List Technical Parameters of “custom precision metal stamping”

Custom precision metal stamping is an advanced manufacturing process that involves the use of precision machinery to shape, cut and form metal parts. The resulting components are used in a wide range of industries, including automotive, aerospace, electronics, medical devices and more. Some of the critical technical parameters for custom precision metal stamping are:

1. Tolerance: Tolerance refers to the degree of precision required during the metal stamping process. The level of tolerance depends on the application for which the metal part is intended and can range from as little as +/-.005 inches to as much as +/-.010 inches or more.

2. Material: The choice of material is critical to the success of custom precision metal stamping. Materials commonly used include stainless steel, copper, brass, aluminum, and various high-performance alloys.

3. Die size: The size of the die determines the maximum size of the metal part that can be manufactured. A larger die size enables the production of larger parts while smaller die sizes are used for smaller parts.

4. Press capacity: Press capacity is the amount of force needed to produce the metal part. This parameter depends on the material used, the size of the part, and the level of complexity of the stamping process.

5. Lead time: Lead time refers to the time taken to complete an order from start to finish, including time for design, tooling, manufacturing, and delivery. The lead time for custom precision metal stamping can vary depending on the complexity of the metal part and the production volume required.

6. Surface finishing: Surface finishing involves modifying the surface of the metal part to achieve a specific texture or appearance. The most common surface finishing techniques include polishing, painting, plating, and anodizing.

In conclusion, custom precision metal stamping is a complex manufacturing process with many technical parameters to consider. The listed parameters, tolerance, material, die size, press capacity, lead time and surface finishing, are critical to the success of the process and must be carefully analyzed to ensure that the final product meets the desired specifications.

List Product features of “custom precision metal stamping”

Custom precision metal stamping is a manufacturing technique used to create high-quality metal parts with precise features. It’s a cost-effective and fast method that reduces material waste while producing finished products with a high level of accuracy. Here are some of the most important product features of custom precision metal stamping:

1. Precision – Custom precision metal stamping provides the highest precision when creating metal parts. It can create intricate shapes and designs that cannot be achieved with other manufacturing methods.

2. Efficiency – This technique delivers a higher level of efficiency than other manufacturing processes. With its fast and accurate results, it is cost-effective compared to other production methods.

3. Customization – Customization is a key feature of custom precision metal stamping. Clients can tailor their products with any design or shape to meet exact specifications.

4. Durability – Metal parts made with custom precision metal stamping have a high level of durability due to the quality materials and production process used.

5. Material Versatility – This process can be utilized with a range of metal materials, including aluminum, copper, steel, zinc, and alloys.

6. Consistency – Consistency is one of the most important features of custom precision metal stamping. With its level of control, it ensures that the parts produced are consistent in quality, shape, and size.

7. Low Waste – Unlike other manufacturing processes, custom precision metal stamping produces less waste. It makes it eco-friendly while keeping the cost lower.

8. Excellent Tolerance – Metal die stamping can achieve very tight tolerance levels, meaning that metal parts created with this process will not shrink, warp, or change the shape after production.

9. Wide Application – Since metal stamping is a flexible manufacturing process, it has a versatile and broad range of uses in various industries.

10. Scalability – Custom precision metal stamping can be utilized for small to large-scale production projects, making it suitable for a wide range of businesses. It produces parts in high volumes and requires low labor costs.

In conclusion, custom precision metal stamping is a manufacturing process capable of producing high-quality products with high precision, consistency, durability, scalability, low cost, low waste, and a broad application range.

List Application of “custom precision metal stamping”

Custom precision metal stamping is a manufacturing process that involves using a metal stamping press and specialized tools to shape and cut metal sheets into various forms. This process is useful in a wide range of applications where precision and accuracy are critical, such as in the manufacture of electrical components, automotive parts, medical devices, and more.

One of the most common applications of custom precision metal stamping is in the production of electrical components, including connectors and switches. These parts require precise shapes and sizes to ensure proper electrical performance and reliability, and custom metal stamping allows for high levels of accuracy and consistency.

The automotive industry also relies heavily on custom precision metal stamping for the production of numerous parts, including brake components, exhaust systems, and suspension parts. These parts must meet strict tolerances and specifications to ensure safety and performance.

Medical device manufacturers also use custom precision metal stamping to create products such as surgical instruments, implants, and diagnostic equipment. These products require high levels of accuracy and precision to ensure effectiveness and safety.

In the aerospace industry, custom precision metal stamping is used to manufacture parts for aircraft engines, airframes, and avionics systems. These parts must meet stringent requirements for strength, durability, and accuracy to ensure reliable operation in high-stress environments.

Another application of custom precision metal stamping is in the production of consumer goods, such as kitchen appliances, power tools, and toys. These products often require intricate shapes and designs that can be achieved through custom metal stamping methods.

Overall, custom precision metal stamping is a versatile manufacturing process that plays a critical role in a wide range of industries. Its ability to produce highly precise and accurate parts makes it an essential tool for many different applications, from electrical components to medical devices and aerospace parts.

List Various Types of “custom precision metal stamping”

Custom precision metal stamping refers to the process of creating high-quality metal parts using specialized equipment. There are several types of custom precision metal stamping, including progressive die stamping, deep draw stamping, and fine blanking.

Progressive die stamping involves using a series of dies to create complex parts with tight tolerances. This method is ideal for high-volume production runs, as it can produce hundreds of parts per minute. Deep draw stamping is another variant of custom precision metal stamping that involves drawing a sheet of metal into a forming die to create complex shapes and contours. This process is ideal for creating parts with a high aspect ratio or complex shapes.

Fine blanking is a specialized form of metal stamping that creates precise, high-quality parts with a tight tolerance. This process involves using a punch and die to manufacture parts with smooth edges that require little or no secondary finishing. Fine blanking is ideal for creating parts with multiple features, such as holes, pockets, and slots.

There are several other types of custom precision metal stamping techniques, including transfer die stamping, which uses a series of dies to make complex parts, and multi-slide stamping, which uses a unique machine to create parts with multiple bends and angles. Additionally, precision metal stamping can be used for various materials, such as copper, brass, aluminum, and stainless steel.

In conclusion, custom precision metal stamping is an essential process for creating high-quality parts with tight tolerances and complex designs. There are various types of custom precision metal stamping, each with its advantages and disadvantages, and can cater to different production needs. To choose the best method for your manufacturing needs, you should consult a reliable custom precision metal stamping company that can help you select the right method for your production needs.

List The Evolution history of “custom precision metal stamping”

Custom precision metal stamping has a rich history that dates back to the 19th century when it was first used in the manufacturing industry. Prior to the use of precision metal stamping, manufacturers would use traditional hand tools to shape and form metal parts, a process that was slow and tedious.

The invention of the first metal stamping press in 1833 revolutionized the manufacturing industry and paved the way for improved efficiency and productivity. These early stamps were made of cast iron and were manually operated, but they were still a significant improvement over traditional hand tools.

Throughout the 20th century, advances in technology led to further improvements in the precision metal stamping process. Presses became larger and more sophisticated, and manufacturers began to use innovative materials, such as steel alloys, to create stronger and more durable stamping dies.

In the 1970s, the introduction of computerized numerical control (CNC) technology further advanced the precision metal stamping process. CNC machines allowed manufacturers to produce highly precise parts with greater consistency and accuracy, leading to improved product quality and reduced waste.

Today, custom precision metal stamping is an indispensable part of the manufacturing industry. It is used in a wide range of applications, from the production of small electronic components to the creation of large automotive parts. Modern stamping presses are capable of producing complex, high-precision parts with speed and efficiency, making it an essential tool for manufacturing companies around the world.

In conclusion, the evolution of custom precision metal stamping has enabled the manufacturing industry to produce high-quality metal parts efficiently and inexpensively. It has come a long way from the early days of manual stamping, and with the continuous advancements in technology, it is likely to remain an essential part of the manufacturing process.

List The Process of “custom precision metal stamping”

Custom precision metal stamping is a process that involves the use of specialized machines and tools to precisely cut and shape metal materials. The process involves several stages, which are outlined below:

Design: Before custom precision metal stamping begins, the first phase is designing the metal component. Clients will work with engineers to create drawings, models, and other designs that create the desired shape and size for the product.

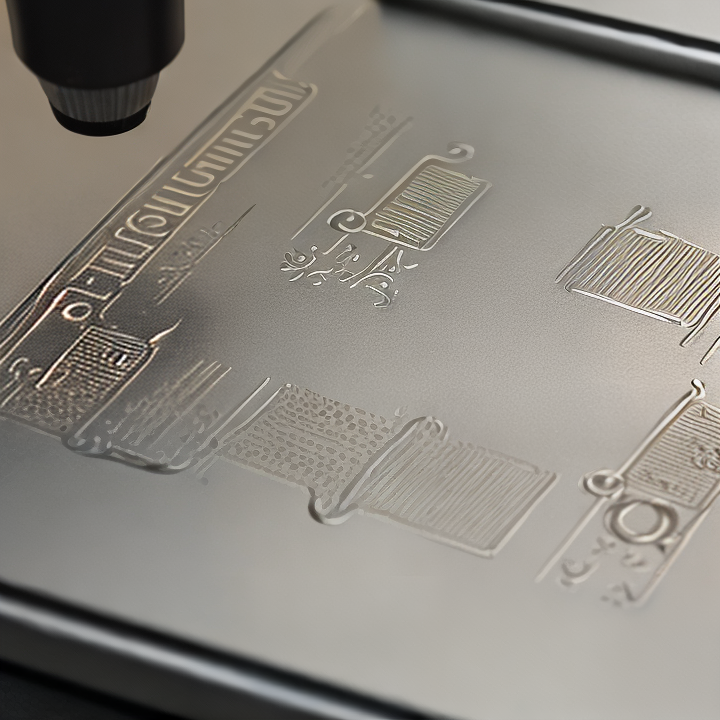

Tooling: After the design phase is complete, tooling begins. Tooling is the process of creating specialized machinery and tools, like dies and molds, to produce the desired metal component precisely. Tooling is a crucial step in custom precision metal stamping, as the tools created will influence the shape and precision of the final product.

Stamping: Once the tools are in place and set up, stamping begins. The metal material is fed through the stamping machine, and the die presses the material into a specific shape.

Finishing: After stamping has taken place, the metal component is trimmed to remove excess material, and any rough edges are smoothed down. Surface finishes are applied to the metal to prevent corrosion and improve the appearance of the finished product.

Inspection: The final stage is inspection. The metal component is checked to ensure that it meets the desired performance and functionality standards. The dimensional accuracy of the component is verified, and quality checks are carried out to identify any defects.

Custom precision metal stamping is an effective and efficient process for producing complex metal components with a high degree of precision. By following the above process, manufacturers can deliver high-quality custom metal components that meet the exacting standards demanded by clients.

How to use “custom precision metal stamping”

Custom precision metal stamping refers to the process of creating metal parts that meet specific design specifications and tolerances. This process is essential in various industries, including automotive, aerospace, electronics, and medical as it allows for the production of parts without the need for machining, welding, or other finishing processes.

The process begins with the creation of a customized die that contains the desired shape and pattern for the metal part. The die is then mounted onto a stamping press, which is used to apply pressure to the metal sheet until the desired shape is achieved. The result is a high-quality, precise metal part that meets strict dimensional tolerances.

Custom precision metal stamping has many advantages over traditional metal fabrication methods. It allows for mass production of parts with high accuracy and consistency, reducing the risk of errors and defects. It also allows for faster production times and lower costs, as it eliminates the need for multiple machines and labor-intensive processes.

Moreover, precision metal stamping can produce complex shapes and patterns that are difficult to achieve with other methods. The process can work with a range of metals, including stainless steel, aluminum, copper, and brass, and can produce parts in a wide variety of thicknesses and sizes.

In conclusion, custom precision metal stamping is an essential process in many industries, enabling the production of high-quality metal parts that meet strict tolerances and design specifications. With its speed, accuracy, and versatility, custom precision metal stamping is a cost-effective and efficient way to produce the metal parts needed for various applications.

List Properties of “custom precision metal stamping”

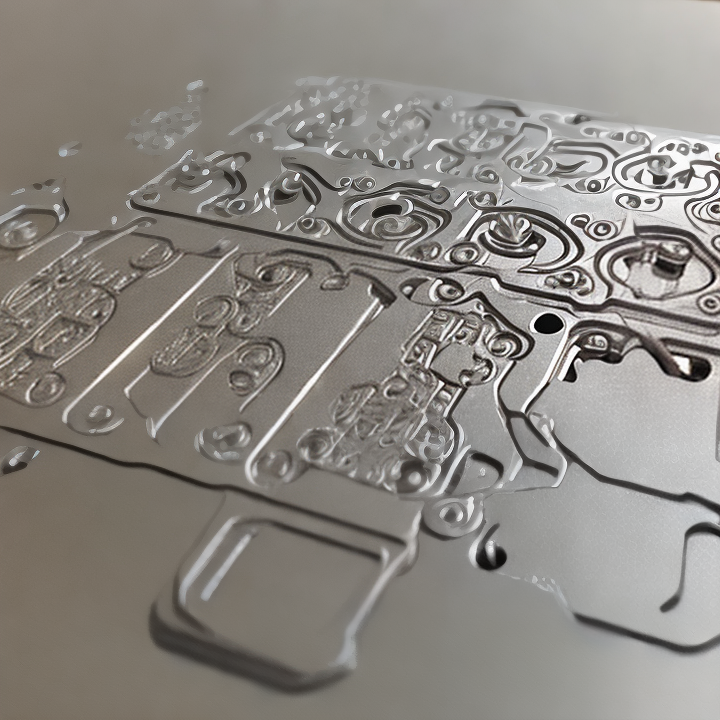

Custom precision metal stamping is the process of creating parts or components from various types of metallic materials using stamping machines. The process involves cutting, bending, coining, punching, embossing, and pressing the sheet metal into the desired shape, size, and thickness. Custom precision metal stamping is widely used in different industries such as aerospace, automotive, electronics, medical, telecommunications, and defense.

One of the essential features of custom precision metal stamping is the ability to produce high-quality parts with tight tolerances. The stamping machines can achieve accuracy within a few thousandths of an inch, ensuring that the final parts meet the required specifications. This precision is vital, especially in industries where the parts must fit together with other components and operate efficiently.

Another important property of custom precision metal stamping is its cost-effectiveness. The process allows manufacturers to produce large quantities of parts quickly and efficiently, reducing the overall cost of production. Additionally, custom precision metal stamping uses raw materials efficiently, resulting in minimal waste, which further lowers the cost of production.

Custom precision metal stamping also offers flexibility in terms of design and customization. Manufacturers can create complex shapes and designs using a variety of materials, including stainless steel, aluminum, copper, brass, and nickel. This allows customers to design unique parts that meet their specific requirements while maintaining the necessary quality and precision.

Finally, custom precision metal stamping offers durability, strength, and corrosion resistance. The process ensures that the finished parts are robust and able to withstand harsh conditions, making them ideal for use in applications such as aerospace and defense. The stamping process also creates a smooth surface that resists rust and corrosion, making the parts long-lasting and reliable.

In conclusion, custom precision metal stamping is a versatile and cost-effective manufacturing process that produces high-quality metal components with tight tolerances, durability, and flexibility. Its properties make it particularly useful in industries that require precision parts that are strong and long-lasting.

List “custom precision metal stamping” FAQ

1. What is custom precision metal stamping?

Custom precision metal stamping is the process of using presses and dies to create shapes, designs, or details on metal surfaces. The technique is ideal for creating intricate or complex designs or features with high accuracy and precision.

2. What types of metals can be used in metal stamping?

A variety of metals can be used in metal stamping, including steel, aluminum, brass, copper, and nickel.

3. What is the process for custom precision metal stamping?

The process of custom precision metal stamping typically involves five steps: design, tooling development, manufacturing, inspection, and finishing. A customized die is created to shape and form the metal into the desired design. After the design is confirmed, the metal is stamped using the die and press equipment.

4. What are the advantages of custom precision metal stamping?

Custom precision metal stamping offers several advantages, including high accuracy and precision, repeatability, and the ability to create complex and intricate designs. Metal stamping can also be a cost-effective alternative to other manufacturing methods.

5. Can custom precision metal stamping be used for high-volume production runs?

Yes, custom precision metal stamping is ideal for high-volume production runs. The process can be automated, making it efficient and cost-effective.

6. What industries use custom precision metal stamping?

Custom precision metal stamping is used in a variety of industries, including automotive, aerospace, electronics, medical device manufacturing, and telecommunications.

7. How does quality control work in custom precision metal stamping?

Quality control in custom precision metal stamping is critical. The process includes inspections at multiple stages, including tooling development, production, and finishing. The use of precision measuring equipment ensures that the final product meets all the necessary requirements.

8. How can I choose the right metal stamping provider for my project?

When choosing a metal stamping provider, it’s important to consider their experience, capabilities, and quality control measures. Look for a provider with a proven track record of delivering high-quality metal stamped products and who can offer design assistance and technical support if needed.