Benefits of Perfume Filling Machine

Perfumes are an important part of the cosmetic industry and have been around for centuries. With the growing demand for perfumes, companies are looking for ways to optimize the production process. One of the ways to achieve this is by using perfume filling machines.

The benefits of using a perfume filling machine are abundant. Firstly, these machines are incredibly efficient, and they can fill a large number of perfume bottles in a short amount of time. This means that companies can produce more perfume in less time, which ultimately translates to more profit.

Secondly, perfume filling machines eliminate the need for manual labor, reducing the chances of human error. This helps to maintain the quality of the perfume, ensuring that it meets the desired standards. Additionally, it also reduces the amount of labor required, which means that the company can reduce their workforce and save on labor costs.

Perfume filling machines are also highly accurate. They can measure and dispense the exact amount of perfume needed for each bottle, so there’s no risk of over-filling or under-filling. This translates to a consistent and high-quality product, which is essential for maintaining customer satisfaction.

Another benefit of perfume filling machines is that they are versatile. They can fill different types of bottles, including different sizes and shapes. This means that companies can produce a variety of perfumes in different types of packaging, which can help to cater to different market segments.

Lastly, perfume filling machines are easy to use and maintain. They do not require specialized skills, and the machines can be operated by anyone with minimal training. Additionally, these machines are durable and reliable, which means that they require minimal maintenance.

In conclusion, using a perfume filling machine is a smart investment for any company in the cosmetic industry. These machines offer numerous benefits, including efficiency, accuracy, versatility, and easy maintenance. With these machines, companies can produce high-quality perfumes in large quantities, ultimately leading to increased profits and customer satisfaction.

Features of Perfume Filling Machine

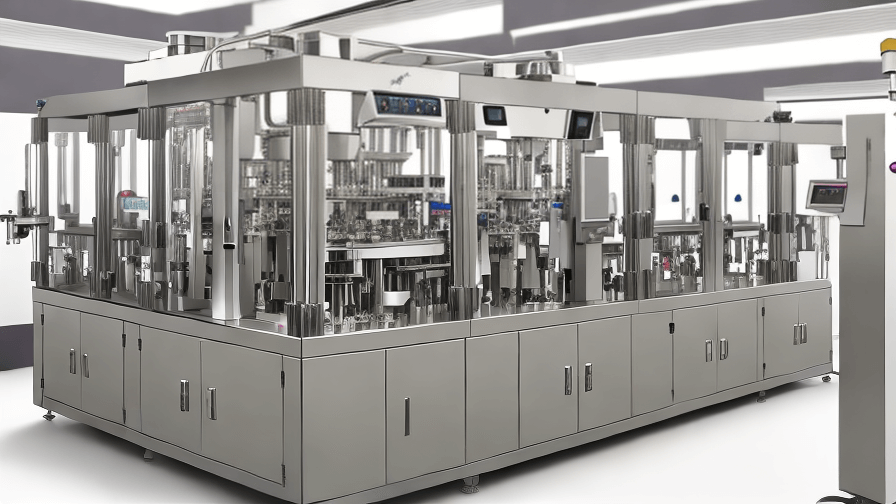

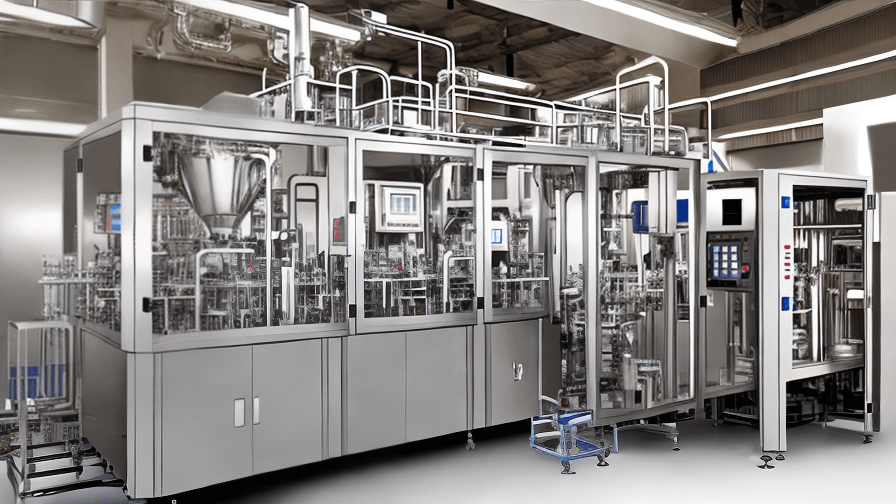

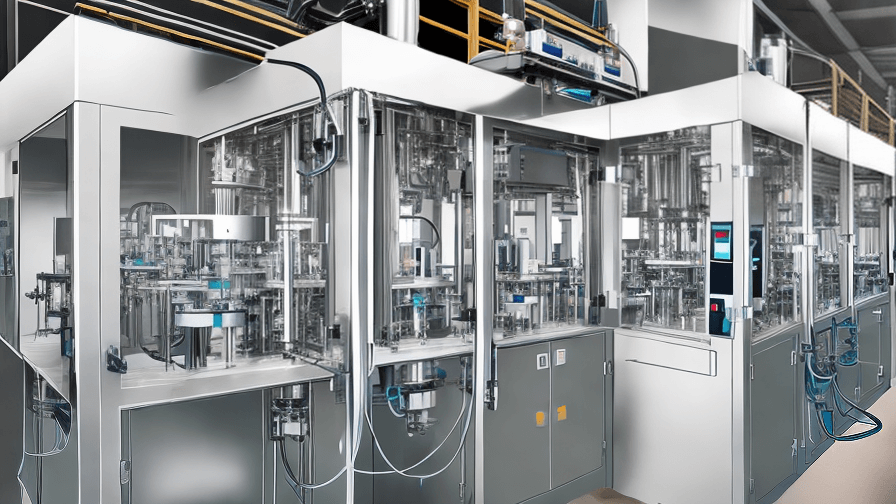

Perfume filling machines are a crucial aspect of the manufacturing process for various beauty and cosmetic companies. These machines provide an efficient and accurate method of filling perfume bottles of different volumes and shapes quickly. The following are essential features of a perfume filling machine.

1. Accurate filling: Most perfume filling machines use advanced technology to provide accurate filling for every bottle. The machines have sensors that detect the liquid level, ensuring precise filling to prevent wastage or spillage.

2. Versatility: Perfume filling machines can fill different volumes of perfume bottles, from standard sizes to unique shapes and sizes. This makes it possible for manufacturers to cater to different market needs and preferences.

3. Rapid filling speed: Perfume filling machines can fill multiple bottles within a short period. The speed is adjustable to suit the production needs, ensuring faster manufacturing processes and increased productivity.

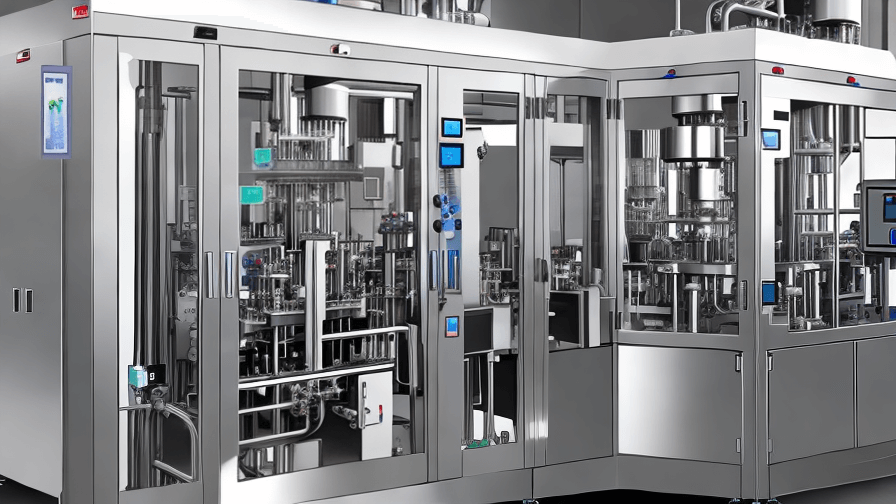

4. Ease of use: Modern perfume filling machines are automated, which makes them easy to use. The machines have user-friendly interfaces that allow operators to control the filling process with ease.

5. Stainless steel construction: Perfume filling machines are made of stainless steel material, which is durable and easy to clean. This ensures that the filling process remains hygienic and that the machine lasts for a long time.

6. Automatic cleaning: Modern perfume filling machines have self-cleaning mechanisms that make cleaning easy and fast. The automatic cleaning process reduces the need for costly manual cleaning and ensures hygienic operations.

In conclusion, perfume filling machines are an essential investment for beauty and cosmetic companies. The features discussed above are what make these machines efficient, accurate, and reliable. Investing in a quality perfume filling machine will increase productivity, reduce wastage, and ultimately increase profitability.

Various Types of Perfume Filling Machine

Perfumes are widely used for their aromatic fragrances and have become an essential part of our daily lives. The perfume industry is growing rapidly, which has led to the need for an advanced system for filling perfumes. The perfume filling machines are automated machines that have an inbuilt system to fill perfumes accurately and efficiently. Different types of perfume filling machines are available in the market, which are designed to meet the requirements of different companies.

The first type of perfume filling machine is the manual perfume filling machine, which is manually operated and is used for small-scale production. The machine is beneficial for startups or businesses that have limited funds and cannot invest much in automation. The manual filling machine is affordable, easy to operate, and does not require much maintenance.

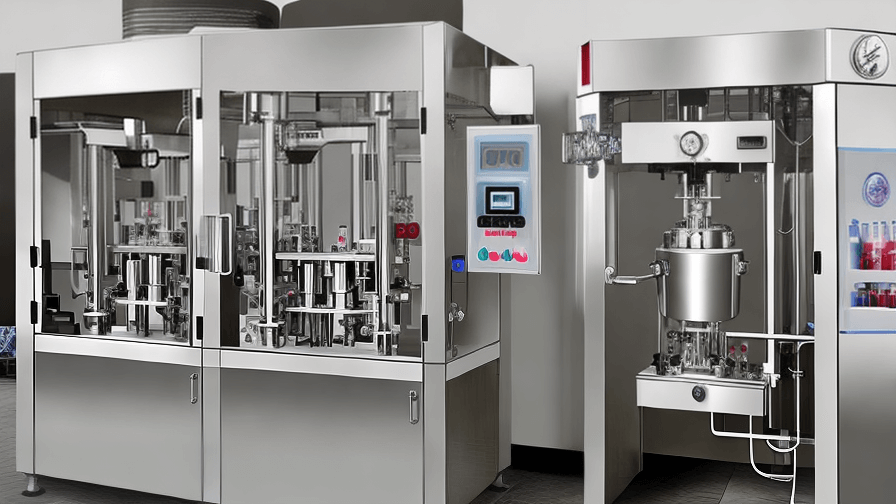

The second type of perfume filling machine is the semi-automatic perfume filling machine, which requires human intervention in the filling process. The machine is designed to fill a pre-set volume of liquid into the bottles, which can be adjusted as per the requirement. The semi-automatic perfume filling machine is ideal for mid-scale production where the production rate is moderate, and quality is essential.

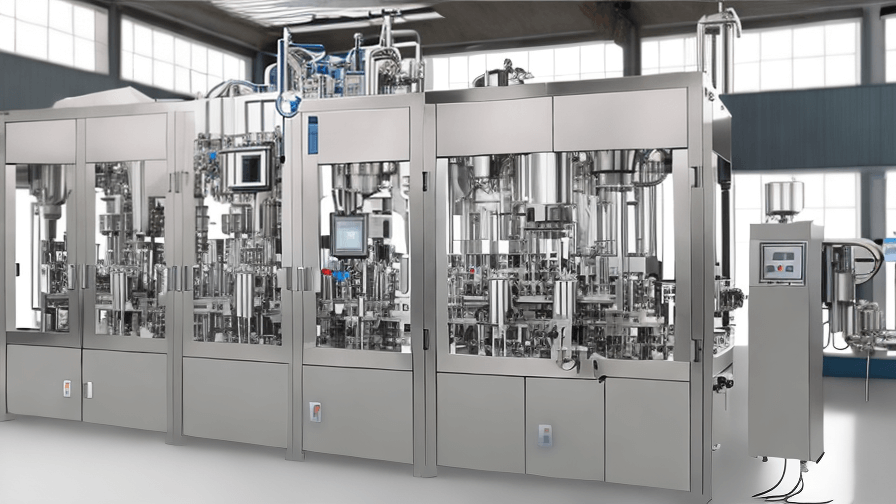

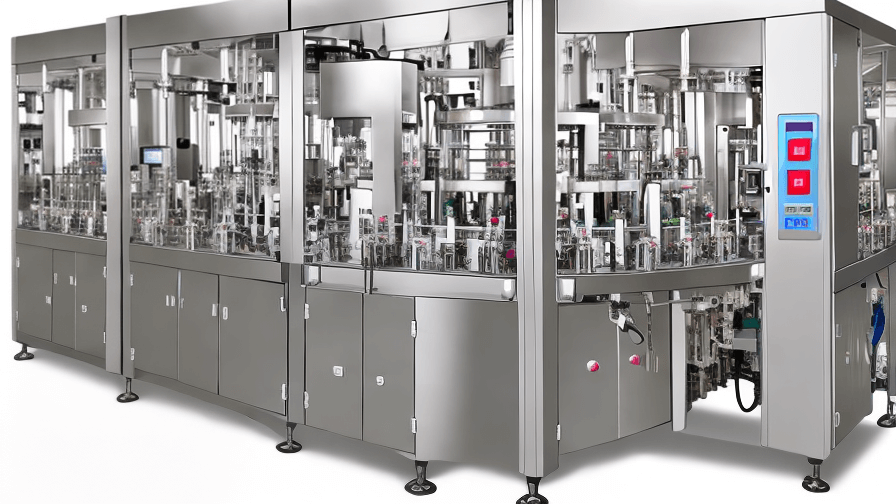

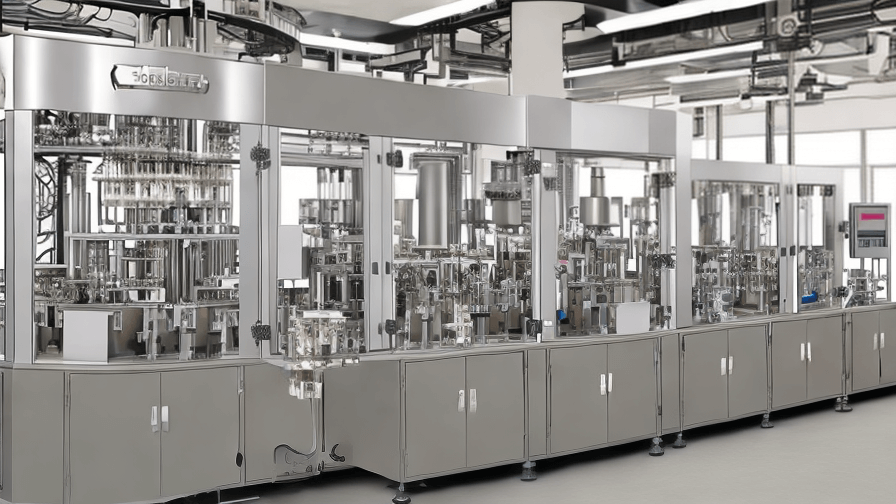

The third type of perfume filling machine is the fully automatic perfume filling machine, which is completely automated and requires no human intervention. The machine is capable of filling perfumes accurately and efficiently, making it ideal for large-scale production. The machine can be customized to fulfill specific needs, such as the filling of different bottle types, sizes, and shapes.

The fourth type of perfume filling machine is the rotary perfume filling machine, which is designed to fill different sizes and shapes of bottles simultaneously. The machine is equipped with a rotating platform that moves the bottles through different stations, such as filling, capping, labeling, and packaging. The rotary perfume filling machine is ideal for large-scale production, where the production rate is high and accuracy is critical.

In conclusion, choosing the right type of perfume filling machine is essential for the success of any perfume manufacturing business. The choice of the machine depends on the scale of production, the level of automation required, and specific needs. Companies should consult with experts to select the most optimal filling machine to ensure efficiency, accuracy, and agility of the production process.

Applications of Perfume Filling Machine

Perfume filling machines play a crucial role in the fragrance industry, as they facilitate the accurate and efficient filling of perfumes and fragrances into bottles. These machines come in different sizes and capacities, ranging from small-scale tabletop machines to high-speed, fully automated industrial machinery.

One of the most common applications of perfume filling machines is in the production of fragrances for personal use. Perfume filling machines are utilized to fill bottles with different types of fragrances, including perfumes, eau de parfums, and aftershaves. The machines are designed to fill the bottles accurately, without any spills or mishaps, ensuring consistent quality and quantity of the perfume.

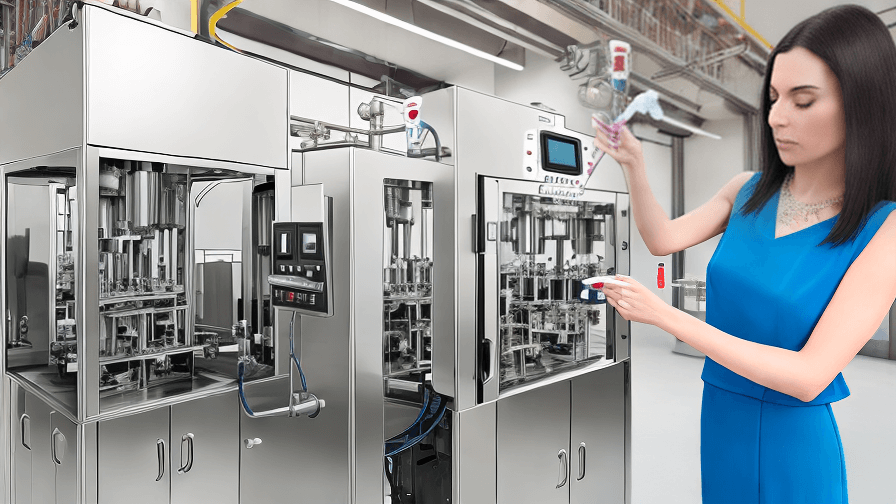

Perfume filling machines are also used in the production of fragrances for cosmetics and personal care products. These products include lotions, creams, and body sprays that require fragrances. In such applications, the perfume filling machines are used to accurately measure and dispense the fragrances into the products.

Another significant application of perfume filling machines is in the production of fragrances for home care products such as air fresheners and cleaning products. These products require fragrances in different forms, such as sprays, diffusers, and plug-ins. The perfume filling machines are used to fill different types of containers with the required scent, ensuring an accurate and consistent fragrance.

In conclusion, perfume filling machines play a vital role in the fragrance industry, enabling the accurate and efficient filling of fragrances into bottles. From cosmetics and personal care products to air fresheners and cleaning products, perfume filling machines are used in a range of applications to ensure consistent quality and quantity of the fragrances.

The Process of Perfume Filling Machine

Perfume filling machines are used to fill and package different types of perfumes. The process of filling the bottles is actually quite complex and involves several steps.

The first step in the process is to prepare the bottles. The bottles are usually made from glass or plastic and are cleaned and sterilized before filling them with perfume. In some cases, the bottles may be pre-labeled with the name of the perfume or the brand logo.

Next, the perfume is carefully mixed in a tank. The mixing process involves combining the different perfume ingredients in a specific ratio, ensuring consistency and quality throughout the filling process. The perfume is then transferred from the mixing tank to the filling machine.

The perfume filling machine has several components, including filling nozzles, conveyors, and sensors. The filling nozzles are responsible for measuring the amount of perfume to be dispensed into each bottle. They can be adjusted to dispense different amounts of perfume based on the size of the bottle.

The conveyors on the machine are used to move the bottles through the filling process. These conveyors are designed to ensure that the bottles are positioned correctly under the filling nozzles.

Once the bottles are in place, the perfume filling machine begins to dispense the perfume. The filling nozzles dispense the perfume at a specific rate, ensuring that the correct amount of perfume is dispensed into each bottle.

Sensors are also used on the perfume filling machine to ensure that the correct amount of perfume is being dispensed. These sensors monitor the amount of perfume in the tank and adjust the filling nozzles as needed.

Once all the bottles have been filled, they are capped and packaged for distribution. The entire process is automated and can fill hundreds of bottles in a matter of minutes.

In conclusion, perfume filling machines play a key role in filling and packaging perfumes. The process involves several steps, including preparing the bottles, mixing the perfume, and using a range of equipment to dispense the correct amount of perfume into each bottle. These machines are essential in ensuring the consistency and quality of the perfume filling process.

How to use Perfume Filling Machine

Perfume filling machines are essential tools that enable businesses in the fragrance industry to pack and distribute their products. These machines come in different types and sizes, but they all have the same objective: to provide a fast and reliable way of filling perfume bottles with the desired amount of fragrance. If you are planning to use a perfume filling machine, here are some tips that can help you get the best out of your equipment.

First, make sure that the perfume filling machine is clean and properly sanitized. Any residue or contamination left inside the machine can affect the quality and shelf life of your products.

Next, prepare the perfume bottles that you will be filling. Ensure that these bottles are also clean and free from any debris or dust. Position them on the conveyor belt of the machine, ensuring that they are correctly aligned and spaced apart.

Adjust the settings of the perfume filling machine to match the desired volume of your fragrance. This may vary depending on the bottle’s size and the product’s viscosity. For instance, thicker perfumes may require a slower flow rate than thinner ones to avoid overflowing and spillage.

Activate the filling process by turning on the machine’s motor, and the fragrance should start to flow into the bottles through the nozzles attached to the filling heads. You can monitor the level of the liquid inside the bottles by checking the machine’s display screen and adjusting the volume as required.

Once the bottles are filled to the desired level, the machine’s sensors or mechanical switches will stop the cutting-edge pump from dispensing the liquid automatically. The machine will then move the bottle to a capping or sealing station.

In conclusion, perfume filling machines are a vital investment for the fragrance industry. By following the above tips, you can ensure that your perfume filling machine runs efficiently, saves time, and produces high-quality perfumes.

Selecting the Ideal Manufacturer Perfume Filling Machine

When it comes to selecting the ideal perfume filling machine, there are several factors that you need to consider. Your choice of equipment plays a key role in the quality and efficiency of your production process. Here are some tips to help you choose the right perfume filling machine.

1. Capacity

The capacity of the machine is a key factor to consider. The size of your production facility and the amount of perfume you produce will determine the size of the machine you need. Consider the number of pieces you intend to fill in a day, and then select a machine with the suitable capacity.

2. Precision

A good perfume filling machine should be able to accurately fill the required amount of perfume to prevent any losses. Consider a machine that can regulate the amount of liquid with accuracy while providing high flow rates and consistency. This will ensure that the perfume is filled to the required amount without excess or wastage.

3. Speed

The speed of the machine is essential to the efficiency of your production process. Consider the amount of time you need to fill each bottle and the amount of perfume you need to produce every day. A fast machine will help increase productivity and enhance your efficiency.

4. Ease of use

A good perfume filling machine should be easy to operate and maintain. The machine should come with a user-friendly interface and easy-to-follow instructions. Additionally, the machine should be easy to clean to prevent contamination.

5. Durability

The durability of the machine is also important. A machine made of high-quality materials will last longer and provide you with a long-term investment. Look for a perfume filling machine made of sturdy materials that can withstand the harsh production environment.

In conclusion, selecting the ideal perfume filling machine requires careful consideration of several factors, including capacity, precision, speed, ease of use, and durability. With these factors in mind, you can choose the right machine that fits the specific needs of your production facility.

list FAQ with answer about Perfume Filling Machine

Perfume filling machines are essential pieces of equipment for cosmetic manufacturers and companies that produce various fragranced goods. To clear out doubts and confusion, here’s a list of frequently asked questions about perfume filling machines, along with their answers.

1. What is a perfume filling machine?

A perfume filling machine is a device used to dispense liquid fragrances into bottles. It helps to reduce human error and fill each bottle consistently.

2. What are the types of perfume filling machines?

Perfume filling machines come in different types like piston fillers, vacuum fillers, overflow fillers, and rotary fillers. Rotary fillers are widely used to fill perfume bottles in bulk.

3. What are the advantages of using a perfume filling machine?

Perfume filling machines help save time, reduce manpower, minimize wastage, improve accuracy, and ensure consistency in bottle filling.

4. What is the filling range of perfume filling machines?

The filling range of perfume filling machines varies from 5ml to 500ml, depending on the model and manufacturer.

5. How much perfume can the machine fill in an hour?

This varies based on the efficiency of the machine. However, a standard perfume filling machine can fill 100-150 bottles per hour.

6. How does the machine prevent cross-contamination?

Perfume filling machines have a variety of measures to prevent cross-contamination. Like using disposable pipes for each product, automatic cleaning and sterilization process, and using drip-free nozzles.

7. What maintenance is required for perfume filling machines?

Regular cleaning and lubrication of the machine’s parts will ensure optimal performance and longevity.

In conclusion, perfume filling machines are beneficial to the cosmetic manufacturing industry. They provide accuracy, consistency in the production process, save time and reduce wastage. With the array of various types and models available, there is a suitable option for every production need.

Things to Consider When Purchasing Perfume Filling Machine

When it comes to the perfume industry, a perfume filling machine is an essential piece of equipment. However, it is important to choose the right one to ensure the quality and efficiency of your production. Here are some things to consider when purchasing a perfume filling machine:

1. Capacity: The capacity of the perfume filling machine is crucial as it determines how many bottles can be filled at a time. Depending on your production needs, you can choose a perfume filling machine that suits your capacity requirements.

2. Compatibility: Your perfume filling machine should be compatible with the type of perfume you are producing. If you are working with a thick or viscous fragrance, you will need a filling machine that can handle it.

3. Accuracy: Perfume is a delicate product, and it requires precision when filling the bottles. Your filling machine should be accurate in measuring the appropriate amount of fragrance to be filled in each bottle.

4. Ease of use and maintenance: Choose a perfume filling machine that is easy to use and maintain. The machine should be user-friendly with easy to follow instructions. You should also consider the availability of replacement parts and the cost of maintenance.

5. Cost: The cost of the machine is of course another important factor to consider. You should select a machine that is within your budget without compromising on quality.

6. Brand reputation: The brand reputation of the perfume filling machine should also be considered. Choose a brand that is reputable and has a history of producing quality equipment.

In conclusion, investing in a perfume filling machine is a significant decision. Consider the above factors when purchasing a perfume filling machine to make an informed decision that will suit all your production needs.

Properties of Perfume Filling Machine

A perfume filling machine is a specially designed machine that is used in the perfume manufacturing industry to fill perfume bottles with different types of fragrances. There are several types of perfume filling machines available in the market, each designed for a specific purpose and to cater to the diverse needs of the perfume industry.

The properties of a perfume filling machine are crucial as they impact the overall efficiency and productivity of the perfume manufacturing process. Some of the key properties of a perfume filling machine are as follows:

1. Versatility: A good perfume filling machine should be versatile and capable of handling a wide range of perfume bottles, sizes, shapes, and closure types. This allows perfume manufacturers to fill different types of perfume bottles with various fragrances without any hassle.

2. Accuracy: Perfume filling machines should be accurate and able to dispense the right amount of fragrance into each bottle. This ensures that the perfume is of high quality, consistent and meets the standards set by the manufacturer.

3. Speed: Time is a critical factor when it comes to perfume manufacturing. A good perfume filling machine should be able to fill several bottles of perfume in a short amount of time, speeding up the production process.

4. Ease of use: A perfume filling machine should be easy to use and operate. Operators should easily navigate the controls and settings of the machine without any difficulty. Additionally, the machine should be easy to clean and maintain to prevent contamination of perfumes.

5. Durability: A perfume filling machine should be made of high-quality materials that can withstand the rigours of everyday use. This will ensure that the machine lasts long, reducing the need for frequent repairs or replacements.

In conclusion, the properties of a perfume filling machine are crucial to the overall manufacturing process of perfumes. Perfume manufacturers should ensure that the machine they acquire meets their specific needs and can deliver on the critical properties outlined above. This will guarantee high-quality fragrances that meet the ever-evolving demands of customers.

Technical Parameters Terms for Perfume Filling Machine

Perfume filling machines are essential equipment for the perfume production industry. They are designed to accurately and efficiently fill perfume bottles with fragrance liquids. To make the most of these machines, manufacturers must have a good understanding of the technical parameters terms used in their operation.

Firstly, there is the filling capacity, which refers to the amount of liquid a perfume filling machine can dispense per unit of time. Some machines have a fixed filling capacity while others have an adjustable one accommodating various bottle sizes.

Secondly, there is the filling accuracy, which is the deviation between the intended filling volume and the actual volume dispensed by the machine. The filling accuracy is usually measured as a percentage of the actual volume dispensed.

Thirdly, there is the bottle diameter, which refers to the size of the bottle opening where perfume will be dispensed. The diameter affects the type of filling nozzle that the machine will require.

Fourthly, there is the viscosity of the perfume, which is the measure of the fluid’s resistance to flow. The viscosity level determines the type of pump and nozzle size needed for efficient dispensing of the liquid.

Other technical parameters that are important for perfume filling machines include the bottle height, capping torque, and conveyor speed. To achieve optimal performance, it is essential to calibrate the machines based on these parameters.

In conclusion, understanding the technical parameters of perfume filling machines is essential for perfumers and manufacturers in the industry. This ensures efficient and accurate dispensing as well as good product quality. By considering the bottle diameter, filling capacity, filling accuracy, viscosity, bottle height, capping, and conveyor speed, users can select the right machine settings for different production needs.

Perfume Filling Machine Price

Perfume filling machine price varies quite significantly depending on the type, brand, and capacity of the machine. The manual perfume filling machine can cost as low as $50 while the fully automatic production line filling machine can cost up to $50,000 or more.

Manual perfume filling machines are perfect when starting a small perfume business as they require low capital investment and are very simple to operate. They typically feature a single nozzle that’s used to fill small batches of bottles, making them ideal for small production runs. The cost of manual perfume filling machines ranges between $50 to $300.

Semi-automatic perfume filling machines cost more than manual machines and come with extra features. They feature multiple nozzles for filling more bottles at once, a touch screen interface which allows the user to set operation parameters, and a conveyor belt that moves bottles automatically. The capacity of these machines depends upon the number of nozzles, but generally, a semi-automatic machine can fill between 30 to 50 bottles per minute. The cost of semi-automatic perfume filling machines ranges from $3,000 to $10,000.

Fully automatic perfume filling machines feature a production line process, allowing users to fill hundreds of bottles in a single pass. These machines come with advanced features such as multiple conveyor belts for transporting bottles, digital filling heads that control the filling volume, filling speed, and the types of liquids to be filled, and auto-capping machines that fit caps on bottles automatically. The cost of fully automatic perfume filling machines ranges from $50,000 to $100,000.

In conclusion, the price of a perfume filling machine is dependent on the type, capacity, and brand. Entrepreneurs can start small with a manual or semi-automatic machine, or opt for a fully automatic machine if looking for high-capacity production. It’s important to choose a machine that suits your business needs and budget.