Bottle Filling Machine Manufacturing for importer customize design supplier

The Bottle Filling Machine is a high-performance, automated filling solution designed to streamline the packaging process for a variety of products. This machine is capable of filling bottles of various sizes and shapes with accuracy and precision, making it an ideal solution for a wide range of industries.

Benefits:

– Increases production efficiency

– Reduces labor costs

– Improves product quality and consistency

– Saves time and reduces the risk of spillage and error

Features:

– Automatic bottle feeding and positioning system

– Adjustable filling volume and speed

– Easy to operate and maintain

– Durable and reliable construction

Applications:

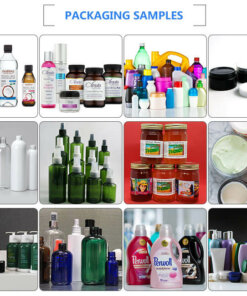

– Food and beverage industry

– Pharmaceutical industry

– Chemical industry

– Cosmetics industry

– Oil and lubricant industry

– And many more

FAQ:

Q: What types of bottles can this machine fill?

A: This machine can fill bottles of various shapes and sizes, including round, square, and rectangular bottles.

Q: Is this machine easy to operate?

A: Yes, the machine is designed to be easy to operate and maintain, with a user-friendly interface and simple controls.

Q: Can this machine fill different products?

A: Yes, the machine can be adjusted to fill different types of products, including liquids, creams, and pastes.

Selling points:

– High efficiency and accuracy

– Versatile and adaptable to different industries and products

– Easy to use and maintain

– Durable and reliable construction

Guides for:

– Installation and setup

– Operation and maintenance

– Troubleshooting and repair

Overall, the Bottle Filling Machine is an essential tool for businesses looking to increase production efficiency, improve product quality, and reduce labor costs. With its versatile capabilities and user-friendly design, this machine is a valuable investment for any industry.

Benefits of Bottle Filling Machine

Bottle filling machines serve as a convenient solution to the packaging needs of businesses across various industries. These machines offer several benefits that have made them a favorite among business owners.

One of the primary benefits of a bottle filling machine is the speed and efficiency it offers. These machines have the capacity to fill a large number of bottles in a relatively short amount of time. This helps businesses increase their production rate and cater to a large number of customers in a shorter period.

Another advantage of bottle filling machines is their accuracy. With precise measurements, businesses can reduce waste and ensure that the exact amount of product is filled in every bottle. This ensures consistent quality and quantity of the product, leading to satisfied customers.

Bottle filling machines also offer improved safety and hygiene. These machines have features that prevent contamination and ensure that the product is filled in a sterile and hygienic environment. This makes them an excellent choice for businesses that work with food, beverages or pharmaceutical products.

Furthermore, bottle filling machines are cost-effective in the long run. These machines automate the filling process, reducing the need for manual labor, which eventually cuts down on operational costs. In addition, the accurate fill settings ensure that there is a minimal amount of wastage, saving the business money in the long term.

Another benefit of bottle filling machines is their versatility. These machines can fill bottles of different shapes and sizes, which makes them an excellent choice for businesses that need to cater to various packaging needs. They can also handle different types of products, such as liquids, powders, and gels.

In conclusion, bottle filling machines offer several benefits to businesses, including increased productivity, improved accuracy, enhanced safety, and hygiene, cost savings and versatility. With these advantages, businesses can streamline their operations, improve their product output, and deliver high-quality products to their customers, leading to customer satisfaction and increased profitability.

Features of Bottle Filling Machine

Bottle filling machines serve a very crucial role in the manufacturing industry by efficiently filling bottles with various products in a matter of seconds. These machines come with several features that make them ideal for different industries. Some of these features are highlighted below.

1. Flexibility

Bottle filling machines have the ability to fill bottles of different shapes and sizes. This allows manufacturers to use the same machine for different products.

2. High speed

Modern bottle filling machines are designed to work at high speeds, filling up to several thousand bottles per hour. This ensures efficient production and reduces downtime.

3. Programmable settings

The machines come with programmable settings that allow manufacturers to set the amount of liquid to be filled in each bottle. The settings can also be adjusted to suit different products and bottle sizes.

4. Automatic capping

Once the bottles are filled, the machine has an automatic capping system that tightens the caps on the bottles. This ensures the bottles are sealed tightly and reduces the chances of leakage.

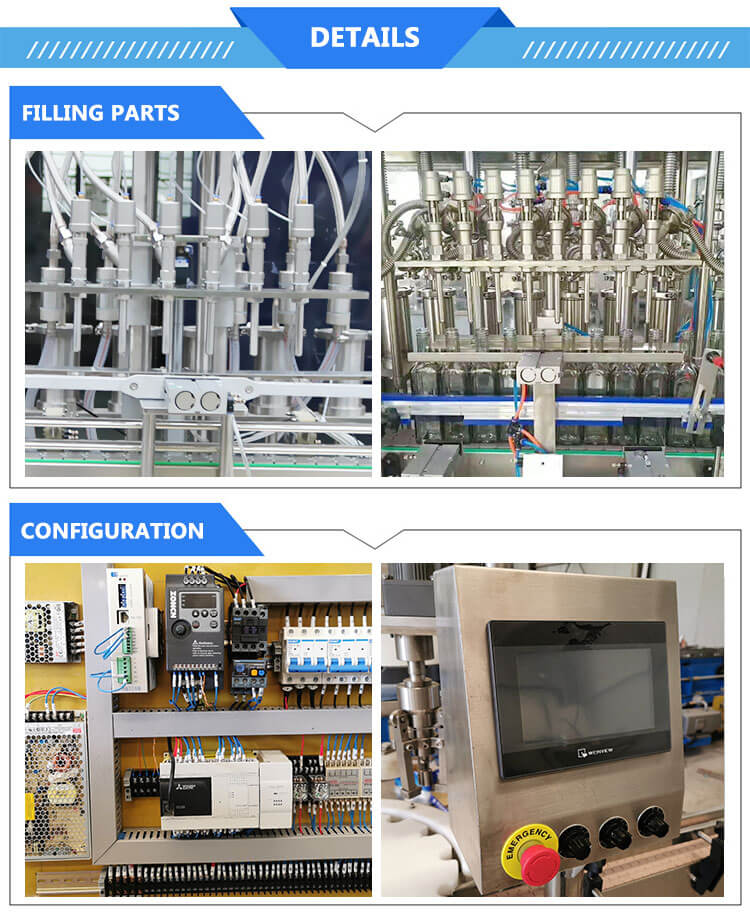

5. Easy to clean

Bottle filling machines are usually made of stainless steel, making them easy to clean and maintain. The design of the machines also makes them easy to disassemble and assemble for cleaning.

6. Energy efficiency

Many modern filling machines are designed to be energy-efficient, reducing the amount of energy used during production. This not only saves on energy costs but also reduces the carbon footprint.

7. Customization

Bottle filling machines can be customized to suit the specific needs of the manufacturer. Customizations may include adding additional filling nozzles, changing the size of the machine or adjusting the capping system.

In conclusion, bottle filling machines have various features that make them efficient and ideal for any production line. These features make bottle filling machines an essential tool for any company that wants to improve the efficiency of its production processes.

Various Types of Bottle Filling Machine

Bottle filling machines are designed to fill liquid products into a variety of container types at high speeds and with high precision. These machines are versatile and come in different types to meet the diverse needs of businesses. In this article, we will discuss various types of bottle filling machines available in the market.

1. Overflow Filling Machine: This type of filling machine works by using a nozzle to overflow a container with liquid until it reaches a predetermined level. This machine is mostly used for filling containers that require precise filling levels.

2. Piston Filling Machine: This type of bottle filling machine uses a piston or cylinder to draw liquid inside the machine and then expel the liquid into the container. It is commonly used for filling viscous liquids and is highly accurate, making it suitable for filling cream, paste, and sauces.

3. Gravity Filling Machine: This type of machine employs gravity to move the liquid from the holding tank to the container. It fills the container in a bottom-up direction and is mostly used for filling non-viscous liquids.

4. Time Gravity Filling Machine: This is a variant of the gravity filling machine. It controls both the flow rate of liquid and the filling time. It is well-suited for filling liquids that have a high foaming nature such as beer or carbonated drinks.

5. Vacuum Filling Machine: The vacuum filling machine works by creating a vacuum in the containers, which draws in the liquid. This type of filling machine is highly efficient and is mostly used for filling sparkling wines and other carbonated drinks.

6. Piston Vacuum Filling Machine: This is a variant of the vacuum filling machine. It uses a piston-cylinder to draw in the liquid and then expel the air before filling the container. It is perfect for filling products with a low fill level such as perfumes and essential oils.

In conclusion, there are several types of bottle filling machine available in the market, each with its unique features and capabilities that meet different industries and applications. Before selecting a bottle filling machine, it is important to consider the filling process speed, level of precision, viscosity of the liquid products, and the type of container to be filled.

Applications of Bottle Filling Machine

Bottle filling machines are widely used in various industries for the efficient filling of bottles with different types of liquids, including pharmaceuticals, beverages, cosmetic products, and chemicals. These machines are designed with a range of automatic and semi-automatic features that facilitate faster filling rates with optimum accuracy and reliability.

One of the most significant benefits of using a bottle filling machine is its ability to save time, manual effort, and money. These machines can easily handle a vast range of bottles with different sizes and shapes, making them a perfect choice for businesses with high production rates.

The pharmaceutical industry uses bottle filling machines to fill medical tablets, capsules, and syrups. These machines are designed with unique features that guarantee the safe and hygienic packaging of medical products. They help pharmaceutical companies improve their overall production process, resulting in a more efficient and cost-effective operation.

In the beverage industry, bottle filling machines help pack a wide range of drinks, including water, juice, soda, and wine. These machines are designed with advanced technology that ensures an accurate amount of liquids is packed in every bottle. They also help businesses reduce their waste production and the cost associated with manual labor.

Cosmetic industries use bottle filling machines to pack various personal care products, such as perfumes, lotions, and creams. These machines are designed with precision and accuracy in mind, ensuring that the products are packed appropriately and hygienically.

Lastly, the chemical industry also uses bottle filling machines for packing different types of chemicals. These machines are designed to handle the hazardous nature of chemicals, ensuring the safety of the workers and the environment.

In conclusion, bottle filling machines are versatile and essential in various industries. They help streamline the production process, increase accuracy and efficiency, reduce waste production, and enhance workplace safety. With the extensive range of bottle filling machines available in the market, businesses can choose the one that best fits their specific needs and requirements.

The Process of Bottle Filling Machine

A bottle filling machine is an essential part of manufacturing and packaging operations. It is a sophisticated machinery system that automates the process of filling various liquids into bottles, jars, and other containers. The filling process is carried out through a series of steps aimed at ensuring the accuracy and efficiency of the process.

The first step in the process is the bottle cleaning, where the bottles are washed with water and then sterilized to ensure that they are free from any contaminants. The sterilization is important to ensure that the products being filled do not get contaminated, which could cause harm to the consumers.

Once the cleaning process is complete, the bottles are transported to the filling unit, where they are filled with the desired liquid. The liquid is pumped into the bottles, and the filling process is monitored to ensure that the correct volume of liquid is dispensed into each bottle.

The next step is the capping process, where the bottles are capped and sealed to ensure that the contents remain safe and secure. The sealing process is also essential to ensure that the bottles do not leak during transportation and storage.

After capping, the bottles are transported to the labeling unit where they are labeled with the necessary information such as the name of the product, ingredients, and expiry dates. The labeling process is important to ensure that the products can be identified by consumers and regulatory authorities.

The final step is the packaging process, where the bottles are packed into boxes, and prepared for shipping. The boxing process is important to ensure that the products are protected during transportation and storage.

In conclusion, the bottle filling machine plays a critical role in ensuring the accuracy and efficiency of the packaging process. The process involves several steps, all of which are aimed at ensuring that the products are safe and meet consumer standards. With the advancement of technology, bottle filling machines have become more sophisticated, ensuring that the process is faster and more efficient.

How to use Bottle Filling Machine

A bottle filling machine is a vital piece of equipment for any business involved in packaging liquid products. It is essential for filling bottles or containers with a product accurately and efficiently. The machine can be used to fill bottles of varying sizes and shapes, including cylindrical, square, and rectangular.

To use a bottle filling machine, first, ensure that it is assembled correctly and all components are in place. Next, determine the appropriate level of product to be filled in each bottle, and set the fill level sensor accordingly.

Once the machine is set up, turn it on, and adjust the settings to the appropriate speed and product flow rate. The rate of flow is determined by the viscosity and chemical properties of the product being filled.

The next step is to load the empty bottles or containers onto the conveyor belt of the machine. Ensure that each bottle is positioned correctly to avoid any spillage or damage.

Once the bottles or containers are placed, activate the machine’s automatic filling process or manually initiate the filling process. During the filling process, the machine quickly and accurately fills the bottles with the desired amount of product.

After the bottles are filled, the machine automatically caps or seals the bottles. It is important to note that the type of closure used depends on the product being filled and the container’s shape.

After the bottles are sealed, they are released from the conveyor belt, and the filling process is complete. The bottles can then be labeled, packaged, and shipped to customers.

In summary, a bottle filling machine is a crucial piece of equipment for accurately and efficiently packaging liquid products. Proper use of the machine involves setting it up correctly, loading the bottles or containers correctly, initiating the filling process, and finally capping or sealing the bottles. With proper usage, a bottle filling machine can significantly increase production rates and reduce wastage.

Selecting the Ideal Manufacturer Bottle Filling Machine

Selecting the ideal bottle filling machine can be a daunting task for any manufacturer. There are various factors that must be considered before making a final decision. Here are a few factors that every manufacturer should keep in mind before selecting a bottle filling machine.

Firstly, the type of container must be taken into account. The filling machine should be compatible with the shape and size of the container. The filling machine should also be able to handle the viscosity of the liquid without any issues.

Secondly, the production capacity of the filling machine must be considered. The manufacturer should have a clear idea about the number of bottles that must be filled within a specific duration of time. This will help in selecting a machine that meets the production requirements.

Thirdly, the filling accuracy of the machine must be considered. It is essential to ensure that the machine fills the container accurately without any variations. This will help ensure that the product meets the desired quality standards.

Fourthly, the maintenance and operating cost of the machine must be taken into account. The manufacturer should choose a machine that is easy to maintain and has low operating costs. This will help in keeping the production costs low, and maximize the profit margins.

Lastly, the after-sales support and service provided by the manufacturer must be considered. The manufacturer should choose a machine that comes with good customer support and after-sales service. This will help ensure that the machine runs smoothly and any issues can be resolved quickly.

In conclusion, selecting the ideal bottle filling machine requires careful consideration of various factors. It is essential to choose a machine that is compatible with the containers, meets the production requirements, fills accurately, has low operating costs, and comes with good customer support. By keeping these factors in mind, manufacturers can choose a filling machine that helps improve their production, maintain quality standards and increase profits.

list FAQ with answer about Bottle Filling Machine

Bottle filling machines are an essential component for bottling industries. Here are some common FAQs and their answers about the bottle filling machine.

Q: What is the purpose of the bottle filling machine?

A: The bottle filling machine is used to fill bottles with liquid products such as water, juice, oil, and so on.

Q: What types of bottle filling machines are available?

A: Different types of filling machines include gravity filler, piston filler, pump filler, rotary filler, overflow filler, and volumetric filler.

Q: What is the production capacity of a bottle filling machine?

A: The production capacity of a bottle filling machine depends on its type and size. Some machines can fill up to 1,000 bottles per hour, while some can fill up to 10,000 bottles per hour.

Q: Can the bottle filling machine fill different types of bottles?

A: Yes, bottle filling machines can fill different types of bottles including glass, plastic, metal, and others. However, machines should be adjusted according to the bottle size and shape.

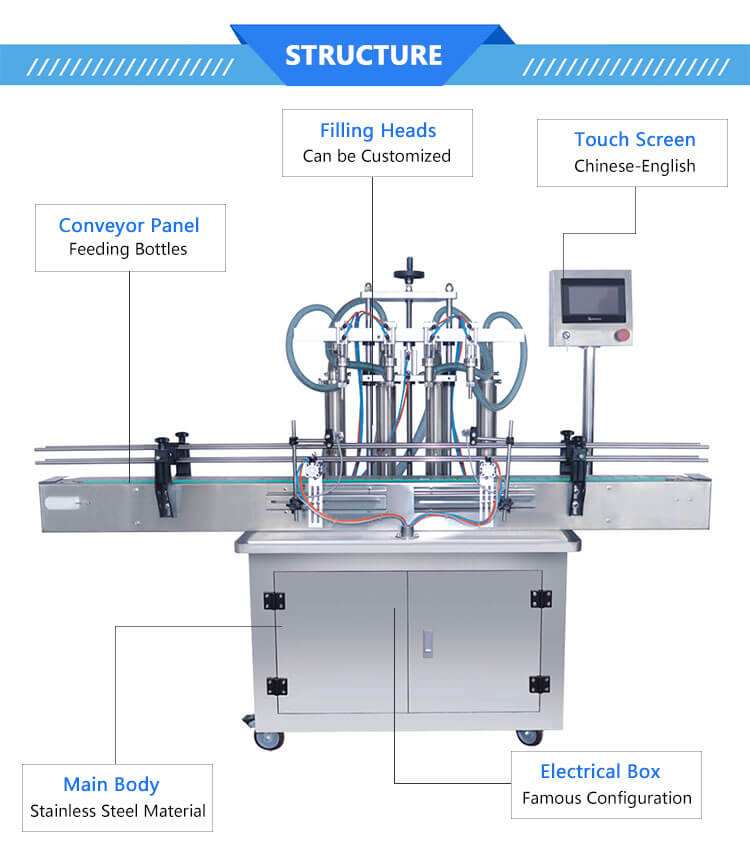

Q: What are the essential components of a bottle filling machine?

A: The bottle filling machine consists of a filling nozzle, bottle conveyor, bottle indexer, filling tank, and a control system.

Q: How to maintain the bottle filling machine?

A: Regular maintenance of the machine is essential to ensure its smooth operation. Maintenance includes cleaning, lubrication, inspection, and replacement of worn-out parts.

Q: Are bottle filling machines expensive?

A: The cost of the machine depends on its type, size, and features. However, investing in a quality bottle filling machine is worth it in terms of productivity and efficiency.

In conclusion, the bottle filling machine is a vital component for bottling industries. Knowing and understanding the FAQs and their answers will help in choosing the right machine for your business needs.

Things to Consider When Purchasing Bottle Filling Machine

When it comes to filling bottles with liquids, there are several factors to consider before choosing the right bottle filling machine for your business. From the type of product to the type of bottle, here are some things to keep in mind when purchasing a bottle filling machine.

1. Types of Products: The type of product you’re filling plays a crucial role in choosing the right machine. Certain products like food or chemicals require specific filling machines to comply with regulatory guidelines.

2. Viscosity: Consider the viscosity of the liquid you’re filling. Some liquids, such as syrup or honey, are thicker and require a different machine than thinner liquids like water or juice.

3. Bottle Size and Shape: The size and shape of the bottles you plan on filling should be accounted for. Some filling machines are only suited for certain bottle sizes, while others are designed to handle various shapes and sizes.

4. Speed and Accuracy: Machines with higher output capacities may be more expensive but they can save you time and increase productivity. Similarly, it’s essential to choose machines that have proper measurement accuracy to avoid wastage and ensure accurate filling.

5. Ease of Maintenance: It’s important to select filling machines that are easy to clean and maintain. This will ensure that the machine is always in perfect condition, which will improve its lifespan.

6. Cost: Finally, it’s important to consider the cost of the machine and whether it falls within your budget. Note that the cheapest option might not be the right one for you in the long run.

In conclusion, choosing the right bottle filling machine for your business requires careful consideration of several factors such as the type, viscosity, size and shape of the bottles, speed and accuracy of filling, ease of maintenance, and cost. With these factors in mind, you can choose a machine that will help you save time, money, and improve your business’s productivity.

Properties of Bottle Filling Machine

Bottle filling machines are designed to fill containers such as bottles, cans, and jars with liquids, powders or granules. These machines are used in a wide variety of industries, including food and beverage, pharmaceuticals, and cosmetics. The properties of bottle filling machines determine their efficiency, accuracy, and ease of maintenance, among other things.

One of the most important properties of bottle filling machines is their capacity. Some machines can fill a few bottles per minute, while others can fill hundreds or even thousands of bottles in the same amount of time. The capacity of a bottle filling machine depends on its design and the nature of the product being filled.

Another important property of bottle filling machines is their accuracy. In some applications, it is essential that each bottle be filled with exactly the same amount of product. This is particularly important in pharmaceuticals and cosmetic industries where precise dosages are required. The accuracy of a bottle filling machine is determined by the quality of its sensors and controls.

The speed of the filling cycle is another important property of bottle filling machines. The cycle time depends on the size of the bottles being filled and the type of product being filled. For example, filling a bottle with a thick and viscous liquid will take longer than one filled with a thin liquid.

Ease of maintenance is also a crucial property of bottle filling machines. These machines have many moving parts and require regular maintenance to keep them running smoothly. Some machines have simple designs that are easy to service, while others have complex components that require specialized expertise to maintain.

In conclusion, the properties of bottle filling machines play a crucial role in their efficiency, accuracy, and ease of maintenance. The capacity, accuracy, speed, and ease of maintenance determine the suitability of a machine for a particular application. Industries requiring precise dosing and filling operations would require more advanced and sophisticated equipment, while simpler designs can suffice for basic applications.

Technical Parameters Terms for Bottle Filling Machine

A bottle filling machine is an essential equipment for any beverage manufacturing company. Technical parameters of a bottle filling machine are critical for its optimal performance. These parameters vary from one machine to another, and a basic understanding of these terms is critical for any decision-making process.

Firstly, the filling volume of a bottle filling machine is one of the most critical technical parameters. This parameter refers to the amount of liquid that the machine dispenses into a bottle per cycle. It is usually measured in milliliters or liters per cycle. This parameter varies depending on the type of liquid being filled, the bottle size, and the machine’s capacity.

Secondly, the filling speed is also an important technical parameter. This parameter indicates the speed at which the machine fills the bottles. It is measured in bottles per minute (BPM) and is dependent on the machine’s configuration.

Another important technical parameter of a bottle filling machine is the bottle size range. This refers to the range of sizes of bottles that the machine can accommodate. It is critical to ensure that the machine can handle the specific bottle size required for production to avoid any downtime.

The filling accuracy is also a vital parameter. This parameter measures the variation in the filling volume of different bottles. The accuracy needs to be optimized to ensure that the machine performs to its maximum efficiency.

Lastly, the material of construction is another essential technical parameter. The material of construction determines the machine’s durability, resistance to corrosion, and ability to handle different types of liquids.

In conclusion, technical parameters terms for bottle filling machine are critical for effective manufacturing. With basic understanding, manufacturers can select the ideal machines for their production needs.

Bottle Filling Machine Price

If you’re looking to invest in a bottle filling machine, one of the first things you’re probably wondering about is the price. Bottle filling machines vary widely in cost depending on factors like the machine’s capacity, level of automation, and manufacturer.

In general, manual or semi-automatic machines will cost less than fully-automatic machines. Manual machines require more labor and are slower, but they can still be a good option for small-scale bottling operations or for those on a tighter budget. Semi-automatic machines typically require less labor and are faster, but may still require some manual intervention.

Fully automatic machines are the most expensive, but also offer the highest level of efficiency and throughput. They require minimal labor and can fill thousands of bottles per hour. These machines are best suited to large-scale bottling operations.

Another factor that affects the cost of bottle filling machines is the type of bottle being filled. Machines that can handle a wide variety of bottle sizes, shapes, and materials may be more expensive than machines that are limited to a specific type of bottle.

Finally, the manufacturer of the machine will also influence its price. Some of the most well-known manufacturers of bottle filling machines include Krones, Bosch, and Tetra Pak. These machines may be more expensive than lesser-known brands, but they often come with a reputation for quality and reliability.

To get an accurate idea of pricing, it’s best to request a quote from a manufacturer or distributor. They will be able to provide specific pricing information based on your needs and requirements. However, as a rough guide, manual machines can start from around $1,000, while fully-automatic machines can cost upwards of $50,000.

In summary, the price of a bottle filling machine will depend on a variety of factors, including the level of automation, the type of bottle being filled, and the manufacturer. While the initial investment can be substantial, investing in a high-quality machine can pay off in the long run with increased efficiency and productivity.

Related products

food machinery

laser machine

food machinery

food machinery

©2023. sourcifychina.com All Rights Reserved.

-

- Home

- Retail Cheap Shop

- Wholesale Featured Pro

- Industries

- List

- Our China Suppliers list

- Auto Parts Suppliers

- Packaging Solution

- Stainless Steel Suppliers

- Steel Pipe Suppliers

- Solar Inverter China

- cable manufacturing

- cnc machining China

- Apparel and Accessories

- fabric manufacturing

- Machinery

- pump China

- Screw

- wigs custom

- valves manufacturing

- hair system custom

- heated gloves wholesale

- indoor lighting fixtures

- solor panel wholesale

- snow boots factory

- Products

- Manufacturing

- Guide

- Apparel / Fashion Accessories

- CNC Tools Valve Pump Parts

- Machinery China Equiment Sourcing Guide

- aac block manufacturers

- acrylic cutting machine

- automatic packing machine

- Auxiliary Equipment

- blister packing machine

- bricks manufacturing

- clay brick making machine

- feed pellet machine

- fly ash bricks machine sourcing guide

- paper bag making machine

- pellet machine

- plastic crusher machine

- pouchpacking machine

- stamping machine

- wood pellet machine

- Outdoor Sports

- Others Sourcing Guide

- FAQ

- About

- Contact

- Login

- Newsletter

- [email protected] whatsapp 8615951276160

- 供应商

Login

- →

- WeChat: 8615951276160