Wire drawing machines have been an integral part of the manufacturing industry for decades. These machines are designed to transform wire rods into thinner wires through a series of drawing dies. The process involves pulling the wire through these dies to reduce its diameter, making it suitable for various applications.

Why are Wire Drawing Machines Important?

The significance of wire drawing machines lies in their ability to produce wires of varying diameters with precision. These wires are then used in a myriad of applications, including:

- Electrical Wiring: The backbone of modern infrastructure, electrical wires power our homes, offices, and cities. The quality and precision of these wires are paramount to ensure safety and efficiency.

- Cable Production: From internet cables to television cables, these are produced using wire drawing machines, ensuring consistent quality and performance.

- Industrial Uses: In industries, wires are used for a multitude of purposes, including machinery, tools, and equipment. The strength and durability of these wires are crucial for the smooth operation of industrial processes.

China’s Role in the Wire Drawing Industry

China has been at the forefront of the wire drawing industry, providing high-quality machines to both domestic and international markets. With a blend of traditional craftsmanship and cutting-edge technology, Chinese manufacturers have set global benchmarks in terms of quality, efficiency, and innovation.

The Evolution of Wire Drawing Machines in China

Historically, China’s manufacturing prowess can be traced back centuries. However, in the context of wire drawing machines, the country’s rise to prominence has been meteoric.

A Historical Perspective

China’s journey in the wire drawing industry began in the early 20th century. Initially, the focus was on catering to domestic demands. However, as the country opened up its economy and embraced globalization, Chinese manufacturers began exporting wire drawing machines to international markets.

Modern-Day Innovations

Today, China is home to some of the world’s leading wire drawing machine manufacturers. These companies invest heavily in research and development, ensuring their machines are equipped with the latest technology. Features such as automation, AI integration, and energy efficiency are now standard in many Chinese-made wire drawing machines.

China’s Global Footprint

China’s dominance in the wire drawing machine industry is evident in its export figures. From Asia to Europe and the Americas, Chinese wire drawing machines are in demand, testament to their quality and reliability.

L-Series Dry Type Continuous Wire Drawing Machine: A Deep Dive

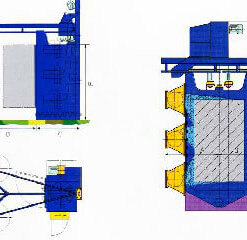

The L-Series Dry Type Continuous Wire Drawing Machine, a flagship product of many manufacturers, is designed to meet the diverse needs of the wire drawing industry. Its state-of-the-art features and robust design make it a preferred choice for many businesses.

Description and Salient Features

- Usage and Applications: This machine is an ideal equipment for drawing wire stock of high, medium, and carbon steel, as well as copper, aluminum, and alloy. It finds applications in wire-steel factories, metal mesh factories, and nail-making factories, among others.

- Structural Components: The machine comprises a main reduction box, die casing, wheel frame, wire brace, and an advanced electrical control system. Each component is designed for optimal performance and durability.

- Cooling System: To reduce residual heat and ensure smooth operation, the machine is equipped with a cooling system installed within the block’s interwall.

Technical Specifications

The L-Series boasts a range of models, each with specific technical specifications. Some key specifications include:

- Model Units: Ranging from 800 to 350.

- Inlet Wire Tensile Strength: Varies based on the model.

- Diameter of Inlet and Outlet Wire: Specific to each model.

- Drawing Passes/Dia. of Block: Specific to each model.

- Motor Power/Block: Varies based on the model.

- Weight and Overall Dimensions: Specific to each model.

Types and Applications of Wire Drawing Machines

Wire drawing machines are not one-size-fits-all. Different models cater to specific applications, ensuring precision and efficiency.

- Fine Wire Drawing Machines: Used for producing fine wires, these machines are essential for industries like electronics where precision is paramount.

- Intermediate Wire Drawing Machines: Ideal for drawing medium-sized wires, these machines find applications in the construction industry, among others.

- Heavy Wire Drawing Machines: Designed for drawing thick wires, these machines are used in industries like construction and automotive.

The Manufacturing Process: From Factory to Final Product

The manufacturing process of wire drawing machines is a blend of traditional craftsmanship and modern technology.

- Design Phase: The process begins with a design phase where engineers draft the machine’s blueprint, keeping in mind the specific requirements of the industry.

- Raw Material Sourcing: High-quality materials are sourced to ensure the machine’s durability and performance.

- Assembly: Once the design is finalized and materials are sourced, the assembly process begins. Each component is meticulously put together to form the final machine.

- Quality Control: Rigorous testing is conducted to ensure the machine meets the set standards. Any discrepancies are addressed before the machine is deemed ready for sale.

Step-by-Step Guide: Using the Wire Drawing Machine

Operating a wire drawing machine requires a blend of technical knowledge and practical skills.

- Safety Precautions: Before starting the machine, operators must ensure they are wearing the necessary safety gear. This includes gloves, safety goggles, and protective clothing.

- Setting Up: The machine is set up by feeding the wire rod and selecting the desired diameter.

- Operation: Once set up, the machine is started, and the drawing process begins. Operators must monitor the process to ensure smooth operation.

- Maintenance: Regular maintenance is crucial to ensure the machine’s longevity. This includes cleaning, oiling, and periodic checks.

Questions International Buyers Should Ask Chinese Suppliers

Sourcing from China offers numerous benefits, but it’s essential to ask the right questions to ensure you’re making a sound investment.

- Certifications: Are the machines certified by international standards?

- Warranty: What is the warranty period, and what does it cover?

- Customization: Can the machines be customized to meet specific requirements?

- After-Sales Support: What kind of support is offered post-purchase?