What is a Slotting Machine?

Slotting machines, often referred to as slotting shapers or simply “slotters”, play a pivotal role in the manufacturing industry. These machines are specifically designed to cut a variety of surfaces, both internal and external. Their primary function revolves around the creation of slots, grooves, and keyways in parts, making them indispensable in various sectors, including automotive, aerospace, and general machinery production.

Historical Evolution and Significance in China’s Manufacturing Sector

The origins of the slotting machine can be traced back to the early industrial revolution. As industries grew and the demand for precision parts increased, there was a pressing need for machines that could produce intricate shapes and designs with high accuracy. This led to the development of the slotting machine.

China, being a global manufacturing hub, recognized the potential of these machines early on. Over the years, China has not only become a significant consumer of slotting machines but also one of the leading producers. The country’s manufacturing sector heavily relies on these machines to produce parts that meet international standards of quality and precision.

The significance of slotting machines in China’s manufacturing sector cannot be overstated. With the country’s emphasis on innovation and quality, slotting machines have undergone numerous advancements. Modern machines are more efficient, precise, and versatile than their predecessors, making them an integral part of China’s industrial landscape.

SourcifyChina’s Contribution

SourcifyChina, with its deep-rooted connections in the Chinese manufacturing sector, has been at the forefront of supplying high-quality slotting machines to various industries worldwide. Their expertise in product sourcing ensures that businesses get the best machines that align with their specific requirements. By bridging the gap between manufacturers and international buyers, SourcifyChina has played a pivotal role in promoting the excellence of Chinese slotting machines on the global stage.

In the next section, we will delve deeper into the key components of a slotting machine, shedding light on their functionality and importance in the machining process.

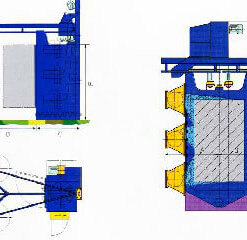

Key Components of a Slotting Machine

Every slotting machine, regardless of its size or complexity, consists of several essential components that work in harmony to produce the desired machining results. Understanding these components is crucial for operators to ensure optimal performance and longevity of the machine.

Base The base is the foundational part of the slotting machine, providing stability and support. Typically made of cast iron, the base absorbs vibrations during the machining process, ensuring precision and smooth operation.

Cross-Slide The cross-slide is a movable component that allows the workpiece to be positioned accurately. It can move both longitudinally and transversely, enabling precise cuts and grooves on the workpiece.

Handwheel The handwheel facilitates manual control over the machine’s movements. By turning the handwheel, operators can adjust the position of the cutting tool, ensuring accurate and precise cuts.

Column The column is a vertical structure that houses the machine’s driving mechanism. It supports the ram and the tool head, allowing for vertical movement during the slotting process.

Ram The ram holds the cutting tool and executes the primary slotting action. It moves in a reciprocating manner, ensuring that the tool cuts the workpiece during its downward stroke.

Table The table supports the workpiece during the machining process. It can be adjusted both rotationally and linearly, allowing for versatile machining operations.

Applications and Uses of Slotting Machines

Slotting machines are versatile tools with a wide range of applications across various industries. Their primary function is to create slots, grooves, and keyways, but their utility extends far beyond these basic operations.

Machining Internal and External Gears One of the primary uses of slotting machines is in the production of gears. Whether it’s internal or external gears, slotting machines offer the precision required to produce them with high accuracy.

Shaping Internal and External Forms Slotting machines are also used to shape various internal and external forms or profiles. This includes intricate designs that might be challenging to produce using other machining methods.

Creating Keyways and Grooves Keyways and grooves are essential components in many mechanical assemblies. Slotting machines provide an efficient way to produce these with high precision.

SourcifyChina: China’s Premier Slotting Machine Supplier

In the global manufacturing landscape, China stands out as a powerhouse, and at the heart of this success is SourcifyChina. With years of experience and a vast network of reliable manufacturers, SourcifyChina has established itself as the go-to supplier for businesses worldwide.

Company Overview and History Since its inception in 2007, SourcifyChina has been dedicated to bridging the gap between international buyers and Chinese manufacturers. Their commitment to quality and customer satisfaction has earned them the trust of over 3,000 clients.

Expertise in Product Sourcing SourcifyChina’s strength lies in its expert product sourcing services. They ensure that businesses get the best value for their money by connecting them with the most suitable manufacturers. Their extensive network and knowledge of the Chinese manufacturing landscape make them an invaluable partner for businesses looking to source high-quality slotting machines.

Custom Services Offered by SourcifyChina

SourcifyChina isn’t just a supplier; they’re a partner in the truest sense. Recognizing that every business has unique needs, they offer tailored solutions that go beyond mere product sourcing.

Tailored Solutions for Businesses Whether a company is looking for a specific type of slotting machine or needs modifications to an existing design, SourcifyChina’s team of experts collaborates closely with clients to understand their requirements and deliver solutions that align perfectly with their objectives.

Case Studies: Successful Collaborations and Partnerships Over the years, SourcifyChina has facilitated numerous successful collaborations between international businesses and Chinese manufacturers. From small enterprises to large corporations, their clientele is a testament to their commitment to excellence and customer satisfaction.

Factors to Consider When Purchasing a Slotting Machine

Investing in a slotting machine is a significant decision that can impact a company’s production capabilities and bottom line. Here are some crucial factors businesses should consider:

Quality, Durability, and Precision It’s essential to choose a machine that offers high precision and is built to last. A durable machine reduces downtime and ensures consistent product quality.

Cost Implications and Return on Investment While initial cost is a factor, it’s vital to consider the long-term return on investment. A slightly more expensive machine that offers better performance and durability can be more cost-effective in the long run.

After-sales Services and Warranty Support doesn’t end after the purchase. It’s crucial to partner with suppliers like SourcifyChina that offer robust after-sales services and warranties, ensuring that businesses get the most out of their investment.

The Manufacturing Process of Slotting Machines in China

China’s manufacturing prowess is globally recognized, and slotting machines are no exception. The country’s emphasis on innovation and quality assurance ensures that slotting machines produced here are among the best in the world.

Production Stages and Quality Control Measures From raw material sourcing to final assembly, every stage of the manufacturing process is meticulously overseen to ensure product quality. Regular quality checks, coupled with advanced manufacturing techniques, ensure that the machines are reliable and efficient.

Innovations and Advancements in the Manufacturing Process Chinese manufacturers are continually innovating, integrating cutting-edge technologies into the production process. This not only enhances the machine’s performance but also ensures they remain competitive in the global market.

Step-by-Step Guide to Operating a Slotting Machine

For businesses new to slotting machines, understanding their operation is crucial. The next section will provide a detailed guide on safely operating these machines, ensuring optimal performance and longevity.

From safety precautions to maintenance tips, we’ll cover everything businesses need to know to get the most out of their slotting machines.

Questions International Buyers Should Ask Chinese Suppliers

Engaging with suppliers from a different country, especially one with a distinct business culture like China, requires due diligence. Here are some pivotal questions international buyers should consider:

Verifying Certifications and Quality Standards

- “What certifications does your factory hold, and can you provide documentation?”

- “How do you ensure that your products meet international quality standards?”

Understanding Lead Times, Shipping, and Customs Processes

- “What is the typical lead time for production and delivery?”

- “Which shipping methods do you recommend, and what are the associated costs?”

- “How do you handle customs documentation and duties?”

Negotiating Prices and Payment Terms

- “Is there flexibility in pricing for bulk orders or long-term contracts?”

- “What are your standard payment terms, and are they negotiable?”

- “Are there any hidden costs or fees that I should be aware of?”

FAQ Tips about slotting machine

Addressing common queries is essential to build trust and provide clarity to potential buyers. Here are some frequently asked questions and their answers:

Q1: What’s the difference between a slotting machine and a milling machine?

- While both machines are used for cutting, slotting machines are specialized for creating slots, grooves, and keyways, whereas milling machines are versatile tools used for various cutting operations.

Q2: How often does a slotting machine require maintenance?

- Regular maintenance is crucial for optimal performance. It’s recommended to conduct a thorough check every month and a comprehensive maintenance routine every six months.

Q3: Can slotting machines handle hard materials like stainless steel?

- Yes, with the right cutting tools and settings, slotting machines can handle a variety of materials, including hard metals.

Q4: What safety precautions should operators adhere to?

- Always wear safety gear, ensure the work area is clean and well-lit, and never operate the machine without proper training.

Q5: How does SourcifyChina ensure the quality of the slotting machines they source?

- SourcifyChina collaborates with trusted manufacturers, conducts regular quality checks, and leverages its extensive network to ensure the machines meet international standards.

Slotting machines are pivotal in the manufacturing landscape, and understanding their intricacies can significantly impact a business’s production capabilities. Partnering with trusted suppliers like SourcifyChina ensures not only high-quality machines but also a seamless buying experience. As industries evolve and manufacturing processes become more sophisticated, leveraging advancements in slotting machine technology will be crucial for businesses aiming for excellence.