List Technical Parameters of “wheel hub supplier”

When choosing a wheel hub supplier, there are a variety of technical parameters to consider. Some of the most important include:

1. Size: The size of the wheel hub must match that of the vehicle for proper fitment. This includes both diameter and width measurements.

2. Material: Wheel hubs can be made from a variety of materials, including steel, aluminum, and even carbon fiber. The chosen material will impact the hub’s weight, strength, and durability.

3. Bearing type: Wheel hubs can come with different types of bearings, including tapered roller, ball, and needle bearings. Each type has its own advantages and disadvantages.

4. Load capacity: The wheel hub’s load capacity must be sufficient to support the weight of the vehicle and any cargo it is carrying. This is typically expressed in terms of a weight rating.

5. Bolt pattern: The bolt pattern of the wheel hub must match that of the vehicle’s wheels. This determines how the wheels attach to the hub and is expressed in terms of the number of bolts and the distance between them.

6. ABS compatibility: If the vehicle has an anti-lock braking system (ABS), the wheel hub must be compatible with it for proper operation.

7. Corrosion resistance: Depending on the environment in which the vehicle will be operated, corrosion resistance may be a concern. High-quality wheel hubs will have a coating or treatment that helps prevent rust and corrosion.

8. Heat dissipation: Wheel hubs can generate a significant amount of heat, especially during high-speed or heavy-duty use. A well-designed hub will have features that help dissipate this heat to prevent damage to the hub or other components.

9. Warranty: Finally, it’s important to choose a wheel hub supplier that stands behind their products with a strong warranty or guarantee. This ensures that you can have confidence in the quality of the hubs you purchase and that you’ll be protected in case of any defects or issues.

List Product features of “wheel hub supplier”

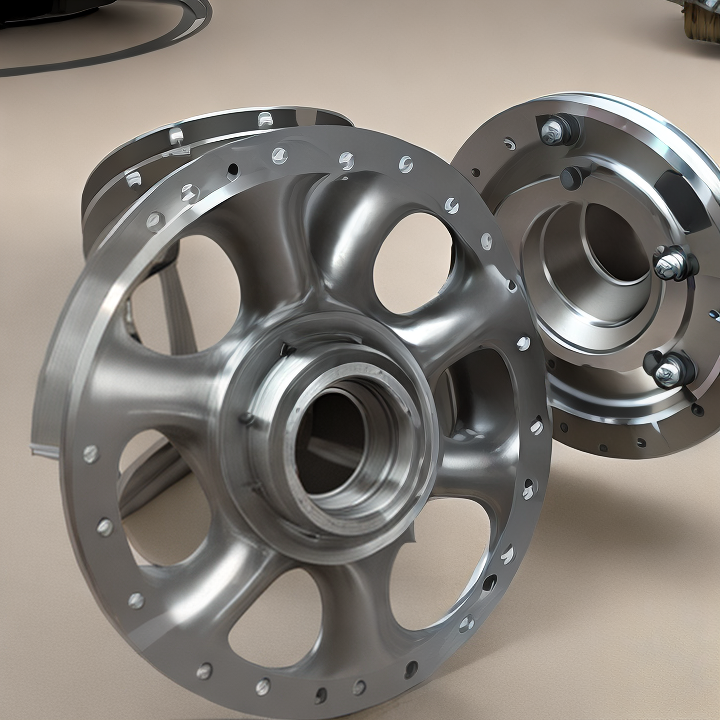

A wheel hub supplier is responsible for providing high-quality hub assemblies for different kinds of vehicles at affordable prices. Hub assemblies are essential car components that are located where the tire and the vehicle meet. The following are product features of a wheel hub supplier:

1. High-Quality Wheel Hubs: Quality is of utmost importance when it comes to wheel hubs. The wheel hub supplier provides hub assemblies that are made with quality materials to ensure longevity and high performance.

2. Compatibility with Different Types of Vehicles: The supplier offers hub assemblies that are compatible with various kinds of vehicles, including cars, SUVs, trucks, and trailers. The assemblies are specially designed to fit perfectly with the type of vehicle model they are intended for.

3. Easy Installation: The hub assemblies supplied by the supplier are straightforward to install, and users can easily do it themselves without needing to engage the services of an auto mechanic.

4. Durability: The wheel hubs are designed to withstand harsh weather conditions and provide optimum functionality even under extreme conditions.

5. Affordable Prices: The supplier offers quality hub assemblies at competitive prices that make it possible for vehicle owners to access high-quality products without breaking the bank.

6. Warranty and Guarantee: A reputable wheel hub supplier should provide warranties and guarantees on its products. This ensures that customers can return any defective items and get a replacement or refund promptly.

7. Excellent Customer Service: The supplier should offer excellent customer service, including fast response times, product knowledge and expertise, after-sale support, and other services that ensure customer satisfaction.

Conclusion

Wheel hub suppliers play a crucial role in providing high-quality hub assemblies that improve vehicle performance and safety. With the features discussed above, customers can rest assured that they are working with a reputable supplier who can provide them with quality products at affordable prices.

List Application of “wheel hub supplier”

Wheel hub suppliers are companies that specialize in manufacturing and supplying wheel hubs, which are an integral part of the wheel assembly in any vehicle. The wheel hub is a component that houses the wheel bearings and connects the wheel to the vehicle’s axle.

One of the primary applications of wheel hub suppliers is in the automotive industry, as wheel hubs are essential components used in the production of cars, trucks, buses, and other vehicles. These suppliers work with original equipment manufacturers (OEMs) to supply wheel hubs for various vehicle models. They also work with after-market suppliers to provide replacement hubs for vehicles that require maintenance or repair.

Another sector that relies on wheel hub suppliers is the transportation industry. This includes companies that provide logistics, warehousing, and distribution services using trucks and trailers. These vehicles require high-quality wheel hubs that can withstand the rigors of long-distance travel and heavy loads. Wheel hub suppliers collaborate with trailer and truck manufacturers to provide hubs that meet these requirements, ensuring the safety and reliability of the vehicles.

Wheel hub suppliers also serve the agriculture sector, providing hubs for tractors and other farm equipment. These vehicles operate in challenging conditions, with exposure to dirt, mud, and debris that can affect the performance of their wheel assemblies. Reliable wheel hubs are essential to maintaining the productivity of this sector, and suppliers work closely with equipment manufacturers to provide the necessary parts and support.

In conclusion, the application of wheel hub suppliers extends to various industries, including automotive, transportation, and agriculture. These companies play a crucial role in providing high-quality components that ensure the safety, reliability, and efficiency of vehicles and equipment. With the increasing demand for reliable and durable wheel hubs in these industries, the importance of wheel hub suppliers will only continue to grow in the future.

List Various Types of “wheel hub supplier”

When it comes to wheel hub suppliers, there are several different types to consider. These include:

1. Original Equipment Manufacturers (OEMs): These suppliers are the ones that manufacture the wheel hubs for the original manufacturers of the vehicle. They are typically held to high quality standards and produce parts that are specific to the make and model of the vehicle.

2. Aftermarket Suppliers: These suppliers produce wheel hubs that are not made by the original manufacturer, but are designed to fit a specific make and model of vehicle. They typically offer a wide variety of options, including different materials and designs.

3. Custom Wheel Hub Manufacturers: These manufacturers produce wheel hubs that are specifically designed for a certain type of vehicle or application. They may work closely with the vehicle manufacturer to create a unique design that meets specific performance or aesthetic requirements.

4. Racing Wheel Hub Suppliers: These suppliers produce wheel hubs that are designed for high-performance racing applications. They typically use lightweight materials and incorporate features like improved cooling and reduced friction to improve performance.

5. Rebuilt or Refurbished Wheel Hub Suppliers: These suppliers take worn or damaged wheel hubs and refurbish them to a like-new condition. This can be a cost-effective alternative to purchasing a new wheel hub.

6. Online Wheel Hub Suppliers: These are suppliers that sell wheel hubs through online platforms. They may offer a wide variety of options and may have lower prices than brick-and-mortar stores.

Overall, the type of wheel hub supplier you choose will depend on your specific needs and priorities. Whether you’re looking for high-quality OEM parts or a cost-effective aftermarket solution, there are many different options to consider.

List The Evolution history of “wheel hub supplier”

The evolution of wheel hub suppliers can be traced back to the 19th century when the automobile industry began to take shape. At that time, most of the wheels were made of wood, and the hubs were cast iron. However, as the automobile industry grew, the demand for more durable and lightweight materials increased. Thus, manufacturers began experimenting with new materials like aluminum and steel.

In the mid-20th century, advancements in technology led to the development of complex hub designs. These new designs incorporated additional features like bearings and seals to improve performance. As a result, hub suppliers began to specialize in the manufacturing of these components.

The 1990s marked a significant shift in the automotive industry, with the advent of computer-aided design and manufacturing (CAD/CAM). This technology allowed wheel hub suppliers to design and produce highly customized components, which further improved performance and reliability.

Today, wheel hub suppliers play a crucial role in the manufacturing of automobiles. They provide essential components to leading automotive companies worldwide and are continually developing new and innovative products to meet the demands of the industry. The need for electric and hybrid vehicles has also led to the development of new hub designs capable of accommodating specialized requirements.

In conclusion, the evolution of wheel hub suppliers has been shaped by technological advancements and changing demands in the automotive industry. From the early days of wood and iron to the present-day specialization in complex hub designs, these suppliers have continuously adapted to meet the demands of the market.

List The Process of “wheel hub supplier”

The process of a wheel hub supplier involves several steps that are essential in manufacturing and distributing a high-quality product.

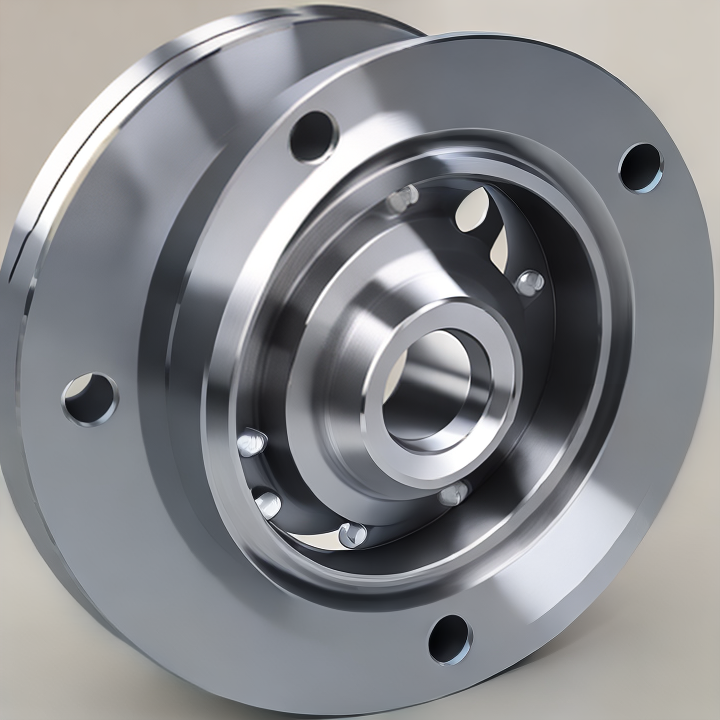

The first step is the design of the wheel hub. Designers create a blueprint of the product using Computer-Aided Design (CAD) software. Here, they decide on the dimensions, materials, and shape of the hub, taking into account factors such as its compatibility with vehicles and load-bearing capacity.

The second step is the selection of raw materials. Manufacturers choose high-quality materials that are strong enough to withstand the load and stresses that the wheel hub will experience during operation. The materials used are typically metal alloys, such as iron, aluminum, or steel.

The third step is the machining of the raw materials into the desired shape. This is done using machines like CNC lathes and milling machines, which cut, drill, and shape the metal as per the design specifications.

The fourth step is the assembly of the wheel hub. This involves pressing or welding the components together to create the final product. Hub manufacturers may also apply surface treatments and coatings to protect the metal against corrosion and wear and to enhance its appearance.

The final step is the distribution of the finished product. The wheel hub supplier ships the product to retailers or distributors who market the items to consumers. The distributors must ensure that the products are of good quality and meet all safety standards before being released to the market.

Throughout the process, quality control measures are implemented to ensure that the wheel hubs meet the required specifications. These measures may include product testing, inspections, and certifications from reputable third-party organizations. The aim is to provide customers with a reliable, safe, and durable product that will perform well even in challenging driving conditions.

How to use “wheel hub supplier”

A wheel hub supplier provides a crucial component for vehicle manufacturing, repair and maintenance. The wheel hub is a cylindrical metal part that houses the wheel bearings and connects the wheel to the vehicle’s axle. It ensures smooth and stable rotation of the wheels, which is vital for safe driving and vehicle performance.

To use a wheel hub supplier, it is important to consider factors such as quality, compatibility, and reliability. This requires researching and selecting a reputable and experienced supplier who offers a range of wheel hubs to suit different vehicle makes and models.

Once a supplier is selected, it is necessary to provide the required specifications and quantities of the wheel hubs. This may involve communicating with the supplier to discuss customisation options, if necessary. The supplier will then manufacture and deliver the wheel hubs to the desired location.

During installation, it is important to follow the manufacturer’s instructions carefully and ensure that the wheel hubs are fitted correctly. Regular maintenance and inspection of the wheel hubs will also help extend their lifespan and prevent potential issues.

In conclusion, a wheel hub supplier plays a key role in the vehicle manufacturing, repair and maintenance industries. By selecting a reliable supplier and following proper installation and maintenance procedures, vehicle owners can ensure the smooth and safe operation of their vehicles.

List Properties of “wheel hub supplier”

A wheel hub supplier is a company that specializes in manufacturing and distributing wheel hubs for vehicles. They play a crucial role in the automotive industry by supplying various types of wheel hubs to automobile manufacturers and aftermarket customers worldwide. Here are some properties of a wheel hub supplier:

1. Quality: The primary property of a wheel hub supplier is the quality of the products they offer. These companies make sure that the wheel hubs they produce meet industry standards and are durable enough to withstand the rigors of everyday use.

2. Expertise: A wheel hub supplier should have a team of experts who understand the different needs of their customers. They must have the technical expertise to design, develop, and manufacture wheel hubs that meet specific customer requirements.

3. Range of Products: A good wheel hub supplier should offer a broad range of products to cater to the needs of different customers. These products should vary in size, shape, and material composition to suit different types of vehicles.

4. Competitive Pricing: A wheel hub supplier should offer competitive pricing to remain competitive in the market. They should provide fair and transparent pricing to their customers, with no hidden costs associated with their products.

5. Customization: Since different vehicles require different types of wheel hubs, a good wheel hub supplier should offer customization services to their customers. They must be able to design and manufacture unique wheel hubs that meet specific customer requirements.

6. Timeliness: A reliable wheel hub supplier should deliver products to their customers on time. They must have efficient supply chain management systems that ensure timely delivery of products.

In summary, a wheel hub supplier should prioritize quality, expertise, a range of products, competitive pricing, customization, and timeliness. By doing so, they can attract and retain customers while remaining competitive in the automotive industry.

List “wheel hub supplier” FAQ

1. What is a wheel hub supplier?

A wheel hub supplier is a manufacturer or distributor that supplies wheel hubs, which are the part of a vehicle that connects the wheel to the axle.

2. What types of wheel hubs do you offer?

We offer a variety of wheel hubs, including front and rear wheel hubs, bolt-on and press-in wheel hubs, and bearing and non-bearing wheel hubs.

3. What materials are your wheel hubs made of?

Our wheel hubs are made of high-quality materials, such as steel, aluminum, and alloy, to ensure durability and long-lasting performance.

4. Are your wheel hubs compatible with all types of vehicles?

We offer wheel hubs that are compatible with different types of vehicles, including cars, trucks, SUVs, and trailers. We also have hub assemblies designed for specific makes and models of vehicles.

5. How do I choose the right wheel hub for my vehicle?

To choose the right wheel hub for your vehicle, you need to consider the make and model of your vehicle, the type of wheel hub you need, and the size and specifications of the hub. You can consult with our experts who can help you choose the right wheel hub for your vehicle.

6. Can you provide custom wheel hubs?

Yes, we can provide custom wheel hubs according to your specific requirements, including size, material, and design. Our engineers use advanced technology and machinery to ensure the highest quality custom wheel hubs.

7. Can you provide installation services for wheel hubs?

We do not provide installation services for wheel hubs. However, we can recommend certified mechanics or auto shops who can install the wheel hubs for you.

8. What is the warranty period for your wheel hubs?

We offer a warranty period for each wheel hub, depending on the manufacturer’s warranty. Our experts can provide you with the details of the warranty for each wheel hub.

In summary, a wheel hub supplier provides a variety of wheel hubs made of high-quality materials such as steel, aluminum, and alloy, which are compatible with different types of vehicles. Customers can choose the right wheel hub for their vehicle by considering their make and model as well as the size and specifications of the hub. Custom wheel hubs are also available and warranty periods vary depending on the manufacturer.