Types and Applications of piston kit

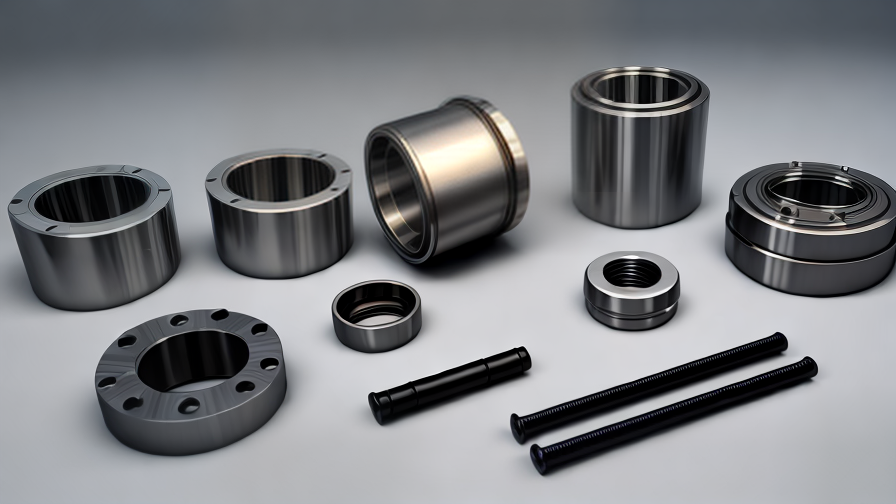

The piston kit is an essential component of an internal combustion engine. As the name suggests, it contains a piston that slides up and down inside the engine cylinder, and various other components such as rings, pins, and clips that help it to function. Here are the types and applications of piston kit.

Cast Piston Kit:

This is the most common type of piston kit. It is made from cast iron or aluminum alloy poured into a mold. Cast piston kits are relatively inexpensive and durable, making them suitable for use in a wide range of vehicles, from cars to trucks and even boats.

Forged Piston Kit:

Forged piston kits are designed for high-performance engines. They are made from high-quality aluminum alloy, which is heated to a high temperature and then compressed into shape using a forging press. Forged pistons are stronger and hold up better under high heat and pressure than cast pistons. They are commonly used in racing engines.

Coated Piston Kit:

Coated piston kits have a thin layer of a protective material applied to their surface. This can be done in several ways, such as thermal spraying, plasma spraying, or electroplating. Coatings can protect the piston from wear and tear, increase its resistance to corrosion, and even improve its heat dissipation abilities.

Applications of Piston Kits:

Piston kits are used in a variety of engines, including gasoline, diesel, and two-stroke engines. They are essential components in cars, trucks, motorcycles, lawnmowers, boats, and many other machines that use internal combustion engines. Piston kits play a critical role in controlling the combustion process and transforming the energy of fuel into mechanical energy to power the vehicle.

In conclusion, the choice of piston kit type depends on the purpose of the engine. For instance, a racing engine will require a forged piston kit, while a regular vehicle can do with a cast piston kit. Coated piston kits are also essential for high-performance engines to increase the lifespan of the piston.

Benefits and Feature of Utilizing piston kit

A piston kit is a crucial component of any engine system as it plays a significant role in the transfer of energy from the fuel to the crankshaft, which results in the vehicle’s movement. It consists of a piston, rings, and connecting rod, which work together to provide smooth operation and durable performance. Here are some of the benefits and features of utilizing a piston kit:

1. Improved Engine Performance: Installing a high-quality piston kit can significantly improve engine performance, increase power output, and enhance fuel efficiency.

2. Increased Engine Lifespan: A piston kit made from high-quality materials can significantly increase the lifespan of an engine by reducing wear and tear on parts.

3. Reduced Emissions: The design of a piston kit can also help reduce emissions by improving combustion efficiency, which leads to a cleaner and more environmentally friendly engine.

4. Easy Installation: Piston kits are designed to be easy to install, making them a popular choice for mechanics and DIY enthusiasts alike.

5. Compatibility with Different Engines: Piston kits are available in a wide range of sizes and specifications, making them compatible with different types of engines.

6. Cost-Effective: Replacing a damaged piston kit is much more cost-effective than replacing the entire engine or buying a new vehicle.

7. Improved Acceleration: A high-quality piston kit can also improve acceleration and help a vehicle achieve higher speeds.

In summary, utilizing a piston kit can offer numerous benefits for engine performance, lifespan and reliability, emissions reduction, and more. It is an investment in both an engine’s lifespan and a vehicle’s continued functionality. By using a piston kit made from high-quality materials, vehicle owners can ensure maximum efficiency, performance, and durability, providing a better driving experience and fewer problems with the vehicle.

The Process of piston kit

A piston kit is a collection of parts that make up a piston assembly. The process of assembling a piston kit involves several steps, which include:

1. Piston manufacturing – The first step in creating a piston kit involves the manufacturing of the piston itself. This involves casting or forging a piece of metal into the shape of a piston.

2. Ring grooving – Once the piston has been manufactured, the next step is to create ring grooves in the piston. These grooves are where the piston rings will be installed.

3. Ring installation – After the ring grooves have been created, piston rings are installed. These rings help seal the combustion chamber, ensuring that the fuel-air mixture burns cleanly and efficiently.

4. Wrist pin installation – The wrist pin is a small metal rod that connects the piston to the connecting rod. This step involves inserting the wrist pin into the piston and securing it in place.

5. Connecting rod installation – The final step in assembling a piston kit is to attach the connecting rod to the piston assembly. This step involves inserting the wrist pin into the connecting rod and securing it in place.

Once the piston kit has been assembled, it can be installed into an engine. The piston kit plays a vital role in the operation of an engine, as it helps control combustion and power production.

How to use piston kit

A piston kit is a set of parts required for restoring the pistons in an engine. It consists of the piston, rings, clips, and wrist pins. Here’s how to use a piston kit:

1. Disassemble the engine: Before installing a piston kit, you have to remove the engine from the vehicle and disassemble it. You need to remove the cylinder head, oil pan, and other components as required.

2. Remove the old pistons: After disassembling the engine, you can remove the old pistons from the cylinder. You can use a piston ring compressor to compress the rings and remove them from the piston.

3. Clean the parts: It’s crucial to thoroughly clean all the parts of the engine before putting it back together. Use an engine cleaning solution and a wire brush to clean the cylinder walls and other components.

4. Install the new piston: Place the new piston into the cylinder, making sure it’s facing the correct direction. Then, install the wrist pin and retaining clips.

5. Install the rings: Place the piston rings into the ring grooves using a piston ring compressor. Ensure the rings are in their proper position.

6. Reassemble the engine: After installing the pistons, reassemble the engine. Install the cylinder head, oil pan, and other components in the reverse order of removal.

7. Test the engine: Once the engine is reassembled, test it to ensure it’s running smoothly without any issues. You can also perform a compression test and leak-down test to ensure the engine is working correctly.

In conclusion, using a piston kit is a straightforward process that requires some technical knowledge. It’s crucial to ensure all parts of the engine are clean and in their proper position during reassembly to prevent any damage.

piston kit Manufacturer,Supplier and Wholesale

A piston kit is a complete set of components that make up a piston assembly in an engine. These components may include a piston, piston rings, wrist pin, and circlips. The purpose of a piston kit is to replace worn-out or damaged components of the piston assembly to restore proper engine function.

As a piston kit manufacturer, supplier and wholesaler, we focus on delivering high-quality solutions for our customers. Our piston kits are made from the best materials, ensuring durability and performance. We have a wide range of piston kits for different engines, including cars, motorcycles, boats, and industrial engines.

We work closely with our customers to understand their needs and provide them with customized solutions. Our team of experts has years of experience in the industry and can help customers choose the right piston kit for their engines. We also offer technical support to ensure that our customers can install and use our products with ease.

As a wholesale supplier, we offer competitive pricing for our products, making it affordable for businesses to purchase in bulk. We understand the importance of timely delivery, and our logistics team works diligently to deliver products on time.

In conclusion, our company is a reliable piston kit manufacturer, supplier, and wholesaler. We provide high-quality products, customized solutions, and excellent customer service to our clients. If you are looking for a reliable partner for your piston kit needs, we are here to help.

piston kit Price

The price of a piston kit varies depending on factors such as the make and model of the vehicle, the quality of the materials used in the kit, and the size of the engine. The price range of piston kits can typically range from $50 to several hundred dollars.

Some manufacturers may offer a standard or economy line of piston kits that are priced lower, but may not have the same level of durability or performance as a higher-end kit. High-performance piston kits may be more expensive due to their advanced design and materials.

While the upfront cost of a piston kit may seem high, it can often be more cost-effective in the long run. Replacing a worn or damaged piston with a quality kit can help extend the life of your engine and prevent more costly repairs down the road.

When shopping for a piston kit, it is important to do your research and compare prices from different manufacturers. Look for kits that are designed for your specific vehicle and engine type to ensure proper fit and function. Additionally, be sure to consider the reputation of the manufacturer and any warranties or guarantees that may be included with the kit.

Overall, investing in a quality piston kit can help keep your engine running smoothly and reliably for years to come.

FAQ sourcing piston kit manufacturer from China with multiple answers

1. What should I look for when sourcing a piston kit manufacturer from China?

When sourcing a piston kit manufacturer from China, there are several factors to consider, such as the manufacturer’s experience, quality control measures, production capacity, and pricing. It is essential to find a manufacturer that has a proven track record of producing high-quality piston kits that meet your specifications and standards. Additionally, you should ensure that the manufacturer has strict quality control measures in place to ensure that the products meet your quality requirements. It is also crucial to consider the manufacturer’s production capacity and lead time to ensure that they can deliver your orders promptly. Finally, you should compare pricing from different manufacturers to find one that offers the best value for money.

2. How can I verify a piston kit manufacturer’s quality?

When verifying a piston kit manufacturer’s quality, you can request product samples for inspection or visit their production facilities to observe their manufacturing processes. You can also ask for their quality control measures or certifications to confirm that they adhere to international quality standards. Additionally, you can check their customer reviews and testimonials to see if they have a good reputation for producing high-quality piston kits.

3. What is the lead time for manufacturing piston kits in China?

The lead time for manufacturing piston kits depends on the manufacturer’s production capacity and the quantity of the order. Generally, the lead time can range from two to eight weeks, depending on the complexity of the product and the manufacturing process. To ensure timely delivery, it is essential to communicate with the manufacturer and agree on a reasonable lead time that suits both parties.

4. Can I customize the design of the piston kit?

Yes, most piston kit manufacturers in China offer customization services to meet their customers’ specific requirements. You can provide your design specifications to the manufacturer, and they can produce the piston kits according to your specifications. However, it is essential to confirm the manufacturing process with the manufacturer to ensure that the customized design meets your quality requirements.

5. What is the pricing structure for piston kits in China?

The pricing structure for piston kits in China varies depending on the manufacturer, quantity, and customization requirements. Generally, the price per unit decreases with an increase in the quantity ordered. Additionally, customized designs and specialized materials may attract higher prices. It is important to compare prices offered by different manufacturers to find one that offers the best value for money while meeting your quality requirements.