Benefits of Bottle Filling And Capping Machine

Bottle filling and capping machines are becoming increasingly popular in the manufacturing industry due to its many benefits.

First, these automated machines provide a faster production rate and higher efficiency than manual labor. They are designed to fill, cap and label bottles all in one streamlined process, eliminating the need for multiple steps and handling. This not only saves time but also reduces the chances of errors and inconsistencies in the production process.

Second, bottle filling and capping machines are incredibly accurate and precise, ensuring that each bottle is filled to the correct level and capped tightly. This helps to maintain the product’s integrity and quality, and reduces the likelihood of spills and leaks during transportation and storage.

Third, these machines help to reduce labor costs as there is no need for manual labor to oversee the filling and capping processes. This means that employees can be assigned to other tasks that require attention, thereby increasing productivity and profitability.

Fourth, bottle filling and capping machines are perfect for businesses that require a high level of hygiene and cleanliness. The machines are easy to clean and maintain, and there is less risk of contamination from human contact.

Finally, these automated machines are customizable and can be adjusted to meet the specific needs of a business. For instance, some machines can handle different types of bottles and products, including liquids, powders, and granules. This allows manufacturers to diversify their product lines and reach a wider range of customers.

In conclusion, bottle filling and capping machines offer many benefits to businesses, including increased efficiency, accuracy, hygiene, and versatility. Investing in this technology can lead to increased productivity, reduced labor costs, and higher profits.

Features of Bottle Filling And Capping Machine

Bottle filling and capping machines are used in various industries including pharmaceutical, food, and beverage to automate filling and capping processes. These machines enhance efficiency, reduce labor costs and improve product quality. Here are some features that make bottle filling and capping machines stand out:

1. Versatility

Bottle filling and capping machines can handle different bottle sizes, shapes, and materials. Whether it is plastic, glass, or aluminum bottles, the machine can fill and cap them effectively. This makes the machines ideal for production lines that handle multiple products that require different bottle types and sizes.

2. High Production Capacity

The machines have a high production capacity, filling and capping several bottles per minute. This means that industries that handle high production volumes can rely on these machines to fast-track their operations.

3. Accurate Filling

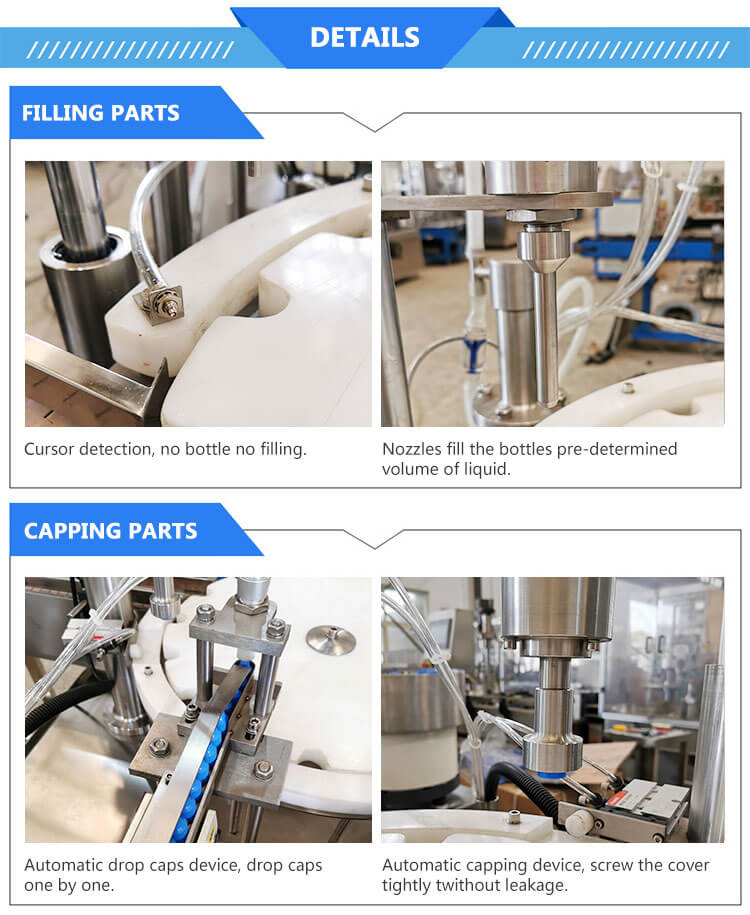

Filling accuracy is a crucial factor in production. Bottle filling and capping machines can accurately fill bottles by using volumetric or gravimetric filling methods. This ensures that the product quantities are uniform, maintaining consistency in size and product quality.

4. Automatic Capping

Capping bottles manually is tedious and laborious. Bottle filling and capping machines use automatic capping technology that ensures bottles are tightly sealed. This not only saves time, but also improves the quality of bottled products by preventing leakages and contamination.

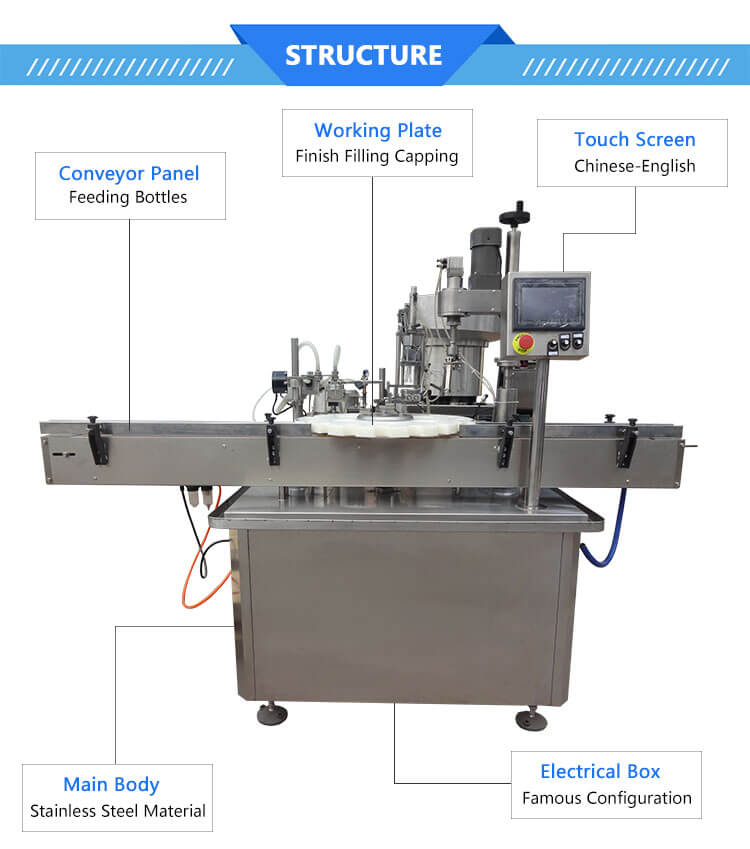

5. Customizable Controls

Modern bottle filling and capping machines have user-friendly interfaces that allow operators to configure filling, capping, and cleaning functions. The controls are customizable, which means they can be adjusted to meet specific production needs. This makes the machines easy to operate, reducing the likelihood of errors.

6. Durability

Bottle filling and capping machines are typically made of high-quality materials that are resistant to wear and tear, ensuring longevity. This makes them ideal for heavy-duty operations in industries with high production volumes.

In conclusion, bottle filling and capping machines are an essential component of modern-day production lines. They provide accuracy, high production capacity, and versatility. These features allow businesses to enhance their efficiency and reduce production costs, resulting in improved profitability.

Various Types of Bottle Filling And Capping Machine

Bottle filling and capping machines are used in various industries for packaging purposes. These machines come in different types depending on the product, bottle size, and production capacity. Here are some of the various types of bottle filling and capping machines:

1. Gravity filling machine – This machine is used for filling free-flowing liquids such as water, juice, and wine. It operates by filling the bottle from the bottom up, using gravity to allow the liquid to flow into the bottle.

2. Overflow filling machine – This machine is ideal for filling foamy and viscous liquids such as soap, shampoo, and other personal care products. It works by filling the bottle to a specific level, and any overflow is directed back to the holding tank.

3. Piston filling machine – This machine is suitable for filling thick and viscous products such as sauces, cream, and honey. It uses a piston to draw the product from the holding tank, and then it dispenses it into the bottle.

4. Auger filling machine – This machine is used for filling powders, granules, and other dry products such as spices, baking mixes, and coffee. It uses an auger to dispense the product into the bottle.

5. Capping machine – This machine is used for sealing the bottles after they have been filled. There are different types of capping machines such as screw capping machines, snap-on capping machines, and crimping machines. Screw capping machines are used for bottles with screw caps, snap-on capping machines are used for bottles with snap-on caps, while crimping machines are used for bottles with crimped caps.

In summary, the type of bottle filling and capping machine used depends on the product, bottle size, and production capacity. Each machine operates differently, ensuring product efficiency and quality. Choosing the right type of filling and capping machine will help increase production capacity and improve product quality.

Applications of Bottle Filling And Capping Machine

Bottle filling and capping machines are used extensively in the food and beverage industry, pharmaceuticals, and consumer goods industries to package liquid products. These machines have been designed to automate the process of filling, capping, and labelling bottles, thereby increasing efficiency and accuracy while reducing waste.

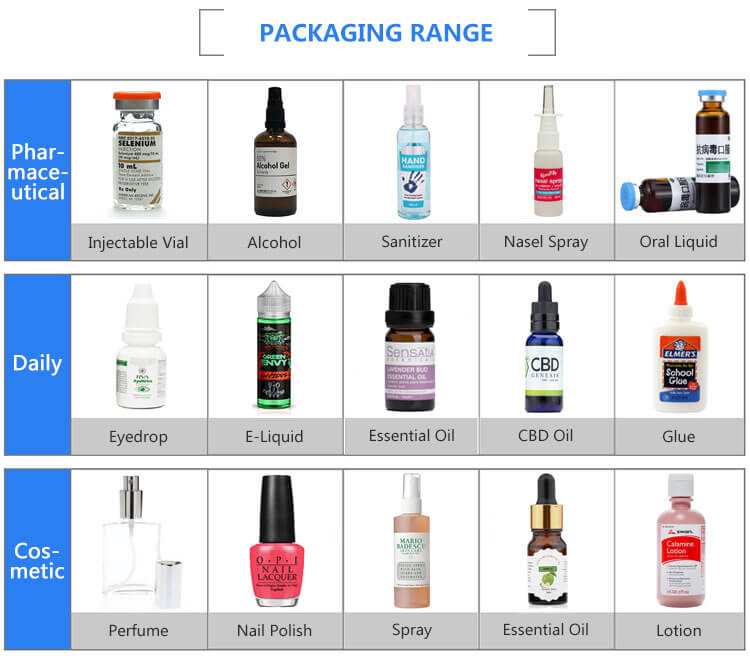

One of the most common applications of bottle filling and capping machines is in the food and beverage industry. Manufacturers of soft drinks, juices, and other drinks rely on these devices to fill bottles with precise quantities of their products. The machines can handle different bottle sizes and shapes, as well as different types of caps, including metal and plastic screw caps, snap-on lids, and cork stoppers.

Another application of bottle filling and capping machines is in the pharmaceutical industry. Manufacturers of medicines, syrups, and other liquid products use these machines to fill bottles with doses of the products. The machines can also seal the containers with tamper-evident caps to ensure they remain sterile and prevent contamination.

Bottle filling and capping machines are also used in the cosmetic industry to package a range of products such as shampoos, conditioners, essential oils, and serums. The machines can fill a range of different containers such as jars, bottles, and tubes, and can apply various types of caps and labels to the products.

Finally, bottle filling and capping machines are also used in the household and cleaning product industry. These machines can fill and cap bottles with detergents, fabric softeners, and other cleaning and household products. The machines are designed to handle viscous and abrasive products and can fill a wide range of bottle sizes and shapes.

In conclusion, the applications of bottle filling and capping machines are vast and varied. These machines are essential in many industries, such as food, pharmaceuticals, cosmetics, and household products, where they help manufacturers to increase efficiency, accuracy, and productivity. Investing in a bottle filling and capping machine is undoubtedly a wise decision for any business looking to streamline their operations and improve their bottom line.

The Process of Bottle Filling And Capping Machine

The process of bottle filling and capping machine entails filling bottles with the desired liquid content, securely capping them and then preparing them for packaging.

The first step of the process is to clean and sanitize the bottles to ensure that they are clean and free of any contaminants. After this, the bottles are loaded onto the filling machine, and the liquid is added through a filling nozzle. The nozzle is designed to fill each bottle to the correct level, avoiding overfilling or spillage.

Once the liquid has been added to the bottles, they are moved to the capping machine. The capping machine has a cap feeder that automatically supplies the caps to the machine. The capping machine then places the caps onto the bottles and secures them tightly.

After the bottles have been filled and capped, they are moved to the next stage where they are labeled and packaged. The labeling process ensures that each bottle has the correct product information, including ingredients, weight, and company details, among others.

The packaged bottles are then prepared for shipping, either to retail stores or to the consumer directly. The process of bottle filling and capping machine is essential in industries such as food, beverages, pharmaceuticals, and cosmetics, among others. It provides an efficient and accurate way of filling and packaging products, saving time and resources.

In conclusion, the process of bottle filling and capping machine is a critical part of the production process in various industries. Modern filling and capping machines are designed to be efficient, accurate, and easy to use, making production more cost-effective, and ensuring that products are delivered to the market in the best possible condition.

How to use Bottle Filling And Capping Machine

Bottle filling and capping machines are essential equipment for companies that engage in mass production of bottled products such as beverages, pharmaceuticals, and cosmetics. These machines are designed to efficiently fill and cap bottles to keep up with the demand for products. It is important to know how to operate the machine to optimize its efficiency and maintain the quality of the products.

To use a bottle filling and capping machine, first, ensure that the machine is clean and free from any debris. Next, turn on the machine and adjust the settings to the required product specifications such as the fill level, filling speed, and cap tightness.

Once the machine is set up, prepare the bottles by placing them on the conveyor belt, making sure that they are aligned and positioned in the right direction. The bottles will be filled as they move along the conveyor belt, and every bottle will be capped as it passes through the capping section.

It is important to pay close attention to the machine during operation to ensure that everything runs smoothly. Check the filling level and adjust as needed to avoid spillage or under-filling. Also, monitor the capping process to make sure that the caps are tightened correctly and securely. Any issues should be addressed immediately to maintain the quality of the products and prevent any potential hazards.

After the filling and capping process is complete, the bottles can then be labeled and packaged for distribution.

In conclusion, bottle filling and capping machines are essential tools for mass production. By following these simple steps, users can effectively operate the machine, maintain the quality of products, and improve production efficiency.

Selecting the Ideal Manufacturer Bottle Filling And Capping Machine

Choosing the right bottle filling and capping machine can be a challenging task, given the numerous manufacturers and vendors in the market. However, selecting the ideal one can streamline your production process, increase efficiency, and boost productivity. Here are some tips to help you choose the best one for your business.

First, consider the type of bottle and product you want to fill. Different machines are designed for different types of bottles, from plastic to glass, and different products, from liquid to viscous substances. Be sure to choose a machine that is compatible with your product and bottle type.

Second, consider the capacity of the machine. Depending on your production demand, you may need a machine with a high output rate to ensure smooth and efficient production. However, selecting a machine that is too big for your production line may incur unnecessary expenses and decrease efficiency.

Third, look for features that will streamline your production process. For instance, some machines come with automatic filling and capping options, which eliminates the need for manual labour and reduces the risk of contamination. Moreover, other machines come with features like liquid level detection, which ensure consistent and accurate filling.

Fourth, consider the after-sales service and support provided by the manufacturer. Ensure that the vendor offers installation, maintenance, and repair services whenever necessary. A manufacturer with a reliable support system can guarantee quick solutions to any technical or mechanical issues that may arise.

Finally, compare prices and research the reputation of the manufacturer before making a purchase. Select a manufacturer with a proven track record of delivering quality products, reliable support, and competitive pricing.

In conclusion, choosing the ideal bottle filling and capping machine requires careful consideration of several factors, including the type of bottle and product, capacity, features, after-sales support, and pricing. With these tips, you can streamline your production process and boost productivity.

list FAQ with answer about Bottle Filling And Capping Machine

Bottle Filling And Capping Machine is a revolutionary invention that has been instrumental in the packaging industry. This machine is capable of filling and capping bottles in a matter of seconds. However, there are some common questions and issues that people face while using it. Here is a list of FAQs with answers about Bottle Filling And Capping Machine.

Q. How does the Bottle Filling And Capping Machine work?

A. The machine fills bottles with the desired liquid or product and then caps them securely to prevent leakage.

Q. Can the machine fill both plastic and glass bottles?

A. Yes, the machine is designed to fill both plastic and glass bottles.

Q. What types of liquids or products can the machine fill?

A. The machine can fill a wide range of liquids and products, including water, juice, soda, milk, and other beverages.

Q. Can the machine fill bottles of different sizes?

A. Yes, the machine can fill bottles of different sizes and shapes.

Q. How many bottles can the machine fill per minute?

A. The filling speed of the machine depends on the size of the bottles and the type of liquid being filled. On average, the machine can fill between 30 to 120 bottles per minute.

Q. Can the machine handle hot liquids?

A. Yes, the machine is designed to handle hot liquids up to 90 degrees Celsius.

Q. How often does the machine need maintenance?

A. The machine needs to be serviced regularly to ensure its optimal performance. The maintenance schedule varies based on the frequency of use, but typically, it needs to be serviced at least once a year.

Q. Can the machine be customized to fit specific requirements?

A. Yes, the machine can be customized to fit specific requirements, such as filling and capping different types of bottles, filling a specific volume of liquid, or adding additional features.

In summary, the Bottle Filling And Capping Machine is a versatile and efficient machine that can fulfill multiple packaging needs. Understanding its operation and maintenance requirements can help ensure its optimal performance for a long time.

Things to Consider When Purchasing Bottle Filling And Capping Machine

When purchasing a bottle filling and capping machine, there are several factors that must be considered. These factors will help ensure that you purchase a machine that fits your specific needs and that will provide reliable operation for years to come.

One of the main things to consider is the type of bottles that will be filled and capped. This will determine the size and shape of the machine that you need. Different types of bottles require different types of filling heads and capping mechanisms, so it is important to choose a machine that is specifically designed for the types of bottles that you will be using.

Another important factor to consider is the speed and capacity of the machine. This will depend on the volume of production that you need to achieve. If your production needs are high, you will need a machine that can handle high speeds and large volumes of bottles. However, if your production needs are lower, you may be able to opt for a smaller, less expensive machine.

The materials of the machine must also be taken into account. The machine should be made of high-quality materials that are durable and easy to clean. Stainless steel is a popular choice as it is resistant to corrosion and can be easily cleaned and sanitized.

Ease of use and maintenance is another consideration. The machine should be easy to operate and maintain, with clear instructions and easy access to all parts that may need to be serviced or replaced.

Finally, cost is always a factor when purchasing any piece of equipment. The cost of the machine should be weighed against its features and capabilities, as well as your budget and production needs.

In conclusion, when purchasing a bottle filling and capping machine, it is important to consider the type of bottles, speed and capacity, materials, ease of use and maintenance, and cost. By taking all of these factors into account, you can choose a machine that is specifically tailored to your needs and will provide reliable operation for many years.

Properties of Bottle Filling And Capping Machine

Bottle filling and capping machine is one of the most essential equipment in the beverage and pharmaceutical industries. This machine efficiently fills and closes bottles of different sizes and shapes with liquids, pharmaceuticals, or even powders according to their requirements. The properties of bottle filling and capping machine are discussed below.

One of the essential properties of bottle filling machines is their versatility. These machines can fill and cap bottles of different shapes and sizes ranging from small plastic bottles to large glass bottles. They can fill bottles with products such as beverages, oils, chemicals, and even powders, with high precision and speed.

Another property is the high level of automation incorporated into these machines. Most bottle filling and capping machines are computer-controlled, making it very easy to operate and control the filling and capping processes. Also, they are designed to run for long hours without the need for much human intervention, thus reducing labor costs.

Bottle filling and capping machines are also designed to operate at a high speed, thereby increasing production efficiency. They can fill thousands of bottles per hour without compromising on precision and accuracy. The capping process is seamless, and with the help of various sensing technologies, the machine can detect errors like overfilled or underfilled bottles, so that the capping process can either be adjusted or aborted entirely.

The strength and durability of the machine is another significant property. A robust bottle filling and capping machine should be able to withstand the rigorous demands that come with the industrial operating environment. The materials used in their construction should be capable of withstanding high-speed operations and harsh chemical environments.

In conclusion, bottle filling and capping machines are significant investments in the pharmaceutical and beverage industries. They are versatile, have high automation levels, operate at high speeds, and also have a high level of durability. Therefore, companies in these industries should ensure they purchase the appropriate machines that meet their production requirements.

Technical Parameters Terms for Bottle Filling And Capping Machine

The bottle filling and capping machine is a widely used machine in various industries, including the beverage industry. Understanding the technical parameters terms for this machine is critical in purchasing, operating, and maintaining it.

The first parameter to consider is the filling volume, which refers to the amount of liquid that the machine can dispense into a bottle at a time. The filling volume is usually measured in milliliters or liters and is determined by the size of the bottle and the type of liquid being filled.

The filling speed is another important technical parameter that determines the number of bottles that the machine can fill in a given time. The filling speed is measured in bottles per minute (BPM) and varies depending on the machine model.

The filling accuracy measures the precision with which the machine can fill the bottles. The accuracy is usually expressed as a percentage of the actual filling volume, and a high level of accuracy is essential for ensuring product quality and consistency.

The bottle diameter and height are also critical technical parameters that determine the compatibility of the bottle with the machine. The machine must be designed to accommodate different bottle sizes and shapes, as well as handle bottles made from different materials such as glass, plastic or metal.

The capping speed and accuracy are other technical parameters that are essential in the bottle filling and capping machine. The capping speed is the number of bottles that the machine can cap in a given time, while the capping accuracy is the precision with which the caps are applied to the bottles. These parameters vary depending on the type of cap being used, e.g. screw caps, snap caps, or twist-off caps.

In summary, understanding the technical parameters terms for bottle filling and capping machines is crucial in optimizing their performance and productivity. Investing in a machine that meets your specific needs guarantees the production of high-quality products while minimizing waste and downtime.

Bottle Filling And Capping Machine Price

Bottle filling and capping machines are essential equipment to have in any beverage or food processing plant. These machines help manufacturers fill and seal bottles quickly and efficiently, saving a considerable amount of time and labor. The price of a bottle filling and capping machine varies depending on factors such as the type of machine, size, and features.

There are different types of bottle filling and capping machines available in the market, including tabletop, automatic, and semi-automatic machines. Tabletop filling machines are smaller in size and are suitable for small-scale production. They are generally affordable, with prices ranging from $1,000 to $5,000.

Semi-automatic bottle filling and capping machines are designed for medium to large-scale production. These machines are more advanced than tabletop models and offer features such as multiple filling heads, adjustable speed, and automatic capping. The prices for semi-automatic machines range from $5,000 to $20,000, depending on the model and features.

Automatic bottle filling and capping machines are the most advanced and are designed for high-speed production. These machines can fill and cap bottles at a rate of up to 500 bottles per minute, making them ideal for large-scale production. However, they are also the most expensive, with prices ranging from $20,000 to $100,000 or more, depending on the brand and features.

In addition to the type of machine, the size and number of filling heads also affect the price. Machines with multiple filling heads can fill several bottles simultaneously, which increases efficiency and productivity. However, machines with more filling heads are generally more expensive.

In conclusion, the price of a bottle filling and capping machine depends on several factors, including the type, size, and features. It is essential to consider the specific needs of your production plant and budget when selecting a bottle filling and capping machine. Choosing the right machine will help you save time, labor, and ultimately increase your production output.