List Technical Parameters of “moule injection plastique”

Moule injection plastique, commonly known as plastic injection moulding, is a widely used manufacturing process that involves the production of plastic products from thermoplastics or thermosetting plastics. The process entails the creation of a mould, which is subsequently filled with molten plastic. Once cooled, the plastic takes the shape of the mould, resulting in a final product.

There are several technical parameters involved in the moule injection plastique process, which include:

1. Clamping Force: This refers to the force applied by the moulding machine to clamp the mould shut during the injection process. The required clamping force depends on the size of the mould and the plastic material being used.

2. Injection Pressure: This parameter refers to the amount of pressure required to inject molten plastic into the mould. Injection pressure depends on the type of plastic being used, its viscosity, and the complexity of the mould.

3. Injection Speed: This parameter refers to the speed at which molten plastic is injected into the mould. It is determined by the material being used and the desired quality of the final product.

4. Injection Temperature: This parameter refers to the temperature at which molten plastic is injected into the mould. Injection temperature depends on the type of plastic being used and the mould material.

5. Cooling Time: This parameter refers to the time it takes for the plastic to cool and solidify within the mould. Cooling time depends on the plastic material, mould design, and required final product quality.

6. Ejection Time: This parameter refers to the time it takes for the final product to be ejected from the mould. Ejection time depends on the complexity of the mould and the mechanisms used to eject the final product.

Overall, moule injection plastique requires the use of sophisticated machines, thermoplastics or thermosetting plastics, and specific technical parameters to produce high-quality plastic products. These parameters must be carefully calibrated to achieve the desired results, including product quality, durability, and safety.

List Product features of “moule injection plastique”

Moule injection plastique is a manufacturing process for creating plastic components. It involves injecting molten plastic into a mold cavity, which then cools and solidifies into the desired product. Here are some product features of moule injection plastique:

1. Precision: The injection molding process allows for precise control over the shape and size of the final product. Mold cavities can be customized to produce parts with complex geometries and intricate details.

2. Consistency: Injection molding is a highly repeatable process, meaning that each part produced is virtually identical to the others. This is particularly important for manufacturing large quantities of products.

3. Durability: Plastic parts produced by injection molding are usually very durable, as the molten plastic is able to fill in even the smallest gaps in the mold cavity to create a solid product.

4. Cost-effective: Injection molding can be a cost-effective way to produce large volumes of plastic parts, as the process is highly automated and can be scaled up or down depending on production needs.

5. Flexibility: Injection molding can be used to produce a wide range of plastic components, from small, intricate parts to large, complex structures.

6. Material selection: Injection molding can be used with a wide variety of plastic materials, including thermoplastics, thermosetting plastics, and elastomers.

7. Surface finish: Injection molding can create parts with a smooth surface finish, eliminating the need for additional finishing or polishing steps.

8. Sustainability: Many plastic materials used in injection molding are recyclable, making the process a more sustainable option for manufacturing plastic components.

List Application of “moule injection plastique”

Mould injection plastique is a manufacturing process that involves producing complex shaped plastic parts using an injection moulding machine. The process is used in various manufacturing industries and has become a popular method because of its simplicity, speed, and precision. Here are some of the key applications of moule injection plastique.

1. Automotive industry – The automotive industry is one of the biggest beneficiaries of moule injection plastique. Cars and other vehicles today are designed with complex shapes and sizes that require advanced moulding techniques. With mould injection plastique, automotive manufacturers can produce various plastic vehicle components, including dashboard parts, door handles, bumpers, and other interior parts.

2. Consumer electronics – Moule injection plastique is also used in the consumer electronics industry. Electronic devices like smartphones, televisions, laptops, and other gadgets often feature plastic components that require intricate moulding. This process enables the manufacturing of plastic parts and casings that are durable, lightweight, and precise.

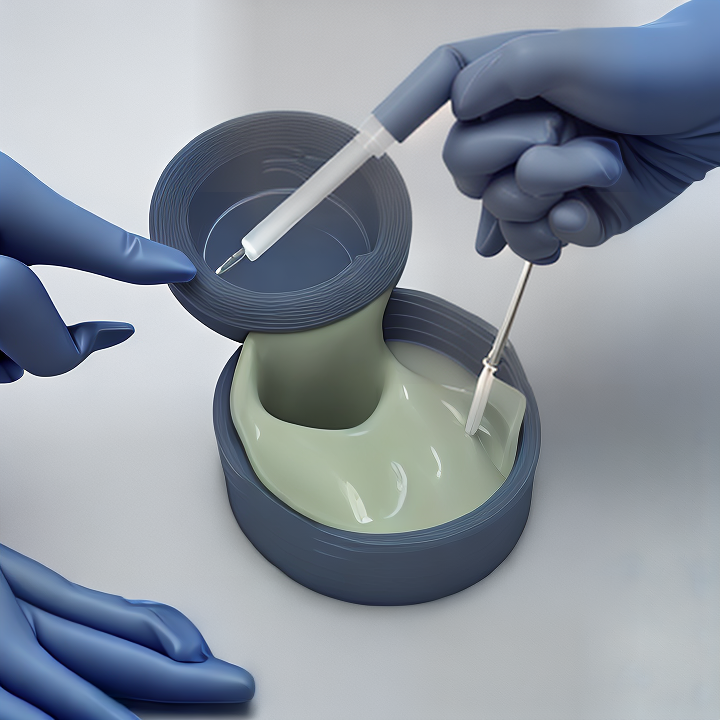

3. Medical equipment – The medical equipment industry requires components that are hygienic and reliable. Plastic injection moulding is used to create parts for various medical devices like infusion sets, syringes, diagnostic equipment, and inhalers.

4. Packaging industry – Plastic injection moulding is also used in the packaging industry to produce plastic bottles, containers, and caps for different products. The process enables manufacturers to create containers with excellent sealing and anti-leak properties that protect the product inside and prevent contamination from outside.

5. Aerospace industry – The aerospace industry also uses moule injection plastique to produce plastic components for airplanes, rockets, and satellites. Some examples include air ducts, cockpit components, and other lightweight parts.

In conclusion, moule injection plastique is a versatile and reliable manufacturing process that is used in diverse industries. Its ability to produce complex shapes, customizable designs, and precision makes it a valuable production method. The applications discussed above are only a few examples of the industries that benefit from this process. With advancements in technology, the applications and possibilities of moule injection plastique are continuing to grow.

List Various Types of “moule injection plastique”

Mould injection plastic, also known as plastic injection molding, is a manufacturing process that involves the injection of molten plastic into a mold. This process is widely used in the production of various plastic products, from small components to large, complex parts.

Here are some of the different types of mould injection plastic:

1. Thermoplastic injection molding: This is the most common type of plastic injection molding. It involves the use of thermoplastic materials, which can be melted and molded repeatedly. This process is ideal for creating complex shapes and designs.

2. Thermoset injection molding: This type of molding involves the use of thermosetting materials, which undergo a chemical reaction during the molding process to form a rigid, permanent shape. This process is used to create parts with high temperature and chemical resistance.

3. Micro injection molding: This type of molding is used to create small and precise parts, usually weighing less than a gram. This process requires specialized equipment and high precision tooling.

4. Liquid injection molding: This type of molding involves the use of liquid silicone rubber, which is injected into a mold and cured to form a solid part. This process is ideal for creating parts with complex shapes and high flexibility.

5. Gas-assisted injection molding: This process involves injecting a small amount of gas into the mold cavity to create a hollow part. This process is used to reduce part weight and improve part strength and stiffness.

Overall, the process of mould injection plastic can be used to manufacture a wide range of products, including automotive parts, medical devices, toys, household appliances, and electronic components. The choice of molding process will depend on the specific requirements of the product, including materials, shapes, and other design considerations.

List The Evolution history of “moule injection plastique”

Moule injection plastique, also known as injection molding, is a manufacturing process used to produce plastic parts. It has a long and interesting history of development, which has transformed the plastic industry. The evolution history of moule injection plastique can be divided into three main periods:

1. Early Development (1868 – 1940s): The early development of injection molding technology was primarily driven by the need to improve the manufacturing of billiard balls. John Hyatt invented a new plastic material, celluloid, in 1868, and later developed an injection molding machine to process it. The first commercial injection molding machine was designed and developed by James Watson Hendry in 1931. This machine used a simple plunger to inject plastic into a mold.

2. Modernization (1950s – 1980s): The 1950s brought significant progress to the injection molding process. With the development of new materials and machines, manufacturers were able to produce a wider range of products. The introduction of the screw injection molding machine in 1956 enabled the production of complex shapes and parts. Advances in computer technology and CAD/CAM software in the 1980s allowed for more precise and reliable design of molds and parts.

3. Current Advancements (1990s – Present): In the 1990s and beyond, the focus shifted towards reducing production time and increasing efficiency. The use of robots and automation to handle the injection molding process has become prevalent. The development of advanced materials and processing techniques has further improved the properties of products made through injection molding. Furthermore, the industry continues to research and develop new technologies that increase sustainability and reduce the environmental impact of injection molding.

In conclusion, the history of moule injection plastique has a rich and complex story that demonstrates the human ingenuity and technological progress. From celluloid to advanced materials and robotics, injection molding has come a long way and its potential for further growth is boundless.

List The Process of “moule injection plastique”

Moule injection plastique, also known as plastic injection molding, is a manufacturing process used to produce a large number of plastic parts. It involves the use of a mold that is shaped to the desired form of the part to be manufactured.

The first step of the process is the design of the mold. The mold is designed to fit into the injection molding machine and create the intended shape of the part. The design is created using computer-aided design (CAD) software.

Next, the mold is manufactured using a precision cutting tool to create the cavities required for the part. The mold is typically made of metal and can withstand the heat and pressure used in the injection process.

Once the mold is ready, it is installed into the injection molding machine. The machine is programmed to inject molten plastic into the mold. The plastic material is melted and injected into the mold through a nozzle. The plastic first enters the runner system and then fills the cavities, forming the part.

As the plastic cools and solidifies, it takes the shape of the mold. The machine then opens the mold and ejects the part from the cavities. The process may be repeated multiple times to produce a large number of identical plastic parts.

In summary, the moule injection plastique process involves designing the mold, manufacturing the mold, installing it into the injection molding machine, injecting molten plastic into the mold, and ejecting the part from the mold after it cools and solidifies.

How to use “moule injection plastique”

Moule injection plastique, also known as injection molding, is a manufacturing process that involves injecting molten plastic into a mold designed to create a specific shape. This process is commonly used in mass production for various industries, including automotive, electronics, medical, and consumer goods.

The first step in using moule injection plastique is designing the mold. This mold is typically made from steel or aluminum and is designed to the specific dimensions and shape required by the product. The molten plastic is then injected into the mold cavity at high pressure, filling it completely.

Once the mold is filled, it is cooled to allow the plastic to solidify. Once the plastic has hardened, the mold is opened, and the newly formed plastic part is ejected. After this, the process may continue until the desired number of parts are produced.

One of the significant advantages of moule injection plastique is the ability to produce complex shapes with high precision and accuracy. The process can also be fully automated, making it highly efficient and cost-effective.

However, the process requires a significant upfront investment in tooling and equipment. Additionally, the setup time to prepare the mold can be lengthy, making it less suitable for producing small quantities.

In conclusion, moule injection plastique is an essential manufacturing process for mass production of various products. Although expensive upfront investments are required, it offers many benefits like high precision and accuracy of the parts produced, making it an excellent option for companies that require large quantities produced with efficiency.

List Properties of “moule injection plastique”

Moule injection plastique is a manufacturing process that is used for producing plastic parts on a large scale. The primary property of moule injection plastique is its ability to create intricate plastic parts with accuracy and precision. The plastic material is melted and injected into a mold cavity that is made up of two halves, which are then placed together to produce the desired shape. The mold is designed with the exact measurements and specifications that are required for the part, which ensures uniformity in the production process.

Another property of moule injection plastique is its ability to produce a wide variety of shapes, sizes, and colors. The process allows for the use of different materials such as thermoplastics, thermosetting plastics, and elastomers, to create parts that meet the specific requirements of the end-users. The versatility also means that moule injection plastique can be used for different industries, including automotive, medical, and consumer goods.

Moule injection plastique provides manufacturers with a fast and cost-effective method for producing high-quality plastic parts. The process is automated, which makes it possible to produce a large volume of parts in a short amount of time. This property is beneficial for companies that are looking to increase their production levels and reduce their costs. The simplicity of the process also means that manufacturers can quickly set up their production lines for any given order.

Moule injection plastique is a reliable manufacturing process due to the precision, accuracy, and repeatability of the molding process. The consistency and uniformity of the plastic parts ensure that the end-product meets the desired requirements and quality standards. This property removes the chances of defects, inconsistencies, and variations in the production process, which minimizes waste and reduces the need for corrective action.

In conclusion, Moule injection plastique offers a wide range of benefits to manufacturers, including accuracy, versatility, cost-effectiveness, and reliability. These properties make moule injection plastique an ideal manufacturing method for producing a large volume of plastic parts that meet high-quality standards.

List “moule injection plastique” FAQ

Moule injection plastique is a French term for plastic injection molding, which is a manufacturing process used to create plastic parts by injecting molten plastic material into a mold. Here are some frequently asked questions (FAQ) about this process:

1. What is the plastic injection molding process?

Injection molding involves melting plastic pellets or resin and then injecting them into a mold cavity where the plastic cools and solidifies, taking on the shape of the mold.

2. What materials can be used in injection molding?

A wide variety of thermoplastic materials can be used for injection molding, including polypropylene, polyethylene, polystyrene, and PVC. Specialty materials like nylon, PET, and ABS are also popular.

3. What are the advantages of plastic injection molding?

Injection molding offers several benefits, including high production rates, precise dimensional control, and the ability to produce complex shapes and geometries.

4. What kinds of products can be produced through injection molding?

Plastic injection molding is used to create a diverse array of parts, including automotive components, medical devices, consumer goods, and electronic housings.

5. What is the typical lead time for injection molding projects?

Lead times can vary depending on the complexity of the design, the material being used, and the size of the production run. However, injection molding can often produce parts on a faster timeline than other manufacturing techniques.

6. How expensive is injection molding?

The cost of injection molding can vary widely depending on factors like the size of the tooling, the materials being used, and the complexity of the design. However, injection molding can often be a cost-effective solution for high-volume production runs.

7. What kind of quality control measures are used in injection molding?

Injection molding facilities use a range of quality control tests to ensure that products meet design specifications, including dimensional checks, material testing, and visual inspections.