Wheel Hub Factory

The Wheel Hub Factory: Creating High-Quality and Durable Wheel Hubs for Optimal Performance

Introducing the Wheel Hub Factory – your go-to resource for top-quality and durable wheel hubs for automobiles, trailers, and other vehicles. Made using the latest technologies and premium materials, our wheel hubs boast an array of features and benefits to ensure optimal performance under various driving conditions.

Benefits

Our wheel hubs are designed to improve your vehicle’s performance by providing a smooth, stable ride and reducing vibrations. They are built to be durable and long-lasting, withstanding harsh driving conditions and rough terrains. Our wheel hubs are also easy to install, reducing maintenance costs and saving you time and effort.

Features

Our wheel hubs are made using high-strength materials to ensure their durability and longevity. They are designed to resist wear and tear, corrosion, and damage caused by temperature fluctuations. Each hub is carefully crafted to meet rigorous quality standards and tested to ensure optimal performance. Our wheel hubs come with precision bearings to reduce friction, increasing fuel efficiency and reducing wear and tear on other components of your vehicle.

Specifications

Our wheel hubs come in various sizes and designs to fit most automobile models and applications. They are customizable to meet your individual needs, with options for finishes, colors, and other design features. Our wheel hubs are compatible with a range of tires and can withstand high speeds and heavy loads.

Applications

Our wheel hubs are suitable for use in various vehicles, including cars, trucks, trailers, and other transport vehicles. They are ideal for use in harsh driving conditions, including off-road and heavy-duty applications. Our wheel hubs are suitable for both professional and personal use.

FAQ

– Q: Are your wheel hubs easy to install?

– A: Yes, our wheel hubs are designed with easy installation in mind, reducing maintenance costs and saving you time and effort.

– Q: What materials are your wheel hubs made of?

– A: Our wheel hubs are made using high-strength materials designed to resist wear and tear, corrosion, and damage caused by temperature fluctuations.

– Q: Are your wheel hubs customizable?

– A: Yes, we offer customization options for finishes, colors, and other design features to meet your individual needs.

– Q: What type of vehicles are your wheel hubs suitable for?

– A: Our wheel hubs are suitable for use in most vehicles, including cars, trucks, trailers, and other transport vehicles.

With the Wheel Hub Factory, you can trust that you are getting the highest quality and most durable wheel hubs on the market. Whether you are looking for improved performance, reduced vibrations, or an easy-to-install solution, our wheel hubs are the perfect choice for you. Contact us today to learn more about our products and services.

List Technical Parameters of “wheel hub factory”

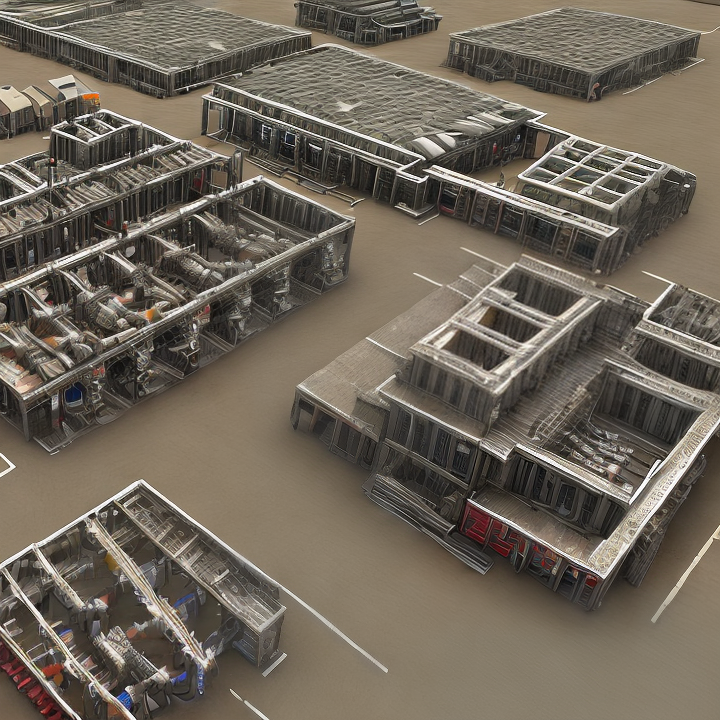

The wheel hub factory is a specialized manufacturing facility that produces wheel hubs for various types of vehicles. These hubs are integral components of vehicle wheels, and they house the bearings and other components that allow the wheels to rotate smoothly.

The technical parameters of a wheel hub factory include a range of manufacturing processes, from the initial design and development of the hub to the final finishing and packaging of the product. Some of the key parameters are as follows:

1. Materials: Wheel hubs can be made from a variety of materials, including steel, aluminum, and various alloys. The choice of material will depend on factors such as the load capacity, durability, and weight requirements of the hub.

2. Design: The design of the wheel hub must be carefully considered to ensure that it is strong enough to withstand the stresses of use, while also being lightweight and efficient. The design will also need to accommodate the specific needs of the vehicle for which the hub is intended.

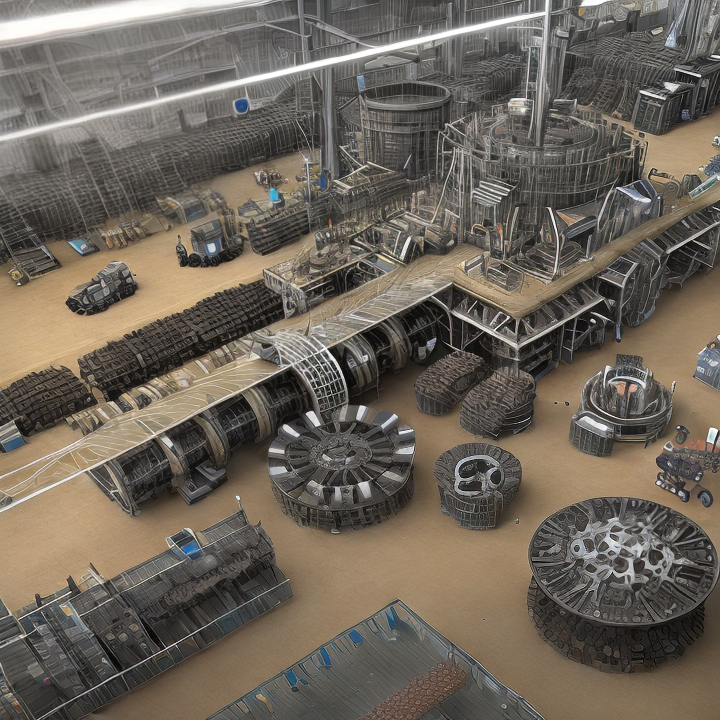

3. Manufacturing processes: Manufacturing processes for wheel hubs typically involve casting, forging, or machining the raw material into the desired shape. The hub will then undergo various cleaning, finishing, and testing processes to ensure that it meets the required specifications.

4. Quality control: Throughout the manufacturing process, quality control measures will need to be implemented to ensure that the hub meets all relevant safety and performance standards.

5. Testing: Once the hub is completed, it will undergo various tests to ensure that it is capable of withstanding the load and stresses of use. These tests may include dynamic testing, vibration testing, and fatigue testing.

Overall, the technical parameters of a wheel hub factory are focused on ensuring that the product is safe, reliable, and efficient. By carefully considering materials, design, manufacturing processes, and quality control measures, the factory can produce high-quality wheel hubs that meet the needs of a range of different vehicles and applications.

List Product features of “wheel hub factory”

A wheel hub factory is a manufacturing facility that specializes in producing wheel hubs for various types of vehicles. These products are the center of the wheel, where the wheel mounts onto the axle, enabling the wheel to rotate.

The products can come in various sizes and designs to accommodate different vehicle models, wheel sizes, and load capacities. Typically, a wheel hub factory should offer the following product features:

1. Material: Wheel hubs can be made from different materials, including steel, aluminum, or composite materials. The factory should offer wheel hubs that are made from high-quality aluminum and steel, which is durable and capable of withstanding various environmental conditions.

2. Design: The factory should provide wheel hub designs that are lightweight, aerodynamic, and functional. The designs can have different finishes such as gloss, matte, or powder coated.

3. Compatibility: Wheel hubs come in various sizes, shapes, and mounting styles. The factory should offer wheel hubs that are compatible with different types of vehicles, including passenger cars, trucks, and trailers.

4. Quality: The factory should produce wheel hubs that are of the highest quality and meet industry standards. This will ensure that the products are dependable and able to handle heavy loads and various driving conditions.

5. Efficiency: The factory should use modern technologies and equipment to manufacture the products. These machines help to increase production speed while maintaining product quality.

6. Customization: The factory should offer customization services, whereby clients can choose to have their wheel hubs designed to meet their unique specifications.

7. Testing: The factory should perform extensive product testing to ensure that the wheel hubs are of high quality and can withstand different conditions.

Overall, the features of a wheel hub factory should be comprehensive and meet the diverse needs of clients. These products are essential for the performance of vehicles, and as such, quality and durability should be paramount.

List Application of “wheel hub factory”

A wheel hub factory is a manufacturing facility where various types of wheel hubs are produced, including those for cars, trucks, bicycles, and other vehicles. Such factories produce wheel hubs for use in the automotive industry, which is one of the most significant end-users of wheel hub assemblies. The application of wheel hub factories includes:

1. Automotive industry: Wheel hub factories are a vital component of the automotive industry, as they produce wheel hubs that are necessary for the operation of various types of vehicles. These wheel hubs are used in cars, trucks, and other vehicles to support the weight of the vehicle, improve handling, and provide a means for the wheel to rotate properly.

2. Bicycle industry: The production of wheel hubs in a factory is also crucial for the bicycle industry, given that bicycles require high-quality hubs to function correctly. Bicycle hubs are available in various sizes and designs, allowing for customization and improved performance.

3. Industrial applications: Wheel hubs are also used in industrial settings, such as machinery, conveyor belts, and other manufacturing processes. These hubs are designed to withstand high loads and extreme environmental conditions, making them essential for the efficient operation of industrial machinery.

4. Aftermarket sales: Wheel hub factories also manufacture hub assemblies for sale in the aftermarket, where customers can purchase replacement hubs for their vehicles. Such replacement products are beneficial for customers looking to replace worn or damaged hubs on their cars or trucks.

In conclusion, the wheel hub factory’s application is far-reaching, making it an essential component of the global manufacturing industry. With its vital role in various sectors of the industry, the wheel hub factory’s demand is expected to continue its growth in the coming years, especially with the automotive industry’s increasing demand for vehicles.

List Various Types of “wheel hub factory”

There are several types of wheel hub factories worldwide, catering to both original equipment manufacturers (OEMs) and aftermarket customers. These factories specialize in the design, development, and production of different types of wheel hubs for various vehicles.

One of the most common types of wheel hub factories is those that specialize in production for passenger cars. These factories manufacture wheel hubs, bearings, and related components for a range of car models from different brands.

Another type is those that focus on producing wheel hubs for commercial vehicles such as trucks, buses, and trailers. These are designed to withstand heavy loads and rough terrain, with increased durability and resistance to wear and tear.

Some wheel hub factories also specialize in producing custom-designed wheel hubs for specialized vehicles such as sports cars, racing cars, and exotic vehicles. These are often manufactured to meet specific performance requirements, such as improved handling, higher speeds, and increased durability.

Additionally, some factories focus solely on producing aftermarket wheel hubs, either as direct replacements for OEM parts or as upgraded products for vehicle customization enthusiasts. These hubs are often designed to cater to specific vehicle models and specifications and can be manufactured in a range of materials, sizes, finishes, and designs.

In summary, there are several types of wheel hub factories worldwide, each specializing in the production of a different range of products for various vehicles, brands, and markets. In addition to passenger cars and commercial vehicles, some factories produce custom-designed and aftermarket wheel hubs catering to specialized vehicle segments and customer requirements.

List The Evolution history of “wheel hub factory”

The history of the wheel hub factory can be traced back to the early 1900s when the automobile industry was gaining momentum. Initially, wheel hubs were made by hand, and the production was limited. In the 1920s, the first wheel hub factory was established to meet the increasing demand.

In the 1930s, improvements in technology and machinery allowed for mass production of wheel hubs. This led to increased efficiency and lower costs. During World War II, the wheel hub factory played a vital role in producing hubs for military vehicles.

In the post-war period, the wheel hub factory continued to modernize and expand its operations. The 1950s and 60s saw significant growth in the industry, stimulated by increased demand as the middle class grew, and more people could afford cars.

In the 1970s, the wheel hub factory faced challenges as the industry shifted towards front-wheel drives. The factory had to adapt to meet the changing demands of the market, resulting in the development of new production processes and technologies.

During the 1980s and 90s, the wheel hub factory continued to innovate, introducing new materials such as aluminum and titanium to improve performance and reduce weight. The use of computer-aided design and manufacturing also allowed for greater precision and consistency in production.

Today, the wheel hub factory continues to evolve, integrating automation and robotics to improve efficiency and reduce costs further. The industry is also exploring new materials and technologies such as 3D printing, which could revolutionize the manufacturing of wheel hubs in the future.

List The Process of “wheel hub factory”

The manufacturing process of a wheel hub factory involves several stages to produce the final product as per the required specifications. The process typically starts with the purchase of raw materials, including cast iron, cast steel, and forged steel, among others.

Once the materials are delivered to the factory, the production team performs quality checks to ensure compliance with the required standards, and then the raw materials are sent for further processing. This process involves machining to remove any excess material or imperfections and drilling or milling to create the necessary holes and features.

After machining, the wheels undergo heat treatment to improve their strength and wear resistance. The hub is then subjected to polishing and plating or painting to enhance its appearance and durability.

The final stage of the process involves quality checks to ensure that the hub meets all specified standards and is fit for use. Testing includes checking for proper fitment, load-bearing capacity, and wear resistance.

Once the product is deemed satisfactory, it is packed and ready for shipment. Throughout the process, strict adherence to safety protocols is essential to ensure safe and efficient operations.

In summary, the process of producing wheel hub assemblies involves raw material preparation, machining, heat treatment, polishing and plating, quality checks, and packing for transportation. The final product must meet strict standards to ensure optimal performance, safety, and durability.

How to use “wheel hub factory”

A wheel hub factory produces wheel hubs for various types of vehicles such as cars, trucks, buses, and motorcycles. The factory is responsible for producing high-quality wheel hubs that can withstand tough road conditions and adhere to strict safety and performance standards.

The production process begins with the inspection of raw materials such as steel and aluminum, which are used to manufacture the wheel hubs. The materials are then shaped into the desired form using advanced CNC machines and casting processes. The wheel hubs are then subjected to rigorous quality control tests, including dimensional analysis, hardness testing, and X-ray techniques, to ensure they meet the specified standards.

The assembly process involves fitting the wheel hub with bearings, seals, and other components that will ensure proper wheel alignment and reliable performance. The assembly line workers use specialized tools, such as torque wrenches, to ensure that all parts are tightened to the correct specifications.

Before the finished wheel hubs are shipped, they undergo a final inspection to verify their quality and performance. The final piece is then painted, coated, or polished as required by the customer’s specifications or design.

The wheel hub factory serves as an integral component of the automotive supply chain, providing essential parts for a wide range of vehicles on the road today. By producing high-quality wheel hubs that meet or exceed industry standards, the factory ensures the safety and reliability of millions of drivers and passengers worldwide.

List Properties of “wheel hub factory”

A wheel hub factory is a manufacturing plant that produces wheel hubs for vehicles such as cars, trucks, and buses. The wheel hub is the part of the wheel that connects the axle to the rim and supports the weight of the vehicle. The following are properties of a wheel hub factory:

1. Advanced Technology: A wheel hub factory must ensure that its operations use the latest technology to produce high-quality wheel hubs. This includes advanced machinery, equipment, and software, which help to increase productivity and reduce manufacturing costs.

2. Quality Control: A wheel hub factory conducts rigorous quality control checks to ensure that the wheel hubs meet the required industry standards, including ISO and SAE standards. These checks include dimensional, hardness, surface finish, and metallurgical tests, among others.

3. Skilled Workforce: A wheel hub factory employs highly skilled technicians, engineers, and operators who understand the process of manufacturing wheel hubs. The team ensures that every wheel hub that leaves the factory is of high quality and meets the desired specifications.

4. Capacity: A wheel hub factory should have sufficient production capacity to meet customer demand. It should have the ability to produce wheel hubs in large quantities while maintaining high quality standards.

5. Material Selection: A wheel hub factory selects materials carefully to ensure that they meet the required specifications. The materials used include steel, aluminum, and composite materials, which are chosen based on their strength, durability, and cost-effectiveness.

6. Sustainability: A wheel hub factory should promote sustainable manufacturing practices that reduce waste, conserve energy, and minimize its impact on the environment. This includes the use of renewable energy sources, responsible waste management, and the use of environmentally friendly materials.

In conclusion, a wheel hub factory is an important player in the automotive industry, providing high-quality wheel hubs that ensure the safety and performance of vehicles. The factory must invest in advanced technology, conduct rigorous quality control checks, employ a skilled workforce, have sufficient production capacity, select materials carefully, and promote sustainable manufacturing practices.

List “wheel hub factory” FAQ

1. What is a wheel hub factory?

A wheel hub factory is a manufacturing plant that produces wheel hubs for various types of vehicles.

2. What materials are used in the production of wheel hubs?

The materials used in the production of wheel hubs include steel, aluminum, and other metal alloys.

3. What types of vehicles do wheel hubs apply to?

Wheel hubs apply to a variety of vehicles, including cars, trucks, and trailers.

4. What is the production process for a wheel hub?

The production process for a wheel hub involves several steps, including casting, machining, finishing, and assembly.

5. What are the quality standards for wheel hubs?

Wheel hubs must meet industry-specific quality standards, including ISO 9001 and TS 16949.

6. What is the typical lead time for a wheel hub order?

The lead time for a wheel hub order depends on a variety of factors, including the quantity and complexity of the order, as well as the factory’s current capacity.

7. How are wheel hubs tested for quality assurance?

Wheel hubs are tested using a variety of methods, including dimensional inspection, material testing, and functional testing.

8. Can wheel hubs be customized to fit specific vehicles?

Yes, wheel hubs can be customized to fit specific vehicles by adjusting the size, shape, and other design elements.

9. What is the capacity of a typical wheel hub factory?

The capacity of a typical wheel hub factory varies depending on the size and complexity of the operation, but most factories can produce thousands of wheel hubs per day.

10. How are wheel hubs packaged and shipped to customers?

Wheel hubs are typically packaged in protective containers and shipped to customers by truck, train, or sea freight, depending on the customer’s location and shipping requirements.

Related products

steel profiles

steel profiles

steel profiles

steel profiles

steel profiles

steel profiles

steel profiles

steel profiles

©2023. sourcifychina.com All Rights Reserved.

-

- Home

- Retail Cheap Shop

- Wholesale Featured Pro

- Industries

- List

- Top Suppliers for Sourcing in China: Best Picks for 2025

- Auto Parts Suppliers

- Packaging Solution

- Stainless Steel Suppliers

- Steel Pipe Suppliers

- Solar Inverter China

- cable manufacturing

- cnc machining China

- Apparel and Accessories

- fabric manufacturing

- Machinery

- pump China

- Screw

- wigs custom

- valves manufacturing

- hair system custom

- heated gloves wholesale

- indoor lighting fixtures

- solor panel wholesale

- snow boots factory

- Products

- Manufacturing

- Guide

- Apparel / Fashion Accessories

- CNC Tools Valve Pump Parts

- Machinery China Equiment Sourcing Guide

- aac block manufacturers

- acrylic cutting machine

- automatic packing machine

- Auxiliary Equipment

- blister packing machine

- bricks manufacturing

- clay brick making machine

- feed pellet machine

- fly ash bricks machine sourcing guide

- paper bag making machine

- pellet machine

- plastic crusher machine

- pouchpacking machine

- stamping machine

- wood pellet machine

- Outdoor Sports

- Others Sourcing Guide

- FAQ

- About

- Contact

- Login

- Newsletter

- [email protected] whatsapp 8615951276160

- 供应商

Login

- →

- WeChat: 8615951276160