List Technical Parameters of “customized machining parts”

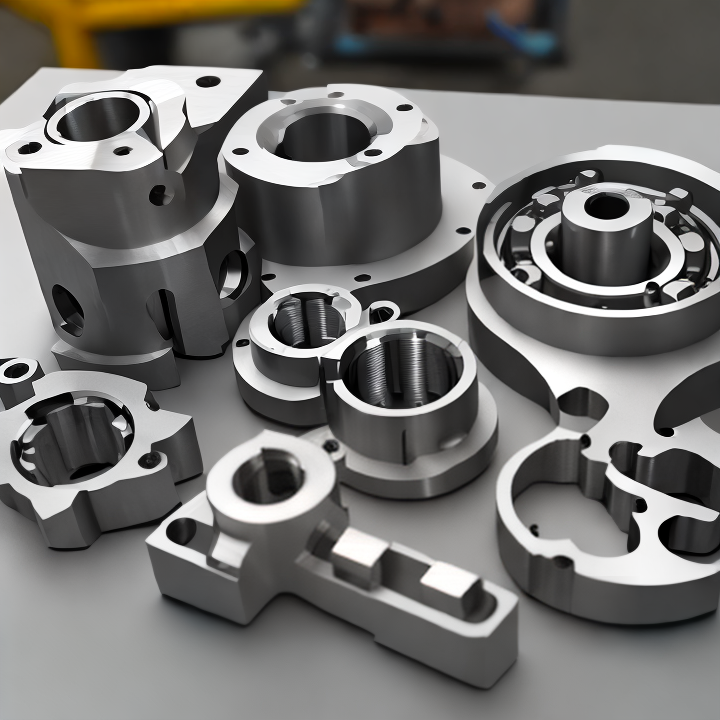

Customized machining parts are made through the process of subtractive manufacturing using CNC (computer numerical control) machines. These machines use computer-aided design (CAD) and computer-aided manufacturing (CAM) software to produce precise and accurately shaped parts. The specifications and technical parameters of these parts vary depending on their intended use and application. Below are some of the technical parameters of customized machining parts:

1. Material: Customized machining parts can be made from a range of materials such as metals (ferrous and non-ferrous), plastics, ceramics, composites, and alloys. The choice of material depends on the part’s intended use, properties, and characteristics.

2. Tolerance: Tolerance refers to the allowable deviation from the intended dimensions of a part. It is a crucial parameter in machining as it determines the accuracy of the finished part. Customized machining parts can have varying tolerances depending on their application and requirements.

3. Surface Finish: Surface finish specifies the smoothness or roughness of a part’s surface after machining. It is a crucial parameter for parts that need to be sealed, painted, or coated. Customized machining parts can have different surface finishes, including mirror finish, satin finish, or brushed finish, among others.

4. Dimensional Accuracy: Dimensional accuracy refers to the degree of conformity of a finished part to its intended dimensions. It is a crucial parameter for parts that must fit or work together with other parts. Customized machining parts can have various levels of dimensional accuracy, ranging from ±0.1mm to ±0.01mm.

5. Hardness: Hardness refers to a material’s ability to resist deformation, penetration, and wear. It is a critical parameter for parts that must withstand high loads or wear. Customized machining parts can have varying levels of hardness, depending on the material used and the intended application.

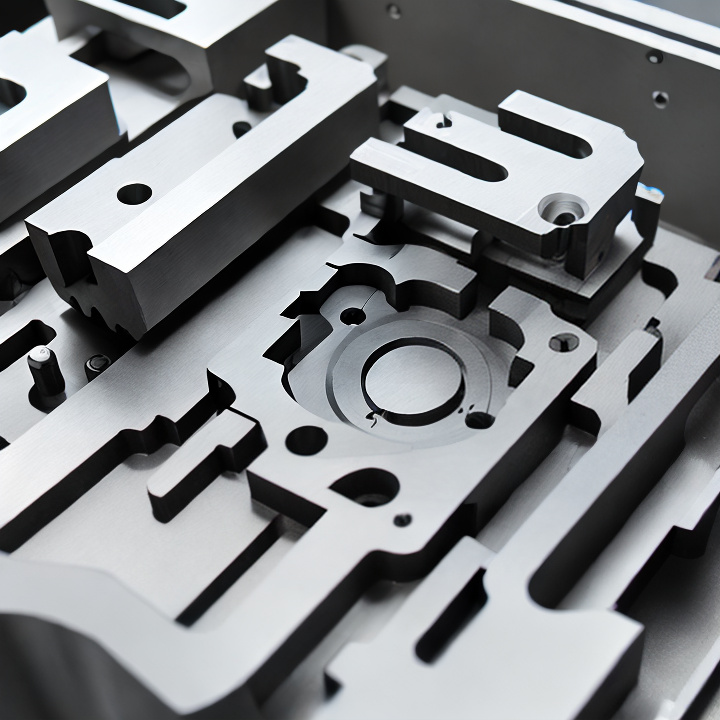

6. Complexity: The complexity of customized machining parts refers to the intricacy of their design. It is a crucial parameter for parts that require high precision and accuracy. Customized machining parts can have complex shapes, including features such as threads, cavities, and undercuts.

7. Lead Time: Lead time refers to the time it takes to produce a part from the start of the design process to the finished product’s delivery. It is a crucial parameter for parts that require urgent production. Customized machining parts can have varying lead times depending on their complexity, quantity, and material.

In conclusion, customized machining parts have various technical parameters, including material, tolerance, surface finish, dimensional accuracy, hardness, complexity, and lead time. These parameters are critical to ensuring the quality, functionality, and performance of the finished parts.

List Product features of “customized machining parts”

Customized machining parts refer to the parts that have been machined or processed according to the specific requests or requirements of the customer. Nowadays, customized machining parts have been widely used in various fields, including automotive, aerospace, medical, and electronic industries. They are popular for their flexibility, precision, and high quality, which effectively enhance the productivity and performance of the equipments. There are many features of customized machining parts, and some of the most important ones are:

1. Material flexibility: The customized machining parts can be machined from a wide range of materials, such as aluminum, steel, copper, brass, plastic, and titanium. The choice of material depends on the requirements of the customer and the application.

2. Precision and accuracy: Customized machining parts are made with high-precision CNC machines, which ensure a high degree of accuracy and repeatability. The parts can meet the tight tolerance requirements, which is essential for their proper functioning.

3. Customized design: The customized machining parts can be designed based on the specific requirements of the customer, which makes them highly customizable. The parts can be designed in various sizes, shapes, and dimensions, which makes them suitable for a wide range of applications.

4. Surface finish: Customized machining parts can be finished in various ways, such as polishing, anodizing, painting, and powder coating. This makes them highly aesthetic and suitable for various applications.

5. Cost-effective: Customized machining parts are cost-effective since they are produced in smaller quantities. This means that the customer does not have to pay for the setup cost of producing huge quantities, which saves money.

6. Fast turnaround time: Customized machining parts can be produced quickly since there is no need for tooling or mold making. This means that the customer can receive their parts within a shorter period of time.

In conclusion, customized machining parts have many features that make them highly suitable for various applications. They are flexible, precise, customizable, cost-effective, and have a fast turnaround time. This is why they have become a popular choice for many industries.

List Application of “customized machining parts”

Customized machining parts are components that have been specifically designed and fabricated to meet the unique requirements of a particular application. These parts are often used in industrial settings where precision and quality are paramount. The following are some of the most common applications of customized machining parts:

1. Aerospace Industry: Machining parts are essential for the aerospace industry. Customized machining parts include components such as turbine blades, engine parts, and aircraft body parts.

2. Automotive Industry: The automotive industry relies heavily on customized machining parts to manufacture a range of components such as crankshafts, piston rods, camshafts, cylinder heads, and brake systems.

3. Medical Equipment Manufacturing: Customized machining parts are used in the manufacturing of medical equipment such as surgical instruments, imaging machines, and diagnostic tools.

4. Defense Industry: The defense industry requires customized machining parts for the development of armored vehicles, ships, and aircraft.

5. Industrial Manufacturing: Customized machining parts are used in the manufacturing of various industrial products for various purposes. Industrial manufacturing applications include hydraulic and pneumatic parts, valves, and pumps.

6. Consumer Goods Manufacturing: Customized machining parts are also used in the manufacturing of various consumer goods, including electronic and electrical components such as circuit boards, connectors, and power switches.

7. Energy Sector: The energy sector uses customized machining parts for the development of drilling and exploration equipment, turbines, pump components, and valves.

8. Robotics: Customized machining parts play a significant role in the manufacturing of robots and their components, including gears, joints, and sensors.

In conclusion, the use of customized machining parts has become an essential element in various industries due to their precision, quality, and versatility. The potential uses for customized machining parts are virtually limitless, enabling industries to achieve greater efficiency, productivity, and performance.

List Various Types of “customized machining parts”

Customized machining parts refer to components that are manufactured according to specific customer requirements. The process involves shaping, drilling, milling, and cutting raw materials such as metals, plastics, and ceramics to produce custom parts with unique specifications.

There are various types of customized machining parts, each of which serves a specific function. Some common types include:

1. Precision machined components – These are highly accurate parts that require precise tolerances and surface finishes. They are commonly used in medical equipment, aerospace, and defense applications.

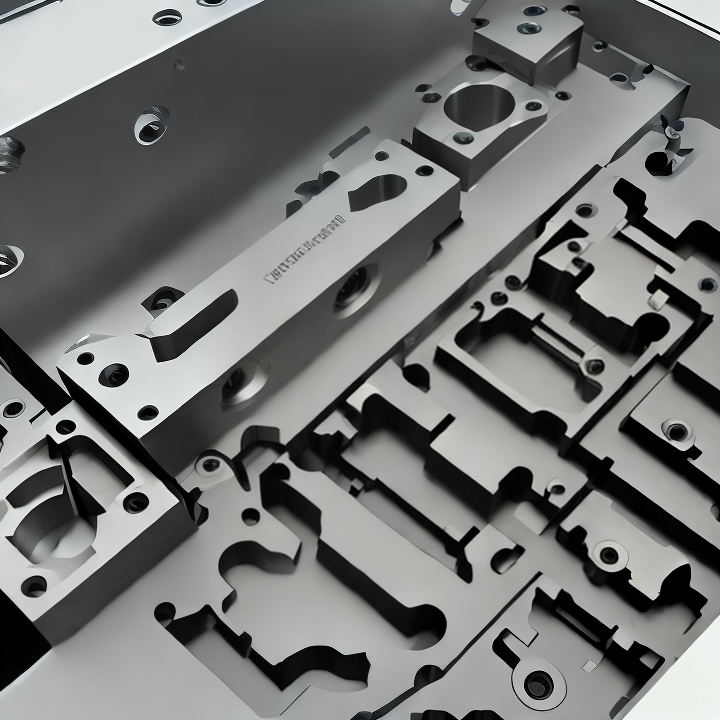

2. CNC machined parts – These are parts made using Computer Numerical Control (CNC) machines, which use programmed instructions to control the cutting tools. CNC parts are highly precise and are used in industries such as automotive, aerospace, and electronics.

3. Turning parts – These are parts that are created by rotating raw materials against a cutting tool. They are commonly used in the production of shafts, pins, and connectors.

4. Milling parts – These are parts that are created by removing material using a rotating cutting tool. They are commonly used in the production of gears, brackets, and housings.

5. Injection molded parts – These are plastic parts that are made by injecting molten plastic into a mold. Injection molding is a highly efficient process and is commonly used in the production of automotive parts, electronic components, and medical devices.

6. Sheet metal parts – These are parts made by cutting and forming sheet metal. They are commonly used in the production of enclosures, brackets, and covers.

7. Welded parts – These are parts created through the joining of two or more metal parts. They are commonly used to produce frames, support structures, and other heavy-duty parts.

In conclusion, customized machining parts play a crucial role in the production of various components across multiple industries. The type of customized machining parts used depends on the specific requirements of a project and the materials involved. Ultimately, customized machining parts are vital for efficient and accurate production, ensuring that high-quality parts are manufactured to meet customer needs.

List The Evolution history of “customized machining parts”

Customized machining parts have a rich history that extends back over a century. Prior to the Industrial Revolution, all parts were hand-crafted by skilled mechanics and machinists. However, with the advent of new manufacturing technologies and machinery, mass-produced parts could be produced on a large scale, resulting in a significant reduction in costs. The assembly line, introduced by Henry Ford, was a game-changing innovation that allowed parts to be produced and assembled efficiently and quickly.

As manufacturing technologies advanced, so did the way that parts were made. The introduction of Computer Numerical Control (CNC) machines in the 1950s enabled more precise and complex parts to be produced, with less risk of human error. These machines use a computer program to guide the cutting tool, resulting in better accuracy and repeatability. In addition, the use of Computer-Aided Design (CAD) software allowed engineers to create three-dimensional models of components and assemblies, making it easier to design and manufacture customized parts.

The introduction of 3D printing technology in the 1980s revolutionized the way that parts were made. also known as additive manufacturing, 3D printing technology allows parts to be produced layer by layer, using materials such as plastics and metals. This technology eliminates the need for expensive molds or tooling and can produce highly complex parts with precision accuracy.

More recently, the digitization of manufacturing has allowed for the creation of smart factories, where machines and equipment are connected through the Internet of Things (IoT), allowing for real-time monitoring and optimization of production processes.

In conclusion, the evolution of customized machining parts can be traced back to the Industrial Revolution, where mass production was first introduced. The introduction of CNC machines and CAD software allowed for more precise and complex parts to be produced. The development of 3D printing technology revolutionized the way that parts were manufactured and eliminated the need for expensive molds and tooling. Finally, the digitization of manufacturing has allowed for the creation of smart factories, improving the efficiency and flexibility of the manufacturing process.

List The Process of “customized machining parts”

Customized machining parts refer to parts that are made to meet the specific requirements of a client. The process of making these parts involves various stages, as explained below:

1. Design: The client provides the specifications for the part that they need. The design team works on creating a 3D model of the part using CAD software.

2. Material selection: Based on the part’s specifications, the team selects the appropriate material, which could be plastic, metal, or composite.

3. Machining: The team uses CNC machines to carve the part out of a block of material. This involves cutting, drilling, milling, and tapping the material to achieve the desired shape and size.

4. Finishing: The part is then polished, sandblasted, or painted to achieve the desired surface finish.

5. Inspection: The part is inspected using a Coordinate Measuring Machine (CMM) or other measuring tools to ensure that it meets the client’s specifications.

6. Delivery: The finished part is shipped to the client.

Customized machining parts are used in a wide range of industries, including aerospace, automotive, medical, and manufacturing. This process ensures that clients get exactly what they need, thus improving production efficiency and reducing costs. Additionally, customization allows for more complex designs, which leads to better performance and functionality of the parts.

How to use “customized machining parts”

Customized machining parts refer to the production of mechanical components that meet specific design requirements. The concept of customization underscores the need for tailor-made mechanical components that match the shape, size, material composition, and other specifications proposed by a client. In many cases, customized machining parts offer clients access to high performance and durable components that are not readily available in the market.

Whether it is for industrial, automotive, or consumer applications, customized machining parts meet unique production needs. Typically, customized machining parts are made using precise manufacturing techniques that guarantee quality and reliability. Unlike the standard machining parts, these components allow customers to achieve high-precision tolerances, precise fitting, and complete assemblies.

One area where customized machining parts find extensive application is in the automotive industry. With the demand for high-performance engines, there is a need for mechanical components that can withstand high levels of stress and pressure. Customized machining parts such as engine cylinders, pistons, crankshafts, and fuel system components offer better performance, fuel efficiency, and lower noise levels.

In the industrial setting, customized machining parts are useful in various applications such as conveyor systems, pumps, motors, and gearboxes. These components can be adapted to handle unique industrial processes, thereby improving productivity, efficiency, and safety.

Finally, in the world of consumer electronics, customized machining parts are useful in developing intricate components such as camera lenses, microphones, and smartphone casings. With the advent of 5G and advanced technologies, the demand for highly specialized and customized machining parts is expected to increase significantly, especially in the aerospace and defense sectors.

In conclusion, customized machining parts offer numerous benefits to clients who have unique production needs. They provide access to high-quality components that meet specific design requirements, and can be tailored to suit industrial, automotive, and consumer applications.

List Properties of “customized machining parts”

Customized machining parts are components that are specifically designed to suit the needs of a particular application. These parts can be manufactured using various materials such as aluminum, steel, titanium, and plastic, and are typically produced using machining processes such as milling, turning, drilling, and grinding. Some of the key properties of customized machining parts include:

1. Precision: Customized machining parts undergo rigorous quality control measures to ensure that the finished product meets the required specifications. This precision is essential for applications that require tight tolerances.

2. Durability: Customized machining parts must be able to withstand the demands of their intended application. This may include exposure to high temperatures, corrosive chemicals, or heavy loads. To ensure durability, these parts are often made from high-strength materials that are resistant to wear and tear.

3. Functionality: Customized machining parts are designed to fulfill specific functions. This may include providing structural support, controlling the flow of fluids, or transmitting power. The design of these parts must take into account the specific requirements of the application.

4. Compatibility: Customized machining parts must be designed to fit seamlessly with other components in the system they are intended for. This means that they must be compatible with other materials, shapes, and sizes within the system.

5. Cost-effectiveness: Customized machining parts are often more expensive to produce than off-the-shelf components. However, they are often more cost-effective in the long run because they are designed to perform more efficiently and last longer than standard parts.

Overall, customized machining parts are essential in a wide range of applications, from aerospace and medical industries to automotive and construction sectors. Their precision, durability, functionality, compatibility, and cost-effectiveness make them a valuable investment for any project that requires reliable and efficient parts.

List “customized machining parts” FAQ

1. What is customized machining, and how does it differ from traditional machining?

Customized machining refers to the process of creating specific parts or components that are tailor-made to meet specific design requirements. Unlike traditional machining, where stock parts are cut to a certain size and shape, customized machining involves the use of Computer Numerical Control (CNC) technology to produce components that meet precise and complex designs.

2. What materials can be used in customized machining?

Customized machining can be used on a wide range of materials, including metals, plastics, composites, and wood. The exact materials that are used will depend on the specific needs of the project, as well as the design requirements.

3. What are the benefits of customized machining?

Customized machining allows for greater accuracy in the production of parts and components, which means that products can be produced more efficiently and effectively. Additionally, customized machining can help to reduce waste and decrease the need for post-production finishing, which can save time and money.

4. Who can benefit from customized machining services?

Companies across a wide range of industries can benefit from customized machining services, from automotive manufacturers to medical device companies. Additionally, individuals or hobbyists who are looking to create unique parts or components for personal projects may also benefit from customized machining.

5. How do customers choose the right customized machining service provider?

When selecting a customized machining service provider, customers should look for a company with a track record of producing high-quality components that meet design and material requirements. Additionally, customers should consider factors such as cost, turnaround time, and communication with the service provider.

6. What level of customization is possible with customized machining?

Customized machining can be used to produce parts and components that are highly customized, with intricate designs and complex shapes. This level of customization is possible due to the use of CNC technology, which allows for precision cutting and milling of even the most complex designs.

7. What industries can benefit from customized machining?

Industries such as aerospace, automotive, medical, and electronics can benefit greatly from customized machining services. These industries require highly specialized components that must meet strict design and material requirements, and customized machining can help to ensure that these requirements are met.

In conclusion, customized machining is a process that involves using CNC technology to produce highly customized parts and components. This technology offers various benefits, including greater accuracy, reduced waste, and decreased need for post-production finishing. Companies across various industries can benefit from customized machining services and should look for a service provider with a proven track record of producing high-quality parts that meet design requirements.