Hydraulic shearing machines are indispensable tools in the manufacturing sector, renowned for their precision and efficiency. These machines play a pivotal role in cutting and shaping metal sheets, ensuring that industries can produce high-quality products consistently. As the demand for such machines surges globally, China has emerged as a leading supplier, offering top-notch machines at competitive prices.

SourcifyChina: Your Trusted Partner in China

In the realm of hydraulic shearing machine suppliers, SourcifyChina stands as a beacon of trust and quality. Established in 2007, the company has carved a niche for itself by providing expert product sourcing services tailored for small and medium-sized foreign trade enterprises.

A Legacy of Excellence

With over 3,000 satisfied customers, SourcifyChina’s reputation is built on a foundation of trust, reliability, and unparalleled service. The company’s commitment to fostering long-term relationships is evident, with over 500 clients maintaining a successful partnership for more than a decade.

Value for Money

SourcifyChina’s services are not just about sourcing the right product; it’s about ensuring the best value for your investment. With a service fee as low as 3%, clients can save significant time and resources, allowing them to focus on their core business operations.

Insights and Expertise

Navigating the vast landscape of Chinese manufacturers can be daunting. SourcifyChina simplifies this process by offering valuable insights, from assessing the creditworthiness of companies to comparing different factories. Their extensive network and experience ensure that clients receive the highest quality products at competitive prices.

Types and Applications of Hydraulic Shearing Machines

Hydraulic shearing machines are versatile tools, catering to a range of applications across industries. Depending on the specific requirements, different types of shearing machines are employed.

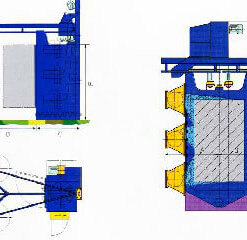

Hydraulic Pendulum Shears

These machines are characterized by their swing beam design, where the upper blade swings in a circular arc around a fixed point. They are ideal for cutting thinner metal sheets and offer precision and speed.

Hydraulic Guillotine Shears

With a straight-moving blade, guillotine shears are perfect for cutting thicker metal sheets. They offer greater cutting force and are commonly used in heavy-duty applications.

Applications

From automotive to construction and electronics, hydraulic shearing machines find applications in various sectors. Their precision and efficiency make them indispensable for producing high-quality metal components integral to numerous products.

Production Process in Chinese Factories

The manufacturing of hydraulic shearing machines in China is a testament to the country’s prowess in blending traditional craftsmanship with modern technology.

Design and Blueprinting

Every hydraulic shearing machine starts as a concept. Engineers and designers collaborate to draft blueprints, ensuring that the machine meets industry standards and specific client requirements.

Material Sourcing

The strength and durability of a hydraulic shearing machine lie in the quality of its materials. Chinese factories source high-grade steel and other essential components, ensuring the machine’s longevity and performance.

Assembly and Calibration

Once the design is finalized and materials are procured, skilled technicians assemble the machine. Every component, from the blades to the hydraulic system, is meticulously installed. Post-assembly, the machine undergoes calibration to ensure precision during operations.

Quality Assurance

Before the machine is deemed market-ready, it undergoes rigorous testing. This quality control phase ensures that the machine operates optimally and safely. Any discrepancies identified are rectified immediately.

User Guide: Operating a Hydraulic Shearing Machine

Operating a hydraulic shearing machine requires a blend of technical know-how and practical skills.

Safety First

- Always wear protective gear, including safety goggles, gloves, and ear protection.

- Ensure the workspace is free from obstructions and distractions.

Machine Setup

- Check the hydraulic fluid levels and ensure all components are well-lubricated.

- Adjust the blade gap based on the thickness of the metal sheet.

- Calibrate the backgauge for precise measurements.

Operation

- Feed the metal sheet into the machine, ensuring it’s aligned correctly.

- Activate the machine, and the hydraulic system will drive the blades to shear the metal.

- Monitor the process, ensuring smooth and precise cuts.

Maintenance

Regular maintenance is pivotal for the machine’s longevity. Clean the machine components, check for any wear and tear, and replace parts as necessary.

Questions International Buyers Should Ask Chinese Suppliers

Engaging with Chinese suppliers can be fruitful, but it’s essential to ask the right questions.

- Certifications: Does the machine adhere to international quality standards?

- Customization: Can the machine be tailored to specific requirements?

- Training: Do you offer operational training for the machine?

- After-Sales Support: What kind of post-purchase support do you provide?

- Shipping and Delivery: How do you handle international shipping, and what are the associated costs?

Q1: What is the primary function of a hydraulic shearing machine? Answer: A hydraulic shearing machine is designed to cut or shear metal sheets with precision, using hydraulic force to drive the cutting blades.

Q2: How does a hydraulic system enhance the machine’s performance? Answer: The hydraulic system provides consistent and powerful force, ensuring smooth and precise cuts regardless of the metal sheet’s thickness.

Q3: Can the machine handle different types of metals? Answer: Yes, hydraulic shearing machines can cut various metals, including steel, aluminum, copper, and more, depending on the machine’s specifications.

Q4: How often does the machine require maintenance? Answer: Regular maintenance is crucial for optimal performance. It’s advisable to check the machine components and hydraulic fluid levels after every significant operation.

Q5: What safety measures are integrated into the machine? Answer: Modern hydraulic shearing machines come with safety features like emergency stop buttons, protective guards, and safety halt gears to ensure operator safety.

Hydraulic shearing machines, with their blend of precision and power, have revolutionized the manufacturing sector. As industries worldwide seek reliable and efficient machines, China, with its blend of tradition and innovation, emerges as a leading supplier. SourcifyChina, with its commitment to quality and customer satisfaction, stands as a testament to China’s prowess in the domain. Whether you’re a seasoned manufacturer or a budding entrepreneur, investing in a hydraulic shearing machine from a trusted supplier like SourcifyChina ensures that you’re equipped with the best tools for success.

FAQ: Hydraulic Shearing Machine

1. What is a hydraulic shearing machine?

A hydraulic shearing machine is an industrial machine used for cutting sheet metal. It operates by using a blade to exert a high amount of force on the metal, causing it to shear or separate along the desired line.

2. How does a hydraulic shearing machine work?

The machine works by using hydraulic cylinders to move the cutting blade, typically in a vertical motion, against a fixed blade. The sheet metal is placed between the two blades, and the moving blade comes down with force, shearing the material.

3. What materials can be cut with a hydraulic shearing machine?

Hydraulic shearing machines are primarily used to cut sheet metal, but they can also cut materials like plastic, fabric, and paper. The thickness and type of material that can be cut will depend on the machine’s specifications.

4. What are the advantages of using a hydraulic shearing machine?

These machines offer several benefits, including precision cutting, the ability to handle high-volume jobs, and minimal waste production. They’re also known for their durability and can handle thicker materials compared to other types of shearing machines.

5. Are there different types of hydraulic shearing machines?

Yes, there are various models based on operational methods, such as swing beam shears and guillotine shears. The type used will depend on the specific requirements of the job.

6. How do I maintain a hydraulic shearing machine?

Regular maintenance includes checking hydraulic fluid levels, inspecting and sharpening blades, ensuring all safety guards are in place, and keeping the machine clean. Always refer to the manufacturer’s manual for specific maintenance tasks.

7. What safety precautions should be taken when using a hydraulic shearing machine?

Operators should wear appropriate safety gear, avoid placing hands or tools near the blades, use machine guards, and follow all operational guidelines. Proper training is also essential for safe operation.

8. Can a hydraulic shearing machine perform angled cuts?

Some machines are equipped with features that allow for angled cuts, known as shearing at an angle or “miter shearing.” However, not all machines have this capability, so it’s important to check the machine’s specifications.

9. What factors should I consider when purchasing a hydraulic shearing machine?

Consider the material types and thicknesses you’ll be cutting, the machine’s cutting length, accuracy, speed, and any additional features you need. Also, consider the machine’s footprint, especially if your workspace is limited.

10. Do hydraulic shearing machines require a lot of energy to operate?

They can require a significant amount of energy, especially larger models or those used for high-volume or thick material cutting. However, modern machines are often designed with energy efficiency in mind.

These FAQs provide a basic understanding of hydraulic shearing machines, their operation, and their benefits. However, specific questions related to particular models or use cases should be directed to the manufacturer or a knowledgeable dealer.