List Technical Parameters of “order custom plastic parts”

Ordering custom plastic parts is a process that requires several technical parameters to be considered to ensure product quality, functionality, and efficiency. Some of the essential technical parameters that need to be considered include:

1. Material properties: The materials used in manufacturing custom plastic parts must have appropriate properties such as strength, durability, impact resistance, UV stability, and chemical resistance.

2. Size and shape: The dimensions of custom plastic parts are crucial to the performance and functionality of the end product. The size and shape must be precise and meet the client’s requirements.

3. Tolerance: Tolerance refers to the allowable difference between the actual and specified dimensions of the custom plastic parts. The tolerance levels of the parts must be kept within acceptable limits to avoid product failure or rejection.

4. Surface finish: The surface finish of custom plastic parts is critical as it affects the appearance, durability, and performance of the end product. The surface finish required depends on the part’s specific application and must be specified in the order.

5. Color: The color of custom plastic parts is an essential aspect, particularly for branding purposes. Clients have the option of specifying the exact color or color code of their plastic parts.

6. Tooling design: Tool design is an essential technical parameter that needs to be considered for custom plastic parts. It ensures the repeatability, consistency, and accuracy of the part’s production.

7. Manufacturing process: There are different manufacturing processes used to produce custom plastic parts, such as injection molding, blow molding, and extrusion. The manufacturing process selected depends on the part’s requirements, including volume, complexity, and cost.

8. Quantity and lead time: The order quantity and lead time are crucial technical parameters in the production of custom plastic parts. The production schedule must be carefully planned and managed to meet the client’s needs.

In conclusion, the technical parameters for ordering custom plastic parts are numerous and require careful consideration to ensure the production of high-quality parts that meet the client’s needs and specifications.

List Product features of “order custom plastic parts”

Ordering custom plastic parts refers to the process of having a manufacturer create plastic components as per the specifications and requirements of a customer. There are various features that this service offers, which make it appealing and beneficial to a wide range of customers across multiple industries.

Customization: The primary feature of ordering custom plastic parts is customization. Customers can customize the dimensions, shape, color, and other physical characteristics of the plastic parts to suit their unique requirements. This feature allows customers to get precisely what they need and avoid the compromise that comes with “one-size-fits-all” options.

Flexibility: Another significant feature of ordering custom plastic parts is flexibility. Manufacturers can typically create any plastic component as long as they have the appropriate specifications. This flexibility means that customers can order custom plastic parts for a broad range of applications.

Durability: Plastic parts are often used in demanding applications such as automotive, aerospace, and medical industries. Order custom plastic parts are typically made of high-quality, durable materials, which ensures that they can withstand the rigorous demands of their intended application.

Cost-effective: Ordering custom plastic parts can also be cost-effective, especially when compared to making the parts in-house or using non-customized standard plastic parts. Customization offers the ability to minimize waste, optimize material use, and reduce overall costs.

Quality: Quality is another key feature of ordering custom plastic parts. Customers can specify the material used during creation, which ensures that there is a low risk of failure and the final products meet all the necessary standards of quality.

Quick Turnaround Times: Many manufacturers who offer custom plastic parts have well-established systems in place to ensure that they can produce parts in a timely manner. Customers can expect to have their parts created and shipped within a reasonable deadline.

In conclusion, ordering custom plastic parts is a useful and versatile service that offers a broad range of features and benefits. From flexibility and durability to cost-effectiveness and quality, customers can expect to receive precisely what they need by ordering custom plastic parts.

List Application of “order custom plastic parts”

Ordering custom plastic parts can be helpful in various industries and applications, such as:

1. Automotive: plastic parts play a vital role in the automotive industry as it helps to make the car lighter, more efficient, and cost-effective. It includes parts such as plastic panels, air intake systems, and interior trim.

2. Medical: plastic parts are used in the medical industry because plastic is easy to clean and can be sterilized easily. It includes parts such as IV catheters, syringes, and medical device housing.

3. Aerospace: plastic parts are also used in the aerospace industry as it helps to reduce the weight of the components. It includes parts such as aircraft’s panels, containers, and other lightweight components.

4. Electronics: plastic parts are used in electronic devices as it helps to provide insulation and protection from the environment. It includes parts such as electronic enclosures, computer housings, and phone cases.

5. Consumer Goods: plastic parts are used in the production of various consumer goods such as toys, kitchen utensils, and household appliances. It includes parts such as plastic containers, plastic cases, and plastic covers.

6. Industrial: plastic parts are also used in the industrial sector to manufacture machinery components, conveyor systems, and other heavy-duty mechanical parts.

Ordering custom plastic parts can also be a cost-effective solution for businesses that require a specific design or functionality from a particular component. It helps to improve the efficiency and effectiveness of the manufacturing process while meeting the specific requirements of the application. Additionally, custom plastic parts can be produced in a variety of colors, sizes, and shapes, making it easier to meet the business’s unique specifications.

Overall, ordering custom plastic parts can provide endless benefits to various industries and applications, from improving the functionality of electronic devices, reducing the weight of aircraft components to creating efficient machinery components.

List Various Types of “order custom plastic parts”

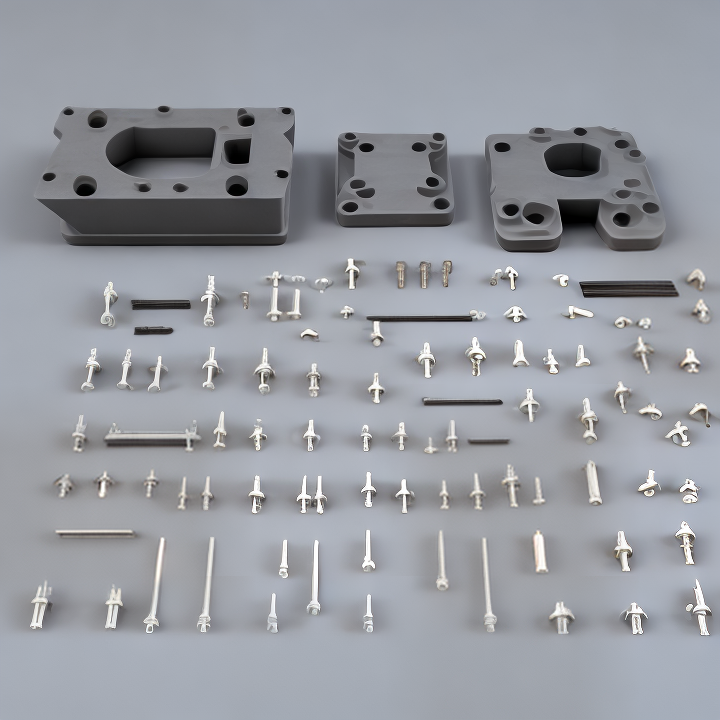

Ordering custom plastic parts involves a lot of planning, design, and precision to ensure that the final product meets the client’s exact specifications. The following are various types of custom plastic parts that clients can order:

1. Injection-molded plastic parts: Injection molding is a common method of manufacturing plastic parts, where molten plastic is injected into a mold cavity to produce the desired shape. It is ideal for mass production of plastic parts, and the final product can be highly detailed.

2. CNC-machined plastic parts: Computer Numerical Control (CNC) machining involves the use of computer-controlled tools to cut, shape, and drill plastic parts from a block of raw material. CNC machining guarantees precision and accuracy, making it ideal for producing parts with intricate designs.

3. Vacuum-formed plastic parts: Vacuum forming is a manufacturing process where a large sheet of plastic is heated and then placed over a mold. A vacuum is then applied to force the plastic onto the mold’s surface to create the final shape.

4. Thermo-formed plastic parts: Thermoforming involves heating a plastic sheet until it becomes malleable before forming it over a mold. The final product is then cooled and trimmed to the desired shape.

5. Blow-molded plastic parts: Blow molding is a manufacturing process where a hollow plastic tube called a parison is inflated using pressurized air. The parison conforms to the shape of the mold to create the final part.

6. Extruded plastic parts: Extrusion is a manufacturing process where plastic pellets are melted and forced through a die to create a continuous profile. The profile is then cut to the desired length.

7. 3D printed plastic parts: 3D printing is an additive manufacturing process that uses a digital file to create a physical object layer by layer. It is ideal for producing small batches of highly customized parts with complex geometries.

In summary, there are different methods for producing custom plastic parts, and the choice of production method will ultimately depend on the client’s requirements, budget, and the desired end product.

List The Evolution history of “order custom plastic parts”

Ordering custom plastic parts has been a common practice in the manufacturing industry since the 1950s. Initially, manufacturers produced plastic parts in-house or outsourced production to specialized molding companies. However, the process was slow, expensive, and required a significant capital investment.

With the rise of computer-aided design (CAD) software in the 1970s, manufacturers gained the ability to design parts digitally and transmit the files to molding companies for production. This method improved the accuracy of the parts and reduced the time and cost of production.

In the 1990s, online marketplaces emerged, allowing manufacturers to submit their designs in digital formats and receive instant quotes from multiple molding companies. This led to increased competition and lower pricing, making custom plastic parts accessible to a wider range of businesses.

As technology continued to advance, 3D printing gained popularity in the early 2000s. Manufacturers could now produce custom plastic parts in-house using additive manufacturing techniques, reducing lead times and costs even further.

Currently, custom plastic parts can be ordered from a variety of sources, including online marketplaces, traditional molding companies, 3D printing services, and in-house production. Many companies also offer design assistance and consultation to optimize part functionality and reduce costs.

Overall, the evolution of order custom plastic parts has been driven by advances in technology, increased competition, and demand for lower costs and faster production times. The industry will likely continue to evolve as new technologies and materials become available.

List The Process of “order custom plastic parts”

Ordering custom plastic parts involves several stages and requires careful consideration to ensure that the final product meets all requirements. Here are the steps involved in the process of ordering custom plastic parts:

1. Define the requirements: The first step is to determine what the final product should look like, its specifications, and the quantity needed. This information will help to guide the manufacturing process and ensure that the final product meets the desired specifications.

2. Choose a manufacturer: After defining the requirements, the next step is to select a manufacturer who can produce the custom plastic parts. Choose a manufacturer based on their experience, quality, and pricing.

3. Submit 3D models or drawings: Submit detailed 3D models or drawings of the custom plastic parts to the manufacturer. The drawings should specify all the required specifications including the size, color, and material to be used.

4. Review and approve the design: Once the manufacturer receives the 3D models or drawings, they will create a prototype of the custom plastic parts based on the specifications provided. A review will be conducted to ensure that the design meets the requirements.

5. Manufacturing process: After the design is approved, the manufacturing process starts. The manufacturer will use the approved design and produce the custom plastic parts according to the required specifications.

6. Inspection and Quality Control: Once the custom plastic parts are manufactured, the manufacturer will conduct a thorough inspection to ensure that the parts meet the required quality standards. This process includes inspecting for any defects or inconsistencies in the material, size, or color.

7. Delivery: Once the custom plastic parts pass the inspection, the manufacturer ensures that the parts are delivered to the client in time.

In conclusion, the process of ordering custom plastic parts involves several steps, including defining the requirements, choosing a manufacturer, submitting 3D models or drawings, reviewing the design, production, inspection, and quality control before finally delivering the parts. It’s essential to choose a reliable and experienced manufacturer to ensure that the custom plastic parts meet the desired specifications.

How to use “order custom plastic parts”

If you need plastic parts for your business or personal use, you can easily order custom plastic parts from a reliable manufacturer or supplier. It is important to choose a manufacturer or supplier who can provide you with high-quality plastic parts that meet your specific requirements.

To order custom plastic parts, you need to follow some simple steps. First, you need to identify the required specifications and dimensions of the plastic parts you need. You can draw a sketch or create a CAD file of your design to provide the manufacturer/supplier with a clear idea of what you want.

Second, you need to consider the manufacturing process that will be used to produce your custom plastic parts. The manufacturer/supplier should be able to advise you on the best manufacturing process for your project, based on your design, budget, timeline, and other factors.

Third, you need to request a quote from the manufacturer/supplier, which should include the cost of material, tooling, labor, and any additional services you may require. You should compare quotes from different manufacturers/suppliers and choose the one that offers the best value for your money.

Fourth, you need to place an order and provide the manufacturer/supplier with the required payment and documentation. The manufacturer/supplier should keep you informed about the status of your order and provide you with updates, such as a sample for approval before production, delivery dates, and tracking information.

Finally, you should inspect the custom plastic parts upon receipt to ensure that they meet your requirements and specifications. If there are any issues with the quality or dimensions of the plastic parts, you should immediately contact the manufacturer/supplier to resolve the issue.

In conclusion, ordering custom plastic parts is a straightforward process that involves identifying specifications, selecting the right manufacturing process, requesting a quote, placing an order, and inspecting the products upon receipt. By following these steps, you can obtain quality plastic parts that meet your needs, budget, and timeline.

List Properties of “order custom plastic parts”

Ordering custom plastic parts entails several important properties that must be taken into account. Custom plastic parts come in different shapes and sizes, depending on the customer’s needs and specifications. They are made from various types of plastic materials, such as polyethylene, polypropylene, PVC, ABS, and polycarbonate. Below are some of the most important properties of order custom plastic parts.

1. Durability – Custom plastic parts are known for their durability, which is why they have become increasingly popular in different industries. These parts can withstand harsh environments, extreme temperatures, and heavy loads, making them ideal for various applications.

2. Precision – Custom plastic parts require high precision during the manufacturing process to ensure that the final product meets the customer’s specifications accurately. These parts are made using modern manufacturing techniques, such as 3D printing, injection molding, and thermoforming.

3. Flexibility – One of the unique properties of custom plastic parts is their flexibility in terms of design. Customers can specify the shape, size, color, and finish of the parts, making them suitable for a wide range of applications.

4. Cost-effective – Custom plastic parts are generally less expensive than other materials, such as metal or wood. They require less raw material, and the manufacturing process is more efficient, reducing the overall cost.

5. Chemical resistance – Custom plastic parts are resistant to chemicals and corrosion, making them ideal for applications where they will be exposed to harsh chemicals or environments.

6. Lightweight – Custom plastic parts are lightweight, making them easy to transport and install. They are also suitable for applications where weight is a concern.

In summary, order custom plastic parts come with several properties that make them suitable for various applications. They are durable, precise, flexible, cost-effective, chemical resistant, and lightweight. These properties make custom plastic parts an essential component in different industries, including automotive, aerospace, electronics, medical, and consumer products.

List “order custom plastic parts” FAQ

1. What plastic materials can be used for custom part orders?

A: Common plastic materials used for custom part orders include polycarbonate, polyethylene, ABS, acrylic, and nylon.

2. What is the minimum order quantity for custom plastic parts?

A: The minimum order quantity for custom plastic parts can vary depending on the manufacturer or supplier. It is important to inquire and clarify with the manufacturer about minimum order requirements.

3. Can I get a sample of my custom plastic part before placing a full order?

A: Yes, most manufacturers offer prototyping or sample services to ensure customer satisfaction before placing a full order.

4. What file formats are acceptable for submitting a design for a custom plastic part?

A: Common file formats accepted by manufacturers for submitting designs include STL, STEP, IGES, and SolidWorks formats.

5. How long does it take to receive a custom plastic part order?

A: The manufacturing and delivery time can vary depending on the complexity of the design and quantity of parts ordered. It is important to inquire about estimated lead time when placing an order with the manufacturer.

6. Can custom plastic parts be made in different colors or finishes?

A: Yes, custom plastic parts can be made with a variety of colors, finishes, and textures to meet specific design requirements.

7. Are there any limitations to the size or shape of custom plastic parts that can be produced?

A: The size and shape capabilities of custom plastic parts can vary depending on the manufacturing process used by the manufacturer. It is important to inquire about the capabilities of the manufacturer or supplier when placing an order.

8. What quality control measures are taken to ensure the custom plastic parts meet specifications?

A: Manufacturers typically have quality control procedures in place to ensure that custom plastic parts meet all specifications and requirements outlined by the customer. These measures can include inspection, testing, and certifications.

9. How does pricing for custom plastic parts typically work?

A: Pricing for custom plastic parts can vary depending on the quantity, complexity of the design, manufacturing process, and lead time required. Be sure to clarify pricing with the manufacturer before placing an order.

10. Can custom plastic parts be made with specific tolerances or tight specifications?

A: Yes, custom plastic parts can be made with very specific tolerances and tight specifications. It is important to specify these requirements with the manufacturer when placing an order.