List Technical Parameters of “beryllium copper c17200 suppliers”

Beryllium Copper C17200 is a high-performance alloy that is known for its excellent strength, toughness, and corrosion resistance. It is used in a variety of applications such as aerospace, electronics, telecommunications, and military. When looking for Beryllium Copper C17200 suppliers, there are several technical parameters to consider such as:

1. Composition: Beryllium Copper C17200 is a copper-based alloy containing 1.8-2% beryllium and small amounts of other elements such as nickel, cobalt, iron, and manganese.

2. Mechanical Properties: Beryllium Copper C17200 has excellent mechanical properties such as high strength, hardness, and toughness. Its tensile strength can reach up to 1250-1450 MPa, and its elongation is 10-15%.

3. Heat Treatment: Beryllium Copper C17200 can be heat treated to improve its strength and hardness. The recommended heat treatment process is solution annealing at 760°C for 1 hour followed by water quenching.

4. Corrosion Resistance: Beryllium Copper C17200 is highly resistant to corrosion in seawater, chlorinated water, and acidic environments. It is also resistant to stress corrosion cracking and hydrogen embrittlement.

5. Weldability: Beryllium Copper C17200 can be welded using various welding techniques such as resistance welding, TIG welding, and laser welding. However, it is important to avoid overheating the material during the welding process to prevent cracking.

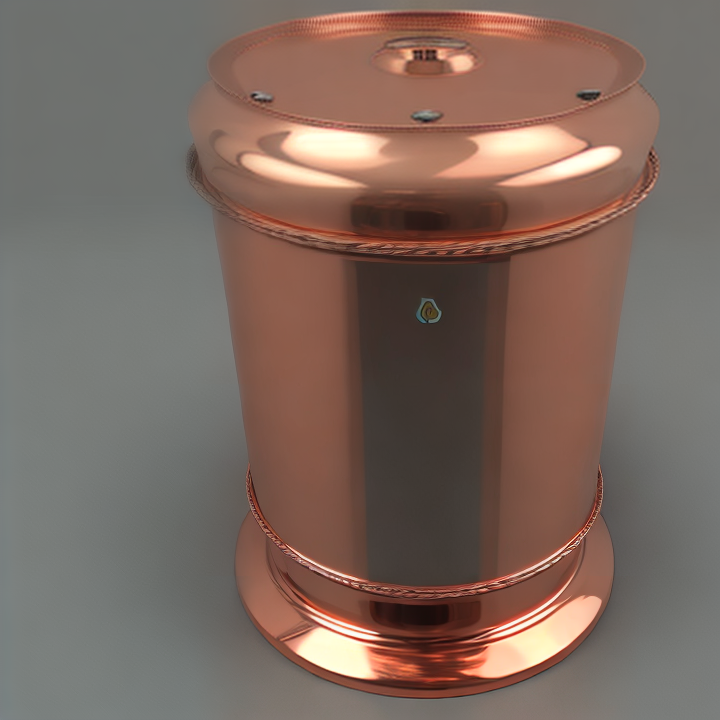

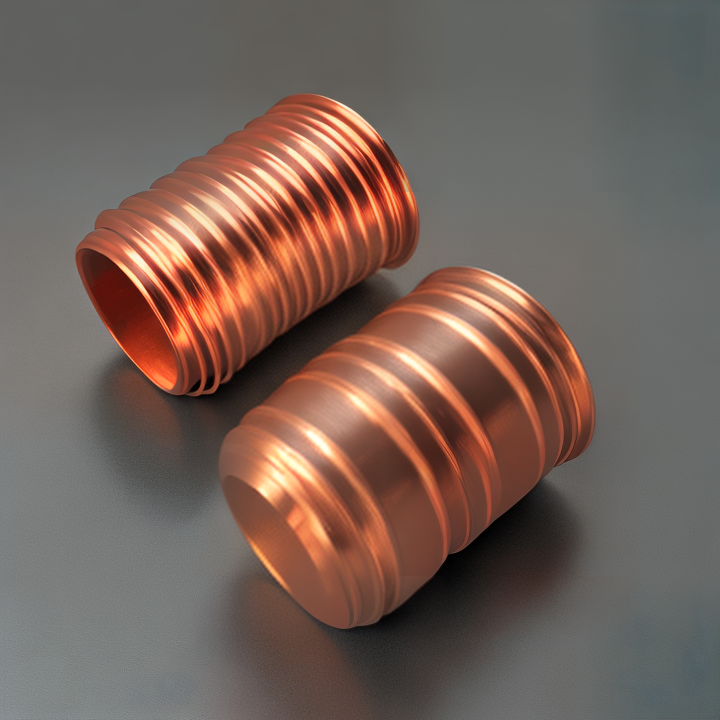

6. Surface Finish: Beryllium Copper C17200 can be machined to a high surface finish due to its excellent maChinability. It can be polished, buffed, or plated for aesthetic purposes.

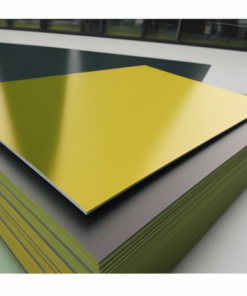

7. Availability: Beryllium Copper C17200 is available in various forms such as sheets, plates, bars, and wires. It can be customized according to the specific requirements of the application.

Overall, when selecting Beryllium Copper C17200 suppliers, it is important to consider these technical parameters to ensure that the material meets the required specifications and standards.

List Product features of “beryllium copper c17200 suppliers”

Beryllium Copper C17200 is an alloy with high strength, hardness, and electrical conductivity. It is widely used in the electrical and electronic industries due to its unique properties. Here are some product features of Beryllium Copper C17200 Suppliers:

1. High Strength: Beryllium Copper C17200 has high strength, making it an excellent material for high-stress applications. The ultimate tensile strength of this material is up to 1250 MPa.

2. High Hardness: Beryllium Copper C17200 has excellent hardness, making it suitable for applications where wear resistance is crucial.

3. High Electrical Conductivity: Beryllium Copper C17200 has excellent electrical conductivity, making it ideal for electrical and electronic applications. It has a conductivity of up to 22% IACS (International Annealed Copper Standard).

4. Resistance to Fatigue: Beryllium Copper C17200 has excellent resistance to fatigue, making it suitable for applications with cyclic loading conditions.

5. Corrosion Resistance: Beryllium Copper C17200 has good corrosion resistance, making it ideal for marine and corrosive environments.

6. MaChinability: Beryllium Copper C17200 is easily maChinable, making it easy to design and produce components of complex shapes.

7. Weldability: Beryllium Copper C17200 is easily weldable, making it ideal for applications where joining is necessary.

8. Heat Resistance: Beryllium Copper C17200 has excellent heat resistance, making it suitable for high-temperature applications.

9. Non-magnetic: Beryllium Copper C17200 is non-magnetic, making it ideal for applications where magnetic interference is not acceptable.

10. Uniform Properties: Beryllium Copper C17200 has uniform properties throughout the material, making it ideal for applications where consistency is vital.

In conclusion, Beryllium Copper C17200 suppliers provide a versatile material with unique properties that make it an excellent choice for various applications. Its high strength, hardness, electrical conductivity, resistance to fatigue, corrosion resistance, maChinability, weldability, heat resistance, non-magnetic properties, and consistency make it ideal for various industries, including electrical and electronic, aerospace, automotive, and more.

List Application of “beryllium copper c17200 suppliers”

Beryllium copper (C17200) is an alloy that is primarily composed of copper and beryllium that typically contains 1.8% to 2% beryllium with about 0.5% of additional alloys such as nickel, cobalt, iron, etc. Beryllium copper is widely used in various industries due to its unique combination of high strength, excellent electrical and thermal conductivity, toughness, corrosion resistance, and non-sparking properties. Here are some applications of beryllium copper:

1. Aerospace and Defense Industry – Beryllium copper is widely used in the aerospace and defense industry due to its high strength, excellent stiffness, and non-magnetic qualities. It is used in aircraft parts, missile and rocket components, helicopter rotors, landing gears, and other critical components that require high strength and non-sparking properties.

2. Electrical and Electronics Industry – Beryllium copper is an excellent conductor of electricity and has a high thermal conductivity, which makes it ideal for electrical and electronic components such as connectors, switches, sockets, springs, and relays that require high conductivity and durability.

3. Automotive Industry – Beryllium copper is used in the automotive industry for various applications such as spark plug electrodes, high-performance engine components, brake pads, and clutch discs due to its high strength, excellent wear resistance, and non-sparking properties.

4. Medical Industry – Beryllium copper is used in the medical industry for various surgical instruments and tools due to its corrosion resistance, non-magnetic, and biocompatibility properties.

5. Oil and Gas Industry – Beryllium copper is widely used in the oil and gas industry for various applications such as drilling tools, valves, pumps, and pressure sensors due to its high strength, excellent resistance to abrasion and corrosion, and non-sparking properties.

In conclusion, beryllium copper has numerous applications due to its unique combination of properties, making it an ideal material for various industries where high strength, durability, and non-sparking properties are required.

List Various Types of “beryllium copper c17200 suppliers”

Beryllium copper c17200 is a copper alloy that contains small amounts of beryllium. It is known for its high strength, hardness, and resistance to fatigue, abrasion, and corrosion. Due to its unique properties, it is used in a variety of industries such as aerospace, automotive, electrical, and defense. To meet the demand for this material, there are various types of beryllium copper c17200 suppliers operating across the globe.

1. Online retailers – Online retailers offer beryllium copper c17200 products through their e-commerce platforms. Customers can easily browse and select the products they need without leaving their desks.

2. Distributors – Distributors act as intermediaries between manufacturers and end-users. They purchase beryllium copper c17200 products in large quantities and resell them to their customers. Distributors offer customers access to a wide range of products and services.

3. Manufacturers – Manufacturers of beryllium copper c17200 products produce the material and sell it directly to their customers. They offer customization options for customers and can produce specialized products that meet specific requirements.

4. Importers – Importers source beryllium copper c17200 products from other countries and sell them in their local markets. They provide customers with access to products that may not be available domestically.

5. Metal service centers – Metal service centers process beryllium copper c17200 products to meet customers’ specific needs. They offer services such as cutting, bending, and forming.

6. Wholesalers – Wholesalers purchase beryllium copper c17200 products in bulk and resell them to retailers or end-users. They offer customers competitive pricing and a large selection of products.

7. Specialty suppliers – Specialty suppliers focus on specific industries that require beryllium copper c17200 products. For example, they may specialize in supplying aerospace or electrical components.

In conclusion, the types of beryllium copper c17200 suppliers are varied, and each type offers unique advantages to customers. Choosing the right supplier is essential to ensure that customers get good quality products at a reasonable price.

List The Evolution history of “beryllium copper c17200 suppliers”

Beryllium copper C17200 is an alloy of copper with 1.9-2.2% beryllium content. It is known for its high strength, hardness, and corrosion resistance, making it ideal for various applications in industries like aerospace, automotive, and electronics. The history of beryllium copper C17200 has evolved gradually over the years as follows:

– 1920s: Beryllium-copper alloys were first developed in the 1920s and were used primarily for spring and wire applications.

– 1940s: During World War II, beryllium copper alloys were used in the manufacture of a variety of weapons and aircraft components due to their exceptional strength and durability.

– 1950s: The electronics industry began using beryllium copper alloys for connectors, switches, and other components due to their high conductivity and corrosion resistance.

– 1960s: The use of beryllium copper alloys in the automotive industry began to grow due to their high fatigue strength and wear resistance. They were used in components such as valve seats, valve guides, and bearings.

– 1970s: Beryllium copper alloys began to be used in the oil and gas industry for drill collars and other downhole equipment due to their excellent resistance to stress corrosion cracking in harsh environments.

– 1980s: The aerospace industry began to use beryllium copper alloys for landing gear components due to their high strength-to-weight ratio and fatigue resistance.

– 1990s: Advancements in manufacturing processes allowed for the production of complex shapes and parts made from beryllium copper alloys, leading to their use in a wider range of applications.

– 2000s: Beryllium copper alloys continued to be used in a variety of industries, with an increasing focus on their environmental sustainability and safety.

Today, beryllium copper C17200 is one of the most widely used types of beryllium copper alloys due to its excellent combination of strength, hardness, and corrosion resistance. The evolution of this material has made it an essential component in various industries, leading to the development of beryllium copper C17200 suppliers who provide high-quality products to meet the growing demand.

List The Process of “beryllium copper c17200 suppliers”

The process of finding beryllium copper C17200 suppliers involves several steps to ensure quality and reliability. These steps include:

1. Research: Firstly, the buyer should research the different beryllium copper C17200 suppliers available in the market. This can be done by either checking business directories or searching online.

2. Material specifications: Once the buyer has identified suppliers, they should review the material specifications offered by each supplier. They should look for suppliers who offer C17200 beryllium copper with the required physical and mechanical properties, including strength, conductivity, and maChinability.

3. Quality assurance: Quality assurance measures should be considered before choosing a supplier. These measures include the supplier’s manufacturing processes, quality control, and assurance programs. The supplier should have an ISO 9001 certification, which ensures that their products meet industry standards.

4. Price and delivery: The buyer should also consider the price and delivery times offered by each supplier. They should compare quotes and delivery options to ensure that they get the best value for their money.

5. Customer reviews: Finally, the buyer should read customer reviews and testimonials to understand the experience of other buyers who have used the supplier’s services. It is important to choose a supplier who has a good reputation of delivering quality products and excellent customer service.

In conclusion, finding good beryllium copper C17200 suppliers requires proper research, understanding material specifications, quality assurance, price and delivery, and customer reviews. By following these steps, the buyer can ensure that they get the best quality beryllium copper C17200 from a reliable supplier.

How to use “beryllium copper c17200 suppliers”

Beryllium copper C17200 is a copper alloy that has excellent strength, conductivity, and corrosion resistance. It is widely used in various industries for a range of applications such as welding electrodes, springs, electrical contacts, and connectors. When selecting beryllium copper C17200 suppliers, it is important to ensure that the supplier provides high-quality products, timely delivery, and excellent customer service.

One of the first steps in selecting a supplier is to research and compile a list of potential suppliers. This can be done through various means such as online searches, industry directories, and referrals from colleagues and other businesses in the industry. Once the list is compiled, it is important to evaluate each supplier based on various factors such as their experience, reputation, certifications, and product range.

When evaluating suppliers, it is important to ensure that they are experienced in the production and supply of beryllium copper C17200. This ensures that they have the necessary knowledge and expertise to manufacture quality products that meet the industry standards. Additionally, it is important to verify that they are certified by relevant organizations to manufacture and supply beryllium copper C17200.

Timely delivery is crucial in the selection of a supplier. This requires assessing the supplier’s ability to deliver products on time and their inventory management systems. The supplier’s inventory should be sufficient to handle customer demands to avoid delays in delivery, which can impact productivity and profitability.

Lastly, excellent customer service is imperative. A good supplier should have a friendly and knowledgeable customer service team that can assist customers with their queries, provide technical support, and resolve issues promptly.

In conclusion, selecting a reliable beryllium copper C17200 supplier requires comprehensive research, evaluation, and verification. It is crucial to evaluate their experience, certifications, product range and quality, timely delivery, and customer service. By taking these factors into consideration, businesses can find a supplier that meets their needs and provides high-quality products and services.

List Properties of “beryllium copper c17200 suppliers”

Beryllium copper C17200 is an age-hardened alloy that is widely used in various industries, including aerospace, automotive, electronics, and medical. This alloy is known for its high strength, durability, and excellent conductivity, making it an ideal choice for applications that require high performance and reliability. Beryllium copper C17200 suppliers offer a range of products and services to meet the needs of different industries. Here are some properties of this alloy and its suppliers:

1. High resistance to corrosion: Beryllium copper C17200 is highly resistant to corrosion, making it an ideal material for use in harsh environments such as marine, aerospace, and chemical industries.

2. Good electrical conductivity: This alloy has excellent electrical conductivity, making it a popular material for use in the electronics industry.

3. High tensile strength: Beryllium copper C17200 has high tensile strength, which makes it ideal for use in applications that require high strength and durability.

4. Heat resistance: This alloy can withstand high temperatures without losing its strength or conductivity, which makes it suitable for use in high-temperature applications.

5. Customizable: Beryllium copper C17200 can be customized to meet specific requirements, making it suitable for use in a wide range of applications.

6. Comprehensive supply chain: Beryllium copper C17200 suppliers offer a comprehensive supply chain, including manufacturing, distribution, and logistics.

7. Quality products: Beryllium copper C17200 suppliers offer high-quality products that meet industry standards and customer specifications.

8. Technical support: Beryllium copper C17200 suppliers provide technical support and assistance to customers to help them choose the right product for their application.

9. Competitive pricing: Beryllium copper C17200 suppliers offer competitive pricing to customers, ensuring that they get value for their money.

In conclusion, beryllium copper C17200 suppliers offer a range of products and services to meet the needs of different industries. They offer high-quality products, technical support, and competitive pricing, ensuring that customers get the best value for their money. With its excellent properties and customizable nature, beryllium copper C17200 is an ideal material for use in a wide range of applications.

List “beryllium copper c17200 suppliers” FAQ

1. What is beryllium copper C17200?

Beryllium copper C17200 is an alloy of copper that contains small amounts of beryllium and sometimes other elements such as nickel or cobalt. It has high strength, conductivity, and resistance to fatigue, making it useful in a variety of applications from electrical connectors to springs and bearings.

2. Where can I find beryllium copper C17200 suppliers?

Beryllium copper C17200 suppliers can be found online through various industrial supply websites and directories. Local metal supply companies and specialized alloy suppliers may also carry the material.

3. What forms does beryllium copper C17200 come in?

Beryllium copper C17200 is available in a variety of forms including round bar, sheet and plate, wire, and tubing. The material can also be custom fabricated into specific shapes and sizes.

4. What are some common applications for beryllium copper C17200?

Beryllium copper C17200 is used in a variety of industries including aerospace, automotive, electronics, and medical. Some common applications include electrical connectors, springs, bearings, and switches.

5. What are the benefits of using beryllium copper C17200?

Beryllium copper C17200 offers high strength, conductivity, and resistance to fatigue. It also has good corrosion resistance and is easy to machine. In addition, its non-sparking properties make it useful in applications where there is a risk of ignition or explosion.

6. What precautions should be taken when working with beryllium copper C17200?

Beryllium copper C17200 contains beryllium, which is a toxic metal. Proper handling and disposal procedures should be followed to avoid exposure to the material. It is also important to use appropriate personal protective equipment when handling the material such as gloves, sleeves, and respiratory protection.