List Technical Parameters of “steel profile manufacturers”

Steel profile manufacturers are entities that specialize in the production of a wide range of profiles made from steel. These profiles are commonly used in a variety of applications such as construction, automotive, and industrial equipment manufacturing. Steel profile manufacturers must adhere to a strict set of technical parameters to ensure their products are of high quality and suitable for use in various applications. The following are some of the technical parameters that steel profile manufacturers must consider:

1. Material selection: Steel profile manufacturers must select the right type of steel to use in their production process. This includes considering factors such as strength, durability, and corrosion resistance, among others.

2. Manufacturing process: The process of manufacturing steel profiles involves several steps, including casting, rolling, extrusion, and cutting. Steel profile manufacturers must ensure that each step is carried out correctly and accurately to produce high-quality profiles.

3. Profile dimensions: The dimensions of steel profiles must be precise and accurately measured to ensure they fit the intended application. Steel profile manufacturers must adhere to strict tolerances for width, height, and thickness.

4. Surface finish: Steel profiles must have a smooth surface finish to prevent corrosion and improve their appearance. Steel profile manufacturers must use appropriate surface treatment methods such as galvanizing or painting to achieve a suitable finish.

5. Tensile strength: Steel profiles must have a high tensile strength to withstand the stress and pressure of various applications. Steel profile manufacturers must use the appropriate steel grade and manufacturing process to achieve the desired tensile strength.

6. Straightness and flatness: Steel profiles must be straight and flat to ensure proper installation and functioning. Steel profile manufacturers must use appropriate machines and equipment to achieve the required level of straightness and flatness.

In summary, steel profile manufacturers must consider a variety of technical parameters to produce high-quality profiles suitable for various applications. These parameters include material selection, manufacturing process, profile dimensions, surface finish, tensile strength, straightness, and flatness.

List Product features of “steel profile manufacturers”

Steel profile manufacturers are companies that specialize in the fabrication and production of various types of steel profiles. These profiles are structural shapes made of steel, which are utilized in a wide range of applications such as construction, transportation, and manufacturing. Some of the product features that steel profile manufacturers offer are:

1. Customization: Steel profile manufacturers offer customized profiles to meet the specific needs of various applications. This ensures that customers can get tailor-made steel profiles that are suited to their requirements.

2. Strength and durability: Steel profiles manufactured by reputable companies are incredibly strong and durable. They can withstand heavy loads, extreme weather conditions, and other adverse factors, making them ideal for various applications.

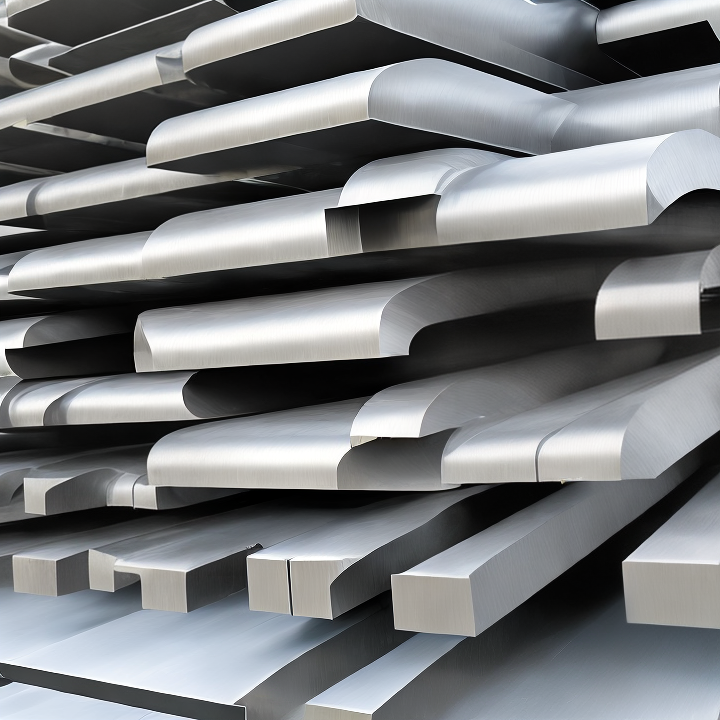

3. Different shapes and sizes: Steel profiles come in different shapes and sizes to cater to various applications. Popular shapes offered by manufacturers include I-beams, H-beams, U-channels, angles, and flats.

4. Corrosion resistance: Steel profiles can be galvanized or coated with other materials to provide corrosion resistance. This makes them suitable for use in environments where exposure to moisture and other corrosive substances is high.

5. High-quality production standards: Steel profile manufacturers use high-quality production standards when producing their products. This ensures that the steel profiles produced meet the required standards for strength, durability, and other essential features.

6. On-time delivery: Reputable steel profile manufacturers offer on-time delivery services to their customers. This ensures that their clients get their products on time, reducing the risk of project delays.

7. Professional customer service: Steel profile manufacturers have a professional customer service team that provides customers with technical support and advice. This ensures that customers get the right products for their applications and that any issues are addressed promptly.

In summary, steel profile manufacturers offer a wide range of product features that ensure that their products are ideal for various applications. Their commitment to customization, strength, durability, different sizes and shapes, corrosion resistance, high-quality production standards, on-time delivery, and professional customer service make them a reliable partner for many industries.

List Application of “steel profile manufacturers”

Steel profile manufacturers are companies that specialize in the production of various types of steel profiles for different industries and applications. Their products can be used in construction, transportation, manufacturing, and other sectors that require strong and durable materials. Here are some applications of steel profile manufacturers.

1. Building and Construction: Steel profiles are widely used in construction, as they are strong, durable, and resistant to fire and corrosion. Manufacturers produce a variety of steel profiles, including beams, channels, angles, and tubes, which are suitable for different types of buildings, such as offices, schools, hospitals, and industrial facilities. Steel profiles are also used in the construction of bridges, tunnels, and other infrastructure projects.

2. Transportation Industry: Steel profiles play an essential role in the transportation industry, as they are used in the production of vehicles, including cars, trucks, boats, and planes. Manufacturers produce steel profiles in different shapes and sizes to meet the specific requirements of different vehicle components, such as frames, chassis, suspensions, and engine mounts.

3. Manufacturing Industry: Steel profiles are used in the manufacturing industry to produce various products, including machinery, equipment, and appliances. Manufacturers produce steel profiles in customized shapes and sizes to meet the specific needs of different manufacturing processes, such as cutting, bending, welding, and stamping.

4. Agriculture and Farming: Steel profiles are widely used in the agriculture and farming industry to produce equipment such as plows, cultivators, and harrows. Manufacturers produce uncompromising quality profiles to resist the heavy-duty conditions of the agriculture and farming sector.

5. Renewable Energy: Steel profiles play a vital role in the renewable energy sector, as they are used in the construction of wind turbines, solar panels, and other renewable energy systems. These profiles are required to have high strength to support the structure of the equipment.

Overall, steel profile manufacturers play a significant role in various industries, providing high-quality steel profiles tailored to the specific needs of the clients and the applications they will serve.

List Various Types of “steel profile manufacturers”

Steel profile manufacturers are companies that make a wide range of steel products for use in various industries such as construction, automotive, and manufacturing. Here are some of the different types of steel profile manufacturers:

1. Structural steel manufacturers: These companies produce structural steel profiles that are commonly used in construction projects for the creation of sturdy and durable frames, beams, trusses, and other load-bearing structures.

2. Bar and wire rod manufacturers: These firms specialize in manufacturing steel bars and wire rods that are utilized in the manufacturing of various industrial products such as screws, nuts, bolts, and other mechanical components.

3. Sheet metal manufacturers: These companies produce steel sheet metals that are widely used in roofing, cladding, and other applications that require a flat or curved surface.

4. Tube and pipe manufacturers: These firms specialize in manufacturing steel pipes and tubes that are used in the transportation of fluids, gases, and other materials in various industries such as oil and gas, automotive, and construction.

5. Rebar manufacturers: These companies produce reinforcing bars or rebar used to reinforce concrete structures such as buildings, bridges, and highways.

6. Stainless steel manufacturers: These firms specialize in manufacturing stainless steel profiles that are used in various industries such as food processing, medical, and high-end construction.

7. Alloy steel manufacturers: These firms produce various types of alloy steel profiles that are used in the manufacturing of specialized components such as aircraft parts, high-stress machinery, and industrial tooling.

8. Special steel manufacturers: These companies manufacture special steel profiles that are used for specific applications such as weather-resistant steel profiles used in marine environments.

Overall, steel profile manufacturers play a critical role in the manufacturing and construction industries and offer a wide range of products to meet the diverse needs of their customers.

List The Evolution history of “steel profile manufacturers”

The history of steel profile manufacturers dates back to the 19th century when iron and steel were first used in industries and construction. However, the production of steel profiles started during the industrial revolution when new manufacturing techniques were developed to produce them on a large scale.

In the early 1900s, steel profile manufacturers began to specialize in producing specific profiles such as I-beams and angles. This was made possible by advances in production techniques that allowed for greater precision in the manufacturing process. The development of electric arc furnaces and continuous casting also made the production process more efficient and economically viable.

During the mid-20th century, steel profile manufacturers began to expand their product offerings and innovate new profiles. This was due to the increasing demand for more specialized profiles in industries such as automotive, aerospace, construction, and infrastructure. The production process was further automated, and quality control measures improved to ensure the manufacture of high-quality profiles.

In recent years, steel profile manufacturers have continued to innovate and develop new profiles to cater to the growing demand for sustainable and energy-efficient buildings and infrastructure. The introduction of computer-aided design and manufacturing (CAD/CAM) has made it easier to design and produce complex steel profiles with greater precision and efficiency.

Furthermore, advancements in digital technologies have made it easier for steel profile manufacturers to communicate with their customers, improve supply chain management, and optimize their production processes to meet customer demands.

Overall, the evolution of steel profile manufacturers has been marked by advancements in manufacturing techniques and technologies, increasing specialization, product innovation, and improving quality control measures. With the growing demand for sustainable and energy-efficient buildings and infrastructure, steel profile manufacturers are well-positioned to continue innovating and meeting the needs of their customers.

List The Process of “steel profile manufacturers”

The process of steel profile manufacturing involves several stages, which include raw material selection, melting and casting, rolling, and finishing.

Raw Material Selection:

Steel profile manufacturers select raw materials like iron ore, recycled steel, and scrap steel. These materials are sorted, cleaned, and melted into liquid form in a furnace.

Melting and Casting:

In this stage, the liquid steel is casted into shapes. Molten steel is poured into a mold and left to solidify. Once the steel has cooled down, it is cut into sections which are suitable for the next stage.

Rolling:

The cut sections of steel are passed through a series of rollers in this stage to reduce the thickness or shape of the steel to meet requirements. This is known as rolling. There are various methods of rolling, including hot rolling, cold rolling, and extrusion. The method chosen is dependent on the type of steel and the required outcome.

Finishing:

This stage is the final stage in Steel Profile Manufacturing. Steel profiles undergo surface treatment, which includes cleaning, rust removal, and coating. The process results in a perfectly finished steel profile that meets the desired specifications.

Overall, the process of steel profile manufacturing involves the selection of raw materials, melting, casting, rolling and finishing to produce high-quality steel profiles with different shapes and sizes. It is a complex and involved process that requires the use of advanced technology and skilled technicians to produce high-quality steel profiles that meet stringent industry standards.

How to use “steel profile manufacturers”

Steel profile manufacturers are companies that specialize in creating steel profiles for a variety of industries and applications. These profiles can be used for everything from structural support to decorative finishes.

To use steel profile manufacturers, you first need to identify the type of profile you need. This could be a standard profile that is readily available or a custom profile that needs to be specially designed and manufactured.

Once you have identified the profile you need, you can reach out to steel profile manufacturers to get a quote on the cost of manufacturing it. You will need to provide them with specifications for the profile, including the size, shape, and any special features or finishes that are required.

Once you have received a quote, you can decide whether or not to move forward with the order. If you decide to proceed, the manufacturer will begin the process of manufacturing the profile according to your specifications.

During the manufacturing process, you may be able to request updates on the progress of your order. Once the profile is complete, it will be shipped to your location for use in your project.

Overall, steel profile manufacturers can be a valuable resource for businesses and individuals who need high-quality steel profiles for a variety of applications. By working with a reputable manufacturer, you can ensure that you get exactly what you need at a price that fits your budget.

List Properties of “steel profile manufacturers”

Steel profile manufacturers are companies that specialize in the production of various steel profiles that are widely used in construction, manufacturing, and other industries. These manufacturers play an essential role in providing high-quality steel products that meet the specific needs of their customers.

One of the properties of steel profile manufacturers is that they have extensive knowledge and expertise about different types of steel profiles. They understand the various mechanical properties of steel alloys and can recommend the best profile to use for different applications. Steel profile manufacturers also have modern manufacturing facilities equipped with state-of-the-art machinery that enables them to produce steel profiles that meet industry standards.

Another essential property of steel profile manufacturers is their ability to customize steel profiles according to customers’ specifications. They can modify the size, shape, and thickness of steel profiles to suit a particular project’s unique requirements. This customization ensures that clients get steel profiles that are fit for purpose, enhancing their performance and durability.

Steel profile manufacturers also source high-quality raw materials from reputable suppliers. These raw materials undergo rigorous testing and quality control to ensure their suitability for the production of steel profiles. By using high-quality materials, steel profile manufacturers produce profiles that are resistant to corrosion, staining, and rusting, making them ideal for use in harsh environments.

Steel profile manufacturers also have a comprehensive quality control process to ensure that their products meet the required standards. They carry out various tests on the profiles, including dimensional checks, visual inspections, and mechanical tests, to verify the profiles’ quality and performance.

Lastly, steel profile manufacturers are environmentally responsible and are committed to minimizing their carbon footprint. They use efficient and sustainable manufacturing processes that reduce waste, energy consumption, and greenhouse gas emissions. By doing so, they ensure that their operations are sustainable and contribute positively to protecting the environment.

In conclusion, steel profile manufacturers are vital to the construction and manufacturing industries. They provide high-quality customized steel profiles that meet the specific needs of their customers while ensuring sustainable and environmentally responsible manufacturing processes.

List “steel profile manufacturers” FAQ

1. What are steel profiles?

Steel profiles are made by rolling or extrusion of steel and are commonly used as structural components in construction and engineering applications. They come in different shapes and sizes, such as beams, channels, angles, and tubes.

2. What materials are used to make steel profiles?

Most steel profiles are made from carbon steel, which is an alloy of iron and carbon. However, other types of steel, such as stainless steel and high-strength low-alloy (HSLA) steel, can also be used.

3. What industries use steel profiles?

Steel profiles are used in a wide range of industries, including construction, engineering, automotive, shipbuilding, and aerospace.

4. What is the process of manufacturing steel profiles?

The manufacturing of steel profiles involves a combination of rolling, hot extrusion, and cold drawing processes. The raw material is first heated to a high temperature and then passed through rollers or dies to give it the desired shape. The profiles are then cooled and cut to the desired length.

5. What are the benefits of using steel profiles?

Steel profiles are strong, durable, and have a high weight-to-strength ratio, making them ideal for use in structural applications. They are also fire-resistant, recyclable, and cost-effective.

6. What standards do steel profile manufacturers follow?

Steel profile manufacturers must comply with industry standards and regulations, such as ASTM (American Society for Testing and Materials), EN (European Standards), and JIS (Japanese Industrial Standards).

7. Can customized steel profiles be made?

Yes, steel profile manufacturers can produce customized profiles according to the customer’s specific requirements. This includes the shape, size, and material.

8. How do I choose the right steel profile manufacturer?

When choosing a steel profile manufacturer, factors to consider include their experience, reputation, quality of products, and customer service. It is also important to check if they have the necessary certifications and standards compliance.