List Technical Parameters of “carbon steel coil manufacturers”

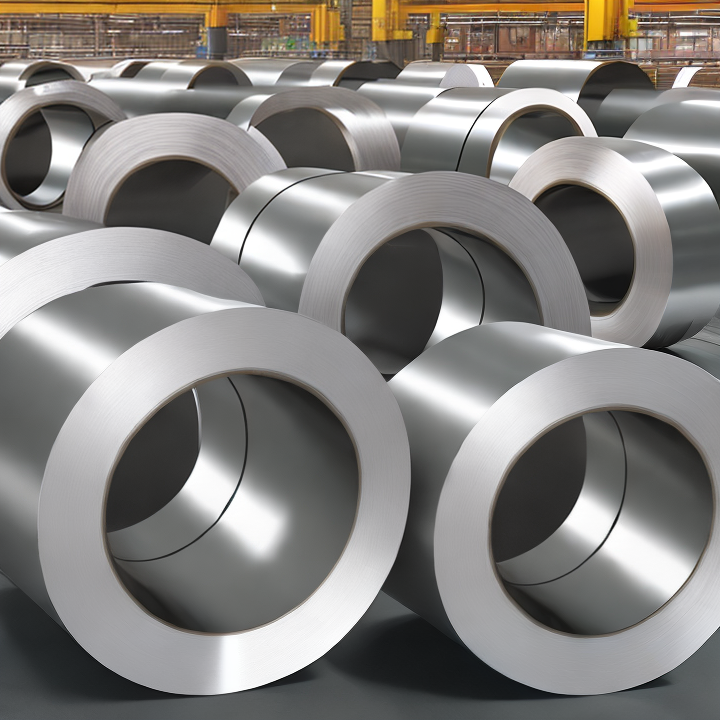

Carbon steel coil manufacturers produce metal coils from low to high carbon content steel. These coils are typically used in several industries, including automotive, construction, and aerospace, among others. The technical parameters of carbon steel coils are crucial in creating a high-quality product that meets the specific needs of the customer.

The dimensions of a carbon steel coil are one of the technical parameters that vary depending on the specific manufacturer. The size of the coil is determined by the customer’s needs and is typically measured in diameter, thickness, and width. Carbon steel coils can range from a few inches to several feet in diameter, with thickness ranging from very thin gauges up to 3/8 inch, while width also varies according to customer requirements, with typical widths ranging from 48 to 72 inches.

The chemical composition and mechanical properties of carbon steel coils also play a significant role in determining their suitability for specific applications. The composition of steel coils usually varies from 0.05% to 2% carbon by weight, with manganese, silicon, and sulfur present in smaller quantities.

Carbon steel coil manufacturers use various techniques such as heat treatment, cold rolling, and pickling to produce a high-quality product. Different grades of carbon steel coils are also available, ranging from low carbon steel to ultra-high carbon steel. The technical parameters of each grade vary, offering customers options for their specific needs.

Finally, carbon steel coil manufacturers also consider the finish of the product when producing coils. The most common coating for carbon steel coils is hot-dip galvanizing for corrosion protection, while other finishes include powder coating, painting, and natural or unpainted finishes.

In conclusion, the technical parameters of carbon steel coils vary widely according to customer requirements and specific manufacturing processes. Manufacturers work with customers to provide the best possible product for the intended application, taking into account the size, chemical composition, mechanical properties, and finish of the coils.

List Product features of “carbon steel coil manufacturers”

Carbon steel coil is a widely used industrial product that has an abundance of features and applications. Some of the most important product features of carbon steel coil manufacturers are:

1. High strength and toughness: Carbon steel coils are known for their high strength and toughness. These coils can withstand high pressure, heavy loads, and extreme temperatures, making them ideal for industrial applications.

2. Corrosion resistance: Carbon steel coils are typically coated with a protective layer to prevent corrosion and rust. This makes them resistant to the damaging effects of moisture and environmental elements.

3. Wide variety of grades and thicknesses: Carbon steel coils are available in a wide variety of grades and thicknesses, making them suitable for a vast range of applications, including metal fabrication, construction, automotive, and aerospace industries.

4. Durability and long life: Carbon steel coils are highly durable and offer a long service life, making them a cost-effective solution for many industries.

5. Customizability: Carbon steel coils can be customized to meet specific requirements in terms of size, shape, and quality. This makes them ideal for specialized applications.

6. High-quality finish: Carbon steel coils can be finished with a high-quality surface finish to provide an attractive appearance and improve performance.

7. Low maintenance: Carbon steel coils require very little maintenance, making them a cost-effective and efficient solution.

8. Low carbon content: Carbon steel coils typically have a low carbon content, making them a more environmentally-friendly alternative to other materials.

In summary, carbon steel coil manufacturers offer a product that boasts many valuable features, including strength, durability, corrosion resistance, customizability, and low maintenance. These features make carbon steel coils a versatile and essential component for a wide variety of industrial applications.

List Application of “carbon steel coil manufacturers”

Carbon steel coils are widely used in a variety of industries due to their high strength, durability, and corrosion resistance. Below are some applications of carbon steel coil manufacturers:

1. Automotive Industry: Carbon steel coils are used in the automotive industry to make various automobile components such as springs, brackets, axles, and frames due to their high strength and resistance to corrosion.

2. Construction Industry: Carbon steel coils are used in the construction industry to manufacture structural parts such as beams, columns, and reinforcement bars, as well as roofing and wall materials.

3. Energy Industry: Carbon steel coils are used in the energy industry to make pipes, tubing, and other components for oil and gas exploration, transmission, and storage. They are also used in the production of wind turbines and other renewable energy technologies.

4. Industrial Manufacturing: Carbon steel coils are used in a variety of industrial manufacturing processes due to their high strength and durability, such as making machinery, agricultural equipment, and transportation equipment.

5. Electrical Industry: Carbon steel coils are used in the electrical industry to make transformers, generators, and other electrical components due to their excellent magnetic properties.

6. Food Industry: Carbon steel coils are used in the food industry to manufacture equipment such as ovens and fryers due to their strength and heat resistance.

In conclusion, carbon steel coils manufacturers play a crucial role in providing raw materials to various industries, including automotive, construction, energy, industrial manufacturing, electrical, and food. Their products are essential for the production of various components used in these industries, and their high strength and durability make them highly sought after.

List Various Types of “carbon steel coil manufacturers”

Carbon steel coil manufacturers are companies that specialize in the creation of coils made from carbon steel. Carbon steel is a type of steel that contains carbon as the main alloying element. It is a strong and durable material often used in various industrial applications, including the manufacturing of automotive parts, piping, and construction materials. Below are some of the types of carbon steel coil manufacturers:

1. Hot-rolled steel coil manufacturers

Hot-rolled steel coil manufacturers specialize in producing coils made from carbon steel that have undergone a hot-rolling process. In this process, steel is heated to a high temperature and then rolled into sheets or coils.

2. Cold-rolled steel coil manufacturers

Cold-rolled steel coil manufacturers create coils made from carbon steel that have undergone a cold-rolling process. This process involves passing the steel through rollers while it is at room temperature, which results in a smoother and more precise finish.

3. Galvanized steel coil manufacturers

Galvanized steel coil manufacturers use carbon steel that has been coated with a layer of zinc. This process is known as galvanization, and it helps to prevent corrosion and rust.

4. Pre-painted steel coil manufacturers

Pre-painted steel coil manufacturers use carbon steel coils that have been coated with a layer of paint or another protective coating. This type of manufacturing is common in the construction industry as it allows for a range of colors and finishes.

5. Stainless steel coil manufacturers

Stainless steel coil manufacturers produce coils made from a type of carbon steel that contains chromium, which provides additional resistance to corrosion. This type of steel is often used in industries where hygiene is critical, such as the food industry.

In conclusion, carbon steel coil manufacturers produce coils made from carbon steel, which is a strong and durable material used in various industrial applications. Different types of carbon steel coil manufacturers specialize in hot-rolled steel, cold-rolled steel, galvanized steel, pre-painted steel, and stainless steel coils.

List The Evolution history of “carbon steel coil manufacturers”

Carbon steel coil manufacturers have a long history that dates back to the Industrial Revolution in the late 18th century. During this era, iron and steel production advanced rapidly, leading to the mass production of carbon steel coils. Initially, steel production was a labor-intensive process that required a lot of energy and skilled workers. However, with the development of new technologies and machines, such as the Bessemer converter and blast furnace, steel production became more efficient.

In the early 20th century, the United States emerged as a dominant player in the steel industry. This was due to the abundance of natural resources, such as coal and iron ore, as well as the development of large-scale steel mills. In the 1950s and 1960s, manufacturers started using more advanced production methods, including continuous casting and hot rolling technologies. These advancements led to higher quality and more uniform carbon steel coils.

During the 1970s and 1980s, the steel industry faced significant challenges due to increased competition from international manufacturers. This led to the closure of many steel mills, particularly in the United States. However, some manufacturers adapted and invested in new technologies to remain competitive.

In recent years, the demand for carbon steel coils has increased due to the growth of industries such as construction, automotive, and transportation. Today, manufacturers use advanced technologies such as electric arc furnaces, which produce high-quality steel while minimizing environmental impact.

In conclusion, the evolution history of carbon steel coil manufacturers has been marked by continual advancements in technology and production methods. Despite facing challenges such as competition and environmental concerns, manufacturers have adapted to remain competitive and continue to meet the growing demand for their products.

List The Process of “carbon steel coil manufacturers”

The process of manufacturing carbon steel coils begins with melting raw materials in a furnace. The furnace uses coke and iron ore to create a molten mixture of carbon, iron, and other alloys. Once this mixture reaches the desired temperature, it is poured into molds and allowed to cool. The resulting ingots are then reheated in a rolling mill and flattened into large slabs.

The slabs are then passed through a series of rolling mills that reduce their thickness and shape them to the desired dimensions. The temperature of the metal is maintained at a high level to prevent cracking or brittleness during the rolling process. The slabs are then coiled, packaged, and sent to further processing or to customers.

The next step is pickling, where the coils are immersed in a sulfuric acid bath to remove impurities and scale from the surface. After this, the coils are washed with water to neutralize the acid and dried. The coils then undergo inspection and testing to ensure they meet the required standards for quality and performance.

The final step is to apply a coating to the surface of the coils to protect them from corrosion and other environmental factors. This is done using a variety of methods, such as hot-dip galvanizing or coating with a layer of zinc or other materials.

Throughout the entire process, strict quality control measures are implemented to ensure the final product meets the customer’s specifications. Carbon steel coils are used in a variety of applications, including construction, automotive, and manufacturing industries, among others.

How to use “carbon steel coil manufacturers”

Carbon steel is a widely used material in various industries and applications due to its durability, strength, and affordability. Carbon steel coils, in particular, are commonly used in construction, automotive manufacturing, consumer goods, and industrial applications.

To source carbon steel coils, it is important to work with reputable carbon steel coil manufacturers. These manufacturers specialize in producing carbon steel coils in different grades and sizes to meet the needs of different industries and applications.

When selecting a carbon steel coil manufacturer, it is essential to consider the manufacturer’s experience, production capabilities, and product quality. A reliable manufacturer should have a proven track record in producing high-quality carbon steel coils using state-of-the-art equipment and technology.

Another crucial factor to consider when working with carbon steel coil manufacturers is the lead time. The lead time can vary depending on the size, grade, and quantity of the carbon steel coils required. Therefore, it is essential to plan ahead and communicate the lead time expectations with the manufacturer.

Furthermore, working with carbon steel coil manufacturers provides additional benefits such as customization options, technical support, and cost savings. Manufacturers can customize carbon steel coils to specific requirements such as size, strength, and coating. They can also provide technical support on product selection, material properties, and maintenance.

In terms of cost savings, working with carbon steel coil manufacturers can result in reduced costs due to economies of scale, bulk purchasing, and production efficiencies.

In conclusion, sourcing carbon steel coils from reputable manufacturers is crucial for achieving high-quality, dependable products to meet varying industry needs. The importance of communication, lead time, customization, and technical support from manufacturers can result in significant cost savings and ultimately produce a high-quality product.

List Properties of “carbon steel coil manufacturers”

1. High Tensile Strength: Carbon steel coil manufacturers produce coils that possess high tensile strength, making them suitable for use in various applications where strength and durability are crucial.

2. Corrosion Resistant: Carbon steel coils are resistant to corrosion and can withstand harsh conditions. This property contributes to their suitability for use in industries such as automotive, construction, and manufacturing.

3. Versatile: Carbon steel coils are highly versatile and can be used in the manufacture of a wide range of products, including pipes, beams, plates, and bars.

4. Ductile: Carbon steel coils are ductile and can be easily formed into various shapes and sizes, making them ideal for use in the construction of buildings, bridges, and other structures.

5. Cost-Effective: Carbon steel coils are cost-effective compared to other materials such as stainless steel. This makes them an ideal choice for budget-conscious industries.

6. Weldable: Carbon steel coils are easily weldable, making it easy to join them to other components and structures.

7. Excellent Heat Conductivity: Carbon steel coils have excellent heat conductivity, making them suitable for use in heat exchangers, boilers, and other applications that require the efficient transfer of heat.

8. High Carbon Content: Carbon steel coils have a high carbon content, which contributes to their strength and durability.

9. Easy Maintenance: Carbon steel coils are relatively easy to maintain, and their corrosion resistance means that they require minimal care.

In summary, carbon steel coil manufacturers produce coils with a range of properties, including high tensile strength, corrosion resistance, versatility, ductility, cost-effectiveness, weldability, excellent heat conductivity, high carbon content, and easy maintenance. These properties make carbon steel coils ideal for use in a range of industries and applications.

List “carbon steel coil manufacturers” FAQ

Q1. What is a carbon steel coil?

A carbon steel coil is a type of metal coil made from carbon steel, which is a type of steel that contains carbon as its primary alloying element. Carbon steel is known for its high strength, toughness, and low cost.

Q2. What are the applications of carbon steel coils?

Carbon steel coils are used in a wide range of applications, including the manufacturing of automotive parts, pipelines, construction materials, machinery, and appliances.

Q3. What are the benefits of using carbon steel coils?

Carbon steel coils offer a number of benefits, including high strength and durability, resistance to corrosion, and the ability to be easily shaped and formed. Additionally, carbon steel coils are relatively inexpensive, which makes them an attractive option for many industries.

Q4. What are the different grades of carbon steel coils?

There are many different grades of carbon steel coils, each with its own unique properties and characteristics. Some common grades include A36, A572, and A1018.

Q5. What should I consider when selecting a carbon steel coil manufacturer?

When selecting a carbon steel coil manufacturer, it is important to consider factors such as quality, price, delivery time, and customer support. Look for a manufacturer that has a good reputation in the industry and can provide you with the products and services you need to grow your business.

Q6. How can I find a reliable carbon steel coil manufacturer?

To find a reliable carbon steel coil manufacturer, begin by researching companies online and reading customer reviews. You can also ask for recommendations from other businesses in your industry or consult with a knowledgeable supplier for guidance. Once you have a short-list of potential manufacturers, reach out to them directly to discuss your needs and learn more about their products and services.