Types and Applications of chrome steel ball

There are various types of chrome steel balls and they have been used extensively in several applications across different industries. Some of the types of chrome steel balls include;

1. Martensitic Chrome Steel Balls: These are the most common type of chrome steel balls and are made using a combination of chromium and carbon. They are used in grinding, cycling, and industrial applications.

2. Austenitic Chrome Steel Balls: These are similar to martensitic chrome steel balls but have different chemical compositions. They are used in the manufacturing of bearings, pumps, and valves.

3. Duplex Chrome Steel Balls: These balls are made using a combination of austenitic and martensitic chrome steel. They are used in high load applications such as pumps, compressors, and turbines.

The applications of chrome steel balls are broad and include products like bearings, valves, pumps, and grinding media. Chrome steel balls are also used in the automotive industry and in aerospace applications. They are suitable for corrosion-resistant applications and for high-temperature applications.

The automotive industry uses chrome steel balls extensively for engine parts, drive shafts, and transmission systems. In the aerospace industry, chrome steel balls are used for high-temperature applications and for manufacturing turbine blades.

Chrome steel balls are also used in the manufacturing of bicycles, motorcycles, and gym equipment. They are used as bearings in the wheels and pedals of bicycles, in the bearings of motorcycle engines, and in the rollers of gym equipment.

In conclusion, chrome steel balls come in different types and sizes, each suitable for specific applications. Their applications cut across various industries from automotive to aerospace, and they are widely used for their corrosion-resistant and high-temperature properties.

Benefits and Feature of Utilizing chrome steel ball

Stainless steel balls are used in a variety of applications such as bearings, valves, and various types of machinery. Below are the benefits and features of utilizing stainless steel balls.

1. Corrosion Resistance: Stainless steel balls are highly resistant to corrosion and rust. This makes them ideal for use in harsh environments, where exposure to moisture, chemicals, and other corrosive substances could damage other types of balls.

2. Strength and Durability: Stainless steel balls are known for their strength and durability, making them an excellent choice for applications where high wear resistance and long service life are required.

3. Low Maintenance: Stainless steel balls require little maintenance, as they do not need to be lubricated or replaced frequently. This makes them an economical choice for businesses that want to reduce maintenance costs.

4. Precision: Stainless steel balls are known for their precision and accuracy. They are manufactured to stringent specifications and can be used in applications where precise movements and positioning are required.

5. Cleanliness: Stainless steel balls are easy to clean and sterilize, making them an ideal choice for applications in the medical and pharmaceutical industries.

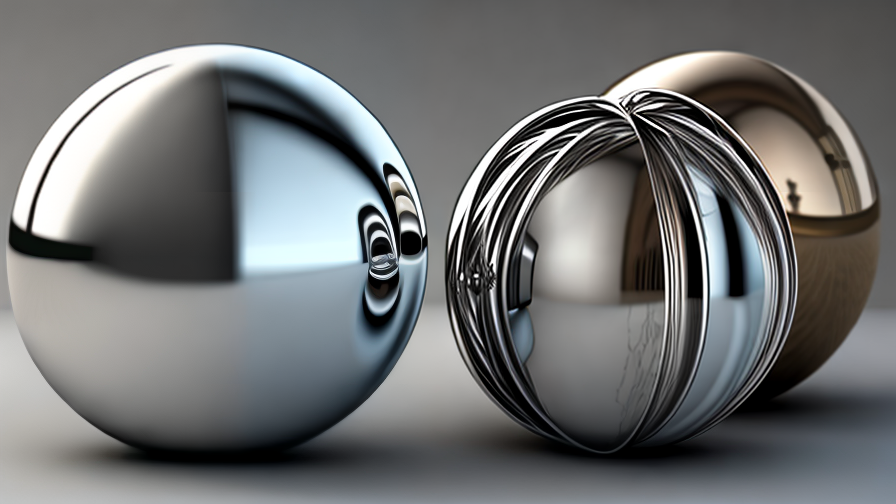

6. Aesthetic Appeal: Stainless steel balls have a sleek, modern look that can enhance the aesthetic appeal of machinery and equipment.

7. Versatility: Stainless steel balls can be used in a wide range of applications, including industrial, automotive, medical, and aerospace.

Overall, utilizing stainless steel balls provides numerous benefits and features that enhance the functionality, performance, and longevity of machinery and equipment.

The Process of chrome steel ball

Chrome steel balls are made from a high-grade steel alloy that contains chromium. The process of making chrome steel balls starts with the melting of raw materials including high-grade steel, chromium, and carbon in a furnace at high temperatures. The molten metal is then poured into a mold of the desired size and shape.

Once the mold is cooled, the ball is removed and subjected to a series of processes that include cleaning, heat treatment, and polishing. The ball is then ground to the appropriate size and shape, using a precision grinding machine. The grinding process ensures that the ball is perfectly round, smooth, and free of any surface imperfections.

After the grinding process, the ball is subjected to a polishing process that gives it a mirror-like finish. The polishing process involves the use of a polishing wheel and a polishing compound that is made from a mixture of abrasive particles and a lubricant.

Finally, the ball is inspected for any defects and coated with a protective layer to prevent rust and corrosion. The protective coating is usually made from a layer of chrome, which gives the ball its distinctive shiny appearance.

Chrome steel balls are widely used in a variety of applications, including ball bearings, valves, pumps, and bicycles. They are known for their high durability, resistance to corrosion, and low friction, making them ideal for applications that require high precision and reliability.

How to use chrome steel ball

Chrome steel balls are widely used in a variety of industrial applications, including bearings, valves, and precision machinery. They offer high hardness, wear resistance, and corrosion resistance, making them ideal for use in harsh environments. Here are some tips on how to use chrome steel balls effectively.

1. Choose the right size: The size of the chrome steel ball you choose will depend on your application. Be sure to select a size that will fit your needs and provide the desired level of performance.

2. Handle with care: Chrome steel balls are brittle and can chip or crack if dropped or mishandled. Use caution when handling them to avoid damage.

3. Keep them clean: Dirt and debris can cause premature wear and damage to chrome steel balls. Clean them regularly to ensure optimal performance and longevity.

4. Lubricate as needed: Depending on the application, you may need to lubricate your chrome steel balls to reduce friction and prevent damage. Be sure to use the proper lubricant for your specific application.

5. Store properly: When not in use, store your chrome steel balls in a dry, clean place to prevent corrosion and damage.

In conclusion, chrome steel balls are a versatile tool that can be used in a variety of applications. By following these tips, you can ensure optimal performance and longevity.

chrome steel ball Manufacturer,Supplier and Wholesale

Chrome steel balls are a type of bearing ball that are widely used in various applications such as aerospace, automotive, industrial, and many others. These balls are made from chrome steel material that contains chromium and carbon, which gives them high levels of toughness and durability.

As a leading manufacturer, supplier, and wholesaler of chrome steel balls, we provide our customers with top-quality products that meet international standards. Our chrome steel balls are manufactured using advanced techniques and precision tools, ensuring consistent and accurate dimensions, smooth surface finish, and high hardness levels.

Our chrome steel balls are available in various sizes ranging from 0.5mm to 50mm, and we can also customize them according to our customers’ specific requirements. We can provide a wide range of chrome steel balls, including stainless steel balls, soft carbon steel balls, and high carbon steel balls.

We supply chrome steel balls to customers worldwide, and we are committed to providing them with reliable and cost-effective solutions. As a trusted supplier, we focus on providing our customers with exceptional services, and we can handle large volume orders with short lead times.

Whether you are looking for chrome steel balls for your industrial or commercial needs, you can rely on us to provide you with the best quality products at competitive prices. Our goal is to become the preferred chrome steel ball supplier for our customers by providing them with high-quality products and exceptional services.

chrome steel ball Price

Chrome steel ball is a type of hardened steel ball that is made of chrome alloy. This type of steel ball is widely used in various industrial applications such as bearings, automotive parts, valves, and other precision machinery. There are several factors that determine the price of chrome steel balls, including the size, grade, and quantity.

The size of the chrome steel ball is one of the most important factors that determine its price. The larger the size of the ball, the more expensive it is. For instance, a small 1/8 inch chrome steel ball might cost only a few cents, while a larger 1-inch ball could cost several dollars.

Grade is another factor that affects the price of chrome steel ball. Chrome steel balls are graded based on their hardness, corrosion resistance, and other physical properties. The higher the grade, the more expensive the ball will be. For example, Grade 25 chrome steel ball is a common and relatively inexpensive ball grade, while Grade 100 provides a higher level of precision and durability.

The quantity of chrome steel balls also affects its price. The more balls you order, the cheaper they become per unit. This is because the manufacturing process for chrome steel balls is relatively expensive, and manufacturers can offer discounts for bulk orders.

In summary, the price of chrome steel ball depends on several factors, including size, grade, and quantity. It is essential to consider these factors carefully before making a purchase to ensure that you get the best value for your money.

FAQ sourcing chrome steel ball manufacturer from China with multiple answers

1. What is chrome steel ball?

Chrome steel ball is a type of bearing ball made of high chromium alloy steel with a small amount of carbon content. It has excellent hardness, corrosion resistance, and wear resistance properties, making it ideal for use in a variety of applications.

2. What are the applications of chrome steel balls?

Chrome steel balls are used in a variety of applications, including precision bearings, valves, pumps, automotive components, and other machinery. They are also used in the aerospace industry, railroad equipment, and medical devices.

3. What are the advantages of buying chrome steel balls from China?

China is one of the leading manufacturers of chrome steel balls and offers a wide range of products at competitive prices. Chinese manufacturers use advanced technology and equipment to ensure the quality and consistency of their chrome steel balls.

4. What should I consider when choosing a chrome steel ball manufacturer in China?

When choosing a chrome steel ball manufacturer in China, consider factors such as the quality of their products, their manufacturing capabilities, their pricing, and their delivery times. It is also important to verify their certifications and their ability to meet your specific requirements.

5. How can I find a reliable chrome steel ball manufacturer in China?

To find a reliable chrome steel ball manufacturer in China, research the company’s reputation, read reviews from past customers, and request samples or references. You can also work with a trusted sourcing agent or partner who can assist in finding a reputable manufacturer and help in navigating the process of importing from China.