Benefits of Pouch Packing Machine

In today’s fast-paced world, consumers expect products to be easily accessible, convenient and safe to use. The packaging industry has been revolutionized with the advent of pouch packing machines, which have become a popular choice for businesses looking for efficient and cost-effective packaging solutions. Pouch packing machines offer numerous benefits, which we will discuss in this article.

1. Versatile Packaging Solution

Pouch packing machines are versatile and can be used to pack a wide variety of products such as food, cosmetics, pharmaceuticals, and chemicals. They come in different types and sizes to accommodate different packaging needs. The machines can produce different types of pouches, including stand-up pouches, zipper pouches, spouted pouches, and flat pouches, to name a few.

2. Increased Efficiency and Productivity

Pouch packing machines are designed to increase productivity and efficiency in the production process. They can pack products at a faster rate than manual labor, thus increasing the output. The machines are also automated, which means they require less human intervention to operate, reducing the chances of human error and increasing consistency in product quality.

3. Reduced Packaging Costs

Pouch packing machines are a cost-effective packaging solution. They require less packaging material than traditional packaging methods, reducing packaging costs. The machines also reduce waste, as they use the exact amount of packaging material required for each product. This not only saves money but also reduces the environmental impact of packaging.

4. Longer Shelf Life

Pouch packing machines use high-quality packaging materials that protect products from environmental factors that can cause spoilage. The materials used are also lightweight, which reduces shipping costs. Products packed using pouch packing machines have a longer shelf life, reducing the chances of spoilage and increasing customer satisfaction.

5. Branding and Marketing Opportunities

Pouch packing machines offer branding and marketing opportunities. The pouches can be printed with logos, graphics, and text, making them an effective marketing tool. This helps businesses to create brand awareness and increase sales.

6. Improved Safety and Hygiene

Pouch packing machines offer improved safety and hygiene. The machines are designed to meet hygiene standards and are easy to clean. They also reduce the chances of contamination during the packaging process, ensuring that products are safe for consumption.

In conclusion, pouch packing machines offer numerous benefits to businesses, including increased efficiency and productivity, reduced packaging costs, longer shelf life, branding and marketing opportunities, and improved safety and hygiene. Investing in a pouch packing machine is a smart choice for businesses looking for a cost-effective and efficient packaging solution.

Features of Pouch Packing Machine

Here are some of the features of Pouch Packing Machines:

1. High-Speed Packaging: Pouch Packing Machines are designed to pack products at high speeds, which can range from 30-150 pouches per minute. This feature is particularly useful for companies that require large-scale packaging for their products.

2. Accurate Filling: One of the most critical features of Pouch Packing Machines is their ability to fill pouches accurately. These machines use advanced technology like load cells and sensors to measure the weight of the product accurately and fill the pouches accordingly. This feature ensures that the product is packed correctly, and the customers get the right quantity of the product.

3. Versatile Packaging: Pouch Packing Machines can be used for a wide range of products, including liquids, powders, granules, and solids. These machines come with different attachments that are designed to handle different types of products. This feature makes Pouch Packing Machines an ideal choice for companies that produce different types of products.

4. User-Friendly: Pouch Packing Machines are designed to be user-friendly. They come with a touch screen interface that allows operators to set up the machine easily. These machines also come with safety features like automatic shut-off, which ensures the safety of the operators.

5. Easy Maintenance: Pouch Packing Machines require minimal maintenance. These machines are designed to be easy to clean and require minimal lubrication. This feature ensures that the machines run smoothly, and the downtime is minimized.

In conclusion, Pouch Packing Machines are a game-changer for the packaging industry. These machines offer high-speed, accurate, and versatile packaging capabilities, making them an ideal choice for companies that require large-scale packaging. With their user-friendly interface and easy maintenance, Pouch Packing Machines are becoming increasingly popular in the packaging industry.

Specifications Pouch Packing Machine

Pouch packing machines are an essential piece of equipment for businesses that want to streamline their packaging processes. These machines are designed to create airtight seals on pouches, making them perfect for packaging food, pharmaceuticals, and other sensitive items. If you’re in the market for a pouch packing machine, it’s important to understand the specifications that will determine which model is right for you.

The first specification to consider is the type of pouch the machine can handle. Some machines are designed to work with specific types of pouches, such as stand-up pouches or flat pouches. Others are more versatile and can handle a wide range of pouch styles and sizes. Make sure you choose a machine that can accommodate the specific pouches you use in your business.

Next, consider the speed of the machine. Pouch packing machines can vary significantly in how quickly they can process pouches. If you have a high-volume production line, you’ll want a machine that can keep up with your demand. However, if you have a smaller operation, a slower machine may be sufficient.

Another specification to consider is the sealing mechanism. Pouch packing machines can use various sealing methods, including heat sealing, ultrasonic sealing, and ziplock sealing. Each method has its advantages and disadvantages, so it’s important to choose the one that is best suited for your product.

You’ll also want to consider the material of the machine itself. Stainless steel is a popular choice because it is durable, easy to clean, and resistant to corrosion. However, other materials may be more appropriate depending on your specific needs and budget.

Finally, think about any additional features that may be important to your business. For example, some machines come with automatic pouch loading, while others require manual loading. Some machines may have built-in printers for labeling, or they may have sensors that detect pouch defects.

In conclusion, there are several specifications to consider when choosing a pouch packing machine. By understanding your specific needs and researching the options available, you can find a machine that will improve your packaging process and help your business run more efficiently.

Types of Pouch Packing Machine

Pouch packing machines are essential equipment in the food, pharmaceutical, and cosmetic industries. They are used for packing products, such as powders, liquids, granules, and solids, in pouches. These machines come in different types, each designed for specific applications. In this article, we will discuss the different types of pouch packing machines.

1. Vertical Form Fill Seal (VFFS) Machine

The VFFS machine is the most common type of pouch packing machine. It is versatile and can pack different types of products, including powders, liquids, and granules. This machine forms a pouch from a roll of film, fills it with the product, and seals it. The VFFS machine is suitable for high-speed production and can pack products in different sizes and shapes.

2. Horizontal Form Fill Seal (HFFS) Machine

The HFFS machine is similar to the VFFS machine, but it operates horizontally. It is ideal for packing products that are difficult to handle vertically, such as liquids and viscous products. The HFFS machine forms a pouch from a flat film, fills it with the product, and seals it. It is suitable for packing small to medium-sized pouches and can be used for low to medium-speed production.

3. Stick Pack Machine

The stick pack machine is designed for packing small products, such as powders and liquids, in stick-shaped pouches. This machine forms a pouch from a roll of film, fills it with the product, and seals it. The stick pack machine is ideal for packing single-serve products, such as sugar, coffee, and ketchup.

4. Sachet Machine

The sachet machine is designed for packing small to medium-sized products, such as powders, liquids, and granules, in flat pouches. This machine forms a pouch from a roll of film, fills it with the product, and seals it. The sachet machine is ideal for packing products that are used in small quantities, such as shampoo and sauces.

5. Stand-up Pouch Machine

The stand-up pouch machine is designed for packing products in stand-up pouches. This machine forms a pouch from a roll of film, fills it with the product, and seals it. The stand-up pouch machine is ideal for packing products that have a high visual impact, such as snacks and pet food.

In conclusion, pouch packing machines are essential equipment in the food, pharmaceutical, and cosmetic industries. They come in different types, each designed for specific applications. The VFFS machine is the most common type of pouch packing machine and can pack different types of products. The HFFS machine is ideal for packing products that are difficult to handle vertically. The stick pack machine is designed for packing small products in stick-shaped pouches. The sachet machine is ideal for packing small to medium-sized products in flat pouches. The stand-up pouch machine is ideal for packing products in stand-up pouches.

Applications of Pouch Packing Machine

Pouch packing machines are a type of packaging equipment that is widely used in the food, beverage, and pharmaceutical industries. These machines are designed to pack a wide range of products, including liquids, powders, granules, and solids, into pouches or bags. Pouch packing machines offer several advantages over traditional packaging methods, such as efficiency, accuracy, and cost-effectiveness. In this article, we will discuss the various applications of pouch packing machines.

Food industry

The food industry is one of the largest users of pouch packing machines. These machines are used to pack a variety of food products, including snacks, confectionery, frozen food, and ready-to-eat meals. Pouch packing machines are ideal for packing food products as they provide an airtight seal, which helps to preserve the freshness and flavor of the food. Additionally, pouches are lightweight and easy to transport, making them an ideal choice for food manufacturers who need to ship their products to different locations.

Beverage industry

The beverage industry is another major user of pouch packing machines. These machines are used to pack a wide range of beverages, including fruit juices, energy drinks, and soft drinks. Pouches can be designed to hold different volumes, making them a versatile choice for beverage manufacturers. Pouch packing machines are particularly useful for packing beverages that are sensitive to light and air, as the airtight seal provided by the pouch helps to preserve the flavor and nutrients of the beverage.

Pharmaceutical industry

The pharmaceutical industry also uses pouch packing machines to pack a wide range of products, including tablets, capsules, and powders. Pouches are an ideal choice for pharmaceutical products as they provide an airtight seal, which helps to prevent contamination and maintain the efficacy of the product. Additionally, pouch packing machines can be designed to meet the strict regulatory requirements of the pharmaceutical industry, ensuring that the products are packed safely and accurately.

Cosmetic industry

The cosmetic industry also uses pouch packing machines to pack a wide range of products, including creams, lotions, and gels. Pouches are an excellent choice for cosmetic products as they can be designed to hold different volumes and are easy to use. Pouch packing machines can also be designed to pack multiple products in a single pouch, making it easier for customers to use and transport the products.

Conclusion

Pouch packing machines offer several advantages over traditional packaging methods, making them an ideal choice for a wide range of industries. These machines are efficient, accurate, and cost-effective, making them an excellent investment for businesses looking to improve their packaging processes. Whether you are in the food, beverage, pharmaceutical, or cosmetic industry, a pouch packing machine can help you pack your products safely and accurately, ensuring that they reach your customers in the best possible condition.

Process of Pouch Packing Machine

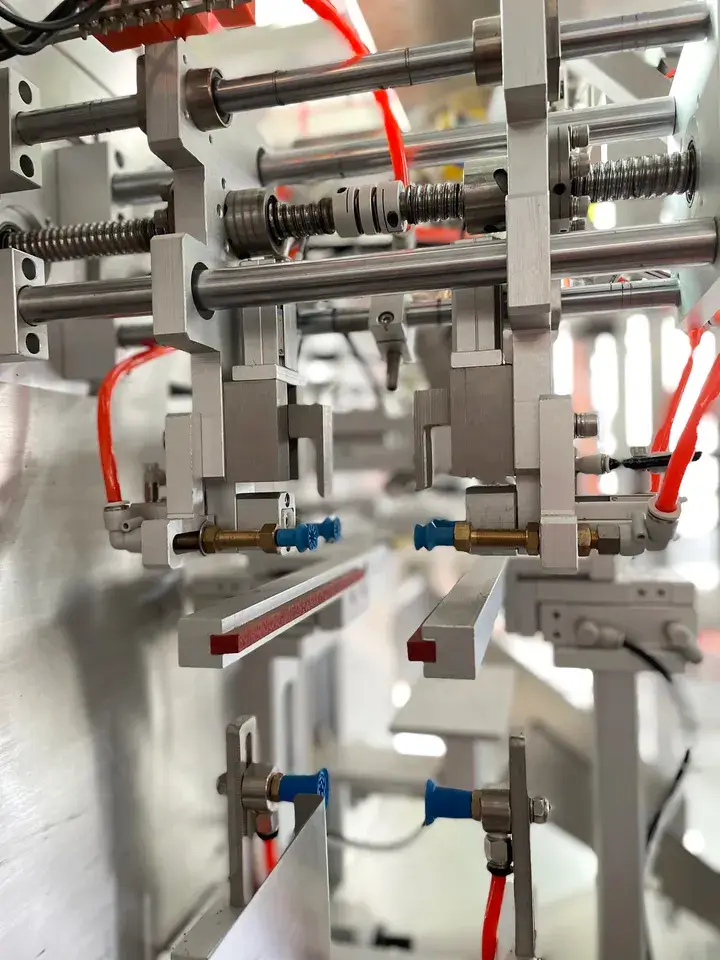

Pouch packing machines are an essential part of modern manufacturing processes. They are designed to fill and seal various types of pouches with a wide range of products, including food, pharmaceuticals, and chemicals. These machines use advanced technology to automate the packaging process, improving efficiency, speed, and accuracy.

The process of pouch packing involves several steps that are performed by the machine. First, the machine will take the empty pouches and open them up, ready for filling. The product is then measured out and dispensed into the pouches through a filling nozzle or tube. The machine will ensure that the correct amount of product is dispensed into each pouch by using sensors and other advanced technology.

Once the product has been filled into the pouches, the machine will seal them shut. The sealing process varies depending on the type of pouch being used and the product being packaged. For example, some pouches may require heat sealing, while others may use ultrasonic sealing or even adhesive sealing.

After the pouches have been sealed, they are then cut and separated from the rest of the pouches. The machine will then move the finished pouches onto a conveyor belt or other packaging equipment for further processing, such as labeling or boxing.

One of the key benefits of using a pouch packing machine is the high level of automation it provides. These machines can operate continuously for extended periods, with minimal human intervention required. This not only improves efficiency but also reduces the risk of errors, improving the quality of the finished product.

Another benefit of pouch packing machines is their versatility. These machines can be used to fill and seal a wide range of pouches, including stand-up pouches, flat pouches, and even vacuum pouches. This makes them suitable for use in a variety of industries, including food and beverage, pharmaceuticals, and cosmetics.

In conclusion, the process of pouch packing involves several steps that are performed by a specialized machine. This machine uses advanced technology to automate the process, improving efficiency, speed, and accuracy. By using a pouch packing machine, manufacturers can improve the quality of their products while reducing the risk of errors and increasing productivity.

How to use Pouch Packing Machine

Pouch packing machines have revolutionized the way packaging is done in the food and beverage industry. These machines are designed to pack products in pouches, which are easy to store and transport. The use of pouch packing machines has made the packaging process faster, more efficient, and cost-effective.

If you’re new to the world of pouch packing machines, it can be intimidating. But fear not, this article will guide you through the process of using a pouch packing machine.

Step One: Choose the Right Pouch

Before you start using a pouch packing machine, you need to choose the right pouch for your product. Pouches come in different sizes, shapes, and materials. Some pouches are made of plastic while others are made of paper. The choice of the pouch will depend on the product you want to pack and the storage conditions.

Step Two: Set Up the Machine

Once you’ve chosen the right pouch, you need to set up the machine. This involves adjusting the machine settings to suit the pouch size and sealing requirements. You’ll also need to test the machine to ensure that it’s working correctly.

Step Three: Load the Product

After the machine is set up, you can start loading the product. The product can be loaded manually or using an automatic feeder. It’s essential to ensure that the product is loaded correctly to avoid spillage or damage to the pouch.

Step Four: Seal the Pouch

Once the product is loaded, the pouch is sealed. The sealing process involves applying heat to the pouch to melt the material and create a seal. The sealing process is crucial, and you need to ensure that the seal is strong and consistent.

Step Five: Package the Pouch

After the pouch is sealed, it’s ready to be packaged. The packaged pouches can be stored in boxes or bags for transport to the market.

In conclusion, using a pouch packing machine is a straightforward process that requires attention to detail. By following the steps outlined above, you’ll be able to pack your products efficiently and cost-effectively. Remember to choose the right pouch, set up the machine, load the product correctly, seal the pouch, and package the pouches for storage and transport.

Selecting the Ideal Manufacturer Pouch Packing Machine

Pouch packing machines are used in various industries to pack products like food, pharmaceuticals, cosmetics, and more. These machines come in different sizes, shapes, and functionalities. Hence, it is essential to select the ideal manufacturer pouch packing machine that meets your requirements. In this article, we will discuss a few factors to consider while selecting the ideal manufacturer pouch packing machine.

1. Quality: The quality of the pouch packing machine is a crucial factor to consider while selecting the ideal manufacturer. A high-quality machine will ensure that your products are packed safely and efficiently. You should look for a manufacturer that uses high-quality materials and follows strict quality control measures.

2. Production Capacity: The production capacity of the machine is another crucial factor to consider. You should select a manufacturer that offers machines that can meet your production requirements. The machine’s speed, size, and capacity should be suitable for your business needs.

3. Customization: It is essential to select a manufacturer that offers customization options. Your business requirements may vary from others, and hence you need a machine that is tailored to your specific needs. A manufacturer that offers customization options will help you in achieving your business goals.

4. Maintenance and Support: The manufacturer should offer maintenance and support services for the machine. The machine can face issues or breakdown, and hence you need a manufacturer that provides prompt services to resolve the problem. The manufacturer should also offer training and guidance on how to use the machine correctly.

5. Cost: The cost of the machine is a crucial factor to consider while selecting the ideal manufacturer. You should look for a manufacturer that offers a reasonable price for the machine without compromising on the quality. You should also consider the long-term cost of ownership, including maintenance and repairs.

In conclusion, selecting the ideal manufacturer pouch packing machine requires careful consideration of various factors. You should look for a manufacturer that offers high-quality machines, customization options, and maintenance and support services. The manufacturer should also offer machines that meet your production requirements at a reasonable cost. Selecting the right manufacturer will ensure that your business operates efficiently and effectively.

Technical Parameters of Pouch Packing Machine

Pouch packing machines are widely used in the food, pharmaceutical and cosmetic industries. These machines are designed to pack different types of products such as powders, granules, liquids, and semi-solids into pouches of various sizes and shapes. In order to achieve optimal performance and ensure the highest level of efficiency, it is important to pay attention to the technical parameters of the pouch packing machine.

The following are some of the most important technical parameters of pouch packing machines:

1. Production capacity: This refers to the number of pouches that the machine can produce per minute. The production capacity of a pouch packing machine depends on the size and complexity of the product being packed, as well as the type of pouch being used. It is important to choose a machine with a production capacity that meets the needs of the production line.

2. Filling accuracy: Filling accuracy refers to the amount of product that is dispensed into each pouch. This is a critical parameter, particularly for pharmaceutical and food products, where accuracy is essential to ensure the safety and quality of the product. The filling accuracy of a pouch packing machine depends on the type of product being packed, the type of filling mechanism used, and the level of automation of the machine.

3. Pouch size and shape: Pouch packing machines can accommodate different sizes and shapes of pouches. The size and shape of the pouch must be compatible with the machine’s filling mechanism and sealing system. It is important to choose a machine that can accommodate the desired size and shape of the pouch.

4. Sealing mechanism: The sealing mechanism is an important technical parameter of a pouch packing machine. There are several types of sealing mechanisms available, including heat sealing, ultrasonic sealing, and cold sealing. The choice of sealing mechanism depends on the type of product being packed, the type of pouch being used, and the desired level of seal strength.

5. Control system: The control system is responsible for the overall operation of the pouch packing machine. It controls the filling, sealing, and cutting mechanisms, as well as the speed and production capacity of the machine. The control system can be manual or automated, depending on the level of control required for the production line.

In conclusion, the technical parameters of pouch packing machines are critical to the successful operation of the production line. It is important to choose a machine with the appropriate production capacity, filling accuracy, pouch size and shape, sealing mechanism, and control system to ensure optimal performance and efficiency. By paying attention to these parameters, manufacturers can ensure that their pouch packing machines deliver high-quality, consistent results.

list FAQ with answer about Pouch Packing Machine

Pouch packing machines are becoming increasingly popular in the food and beverage industry. These machines offer a fast and efficient way to package a wide range of products, from powdered drinks to snacks, sauces, and more. However, with so many pouch packing machines available on the market, it can be difficult to know which one is right for your business. In this article, we’ll answer some of the most frequently asked questions about pouch packing machines to help you make an informed decision.

1. What is a pouch packing machine?

A pouch packing machine is a type of packaging machine that is used to package products in pouches or bags. These machines typically use film roll stock that is formed into pouches and filled with the product before being sealed.

2. What are the different types of pouch packing machines?

There are several different types of pouch packing machines, including vertical form fill seal (VFFS) machines, horizontal form fill seal (HFFS) machines, and stick pack machines. VFFS machines are the most common and versatile, while HFFS machines are typically used for larger products. Stick pack machines are ideal for packaging small, single-serve products.

3. What types of products can be packaged with a pouch packing machine?

A pouch packing machine can be used to package a wide range of products, including powders, granules, liquids, and solids. This makes them ideal for use in the food and beverage industry, as well as in the pharmaceutical and cosmetic industries.

4. What are the benefits of using a pouch packing machine?

Pouch packing machines offer several benefits, including increased efficiency, reduced labor costs, and improved product quality. They also offer greater flexibility, allowing businesses to package a wide range of products with a single machine.

5. What factors should I consider when choosing a pouch packing machine?

When choosing a pouch packing machine, it’s important to consider factors such as the type of product you are packaging, the size and shape of the pouches, and the production volume you require. You should also consider the level of automation you need, as well as the cost and maintenance requirements of the machine.

6. How do I maintain my pouch packing machine?

Regular maintenance is essential to ensure the smooth and efficient operation of your pouch packing machine. This includes cleaning and lubricating the machine, inspecting and replacing worn parts, and performing regular calibration and testing.

In conclusion, pouch packing machines offer a fast and efficient way to package a wide range of products. By considering factors such as the type of product you are packaging and the production volume you require, you can choose the right machine for your business and ensure its smooth and efficient operation through regular maintenance.

Pouch Packing Machine Price

Pouch Packing Machine Price: A Comprehensive Guide

Pouch packing machines provide a convenient and efficient way to package items such as food, beverages, and other consumer goods. These machines are widely used in various industries, including food and beverage, pharmaceuticals, cosmetics, and more. If you are planning to invest in a pouch packing machine, it is essential to have an idea of the cost involved. In this article, we will take a closer look at the pouch packing machine price and factors that affect it.

Factors Affecting Pouch Packing Machine Price

1. Machine Type: There are various types of pouch packing machines available in the market, including vertical form-fill-seal (VFFS) machines, horizontal form-fill-seal (HFFS) machines, and pre-made pouch filling machines. The cost of these machines varies depending on their type and features.

2. Production Capacity: The production capacity of a pouch packing machine is another significant factor that affects its price. Machines with higher production capacity tend to be more expensive than those with lower capacity.

3. Automation Level: The level of automation in a pouch packing machine also affects its price. Fully automated machines are more expensive than semi-automated or manual machines.

4. Brand and Quality: The brand and quality of a pouch packing machine also play a crucial role in determining its price. High-end brands that offer superior quality machines tend to be more expensive than other brands.

Pouch Packing Machine Price Range

The price of a pouch packing machine can vary widely depending on the factors mentioned above. However, as a general guideline, here is an overview of the price range for different types of pouch packing machines:

– VFFS Machines: VFFS machines are the most common type of pouch packing machines. The price of these machines ranges from $10,000 to $100,000, depending on their production capacity, automation level, and brand.

– HFFS Machines: HFFS machines are ideal for packaging items such as liquids, powders, and granules. The price of these machines ranges from $20,000 to $150,000, depending on their production capacity, automation level, and brand.

– Pre-made Pouch Filling Machines: Pre-made pouch filling machines are suitable for packaging items such as snacks, pet food, and more. The price of these machines ranges from $30,000 to $200,000, depending on their production capacity, automation level, and brand.

Conclusion

Investing in a pouch packing machine can provide several benefits for your business, including increased efficiency, productivity, and profitability. However, it is essential to have a clear understanding of the pouch packing machine price and factors that affect it before making a purchase. By considering the factors mentioned above, you can choose the right pouch packing machine that meets your production needs and budget.