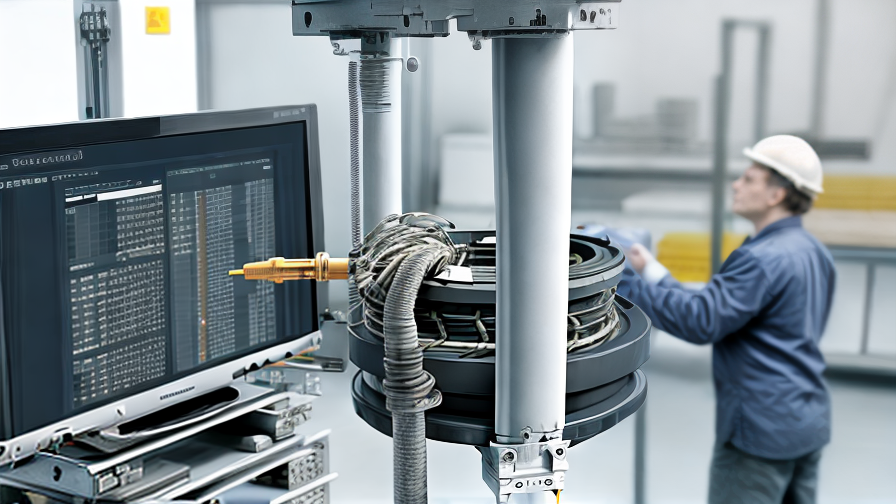

coaxial cable manufacturer

Benefits:

– Provides reliable and fast transmission of data

– Reduces signal interference and noise

– Long-lasting

– Versatile and can be used in different applications and industries

Features:

– Made with high-quality materials

– Well-insulated to prevent signal loss

– Available in different lengths and sizes

– Can handle high frequency signals

– Compatible with different types of connectors

Specifications:

– Impedance: 50 or 75 Ohms

– Shielding Material: Aluminum foil, copper tape or braiding

– Jacket Material: PVC, PE or LSZH

– Frequency Range: Up to 6 GHz

– Operating Temperature Range: -40°C to 85°C

Applications:

– Telecommunications industry

– Broadcast industry

– Medical equipment

– Aerospace and military industry

– Home and office networking

List Technical Parameters of “coaxial cable manufacturer”

Coaxial cable is a popular type of cable that is used to transmit radio frequency signals for communication purposes. Some of the technical parameters that are important for coaxial cable manufacturers include:

1. Impedance: Coaxial cables are designed to have a specific impedance, usually either 50 or 75 ohms. This impedance affects the signal strength and quality that the cable can deliver.

2. Attenuation: Attenuation refers to the amount of signal loss that occurs as the signal travels through the cable. Lower attenuation is generally better, as it means the signal can travel further without losing quality.

3. Capacitance: Coaxial cables have a specific capacitance, which affects how much energy the cable can store and how quickly it can release it. This can impact the quality and strength of the signal.

4. Velocity of propagation: The velocity of propagation refers to how quickly the signal travels through the cable. The higher the velocity of propagation, the faster the signal can travel.

5. Shielding: Coaxial cables need to be shielded to protect the signal from interference. The type and quality of shielding can vary between different coaxial cable manufacturers.

6. Environmental resistance: Coaxial cables need to be able to withstand exposure to different weather conditions, UV radiation, and other environmental factors. This is an important consideration for manufacturers who need to ensure their cables can be used in a variety of settings.

Overall, coaxial cable manufacturers need to carefully balance these technical parameters to create a cable that is reliable, high-quality, and suitable for a range of applications.

List Product features of “coaxial cable manufacturer”

Coaxial cable manufacturers produce a type of cable transmission that is used widely in various settings, mostly in radio and television broadcasting, as well as in computers and other electronics. Here are some of the essential features of coaxial cable manufacturers:

1. Durability: Coaxial cable manufacturers use high-quality materials that make their products highly durable. They are designed to withstand harsh weather conditions, impacts, and interference.

2. Signal attenuation: The cable should have low attenuation to ensure that there is minimal signal loss as it travels through the cable. This feature helps to maintain the integrity of the signal and prevents it from distorting as it moves from the transmitter to the receiver.

3. Frequency range: Coaxial cable manufacturers produce cables with a broad range of frequencies, which allows them to be used for different applications depending on the signal requirements. Some coaxial cables can transmit signals with frequencies as high as 10 GHz.

4. Shielding: Manufacturers provide various shielding options to protect the signal from outside interference. Coaxial cables have a metallic shielding layer that prevents interference from outside EMF frequencies.

5. Connectors: A variety of connectors are available with coaxial cables to ensure that they are versatile and can be used in different settings. Connectors include BNC, F-type, and SMA connectors.

6. Weight and length: Manufacturers produce cables in a range of sizes with varying lengths, depending on the application. This feature allows users to choose the appropriate length and size of the cable to fit their needs.

7. Price: The cost of coaxial cables varies depending on the manufacturer and the product’s features. However, most manufacturers offer affordable options to meet different budgets.

8. Compatibility: Coaxial cables are compatible with most electronic devices, making them a versatile option for transmitting signals.

Coaxial cable manufacturers provide a variety of features that make their products durable, versatile, and suitable for different applications. The cables’ reliability is one of the reasons they are widely used in

List Application of “coaxial cable manufacturer”

1. Broadcasting and Transmission Systems: Coaxial cables play a critical role in broadcasting and transmission systems, which are used to transmit audio, video, and data signals over long distances. As a result, coaxial cables are extensively used in radio and television broadcasting, telecommunications, and satellite communication systems. Cable manufacturers may produce specialized coaxial cables for specific applications, such as low-loss and high-frequency cables for high-definition television systems or broadband internet service providers.

2. Security and Surveillance Systems: Coaxial cables are commonly used in security and surveillance systems to distribute video signals from cameras to recording equipment, monitors, and control rooms. Cable manufacturers may produce specialized cables with extra shielding or insulation to withstand harsh outdoor conditions or high-voltage power lines.

3. Medical Equipment: Coaxial cables are used in a variety of medical equipment, such as magnetic resonance imaging (MRI) machines, computed tomography (CT) scanners, and ultrasound machines. Cable manufacturers may produce specialized coaxial cables that are non-magnetic or non-conductive, making them safe for use in these sensitive medical devices.

4. Aerospace and Military Applications: Coaxial cables are extensively used in aerospace and military applications, such as aircraft communication systems, radar systems, and missile guidance systems. Cable manufacturers may produce specialized cables with high-temperature resistance and low signal loss to meet the stringent requirements of these applications.

5. Industrial Automation: Coaxial cables are used in industrial automation applications, such as factory automation systems and process control systems. Cable manufacturers may produce specialized cables that are resistant to chemicals, moisture, and other environmental factors, making them suitable for use in harsh industrial environments.

6. Consumer Electronics: Coaxial cables are commonly used in consumer electronics, such as televisions, DVD players, and home theater systems. Cable manufacturers may produce low-cost, high-quality coaxial cables for use in these applications.

7. Computer Networks: Coaxial cables are used in computer networks to connect computers and other network devices to

List Various Types of “coaxial cable manufacturer”

Coaxial cable is a type of cable that is used to transmit radio frequencies from one point to another. There are multiple types of coaxial cable manufacturers in the market that produce cables for specific applications.

1. RG Cable Manufacturers: RG stands for Radio Guide and refers to a family of cables that are used in low-power communication applications. RG cables are available in different variants; each has a specific characteristic impedance, shielding, and frequency range to suit different requirements. RG6 and RG11 are the most common types of cables used for cable television.

2. Semi-Rigid Coaxial Cable Manufacturers: Semi-rigid coaxial cables have a solid outer conductor and a copper or copper-clad steel inner conductor. The solid outer conductor gives the cable its stability, and the inner conductor carries the signal. Semi-rigid cables are used in applications where precise routing and positioning of the cable is required.

3. Flexible Coaxial Cable Manufacturers: Flexible coaxial cables use a stranded inner conductor and a braided outer conductor to provide flexibility. They are used in applications where the cable needs to be bent or flexed. RG174 is the most commonly used flexible coaxial cable for low-power applications.

4. Triaxial Cable Manufacturers: Triaxial cable is a type of cable that has three concentric conductors. The inner conductor carries the signal, the outer conductor provides shielding, and the middle conductor provides additional shielding. This cable is used in applications where high-frequency signals are required to be transmitted with minimal interference.

5. Twinaxial Cable Manufacturers: Twinaxial cable has two conductors that run parallel to each other. The conductors are separated by a dielectric material and a shield. Twinaxial cable is used in applications where high-speed data transfer is required, such as computer networking.

In conclusion, there are several types of coaxial cable manufacturers in the market. They produce cables that are used in various applications, and each cable has its specific characteristics. Understanding the different

List “coaxial cable manufacturer” FAQ

1. What is coaxial cable?

Coaxial cable is a type of wire that consists of a central conductor surrounded by an insulating layer and a shield layer. It is commonly used in cable television, internet, and other communication systems to transmit high-frequency signals.

2. What are the benefits of using coaxial cable?

Coaxial cable is known for its high bandwidth and low signal loss, making it ideal for transmitting digital and high-definition signals over long distances. It also provides great shielding from electromagnetic interference, ensuring a clear and reliable signal.

3. What types of coaxial cables are available?

There are various types of coaxial cables available in the market, each designed to handle different frequencies, power levels, and applications. Some common types include RG-6, RG-11, RG-59, and LMR-400.

4. What factors should I consider when selecting a coaxial cable?

Factors to consider when selecting a coaxial cable include the frequency range, power rating, impedance, attenuation, shielding, and connector type. It is important to choose a cable that is compatible with your equipment and can handle the required signal strength and transmission distance.

5. How do I install coaxial cable?

Coaxial cable installation involves connecting the cable to your equipment and running it through your walls or ceilings, if necessary, to reach your desired location. It is important to follow proper installation guidelines to ensure a high-quality and safe installation.

6. How can I maintain my coaxial cable?

Regular maintenance of your coaxial cable involves checking for damage or wear on the cable and its connectors, and cleaning any dust or debris. If you notice any issues, it is important to repair or replace the cable as soon as possible to avoid signal degradation or failure.

7. What other services do coaxial cable manufacturers offer?

In addition to manufacturing and distributing coaxial cables, many manufacturers also offer custom cable assemblies, engineering consulting, and testing and certification services. These additional services can help

List The Evolution history of “coaxial cable manufacturer”

The evolution of coaxial cable manufacturing began in the early 1920s when Lloyd Espenschied and Herman Affel of Bell Labs invented the coaxial cable for use in telephone communication. By the 1950s and 1960s, coaxial cables were used for television broadcasting and military communication systems, and manufacturers began to produce these cables in large quantities.

In the late 1970s, the development of high-speed data transmission for computer networks led to the creation of improved coaxial cables with higher bandwidths and lower signal loss. Manufacturers such as Belden, CommScope and Times Microwave emerged as leaders in the coaxial cable industry, offering a range of cables with varying properties to meet different requirements.

In the 1990s, advancements in digital technology led to the creation of digital coaxial cables capable of transmitting high-quality audio and video signals. Manufacturers such as Monster Cable and AudioQuest entered the market, offering specialty high-end cables for home theater and entertainment systems.

With the rise of the internet and broadband communication, the demand for high-speed data transmission increased, leading to the development of coaxial cables with even higher bandwidths such as the RG-6 and RG-11. Manufacturers also began to produce hybrid cables for use in complex telecom and data communication systems.

Currently, the coaxial cable industry continues to evolve with the demands of technology, offering cables with increasingly higher capacities, improved resistance to interference, and more cost-effective production methods. The use of fiber optic cables for long-distance data transmission has also impacted the industry, but coaxial cables remain prevalent in many applications due to their reliability, durability and cost-effectiveness.

List The Process of “coaxial cable manufacturer”

The process of coaxial cable manufacturing starts with gathering the raw materials. These include a copper or aluminum core for the conductor and a dielectric material, which is usually made of foamed polyethylene.

Once the materials are gathered, the first step is to prepare the core wire. This is done by drawing a thick strand of copper or aluminum through a series of dies to reduce its diameter to the required size. The wire is then annealed in an oven to make it more pliable.

After the core wire is prepared, the next step is to apply the dielectric material. This is accomplished by extruding the foam polyethylene onto the core using a specially designed machine. The extrusion process ensures that the dielectric material is evenly distributed around the core wire.

Next, a metallic shield is added to provide protection against electromagnetic interference. This can be done by either wrapping the cable with a thin layer of foil or braiding it with a layer of copper wire. The shield is connected to a ground wire which runs parallel to the conductor.

Finally, a durable sheath is added to protect the cable from damage during installation and use. This sheath is usually made of PVC or another type of plastic material. The finished cable is then coiled onto spools and tested for electrical conductivity and durability.

In conclusion, the manufacture of coaxial cable involves several steps starting from raw materials to the finished product. The process includes preparing the core wire, applying the dielectric material, adding a metallic shield, and applying the final sheath to protect the cable from damage. The cable is then tested for quality before it is packaged and shipped to customers.

List Properties of “coaxial cable manufacturer”

Coaxial cable manufacturer is a business that specializes in producing coaxial cables. Coaxial cables are cables that are designed to transmit data signals and are commonly used in telecommunications, television, and computer networking.

The properties of a coaxial cable manufacturer are as follows:

1. Quality: As a manufacturer of coaxial cables, the quality of the product is paramount. The cables must be constructed to meet the highest standards of quality to ensure that they are durable and reliable.

2. Range of Products: A good coaxial cable manufacturer will offer a wide range of products to cater to the varying needs of the market. The range of products will depend on the needs of the customer, as well as the technological trends of the time.

3. Technical Expertise: A good coaxial cable manufacturer will be staffed by experts who have a thorough understanding of the technology behind the cables. These experts will be able to provide valuable advice to customers regarding the best types of cables to use for their specific needs.

4. Competitive Pricing: A good coaxial cable manufacturer will offer competitive pricing to its customers. This means that the prices will be affordable but still reflect the quality of the product.

5. Customer Service: A good coaxial cable manufacturer will provide excellent customer service. They will be committed to providing their customers with the best possible experience and will be responsive to any inquiries or requests.

In conclusion, a good coaxial cable manufacturer is one that offers quality products, a wide range of products, technical expertise, competitive pricing, and excellent customer service.

List Knowledge about “coaxial cable manufacturer”

A coaxial cable manufacturer is a company that specializes in producing coaxial cables, which are specialized cables that are used mostly for telecommunication and cable TV industries. Coaxial cables are designed to carry radio frequency signals with low signal loss over a long distance. These cables have a hollow center conductor and an outer conductor that surrounds it. The two elements are separated by an insulating layer and covered with a protective sheath.

Coaxial cable manufacturers produce these cables in different types, including RG6, RG11, and RG59. RG6 cables are the most commonly used coaxial cables, while RG11 cables are used for longer distances, and RG59 cables are used for short distances. These cables are made from copper or aluminum with insulating materials that can withstand extreme temperatures and environmental conditions.

Coaxial cable manufacturers use advanced technologies to produce high-quality cables. They design the cables to meet specific requirements of their clients, which can be customized in terms of cable length, diameter, shielding, and insulation. The cables must meet strict standards and regulations set forth by industry associations like the National Electrical Manufacturers Association (NEMA) and the International Electrotechnical Commission (IEC).

Manufacturers employ different production techniques to produce these cables, including extrusion, lamination, braiding, and testing. The production process can involve multiple stages of quality control and testing to ensure that the final product meets industry standards.

In conclusion, coaxial cable manufacturers play a critical role in the telecommunication and cable TV industry by providing high-quality and reliable cables that transmit signals over long distances. They use advanced production techniques and adhere to strict regulations to produce top-grade coaxial cables that meet the demands of their clients.

How to use “coaxial cable manufacturer”

A coaxial cable manufacturer is a company that specializes in producing coaxial cables, which are used to transmit signals in a variety of applications, such as telecommunications, cable television, and internet connectivity. The coaxial cable is a type of high-frequency transmission line that consists of a central conductor, surrounded by a dielectric insulating layer, and an outer shield or conductor. The coaxial design allows for low signal attenuation, high bandwidth, and shielding from electromagnetic interference.

To use a coaxial cable manufacturer, a consumer or user typically makes an order based on the specific application and required cable specifications. The manufacturer then produces the required length, diameter, and impedance of the cable, selecting materials that meet the required standards and regulations. Quality control is an essential aspect of the production process to ensure that the cables meet the required electrical and mechanical properties. Most coaxial cable manufacturers have a range of products with varying characteristics and features to cater to different applications.

Coaxial cable manufacturers typically use advanced manufacturing technologies, such as high-speed extrusion, laser marking, and automated testing to optimize their production processes. This helps to reduce costs and improve the efficiency of the production line, as well as ensuring consistent quality across different batches. Some manufacturers offer customized cables and products based on specific requirements, such as color coding or unique connectors. Coaxial cable manufacturers also provide technical support and guidance to help customers select the right products for their applications.

In conclusion, the use of a coaxial cable manufacturer is essential when looking for cables to use in various applications, whether in telecommunications or cable television. Manufacturers, through the use of advanced technologies, provide a range of products with varying characteristics to meet different requirements. They also offer technical support to help customers make informed decisions when selecting products for their applications.

Terms “coaxial cable manufacturer”

A coaxial cable is a type of cable that is used in telecommunications and broadcasting to transmit radio-frequency signals. These cables consist of a central conductor wire that is surrounded by a layer of insulation and a shielding layer. The shielding layer consists of a braided copper wire that provides protection against electromagnetic interference. Coaxial cables are widely used in a variety of applications, including cable TV, internet, and telephone systems.

As the demand for high-speed data transfer and better connectivity is increasing, the need for high-quality coaxial cables is also growing. To meet this demand, there are many coaxial cable manufacturers around the world. These manufacturers specialize in producing high-quality, reliable, and durable coaxial cables that can provide the required data transfer speed and attenuation.

Coaxial cable manufacturers use advanced technologies and materials to produce cables with high-quality performance. They also follow international standards and safety regulations to ensure their products meet the required specifications. Additionally, some manufacturers go the extra mile to provide customized coaxial cables to their customers according to their unique requirements.

To produce high-quality coaxial cables, manufacturers use specialized equipment and machinery that are capable of accurately measuring the electrical properties of the cable. They also conduct regular testing and quality control checks to ensure that their products meet the required standards. Moreover, some manufacturers offer warranties and after-sales services to their customers to ensure their satisfaction and loyalty.

In conclusion, coaxial cable manufacturers play a vital role in ensuring reliable and efficient data transfer in various industries. They produce high-quality coaxial cables that are used in communication systems and are essential for transmitting radio-frequency signals. By investing in advanced technology, materials, and quality control, coaxial cable manufacturers are providing their customers with high-performance and durable cables that meet their specific needs.

FAQ

Q: What is a coaxial cable?

A: A coaxial cable is a type of cable that is used for transmitting radio frequency signals.

Q: What are the benefits of using a coaxial cable?

A: Coaxial cables provide reliable and fast transmission of data, reduces signal interference and noise, can handle high frequency signals and are suitable for different applications and industries.

Q: What is the difference between 50 Ohms and 75 Ohms coaxial cable?

A: 50 Ohms coaxial cables are typically used for data communications and industrial applications, while 75 Ohms is used for video and audio applications.

Q: What is the frequency range of a coaxial cable?

A: The frequency range can vary depending on the type of coaxial cable, but can handle high frequencies up to 6 GHz.

Q: Who typically uses coaxial cables?

A: Coaxial cables are used in various industries such as telecommunications, broadcast, medical equipment, aerospace and military, and home and office networking.

Related products

Copper Alloys

Copper Alloys

Metal CNC Tools Vavle Pump

Metal CNC Tools Vavle Pump

Copper Alloys

Copper Alloys

Metal CNC Tools Vavle Pump

bolt manufacturer Manufacturing from China for importer customize design, wholesale

©2023. sourcifychina.com All Rights Reserved.

-

- Home

- Retail Cheap Shop

- Wholesale Featured Pro

- Industries

- List

- Our China Suppliers list

- Auto Parts Suppliers

- Packaging Solution

- Stainless Steel Suppliers

- Steel Pipe Suppliers

- Solar Inverter China

- cable manufacturing

- cnc machining China

- Apparel and Accessories

- fabric manufacturing

- Machinery

- pump China

- Screw

- wigs custom

- valves manufacturing

- hair system custom

- heated gloves wholesale

- indoor lighting fixtures

- solor panel wholesale

- snow boots factory

- Products

- Manufacturing

- Guide

- Apparel / Fashion Accessories

- CNC Tools Valve Pump Parts

- Machinery China Equiment Sourcing Guide

- aac block manufacturers

- acrylic cutting machine

- automatic packing machine

- Auxiliary Equipment

- blister packing machine

- bricks manufacturing

- clay brick making machine

- feed pellet machine

- fly ash bricks machine sourcing guide

- paper bag making machine

- pellet machine

- plastic crusher machine

- pouchpacking machine

- stamping machine

- wood pellet machine

- Outdoor Sports

- Others Sourcing Guide

- FAQ

- About

- Contact

- Login

- Newsletter

- [email protected] whatsapp 8615951276160

- 供应商

Login

- →

- WeChat: 8615951276160