Benefits of Types Of Coatings

Types of coatings have become an essential part of various industries for their unique benefits. These coatings are used to protect surfaces against extreme temperatures, corrosion, and wear and tear. By applying the right type of coating, you can enhance the durability and performance of your products. Here are some benefits of different types of coatings.

Powder Coating: Why use liquids when you can use powder? Powder coatings are known for their durability and resistance to corrosion, chemicals, and UV rays. They are applied electrostatically and cured in an oven, making them an environmentally friendly option without any solvents.

Electroplating: Electroplating is the process of coating a conductive object with a metal. This process enhances the appearance and provides protection against corrosion and wear. The surface is first cleaned, then dipped into a solution containing metal ions, and finally is electroplated by passing an electric current through it.

Ceramic Coating: Ceramic coatings create a hard, protective layer on a substrate, which protects it from heat, wear, and corrosion. They are used on engine parts, headers, and exhaust systems of automobiles, and the turbines and fuel nozzles of airplanes.

Anodizing: Anodizing is an electrochemical process that creates a protective layer on the surface of metal parts. It is used extensively in the aerospace and automotive industries. The anodizing process converts the surface of the metal into a protective and durable oxide layer, which prevents corrosion and improves adhesion.

Polyurea Coating: Polyurea coatings are known for their fast curing time, water resistance, and chemical resistance. They are ideal for use in waterproofing, containment, and protection of concrete, metal, and other surfaces.

In conclusion, different types of coatings offer various benefits to the user. Using the right type of coating can increase product durability, resistance to corrosion and wear, and improve appearance. By identifying the needs of your product and understanding the benefits of different types of coatings, you can make an informed decision on the best type of coating to use.

Features of Types Of Coatings

Coatings are commonly used in everyday life, from protecting surfaces to enhancing their appearance. There are numerous types of coatings available in the market, each with its unique features and uses. In this article, we will discuss the features of different types of coatings.

Acrylic Coatings: Acrylic coatings are water-based paints that dry quickly and provide a high-gloss finish. They are resistant to UV rays, weather, and chemicals. Acrylic coatings are commonly used in automotive, industrial and marine applications.

Epoxy Coatings: Epoxy coatings are known for their superior durability and resistance to wear and tear. They are commonly used in industrial flooring, garage floors, and metal primers. Epoxy coatings offer excellent adhesion, chemical resistance, and are also waterproof.

Polyurethane Coatings: Polyurethane coatings are known for their durability, high-gloss finish, and excellent resistance to abrasions and chemicals. They are commonly used for protecting wooden floors, furniture, and metal surfaces. They can be applied to interior and exterior surfaces and are resistant to UV rays and weather.

Polyaspartic Coatings: Polyaspartic coatings are known for their fast curing time and excellent resistance to stains and chemicals. They are commonly used in industrial flooring, garage floors, and outdoor surfaces. Polyaspartic coatings can be applied to damp surfaces and are resistant to UV rays and weather.

Ceramic Coatings: Ceramic coatings offer excellent heat resistance, chemical resistance, and durability. They are commonly used in high-temperature applications, such as engine components and kitchen appliances. Ceramic coatings can also be used to protect surfaces from corrosion, abrasion, and wear.

In conclusion, coatings are used to protect and enhance the appearance of surfaces. Each type of coating has its unique features, and choosing the right one for each application is crucial. When selecting a coating, consider the level of protection, durability, and chemical resistance required for the specific application.

Various Types of Types Of Coatings

Coatings are an essential part of many industries. They are used to protect and enhance products, reducing damage from wear and tear, corrosion and other environmental factors. The type of coating used depends on the application and the requirements of the object being coated. In this article, we’ll take a look at the various types of coatings available.

1. Paint

Paint is the most common type of coating used in many industries. It is usually a liquid that is applied to surfaces using brushes or sprays. Paints can be water-based or oil-based and can come in a variety of colors and finishes.

2. Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. It is mostly used for metals and is applied using an electrostatic charge, ensuring an even coating. Once applied, it is placed in an oven to cure.

3. Ceramic Coating

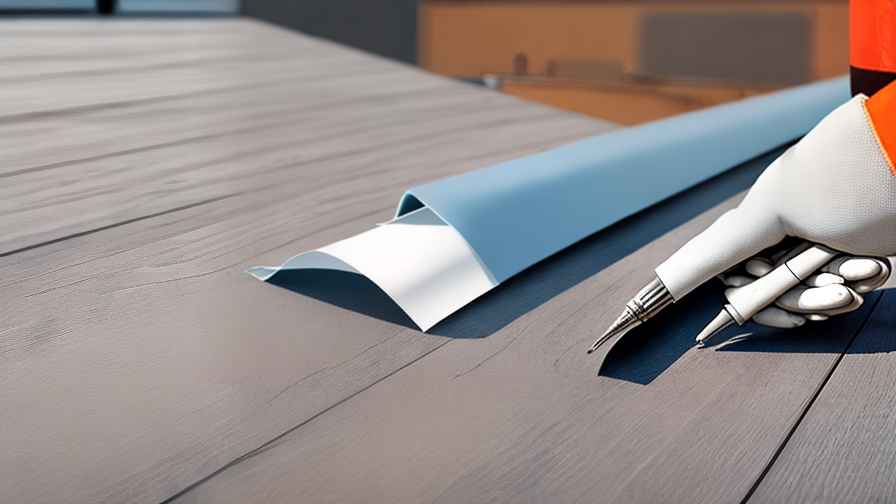

Ceramic coatings are mainly used for the automotive industry. They are a liquid that is applied to the surface of the vehicle and then cured using heat. The ceramic coating provides a high level of protection, making it resistant to scratches, chemicals, and UV rays.

4. Anodizing

Anodizing is an electroplating process that is used to increase the thickness of the natural oxide layer on metals. It provides a protective layer that is resistant to corrosion and wear and tear.

5. Galvanizing

Galvanization is a process used to coat steel or iron products with a layer of zinc. The coating protects the metal from corrosion, and it is often used for applications that are exposed to harsh environments.

In conclusion, there are various types of coatings used in various industries, and the choice of the coating depends on the application and the requirements of the object being coated. Paint, powder coating, ceramic coating, anodizing, and galvanizing are just a few examples of the many types of coatings available.

Applications of Types Of Coatings

Coatings are materials that are applied to surfaces to enhance their performance properties. They can be used for a variety of purposes, including protection, decoration, and functionality. There are many different types of coatings available on the market, including paint, varnish, enamel, and powder coatings. Each type of coating has its unique set of properties and applications.

One of the most common uses of coatings is for corrosion protection. This is especially true for metal surfaces exposed to aggressive environments such as saltwater, harsh chemicals, and extreme temperatures. Corrosion-resistant coatings are used to protect these surfaces from degradation and extend their lifespan.

Another important application of coatings is for decoration. Paints and varnishes can be used to improve the appearance of a surface, making it more aesthetically pleasing. This is especially true for architectural applications, where coatings are used on the exterior and interior surfaces of buildings to enhance their visual appeal.

Coatings can also be used to improve the performance of surfaces. For example, non-stick coatings are used on cookware to prevent food from sticking, making it easier to clean. Anti-static coatings can be applied to electronic components to prevent the buildup of static electricity, which can damage sensitive electronic devices.

In addition, coatings can also be used for functional purposes. Powder coatings are often used for industrial applications where durability is critical. They are highly resistant to abrasion, chemicals, and impact, making them ideal for use in heavy-duty equipment.

Overall, coatings have a wide range of applications, and the type of coating used depends on the specific application. Whether it’s for protection, decoration, or functionality, coatings play a crucial role in improving the performance and lifespan of surfaces.

The Process of Types Of Coatings

Types of coatings are important in protecting surfaces from damage, wear and tear, and corrosion. These coatings provide a barrier layer between the surface and any harmful elements that may be present. Some common types of coatings include powder coating, electroplating, and spray coatings.

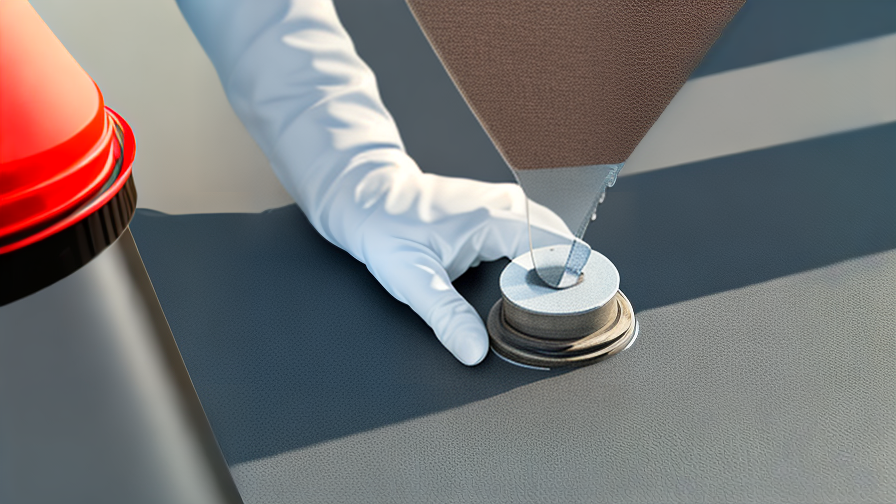

Powder coating involves the deposition of a dry powder onto a surface. This is done by either electrostatically charging the powder or by using compressed air to spray it onto the surface. The powder is then cured by heat to form a hard, durable coating. Powder coating is often used in the automotive industry for body panels, wheels, and other parts.

Electroplating involves the use of an electrical current to deposit a layer of metal onto a surface. This process can be used to add a layer of corrosion-resistant metal to a substrate, or to improve the durability and appearance of a substrate by adding a decorative layer of metal. Electroplating is commonly used in the production of jewelry, automotive parts, and electronics.

Spray coatings involve the use of a spray gun to deposit a liquid coating onto a surface. This process can be used with a wide range of materials, including paint, enamel, and lacquer. Spray coatings can be applied by hand or by using a robotic system, and can be used to create a range of finishes, from matte to high gloss.

In conclusion, the process of types of coatings is an important consideration in protecting surfaces from damage, wear and tear, and corrosion. Whether it be powder coating, electroplating, or spray coatings, a proper understanding of the process involved can lead to better decision making and more effective protection of surfaces.

How to use Types Of Coatings

Coatings are applied to protect surfaces from environmental factors such as moisture, corrosion, and abrasion. There are different types of coatings available, each with its own set of advantages and disadvantages. Here are some of the most common types of coatings and their recommended uses:

1. Powder Coating – Powder coating offers excellent protection against abrasion, impact, and chemicals. It is ideal for use on metal surfaces, such as automobile parts or machinery. The process involves applying the coating in the form of dry powder, which is then heated to create a protective layer.

2. Ceramic Coating – Ceramic coatings are known for their ability to resist high temperatures and harsh environments. They are commonly used on engines, exhaust systems, and other high-heat components. Ceramic coatings also offer protection against corrosion, UV rays, and oxidation.

3. Epoxy Coating – Epoxy coatings are durable and offer high chemical resistance. They are commonly used in industrial applications, such as warehouses, factories, and automotive repair shops. Epoxy coatings can be applied to concrete, metal, and other surfaces.

4. Acrylic Coating – Acrylic coatings offer excellent durability, flexibility, and resistance to weathering. They are ideal for use on exterior surfaces, such as adobe walls or wood siding. Acrylic coatings are also commonly used on metal surfaces to protect against corrosion.

5. Polyurethane Coating – Polyurethane coatings are known for their excellent adhesion, abrasion resistance, and flexibility. They are ideal for use on wood, metal, and concrete surfaces. Polyurethane coatings are also commonly used as a topcoat over epoxy coatings.

When selecting a coating, it is important to consider the substrate to be coated, exposure to environmental factors, and desired performance characteristics. Applying a coating requires proper surface preparation and application techniques. It is recommended to consult with a professional before selecting and applying any type of coating.

Selecting the Ideal Manufacturer Types Of Coatings

Selecting the ideal manufacturer for coatings can be a daunting task, especially with the numerous types of coatings available in the market. The right manufacturer should be equipped with the right technology and have a proven track record of producing high-quality products that meet customer specifications. Here’s what to consider before selecting a manufacturer for your coatings.

1. Quality

The manufacturer should demonstrate a strong commitment to quality from R&D all the way to the final product. The manufacturer should have quality control processes in place to ensure that the final product meets the required standards.

2. Lead Time

Lead time is the time it takes from the placement of the order to the delivery of the product. The manufacturer should have a short lead time and be able to deliver the product within the agreed upon timeline.

3. Product Range

The manufacturer should have a wide range of coatings that can cater to the specific needs of the customer.

4. Customer Service

The manufacturer should have a responsive customer service team that can respond to customer inquiries and address any issues that may arise.

5. Technical Expertise

The manufacturer should be knowledgeable in their field and be able to provide technical support when required. They should have a team of experts who can provide technical advice on the application of the coating.

6. Cost

The manufacturer should offer competitive prices for their products without compromising on quality.

In conclusion, selecting the ideal manufacturer for coatings requires careful consideration of various factors. Quality, lead time, product range, customer service, technical expertise, and cost should be considered before making a decision. A good manufacturer should be able to provide high-quality products, fast delivery, technical support, and excellent customer service at a competitive price.

list FAQ with answer about Types Of Coatings

Types of coatings are used to protect different surfaces from environmental pollutants, weather conditions, and other factors that may cause damage. Some of the types of coatings available in the market include powder coatings, liquid coatings, and ceramic coatings. Below are some of the frequently asked questions about the different types of coatings.

1. What is powder coating?

Powder coating involves electrostatic spraying of a dry powder onto a surface. The powder is then heated to form a smooth, hard surface. Powder coatings are commonly used to protect metal surfaces from corrosion, and they provide a durable finish.

2. What are liquid coatings?

Liquid coatings, also known as wet coatings, are applied by spraying or brushing onto a surface. They are commonly used for painting walls or cars, and they provide a glossy finish. Liquid coatings are also used to protect metals and other surfaces from corrosion.

3. What is ceramic coating?

Ceramic coating is a type of protective layer that is applied to automotive paint, wheels, and glass. It provides a glossy finish and protects against scratches, minor dings, and UV rays. Ceramic coatings provide a long-lasting protective layer that seals and protects the surface.

4. Can coatings be applied to plastic surfaces?

Yes, coatings can be applied to plastic surfaces. There are different types of coatings for plastics, including UV-cured coatings, powder coatings, and liquid coatings.

5. Are coatings environmentally friendly?

Most coatings are designed to be environmentally friendly. Powder coatings are especially eco-friendly as they do not release harmful solvents or volatile organic compounds (VOCs) into the environment.

In conclusion, types of coatings are essential in protecting various surfaces from damage. Powder coatings, liquid coatings, and ceramic coatings are some of the common types of coatings used. When choosing a coating, it is vital to consider its environmental impact and its effectiveness in protecting the surface.

Things to Consider When Purchasing Types Of Coatings

When considering purchasing a type of coating, it is important not to rush into a decision. Taking time to assess which type of coating is best suited for your needs is crucial in ensuring the longevity and effectiveness of the coating. Here are some things to consider when purchasing different types of coatings.

The intended surface: Coatings are applied to surfaces to protect them from damage, corrosion, and wear. The type of coating used varies depending on the intended surface, whether it is metal, concrete, or wood. Some coatings are designed specifically for certain materials, and may not be suitable for others.

The environment: The environment in which the coating will be used is critical in determining which type of coating is best suited. Factors such as temperature, humidity, and exposure to chemicals can all impact the effectiveness of the coating. It is important to choose a coating that can withstand the environmental conditions to which it will be exposed.

The application method: Different coatings require different application methods. Some coatings require spraying, while others are applied with a brush or roller. The application method also affects the amount of preparation required before application, such as sanding or priming.

The cost: Cost is always a consideration when purchasing any product. Coatings can vary greatly in price, depending on factors such as the brand, type, and size required. While cost may be a deciding factor, it is important to consider the long-term cost-effectiveness of the coating, as a cheaper coating may require more frequent replacement and upkeep.

The intended use: Finally, it is important to consider the intended use of the coated surface. Will it be exposed to heavy foot or vehicle traffic, or harsh chemicals? Will it be used for decorative or practical purposes? The intended use will determine which type of coating is best suited for the job.

In conclusion, when purchasing a type of coating, it is important to carefully consider the intended surface, environment, application method, cost, and intended use. By doing so, you will be better equipped to choose the best coating for your needs, ensuring the longevity and effectiveness of the coating.

Properties of Types Of Coatings

Coatings are essential for protecting and enhancing the surface properties of various materials. There are different types of coatings with unique properties. Here are some properties of the most common types of coatings:

1. Epoxy Coatings: Epoxy coatings are known for their high chemical resistance, adhesion, and protection against moisture. These coatings are used primarily for industrial applications such as flooring, metal coatings, and tank linings.

2. Polyurethane Coatings: Polyurethane coatings offer excellent durability, UV resistance, and weatherability. These coatings are commonly used in decorative coatings, automotive, and electronic applications.

3. Acrylic Coatings: Acrylic coatings are known for their versatility, and they can be used in various applications such as aerospace, marine, and automotive industries. They offer durability, resistance to UV rays, and retain their color for a long time.

4. Fluoropolymer Coatings: Fluoropolymer coatings are known for their non-stick and low friction properties. These coatings offer excellent chemical resistance and are used in various industries such as medical, aerospace, and electronics.

5. Ceramic Coatings: Ceramic coatings offer high-temperature resistance, hardness, and wear resistance. They are commonly used in the aerospace, automotive, and industrial fields.

In conclusion, the properties of coatings vary according to the application and the type of material being coated. Each type of coating has its own unique advantages and disadvantages, but all provide essential protection and enhancement to the surfaces they cover. Selecting the right type of coating can improve the lifespan of the material, reduce maintenance costs, and improve the overall appearance or functionality of the material.

Technical Parameters Terms for Types Of Coatings

Technical Parameters Terms for Types of Coatings

A coating is a material that is applied to a substrate to enhance its appearance and properties or provide protection against various environmental elements. The properties of coatings differ from one type to another, ranging from oil-based coatings, water-based coatings, solvent-based coatings, powder coatings, and solventless coatings. Understanding the technical parameters of different types of coatings is highly essential in selecting the best coating for your specific needs.

Here are some technical parameters for the different types of coatings:

1. Adhesion- This denotes the degree of attachment between the coating and the substrate. A good coating should stick firmly to the substrate surface for optimal performance.

2. Durability- This parameter determines the coating’s ability to withstand damage or wear and tear from various environmental factors. Durable coatings last longer and offer more protection.

3. Chemical Resistance- This indicates the coating’s ability to resist damage from acid, alkali, and other chemical agents. It is highly significant in selecting the coating for industrial uses.

4. Temperature Range- This establishes the range of temperature that the coating endures without peeling, chipping, or other deteriorations.

5. Flexibility and Elongation- This technical parameter describes the coating’s strength to withstand any deformation caused by contraction, expansion, or thermal shock.

6. Curing Time- The time taken for the coating to dry & cure impacts the efficiency of the coating process.

7. Thixotropy- This characterizes the coating’s ability to remain stable despite any external factors and get transformed into a more fluid state if stirred or agitated.

8. Solids Content- This refers to the percentage of solids in a coating composition once the solvent evaporates.

In conclusion, selecting the right type of coating for your specific needs is essential. Understanding the above parameters and conducting thorough research about the properties of different coatings is imperative to make an informed decision. It is always advisable to hire a professional coating service provider to select the perfect coating for your intended purpose.

Types Of Coatings Price

When it comes to creating a long-lasting and durable surface finish, coatings are a must-have. They come in various types and materials that provide different functions in protecting an object’s surface from damage or wear and tear.

There are many types of coatings available in the market, and the prices for each of them vary accordingly. Here are some of the types of coatings and their corresponding prices:

1. Powder Coatings: Powder coating involves applying dry powder to a surface that is then heated to a specific temperature. This type of coating is known for its resistance to chipping, rusting, and fading. The cost of powder coatings ranges from $2 to $5 per square foot.

2. Epoxy Coatings: Epoxy coatings are widely used in industrial and commercial applications due to their durability and resistance to chemicals, abrasion, and heat. The average cost of epoxy coating is $3 to $12 per square foot.

3. Ceramic Coatings: Ceramic coatings are known for their resistance to high temperatures and their ability to reducing heat transfer. They are commonly used in automotive and aerospace industries. The cost of ceramic coatings ranges from $8 to $12 per square foot.

4. Polyurethane Coatings: Polyurethane coatings are used in many applications due to their ability to withstand harsh environments, weathering, and abrasion. The average cost of polyurethane coating is $2 to $8 per square foot.

5. Acrylic Coatings: Acrylic coatings are known for their versatility and the ability to offer a waterproof finish. They are commonly used in roofing, masonry, and wood surfaces. The cost of acrylic coatings ranges from $0.50 to $3 per square foot.

In conclusion, the price of coatings depends on the type of coating and its intended use. Before choosing a coating, it is essential to consider factors such as durability, application method, and cost to ensure that you get value for your money.