Benefits of Juice Packing Machine

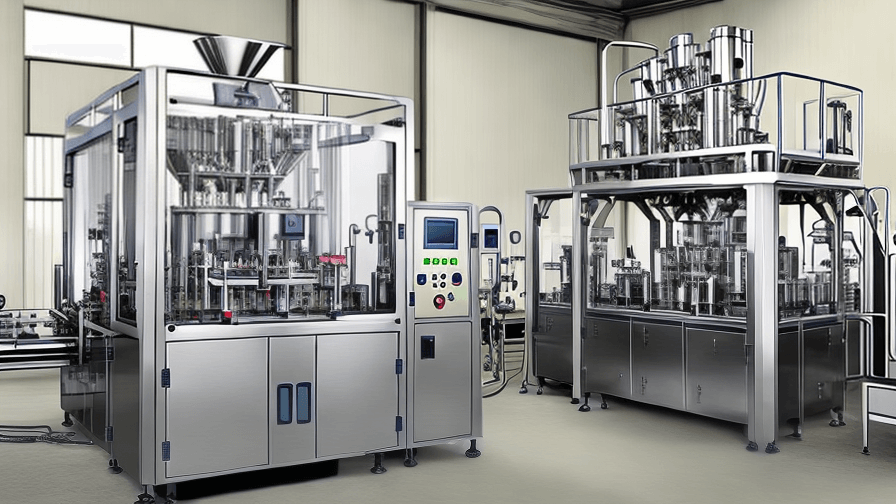

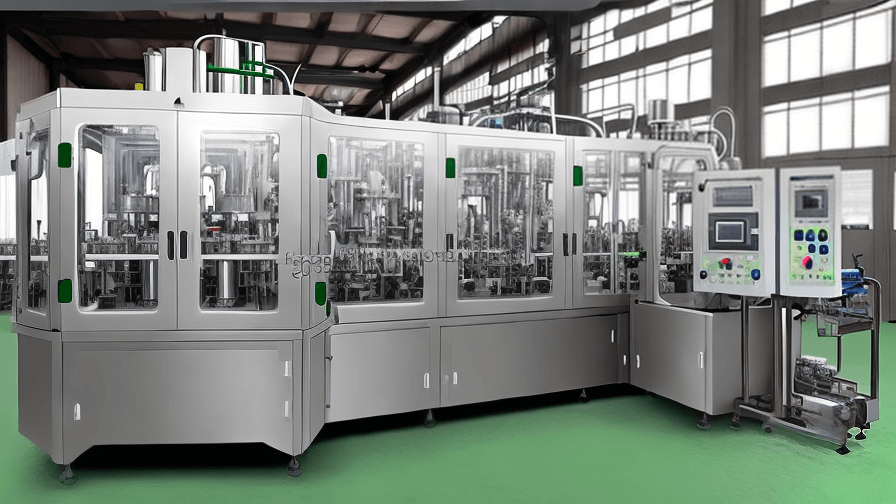

Juice packaging machines are a game-changer in the juice-making industry. They allow for an efficient, fast, and smooth process of packing juices. These machines have revolutionized the industry by providing a range of benefits that have made juice production easier and more profitable for juice producers.

One of the most significant benefits of juice packaging machines is their efficiency. These machines are designed to handle a large volume of juices in a short amount of time, saving time and increasing productivity. This is particularly beneficial for juice production companies that need to keep up with demand and remain competitive.

Juice packaging machines also help ensure hygiene standards are maintained. The machines are designed with parts that are easy to clean and disinfect, which ensures that the juice remains free from contaminants, ensuring the quality of the juice.

Another key benefit of juice packaging machines is their versatility. They can be used to package different types of juices and can be customized according to the specific needs of the juice producer. They can also be used to package different sizes of bottles and pouches, giving the juice producer the flexibility to cater to the needs of different markets.

Juice packaging machines have also helped juice producers reduce costs. These machines require minimal manpower to operate, and they are highly efficient, which reduces wastage, leading to cost savings. They also help reduce the amount of space needed for production, leading to cost savings on rent and utility costs.

Finally, juice packaging machines help juice producers meet their customer demands by providing them with high-quality, hygienic, and efficiently packaged juices. Customers are increasingly looking for packaged juices as a convenience, and juice packaging machines help juice producers meet this demand profitably.

In conclusion, juice packaging machines have become an essential tool for juice producers, providing numerous benefits such as efficiency, hygiene, versatility, cost savings, and meeting customer demands. As the juice industry continues to grow, the need for such machines will only increase, and juice producers who embrace these technologies will undoubtedly gain a competitive advantage in the market.

Features of Juice Packing Machine

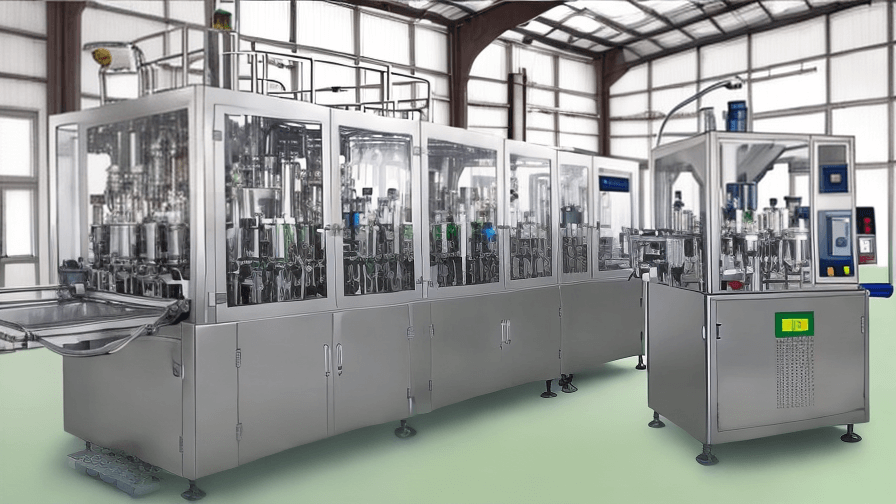

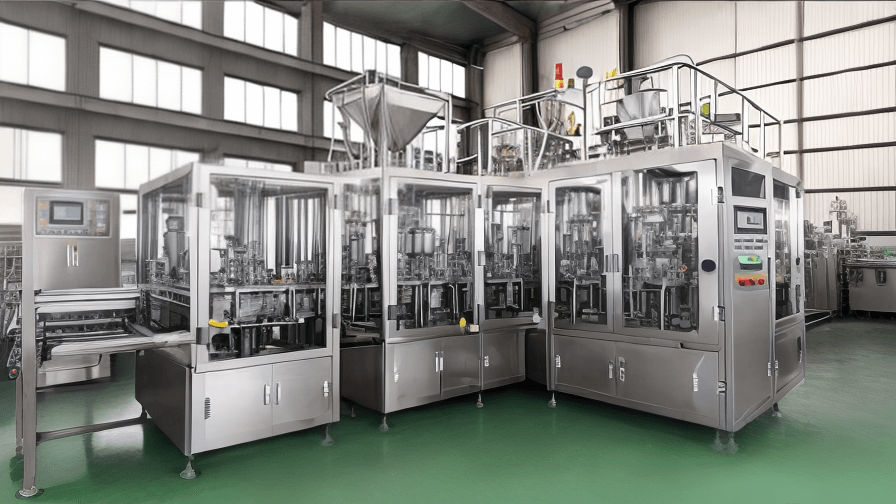

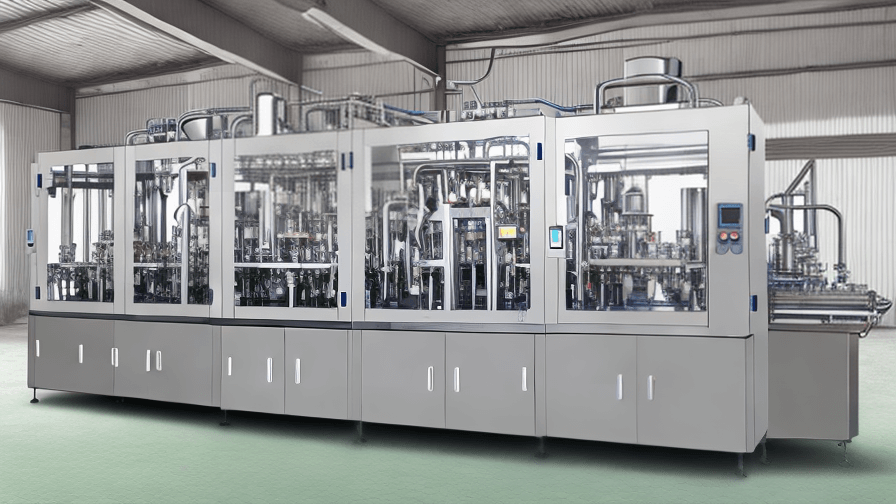

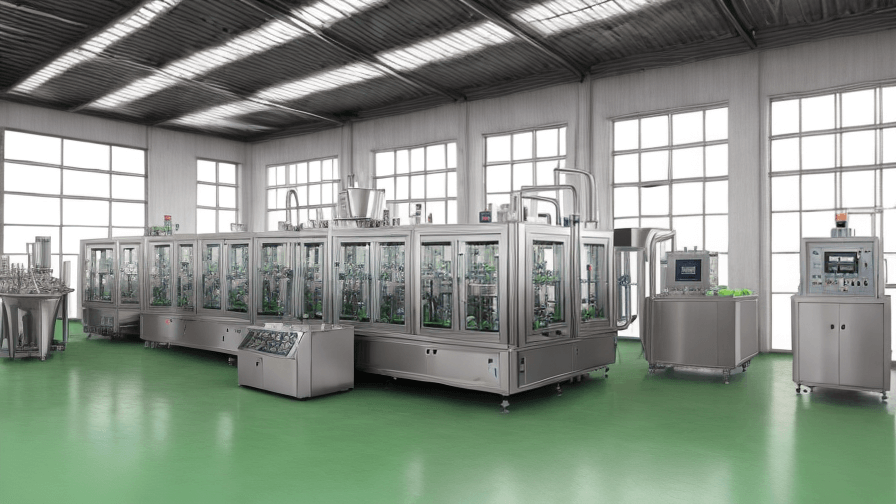

A juice packing machine is an essential equipment for companies and businesses that are into juice production. Juice packing machines are designed to package juices automatically, quickly and efficiently. These machines come with features that make the juice packaging process more efficient, effective, and convenient for juice entrepreneurs.

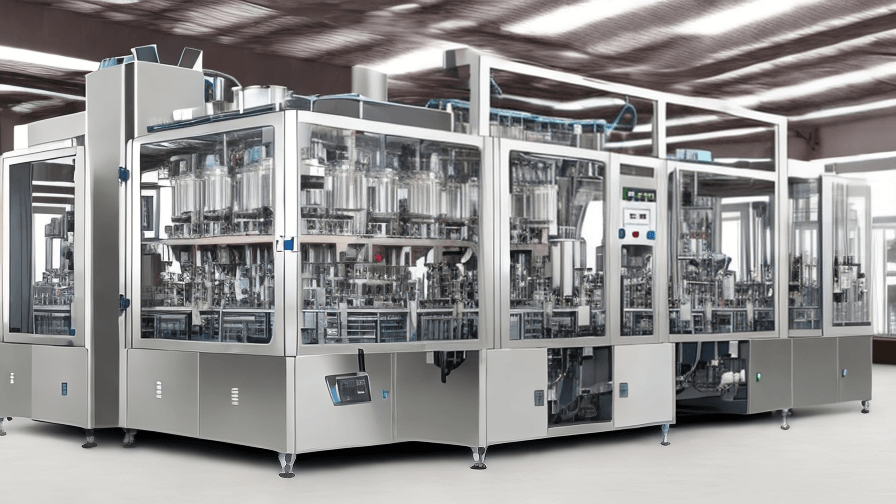

One of the features of a juice packing machine is precision. This machine is designed to measure and fill each bottle or container with precise amounts of juice, making sure that each packaging unit contains the same amount of juice. This feature helps to maintain consistency in the quality of juice produced and also ensures that customers get the same amount of juice every time.

Another feature of a juice packing machine is the automatic filling system. This feature enables the machine to fill bottles or containers without any human intervention. Once the juice is poured into the machine, the filling process is swift, thus making the packaging process much quicker and more efficient. The automatic filling system also helps to conserve the juice, making sure there is no waste through spilling.

Juice packing machines are also designed with an effective sealing system. The sealing system ensures that the caps or lids are properly placed and sealed onto the bottles or containers of juice. This helps to preserve the quality and freshness of the juice and ensures that the juice is packaged correctly.

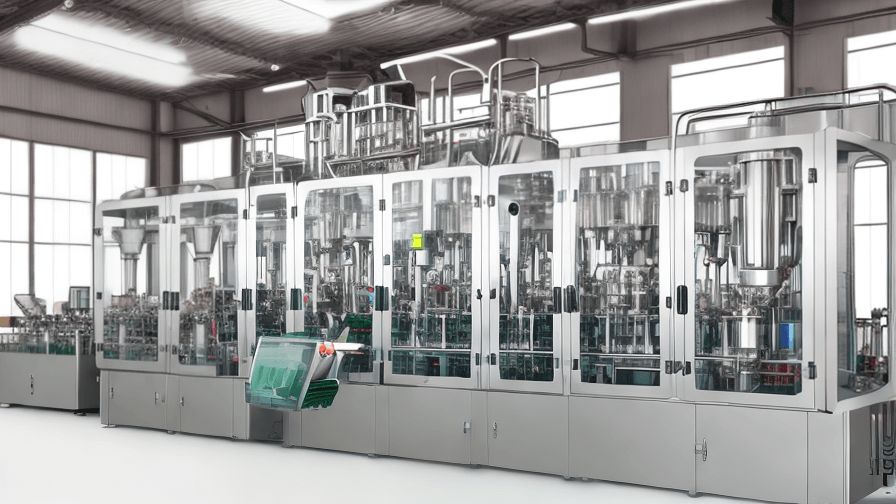

Most juice packing machines are made from high-quality materials like stainless steel and plastics that are easy to clean, durable, and hygienic. This feature ensures that the machine is sanitary, clean, and easy to maintain, reducing the risk of contamination during the production process.

In conclusion, the features of a juice packing machine are essential to ensure efficiency, effectiveness, and convenience in the juice packaging process. The juice packing machine ensures precision in the quantity of juice, an automatic filling system for quicker and more efficient production, effective sealing to preserve the quality and freshness of the juice, and high-quality materials that make it easy to clean and maintain.

Various Types of Juice Packing Machine

Juice packing machines are a vital part of the juice manufacturing industry. These machines are designed to efficiently and effectively package juices into various types of containers. The juice packing machines range from small, compact machines to larger, more industrial-sized machines. Here are some of the various types of juice packing machines available in the market.

1. Filling Machines

Filling machines are used to fill juice into bottles, cartons, and pouches. They are available in different capacities and are used for different types of juice packaging.

2. Bottling Machines

Bottling machines are used for filling and sealing juice into bottles. They can be used for filling bottles of different sizes and shapes.

3. Pouch Packing Machines

Pouch packing machines are used for packaging juice into various types of soft or flexible pouches. They are popular for their durability, flexibility, and ability to run at high speed.

4. Carton Packing Machines

Carton packing machines are used for packaging juice into cartons. They are designed to handle large volumes of juice in a short period.

5. Cup Filling Machines

Cup filling machines are used for filling juice into cups. They are popular for their ability to accurately measure the volume of juice being packed.

6. PET Bottle Filling Machines

PET bottle filling machines are used for filling juice into PET bottles. These machines are efficient, accurate, and easy to use.

7. Can Filling and Sealing Machines

Can filling and sealing machines are designed to fill juice into cans and then seal them. These machines are suitable for large-scale juice manufacturing.

In conclusion, the juice packing machines have played a vital role in the juice manufacturing industry, and they have significantly improved the speed, accuracy, and efficiency of juice packaging. The above-listed machines are some of the most common ones available in the market, and they come in different sizes, shapes, and capacities to suit different manufacturing needs.

Applications of Juice Packing Machine

The juice packing machine has revolutionized the food and beverage industry. It is a highly specialized piece of equipment that efficiently packs juices and other beverages in a variety of containers, including glass and plastic bottles, jars, and cartons.

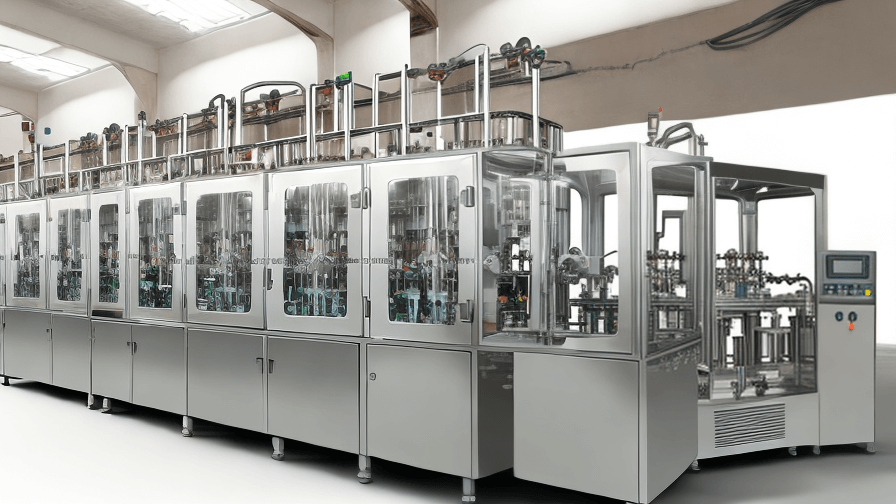

This machine has been widely used across several industries, and it has various applications. One common application is in the production of bottled juices, where the machine provides an efficient and speedy packing solution. The machine can handle high volumes of juice production, filling and sealing bottles at high speeds, which helps companies produce large quantities of juices in shorter periods.

Another application of the juice packing machine is in the dairy industry. It’s widely used to package milk, yogurt, and other dairy products. The machine can handle dairy products with high viscosity, ensuring that they are packed with no spillage or wastage.

The machine supports catering and vending industries too. In these industries, the machine packs soft drinks and other beverages that are quickly consumed, and where hygiene and speed are crucial. The juice packing machine provides an efficient method to send drinks to a serving area, according to customer desires.

Furthermore, the machine has become an essential tool in several food processing industries, where it’s used to pack liquid concentrates. These industries rely on the juice packing machine to fill and seal products such as tomato paste, soluble coffee, fruit purees, and other processed liquid foodstuffs.

In conclusion, the juice packing machine is a highly automated piece of equipment with various applications. It has revolutionized the food and beverage industry, allowing for faster and more efficient packaging of juices, dairy products, and other beverages. Dependent on the type of application, industries benefit from the efficiency of the juice packing machine, increased productivity, cost reduction, and minimized chance of contamination, among others.

The Process of Juice Packing Machine

Juice packing machines are designed for use in the food and beverage industry to package and seal different types of juice products. The process of juice packing machine is a complex and systematic one, involving several stages from filling the juice into the packaging to final sealing. This article describes the typical process of juice packing machines.

Firstly, the juice is prepared and measured to the specific quantity that is required for the package. The juice is usually stored in a large tank, which is then connected to the juice filling machine. Next, the packaging material is fed into the packing machine, where the juice is then filled into the packaging containers. Depending on the type of machine used, the packaging containers may be bottles, pouches, cans or tetra packs.

Once filled, the containers then go through a sealing process to ensure their contents are properly protected from outside elements and to give them a longer shelf-life. This sealing process is usually through a combination of heat and pressure, which securely seals the packaging material and provide a tamper-proof seal. At this stage, the containers are also labeled with appropriate labels to show the product’s name, manufacturing date, expiry date, and other necessary information.

After the sealing process, the containers are then automatically loaded onto a conveyer belt, which moves them towards the next stage of the packing process. Here, the containers are checked for leaks, weight, and any packaging defects before being packed into boxes for easy transportation. The packed boxes are then ready to be shipped to various retail stores, supermarkets, and other outlets where they can be purchased by consumers.

In conclusion, the process of juice packing machine involves preparing the juice, measuring it, filling it, sealing it in the packaging containers, labeling the containers, checking for defects, and packing the containers into boxes. With the help of automated juice packing machines, juice manufacturing companies can meet market demands while minimizing the risk of human error. Ultimately, the juice packing machine helps to reduce the time and effort needed to process and package juice while also ensuring quality and consistency every time.

How to use Juice Packing Machine

Juice packing machines are essential tools for the beverage industry as they provide a speedy and efficient way to pack and ship juices to consumers. If you’re new to juice packing machines, here’s a step-by-step guide on how to use them.

Step 1: Prepare the Machine

Before using the juice packing machine, make sure to clean and sanitize it thoroughly. Then, ensure that the machine is assembled correctly and ready for use. Depending on the model and type of machine, you may need to fill the hopper with juice, attach the packaging material, or adjust the settings.

Step 2: Set the Parameters

Once the machine is set up correctly, set the parameters such as the temperature, fill level, and sealing time. These settings will vary depending on the type of juice, packaging material, and machine specifications, but your manufacturer’s instructions should guide you in these settings.

Step 3: Start the Machine

Starting the machine is as simple as pressing the start button. The machine will automatically fill the packaging material with juice, seal it, and cut the bag to the required size. Most machines include an output conveyor that sends the packaged juices to a collection bin.

Step 4: Monitor the Machine

During operation, make any necessary adjustments as needed and keep a watchful eye on the machine to ensure smooth operation. If an issue arises, stop the machine and check for any mechanical issues or operational errors.

Step 5: Clean the Machine

After the packaging process is complete, it’s crucial to clean and sanitize the machine. This cleaning process helps to ensure the longevity of the juice packing machine and the safety of the packed juices.

In Conclusion

In conclusion, using a juice packing machine is easy, and with the right knowledge and guidance, anyone can operate it. Follow the steps above, and you’ll be packing and shipping juices in no time. Remember that regular maintenance and cleaning are key to the durability and efficient operation of your juice packing machine.

Selecting the Ideal Manufacturer Juice Packing Machine

Choosing the right juice packing machine manufacturer is a decision that can have a significant impact on the success of your juice production line. Here are some key factors to consider when selecting the ideal manufacturer for your juice packing machine.

First, look for a manufacturer that specializes in juice packing machines. They will have the expertise and experience to understand the unique requirements of juice packaging, such as the need for airtight seals and protection against oxidation.

Next, consider the capacity and efficiency of the machine. How much juice can it pack per hour? Does it have the necessary features and functions to meet your production needs? Look for a machine that is easy to operate, maintain and clean to optimize operation time.

Another key factor is the level of customization and flexibility offered by the manufacturer. Can they customize the machine to meet your specific production needs? Do they offer add-ons or upgrades to enable you to adapt the machine to future requirements? Selecting a flexible manufacturer will ensure that you can adapt to changing market trends, customer preferences, and regulatory requirements.

Before making a purchase, also check the reputation and reliability of the manufacturer. Look for reviews and testimonials from current customers. It is preferable to select established manufacturers with proven track records of delivering high-quality machines and excellent customer service.

Lastly, consider the overall cost and ROI of the machine. While it may be tempting to choose the least expensive option, focus on long-term value and how the machine can contribute to your business’s success. Analyze the expected ROI from increased productivity, efficiency, and reduced waste.

Selecting the ideal juice packing machine manufacturer requires careful consideration of various factors. By choosing a specialized and reliable manufacturer that offers a customized, flexible and efficient machine, you can boost your juice production and maximize your business growth.

list FAQ with answer about Juice Packing Machine

Juice Packing Machine, also known as Juice Filling Machine, is an important machine for the juice industry. If you are thinking about buying a juice packing machine or just want to know more about it, this article will answer some frequently asked questions.

1. What is a Juice Packing Machine?

A Juice Packing Machine is a device that fills juice into bottles or containers and seals them for distribution. It is an automated machine that saves time and increases efficiency.

2. What are the different types of Juice Packing Machines?

There are various types of juice packing machines, including automatic, semi-automatic, and manual juice filling machines. Automatic machines are fully automated and can fill and seal bottles without human intervention, while a semi-automatic machine requires the operator to place and remove bottles manually. Manual machines, on the other hand, are operated entirely by hand.

3. What are the materials used for Juice Packing Machines?

Juice packing machines are typically made of stainless steel, which is durable and easy to clean. Some machines may also incorporate food-grade plastic materials for certain parts.

4. What is the capacity of a Juice Packing Machine?

The capacity of a juice packing machine varies depending on the model. Some machines have a production capacity of 20 to 50 bottles per minute, while others can fill over 500 bottles a minute.

5. What is the maintenance schedule for a Juice Packing Machine?

The maintenance schedule for a juice packing machine varies depending on the hours of operation and the manufacturer’s recommendations. However, it is generally recommended that routine maintenance is done every six months.

Juice packing machines are critical for the juice industry. Ensure that the machine is well maintained, and all the necessary precautions are taken to avoid downtime. By knowing these basic questions about a Juice Packing Machine, you’ll be able to choose the right type for your business needs.

Things to Consider When Purchasing Juice Packing Machine

When looking to purchase a juice packing machine, there are several factors to consider. Making a wise decision is essential to ensure that you get the best value for your investment. Here are some things to think about before making a purchase:

1. Capacity: The capacity of the machine is one of the most crucial factors to consider. It determines the amount of juice the machine can handle and the number of bottles it can fill per minute. It is essential to know the amount of juice you need to produce before selecting a machine to purchase.

2. Type of juice: Some machines are specialized in handling specific types of juice like orange, apple, or grape juice. It is therefore essential to choose a machine that is best suited for the type of juice that you will be producing.

3. Automation: Automated machines offer more speed and accuracy in filling and capping bottles. They are more efficient and require less labor compared to manual machines. It is important to determine which type of machine would be best suited for your production line.

4. Quality of the machine: The quality of the machine is crucial in determining its durability and efficiency. It is essential to purchase a machine from a reputable manufacturer who offers quality products and reliable customer support.

5. Cost: The cost of the machine is an important factor to consider. It is important to determine your budget before making a purchase and select a machine that offers the required features and is within your budget.

6. Maintenance: Proper maintenance is crucial to ensuring the longevity of the machine. It is important to consider the ease of maintenance and availability of spare parts before making a purchase.

7. Warranty: A warranty is essential in protecting your investment in case of malfunction or damage to the machine. It is important to choose a machine with a reliable warranty from a reputable manufacturer.

In conclusion, the decision to invest in a juice packing machine requires careful consideration of various factors. By evaluating the capacity, type of juice, automation, quality, cost, maintenance, and warranty of the machine, you can make an informed decision and get the best value for your investment.

Properties of Juice Packing Machine

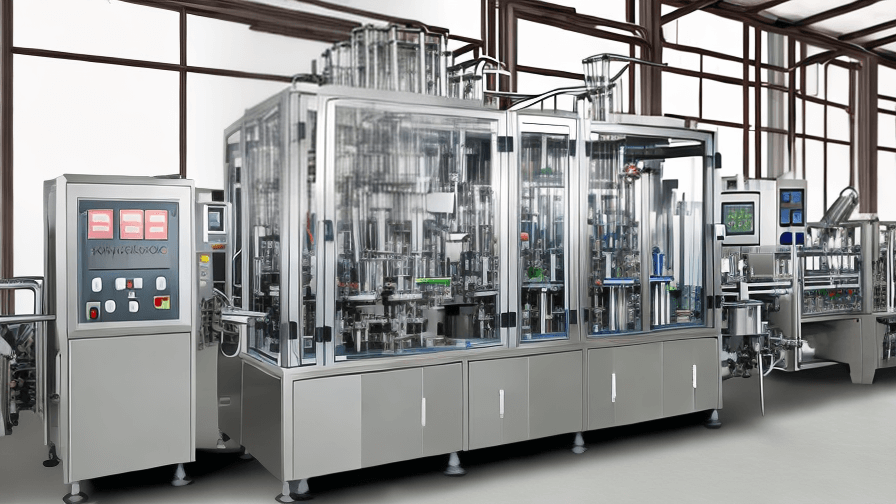

A juice packing machine is a highly specialized piece of equipment that is used to package different types of juices into various containers. It is an important component of the modern food processing industry, especially for juice manufacturing companies. The properties of juice packing machines are as follows:

1. Capacity: The juice packing machine’s capacity refers to the amount of juice that it can package in a given period. This property is dependent on the model of the machine and ranges from a few hundred packages per hour to thousands per hour.

2. Speed: Another important property of juice packing machines is their speed. The machine’s speed determines how quickly they can fill and seal bottles or pouches. High-speed machines can fill and seal hundreds of packages per minute, whereas low-speed machines take longer to complete the same task.

3. Flexibility: A good juice packing machine should be able to handle different types of juices, bottle sizes, and packaging materials. It should also have the ability to adjust to changes in product specifications quickly.

4. Efficiency: Efficiency refers to the machine’s ability to minimize waste and maximize production output. A juice packing machine that runs efficiently can fill juice packages with minimal errors, improving productivity and reducing production costs.

5. Maintenance: A well-designed juice packing machine should be easy to maintain and repair. The machine should have easy-to-replace components, and the manufacturer should offer support and training for repairs and maintenance.

6. Accuracy: The juice packing machine should be able to measure and fill the juice accurately. It should also be able to package the juice uniformly to ensure consistent quality of the final product.

In conclusion, juice packing machines are essential to the food processing industry, and their properties should be considered when choosing a specific model. A juice packing machine with high capacity, speed, flexibility, efficiency, ease of maintenance, and accurate measurements is essential for a successful juice manufacturing business.

Technical Parameters Terms for Juice Packing Machine

Juice packing machines are an essential component in the manufacturing process of juice products. Technical parameters in juice packing machines refer to the specific settings and characteristics that determine how the machine performs. These parameters are crucial to ensure that the machine functions efficiently and effectively to produce high-quality juice products.

One of the most important technical parameters is the filling volume, which refers to the amount of juice that the machine dispenses into each package. The filling volume must be precise to ensure consistent product quality and prevent wastage of both juice and packaging materials. Other technical parameters include filling speed, sealing temperature, and sealing pressure, all of which affect the overall performance of the machine.

Filling speed determines how quickly the juice packaging machine fills the containers, while sealing temperature and pressure influence the quality of the seal on the packaging material. The machine’s sealing strength and rate can determine how tightly the lid is secured and for how long the product remains fresh.

The machine’s power consumption is another crucial technical parameter, as it determines the energy consumption and operating costs of the device. It is essential to consider energy efficiency when selecting a juice packaging machine to minimize costs and reduce the carbon footprint of the manufacturing process.

Finally, the material used in the construction of the juice packing machine is another crucial technical parameter. A high-quality material such as stainless steel ensures durability and long-lasting performance, making it a worthwhile investment.

In conclusion, technical parameters are critical factors to consider when selecting a juice packaging machine. The factors outlined above are merely a few of the key technical parameters that determine the functionality and performance of juice packing machines, but they are essential to produce high-quality juice products efficiently. By examining these technical parameters, manufacturers can select a machine that will provide consistent results, minimize costs, and improve overall product quality.

Juice Packing Machine Price

Juice is one of the most popular beverages in the world due to its numerous health benefits. To meet the increasing demand for juice, manufacturers are investing in high-tech juice packing machines to produce and package juice products in large quantities.

Juice packing machine prices vary depending on the size, features, and level of automation. A small-scale manual juice packing machine can cost around $1000, while a fully automated juice packing machine can cost upwards of $50,000.

When considering a juice packing machine, it is important to choose a machine that best fits the needs of the manufacturer. A machine with a higher level of automation can significantly reduce labor costs and increase production efficiency. Automated machines can handle several tasks simultaneously, such as filling, capping, and labeling, which minimizes the downtime caused by changing machines between each stage.

The size of the juice packing machine must also be considered. Smaller machines are suitable for manufacturers with low production volumes, while larger machines are ideal for high-volume productions. It is also important to choose a machine that can accommodate the type and size of packaging material needed for the juice product.

Other factors that can affect the price of juice packing machines include the brand and durability of the machine. Well-established brands that offer quality machines tend to charge higher prices. A durable machine can last longer, reducing maintenance costs and increasing the machine’s overall value.

In summary, juice packing machine prices vary and depend on the level of automation, size, type of packaging material, brand, and durability. Investing in a suitable machine that can meet the production needs of the manufacturer can increase production efficiency, lower costs, and increase the overall profitability of the business.