheets come in various grades depending on the intended use. Some of the grades suppliers offer include oxygen-free copper, electrolytic tough pitch copper, and Phosphorous Deoxidized Copper.

4. Surface Finish: Copper sheet suppliers provide copper sheet products with different surface finishes, such as polished, shiny, brushed, matte, or antique.

5. Hardness: Copper sheets can vary in hardness depending on the desired level of ductility and yield strength.

6. Annealing: Copper sheets can be offered in different annealing conditions, such as fully annealed, half-hard, quarter-hard, and hardened.

7. Resistance: Copper sheet suppliers offer copper sheets with high electrical and thermal conductivity, making them ideal for use in electrical and heat transfer applications.

8. Corrosion Resistance: Copper sheet products are resistant to corrosion and have a long lifespan.

9. Coatings: Suppliers can offer copper sheets with different coatings such as tin, nickel, and silver.

10. Availability: Copper sheet suppliers offer copper sheets in large quantities and a range of dimensions to meet the demands of their customers.

In conclusion, copper sheet suppliers offer a variety of technical parameters to meet the diverse needs of different industries. These parameters include thickness, width, length, hardness, grade, and surface finish, among others. Copper sheet products provided by suppliers are highly durable, resistant to corrosion, and have excellent electrical and thermal conductivity.

List Product features of “copper sheet suppliers”

Copper sheet suppliers provide a variety of products and services to individuals, businesses, and industries for a range of applications. Some of the key features and benefits of copper sheet suppliers include:

1. Wide Range of Copper Sheets: Copper sheet suppliers typically offer a wide range of copper sheets in different sizes, thicknesses, alloys, and grades to meet the varying needs of different applications. These sheets can be customized according to specific requirements and applications.

2. High-Quality Materials: Copper sheet suppliers ensure that the materials they supply meet the highest quality standards and are free from defects or impurities. They source their materials from reputable and reliable sources, and their products are tested and certified to ensure their quality and performance.

3. Competitive Pricing: Copper sheet suppliers offer competitive pricing on their products, making them affordable and accessible to a wide range of customers. They also offer discounts and special deals on purchases made in bulk or large quantities.

4. Expertise and Technical Support: Copper sheet suppliers employ experienced and knowledgeable professionals who are experts in their field. They provide guidance and technical support to customers to help them choose the right copper sheet for their specific needs and applications.

5. Timely Delivery: Copper sheet suppliers ensure that their products are delivered timely and efficiently to their customers. They have a well-established logistical system that enables them to deliver products quickly and safely to any location.

6. International Shipping: Many copper sheet suppliers offer international shipping services, making their products available to customers around the world. This enables businesses and industries to access high-quality copper sheets and materials from reliable sources.

7. Excellent Customer Service: Copper sheet suppliers are committed to providing excellent customer service to their clients. They have a dedicated customer support team that is available to answer questions, provide guidance, and assist customers with their purchases and deliveries.

In summary, copper sheet suppliers offer a wide range of copper sheets, high-quality materials, competitive pricing, expertise, and technical support, timely delivery, international shipping, and excellent customer service. These features make them an essential partner for businesses and industries that require copper sheets and materials for their operations.

List Application of “copper sheet suppliers”

Copper sheet suppliers provide copper materials that are useful in a variety of applications. Here are some applications of copper sheet suppliers:

1. Electrical wiring: Copper is an excellent conductor of electricity, making it an ideal material for electrical wiring. It is used in homes, buildings, and industrial applications.

2. Roofing: Copper sheet suppliers provide materials that are commonly used in roofing applications due to its durability and resistance to the elements. Copper roofs are also visually appealing and can be found on many historic buildings.

3. Artwork: Copper can be shaped and formed into different shapes and designs, making it a popular choice for artwork and sculpture. Copper sheet suppliers provide artists with the raw materials needed to create stunning pieces.

4. Jewelry Making: Copper is also a popular material for jewelry making due to its affordability and unique aesthetic qualities. Copper sheet suppliers can provide materials that are used to make earrings, bracelets, necklaces, and more.

5. Plumbing: Copper is also used in plumbing applications due to its corrosion resistance and durability. It is commonly used for water pipes in homes and buildings.

6. Cookware: Copper is a popular material for cookware due to its superior heat conductivity. Copper pots and pans are often used by chefs and can be found in many professional kitchens.

7. Construction: Copper is often used in construction applications such as HVAC systems, gutters, and downspouts due to its durability and resistance to corrosion.

In conclusion, copper sheet suppliers offer materials that are used in a variety of applications including electrical wiring, roofing, artwork, jewelry making, plumbing, cookware, and construction. With its unique properties and aesthetic qualities, copper materials are in high demand among various industries.

List Various Types of “copper sheet suppliers”

There are different types of copper sheet suppliers that cater to a wide range of industries and customers. Here are some of the most common types of suppliers:

1. Metal service centers – They are the largest suppliers of copper sheets that offer a range of sizes, thicknesses, and alloys. They cater primarily to industrial and manufacturing clients that require large volumes of copper sheets.

2. Online retailers – These suppliers sell copper sheets through e-commerce platforms like Amazon, eBay, or their websites. They offer a wide range of copper sheets and have competitive pricing options.

3. Local or regional suppliers – These suppliers are generally small-scale businesses that offer copper sheets to the local market. They cater to individuals and small business owners who require copper sheets for projects.

4. Specialty suppliers – These suppliers sell copper sheets with unique finishes, textures, and designs. They cater to a specific niche market, such as architects, interior designers, and artists.

5. Scrap metal dealers – These suppliers mostly deal with recycled copper sheets. They may not have a wide range of sizes or alloys, but they offer copper sheets at a lower price point.

6. Copper fabricators – These suppliers specialize in fabricating copper sheets and other copper-based products. They cater to clients who require customized copper sheets for specific applications.

7. Distributors – These suppliers buy bulk quantities of copper sheets from manufacturers and sell them to small-scale suppliers or end-users. They offer copper sheets at a competitive price and may also provide logistics and transportation services.

In conclusion, understanding the different types of copper sheet suppliers can help individuals and businesses find the right supplier that can cater to their specific needs.

List The Evolution history of “copper sheet suppliers”

Copper has been in use for more than 10,000 years, making it one of the oldest metals used by humans. Copper sheet suppliers have been an essential part of the metalworking and construction industry for centuries.

In ancient times, copper was mined in civilizations such as the Egyptians, Greeks, and Romans. Copper sheets were used for various purposes, including weapons, tools, and ornamental objects.

During the industrial revolution, the demand for copper increased dramatically, leading to the establishment of copper sheet suppliers in various parts of the world. The use of copper expanded from its traditional applications in construction and metalworking to include electrical and plumbing systems.

In the mid-twentieth century, as new technologies and manufacturing processes emerged, copper sheet suppliers evolved to keep up with demand. Copper-coated stainless steel and other alloys appeared, and copper began to be used in various industries, including automotive and electronics.

Today, copper sheet suppliers continue to evolve as demand for copper sheets increases, making copper one of the most popular metals in the construction, electrical, and transportation industries. Copper is also increasingly being used in renewable energy systems such as solar and wind power.

In conclusion, copper sheet suppliers have a long and rich history dating back thousands of years. From its early use by ancient civilizations to its modern-day applications in renewable energy, copper continues to play a crucial role in various industries, making the evolution of copper sheet suppliers critical to meet the growing demands of the market.

List The Process of “copper sheet suppliers”

The process of copper sheet suppliers starts with identifying customer needs and the type of copper material required. Copper sheet suppliers source the copper from reliable and certified manufacturers, ensuring top quality and standards are met. Before delivery to customers, the copper sheets undergo rigorous testing and quality control procedures to ensure they are up to the required standards.

Once the quality is confirmed, the copper sheets are cut to size depending on customer requirements. Suppliers use specialized cutting tools such as saws or water jets to shape the copper sheets accurately. The copper sheets are carefully packed and shipped to the customer’s desired location.

In addition to supplying copper sheets, some suppliers also offer additional services such as metal fabrication, surface finishing, and customized machining services. For instance, a customer may require the copper sheets to be bent or formed into a specific shape to fit their project requirements. In such instances, copper sheet suppliers have the expertise to fabricate and modify the copper sheets as per customer needs.

Copper sheets are widely used in many industries, including construction, manufacturing, automotive, and electrical applications, among others. These types of industrial applications require a high level of expertise and experience in sourcing the best copper sheets and providing quality services to customers.

In conclusion, copper sheet suppliers play a crucial role in providing high-quality copper materials to various industries. With a deep understanding of customer needs and attention to detail, these suppliers provide top-quality products that meet industry standards and customer requirements.

How to use “copper sheet suppliers”

Copper sheet suppliers are businesses that specialize in providing copper sheets of various sizes, thicknesses, and shapes to different industries and individuals. Such suppliers can be found online or through physical stores that sell metals and metal products.

To use copper sheet suppliers, the first step is to determine the specification of the copper sheet needed. This includes the thickness, size, and shape of the sheet. This information is important when contacting suppliers to ensure that they have the correct type of copper sheet.

Once the specification has been decided, the next step is to search for reputable copper sheet suppliers. One can do this by searching online or by asking recommendations from industry experts or peers. It is essential to consider the supplier’s reputation, experience, and reliability to ensure that they can provide high-quality copper sheets.

After identifying potential copper sheet suppliers, it is essential to compare their prices, delivery times, minimum order quantity, and payment terms. This helps in finding a supplier that provides the best value for money and meets specific business requirements.

When ordering copper sheets from suppliers, it is crucial to communicate effectively and provide accurate details of the required specifications, such as measurements, thickness, and shape. This ensures that the supplier provides the right product and reduces the risk of delays or returns.

In conclusion, copper sheet suppliers provide essential services to different industries that require copper sheets for various applications. To use copper sheet suppliers effectively, one needs to identify the correct specifications, find reputable suppliers, compare prices and delivery times, and communicate effectively when ordering.

List Properties of “copper sheet suppliers”

Copper sheet suppliers are companies or individuals who supply copper sheets. Copper is a chemical element with the symbol Cu (from Latin: cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. Copper is widely used in various industrial applications due to its excellent mechanical and thermal properties.

The properties of copper sheets make them ideal for various applications in industries such as electronics, telecommunications, construction, and plumbing. Some of the properties of copper sheets include:

1. High conductivity: Copper is one of the most conductive metals, making it ideal for use in electrical wiring and circuits.

2. Ductility: Copper is highly ductile, meaning it can be easily shaped and formed into various shapes and sizes, making its implementation versatile.

3. Corrosion resistance: Copper is resistant to corrosion, which means it can last longer and perform better in harsh environmental conditions.

4. Heat resistance: Copper has a high melting point and is also an excellent conductor of heat, making it ideal for use in high-temperature environments.

5. Thermal conductivity: Copper is an excellent thermal conductor, making it ideal for use in heat exchangers and cooling systems.

Copper sheet suppliers generally offer various dimensions, thicknesses, and grades of copper sheets to meet various industrial requirements. They may also provide customized copper sheets, according to the specific needs of their customers.

The cost of copper sheets may vary depending on the specific requirements of the customer, such as the thickness, grade, and quantity of copper sheets required. Copper sheet suppliers often provide competitive pricing, quality products, and timely delivery services.

Overall, copper sheet suppliers play a crucial role in providing businesses and industries with high-quality copper sheets that can be used for various applications. With their expertise and experience, they help their customers find the right copper sheet products that meet their specific requirements and can enhance their production processes.

List “copper sheet suppliers” FAQ

1. What is a copper sheet?

A copper sheet is a thin, flat piece of copper that is often used for decorative or functional purposes in various industries, including manufacturing, construction, and art.

2. What are the typical sizes and thicknesses of copper sheets?

Copper sheets are available in various sizes and thicknesses, depending on the supplier. Common thicknesses range from 0.32 mm to 1.27 mm, and sizes can range from small pieces for art projects to large sheets for industrial applications.

3. What are the different grades of copper sheet?

Copper sheets are available in different grades, including C101, C110, C122, C194, and C260, among others. The grade of copper sheet required will depend on the specific application.

4. How is copper sheet manufactured?

Copper sheet is typically produced by rolling copper ingots or blocks to the desired thickness and size. The sheet is then annealed to improve malleability and remove any stress from the rolling process.

5. What are the typical uses for copper sheet?

Copper sheet is used for a wide range of uses, including roofing, electrical wiring, automotive and industrial applications, decorative art, and jewelry making.

6. How can I purchase copper sheet?

Copper sheet can be purchased from various metal suppliers, either in-person or online. It is important to research the supplier and ensure they offer high-quality materials and reliable customer service.

7. How do I care for my copper sheet?

Copper sheet requires regular maintenance to prevent oxidation and tarnishing. This can be accomplished by regularly cleaning the surface and applying a protective coating or sealant.

8. What are the environmental benefits of using copper sheet?

Copper is a sustainable and eco-friendly material that can be recycled indefinitely without losing its properties or quality. Using copper sheet in place of other materials helps reduce environmental impact and conserves natural resources.

Related products

Metal CNC Tools Vavle Pump

Metal CNC Tools Vavle Pump

Copper Alloys

Metal CNC Tools Vavle Pump

Metal CNC Tools Vavle Pump

Copper Alloys

©2023. sourcifychina.com All Rights Reserved.

-

- Home

- Retail Cheap Shop

- Wholesale Featured Pro

- Industries

- List

- Our China Suppliers list

- Auto Parts Suppliers

- Packaging Solution

- Stainless Steel Suppliers

- Steel Pipe Suppliers

- Solar Inverter China

- cable manufacturing

- cnc machining China

- Apparel and Accessories

- fabric manufacturing

- Machinery

- pump China

- Screw

- wigs custom

- valves manufacturing

- hair system custom

- heated gloves wholesale

- indoor lighting fixtures

- solor panel wholesale

- snow boots factory

- Products

- Manufacturing

- Guide

- Apparel / Fashion Accessories

- CNC Tools Valve Pump Parts

- Machinery China Equiment Sourcing Guide

- aac block manufacturers

- acrylic cutting machine

- automatic packing machine

- Auxiliary Equipment

- blister packing machine

- bricks manufacturing

- clay brick making machine

- feed pellet machine

- fly ash bricks machine sourcing guide

- paper bag making machine

- pellet machine

- plastic crusher machine

- pouchpacking machine

- stamping machine

- wood pellet machine

- Outdoor Sports

- Others Sourcing Guide

- FAQ

- About

- Contact

- Login

- Newsletter

- [email protected] whatsapp 8615951276160

- 供应商

Login

- →

- WeChat: 8615951276160